Axial-flow-type switch valve

An opening and closing valve, axial flow technology, applied in the field of axial flow opening and closing valve, can solve the problems of valve failure, change of pipeline, easy damage to the sealing surface of the valve, etc., to improve the switching response speed, increase the control pressure, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

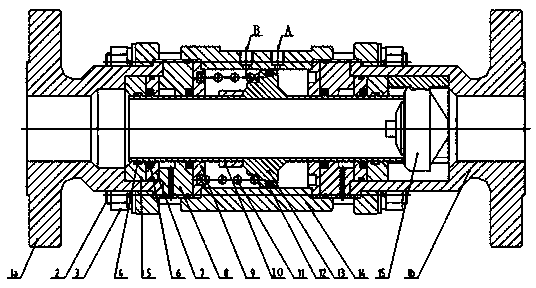

[0018] As shown in the figure, an axial-flow opening and closing valve includes an actuator piston cylinder 14, a left flange connection sleeve 1a and a right flange connection sleeve 1b, and the three are fixed by studs 2 and nuts 3 in a coaxial structure. combined.

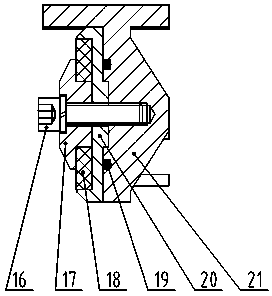

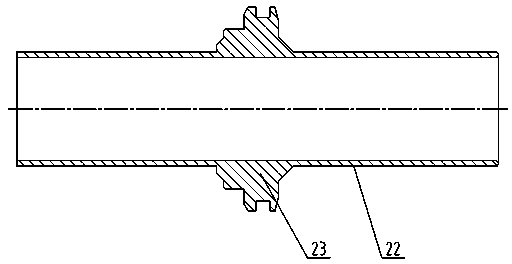

[0019] A piston-type driving mechanism 13 is set in the piston cylinder 14 of the actuator. The piston-type driving mechanism 13 includes a cylindrical valve core 22 and a piston 23 sleeved outside the valve core 22. The valve core 22 and the piston 23 are integrally formed. . Wherein, the piston 23 and the spring pad 9 arranged in the piston cylinder 14 of the actuator cooperate elastically through the spring 11 provided, and the spring 11 controls the initial position of the spool 22; the piston seal is arranged in cooperation between the piston 23 and the piston cylinder 14 of the actuator 12. To en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com