Patents

Literature

51results about How to "Meet the needs of working conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

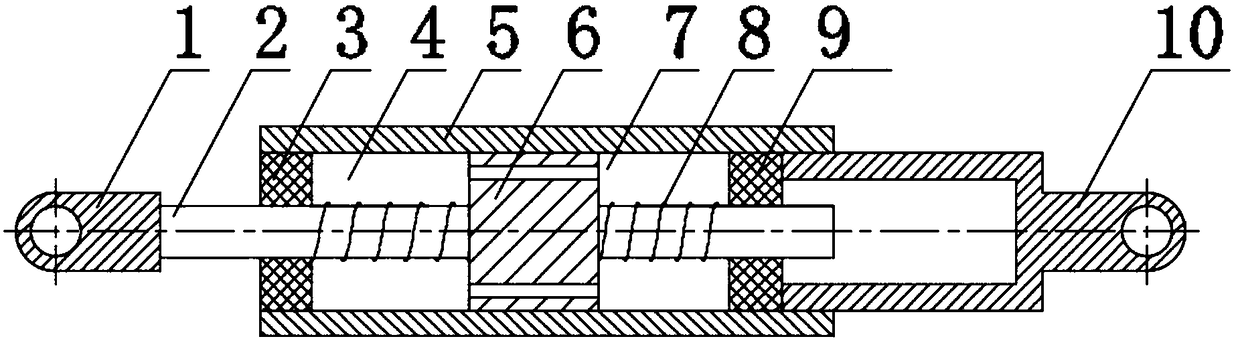

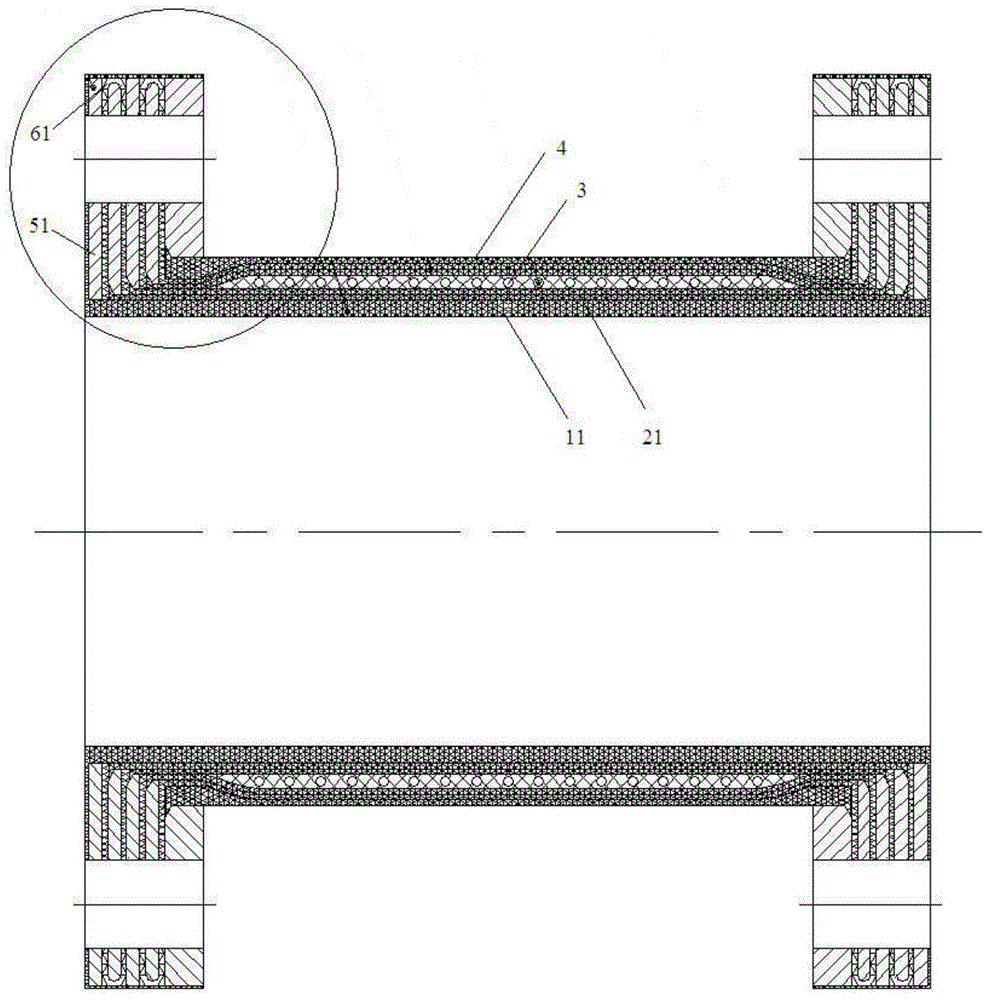

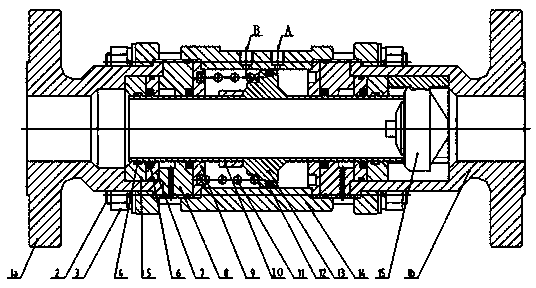

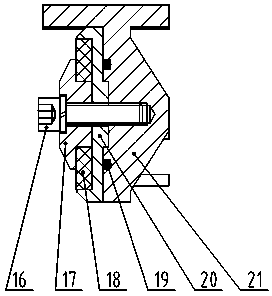

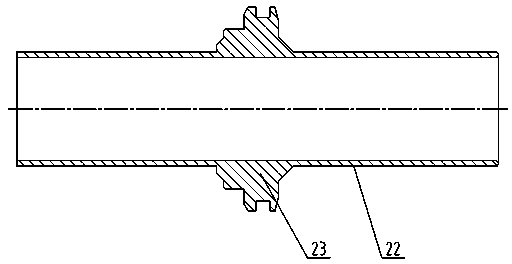

SMA spring-STF viscous damper

InactiveCN109404477AGood shock absorptionGood reset functionSprings/dampers functional characteristicsSprings/dampers design characteristicsControl theoryPiston rod

The invention provides an SMA spring-STF viscous damper which comprises a first connecting component, a piston rod, a left end cover, a first damping cavity, a damping cylinder, a piston, a second damping cavity, two SMA springs, a right end cover and a second connecting component, wherein the left end cover is arranged at one end of the damping cylinder; the right end cover is arranged at the other end of the damping cylinder; the interior of the damping cylinder is divided by the piston into the first damping cavity and the second damping cavity; the SMA springs which sleeve the piston rod are correspondingly arranged in the first damping cavity and the second damping cavity; the first damping cavity and the second damping cavity are filled with an STF shearing thickener; when the pistonmoves towards one side, the SMA spring on one side is compressed, and the SMA spring on the other side is restored towards the trend of the original length; and due to the different expansion and contraction degrees of the SMA springs on both sides, the resistance difference is produced, and the damping force is provided for the viscous damper. The SMA spring-STF viscous damper provided by the invention has the effects of improving the energy consumption under low-frequency loads and causing limiting resistance to the structural excessive displacement; furthermore, the self-resetting effect can be achieved after unloading; and the SMA spring-STF viscous damper has the advantages that the structure is simple and the space is saved.

Owner:SHENYANG JIANZHU UNIVERSITY

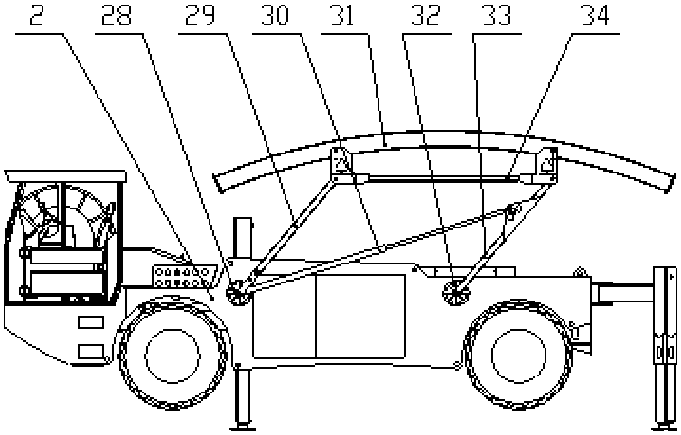

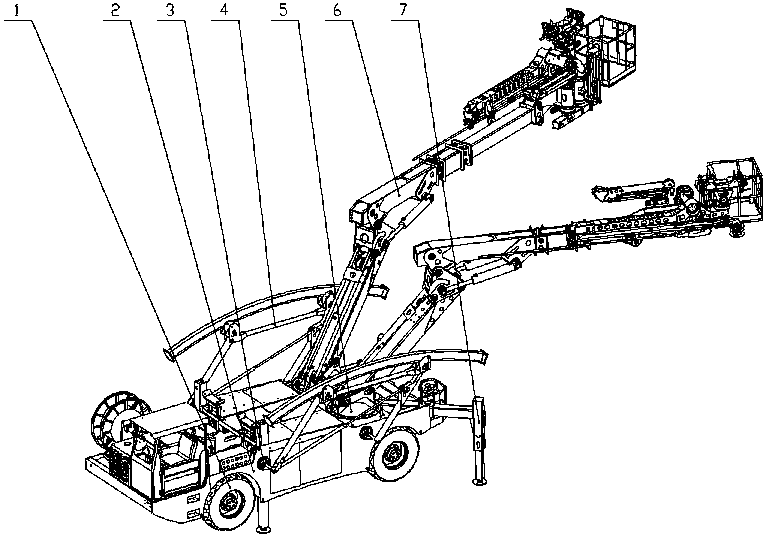

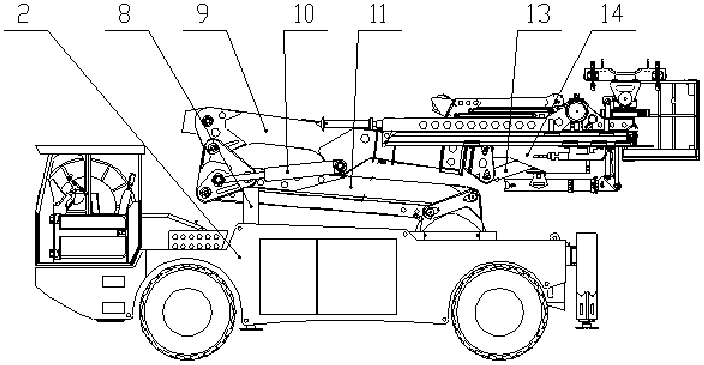

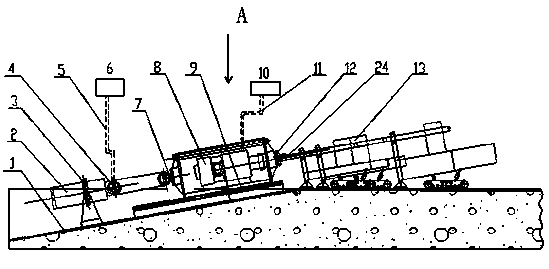

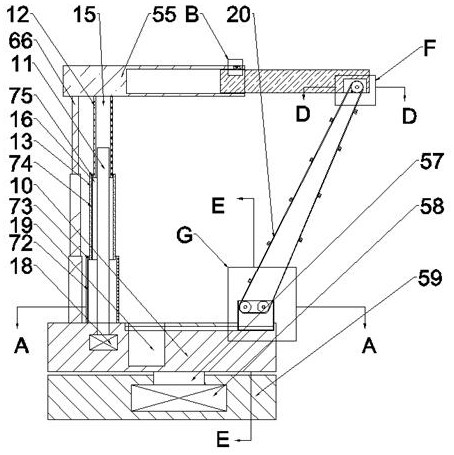

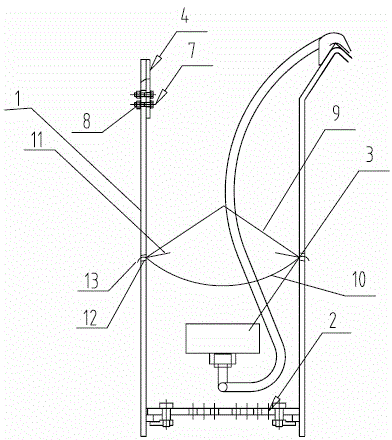

Multi-function tunnel rock drilling and arching all-in-one machine

PendingCN107842311AGrow fastSolve the problem that the vehicle cannot be retracted and the vehicle is too long and has a large turning radiusUnderground chambersDerricks/mastsEngineeringDrilling machines

A multi-function tunnel rock drilling and arching all-in-one machine comprises a host platform (2) which is arranged on a basal disc (1); two arm frames (6) are arranged at the rear portion of the host platform by a rotation seat (5), and the arm frames can be folded and stored in a driving or static state; the front end of a forearm is rotationally provided with an arch grabbing device (18), a rock drilling device (19), a manned platform (24), and a truck crane (23). The multi-function tunnel rock drilling and arching all-in-one machine can perform the arch support operation during full section, two-step and three-step excavating of a tunnel. Through the coordination of the two arm frames and the above working devices, the arch frame transported by car, the installation of the arch, the hanging of the reinforcing mesh, the welding of the transverse reinforcement and the installation of a bolt and a drill hole of leading small tube can be realized; the efficiency is far higher than that of the manual operation.

Owner:CHANGSHA KEDA INTELLIGENT EQUIP INC CO

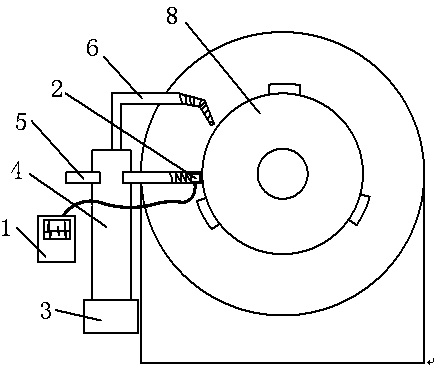

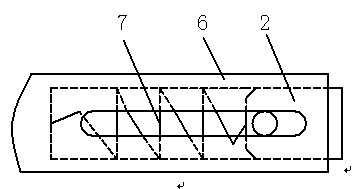

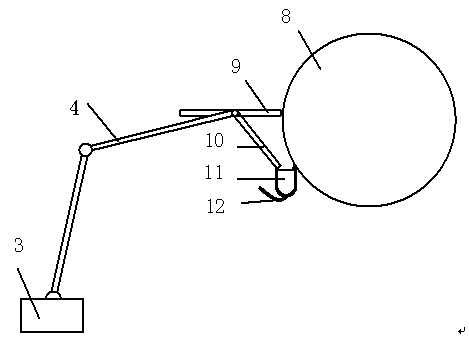

Ultrasonic flaw detection apparatus

InactiveCN104020219AMeet the needs of flaw detectionSimple structureAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringPortable ultrasound

The invention relates to the technical field of ultrasonic flaw detection equipment. An ultrasonic flaw detection apparatus comprises a portable ultrasonic detector and a detection probe, and also comprises a magnetic gauge stand and a movable support installed on the upper end face of the magnetic gauge stand; a free end of the movable support is provided with a clamping device; one end of the detection probe is installed in a chute at the end of the clamping device and is connected with an adjusting spring; and the periphery of a working end of the detection probe is provided with a plurality of spray pipes which are fixedly connected with the movable support and communicated with an automatic water tank. The ultrasonic flaw detection apparatus is simple in structure, convenient to adjust and rapid in mounting and dismounting, and is capable of satisfying requirements of most of working conditions, especially flaw detection requirements of relatively large specification aluminium rods.

Owner:广西南南铝加工有限公司

Compensator for slurry balance shield mud circulation system

ActiveCN104964113AHigh strengthImprove axial tensile capacityFlanged jointsAdjustable jointsEngineeringSlurry

The invention provides a compensator for a slurry balance shield mud circulation system. The compensator comprises an inner rubber layer, a first body enhancement layer, a second body enhancement layer, a skeleton layer, a third body enhancement layer, a fourth body enhancement layer, flange pieces and connector enhancement layers, wherein the first body enhancement layer, the second body enhancement layer, the skeleton layer, the third body enhancement layer, the fourth body enhancement layer are sequentially arranged from the outer circular face of the inner rubber layer outwards, and the flange pieces and the connector enhancement layers are arranged at the two ends of the inner rubber layer. The connector is sequentially provided with the first flange piece, the first connector enhancement layer, the second flange piece, the second connector enhancement layer, the third flange piece, the third connector enhancement layer, the fourth flange piece and the fourth connector enhancement layer in the axial direction, wherein the first connector enhancement layer and the first body enhancement layer are integrally arranged, the second connector enhancement layer and the second body enhancement layer are integrally arranged, the third connector enhancement layer and the third body enhancement layer are integrally arranged, and the fourth connector enhancement layer and the fourth body enhancement layer are integrally arranged. The first connector enhancement layer and the second connector enhancement layer are integrally arranged on the outer circle side of the flange pieces, and the third connector enhancement layer and the fourth connector enhancement layer are integrally arranged on the outer circle side of the flange pieces. The compensator is high in strength.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Quasi-crystal abrasive paste applicable to surface mechanical finishing of soft metals

InactiveCN103242803AImprove smoothnessReduce wearOther chemical processesPolishing compositions with abrasivesSurface finishGranularity

The invention discloses a quasi-crystal abrasive paste applicable to the surface mechanical finishing of soft metals, and the adopted abrasive material thereof is a quasi-crystal alloy powder material. The quasi-crystal abrasive paste comprises a quasi-crystal alloy and related phase materials; the granularity of a powdered abrasive material is less than or equal to 50mu m; the mass percentage of the quasi-crystal powdered abrasive material in the abrasive paste is 1-90%, and the balance of the abrasive paste refers to abradant auxiliary materials such as oil-soluble or water-soluble pastes and the like. According to the invention, based on the unique grinding behavior and mechanism, the abrasive paste has an efficient mechanical finishing and defect repair capacity to the surfaces of soft metals / alloy specimens or workpieces; and compared with traditional abrasive materials, a surface finishing effect required by workpieces can be achieved efficiently, and the erosion amount is low, therefore, the abrasive paste is applicable to the surface finishing of high-precision workpieces, namely, the dimensional accuracy of workpieces can be kept while the surface quality of workpieces is satisfied. The abrasive paste disclosed by the invention has the characteristics of high stability, high liquidity, no adhesiveness and easiness for cleaning, therefore, the abrasive paste is an ideal grinding material for the mechanical finishing of soft materials.

Owner:DALIAN UNIV OF TECH

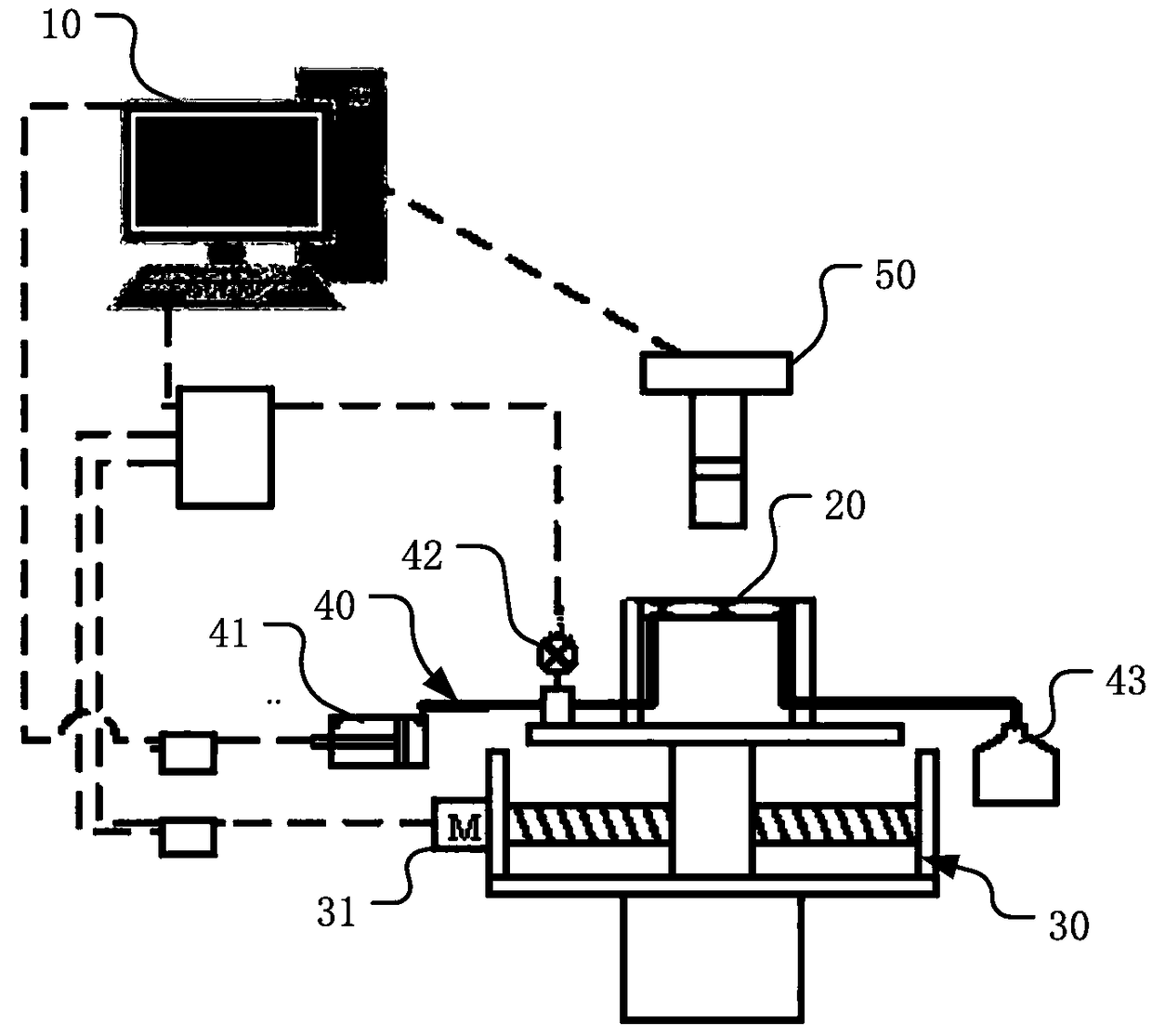

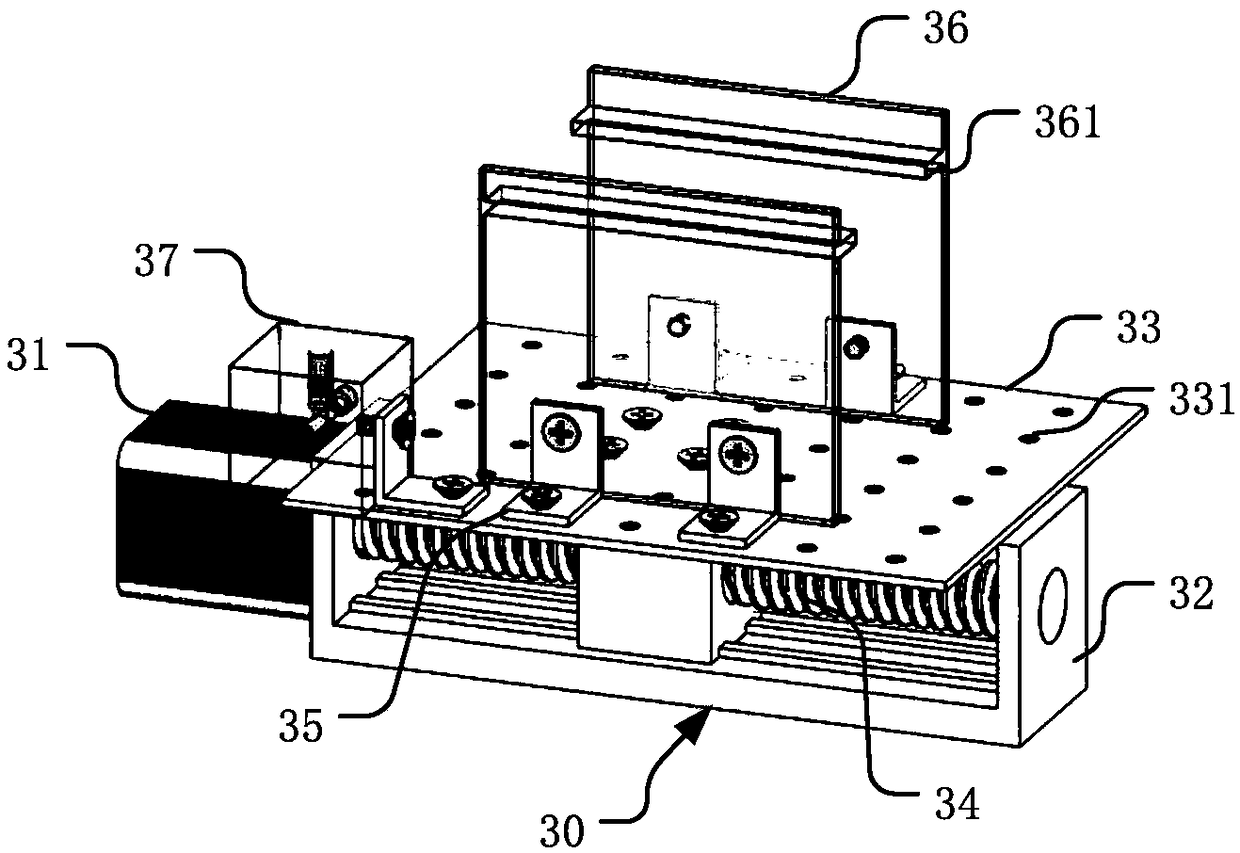

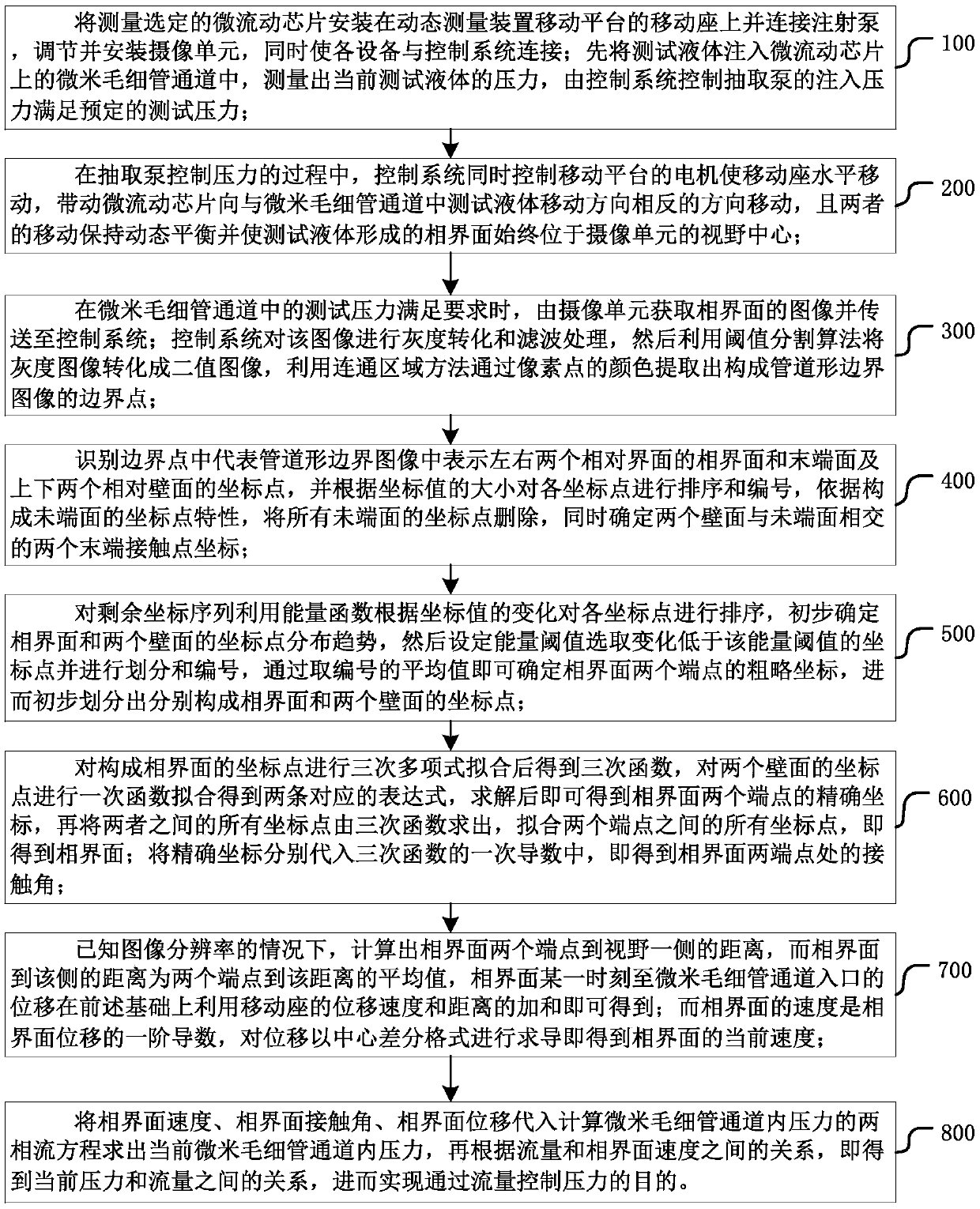

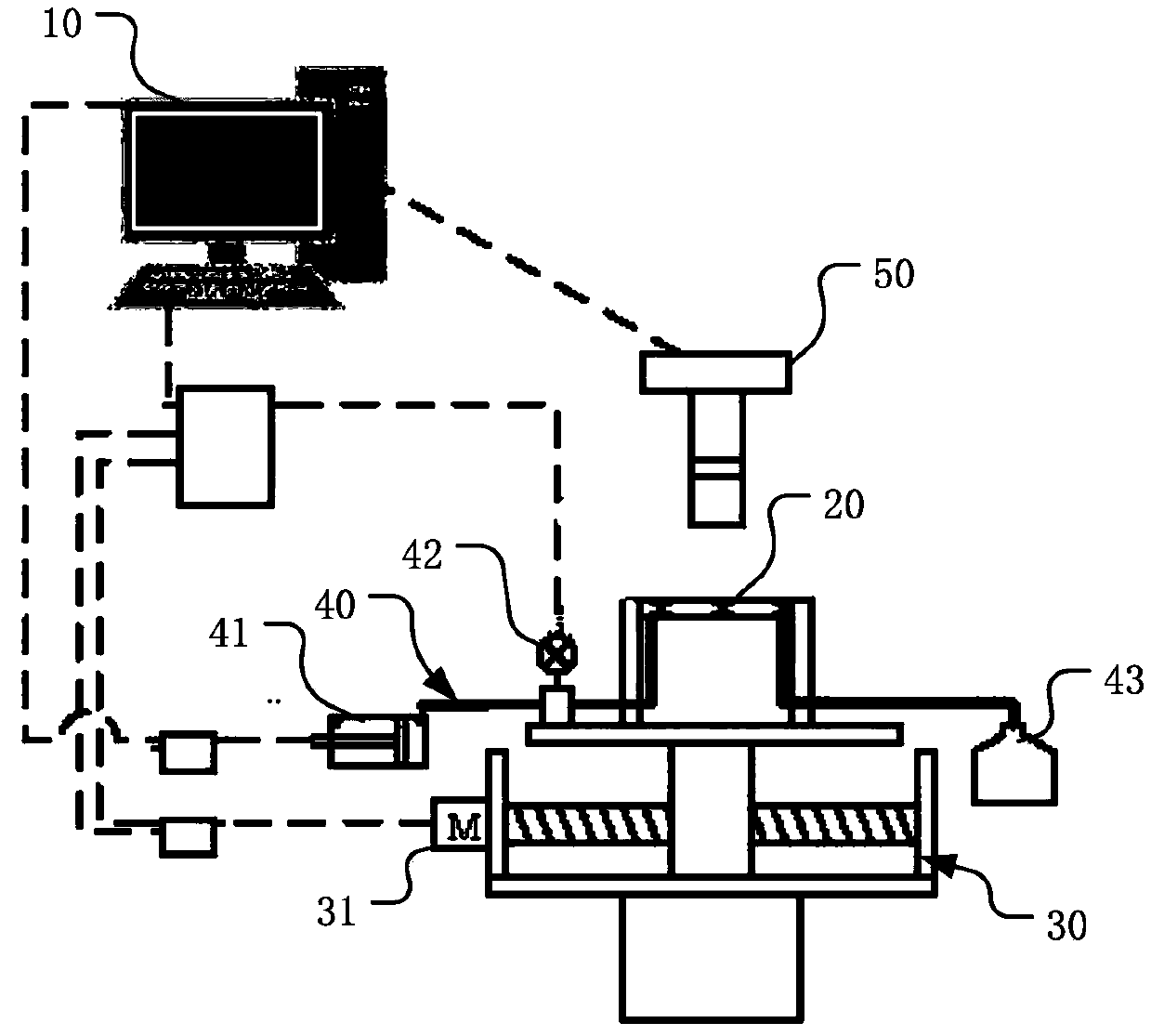

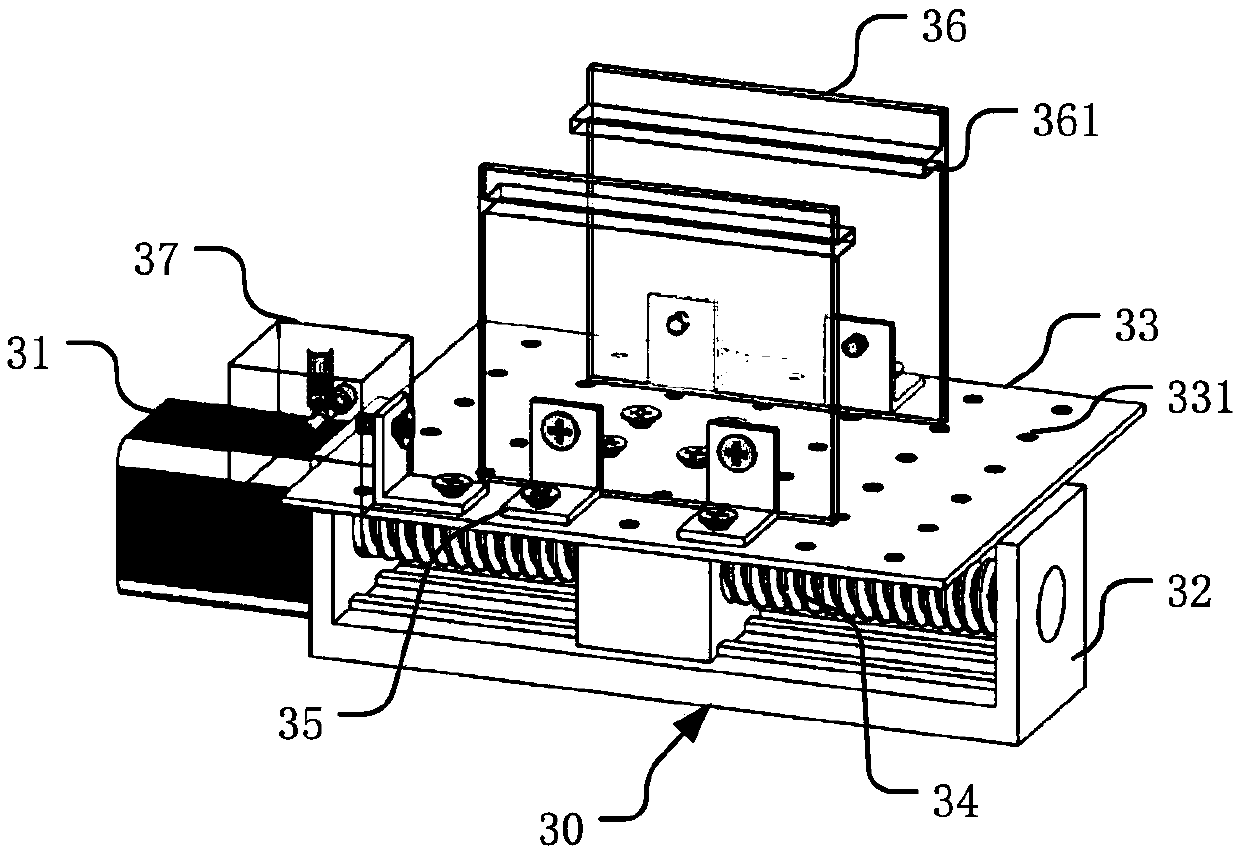

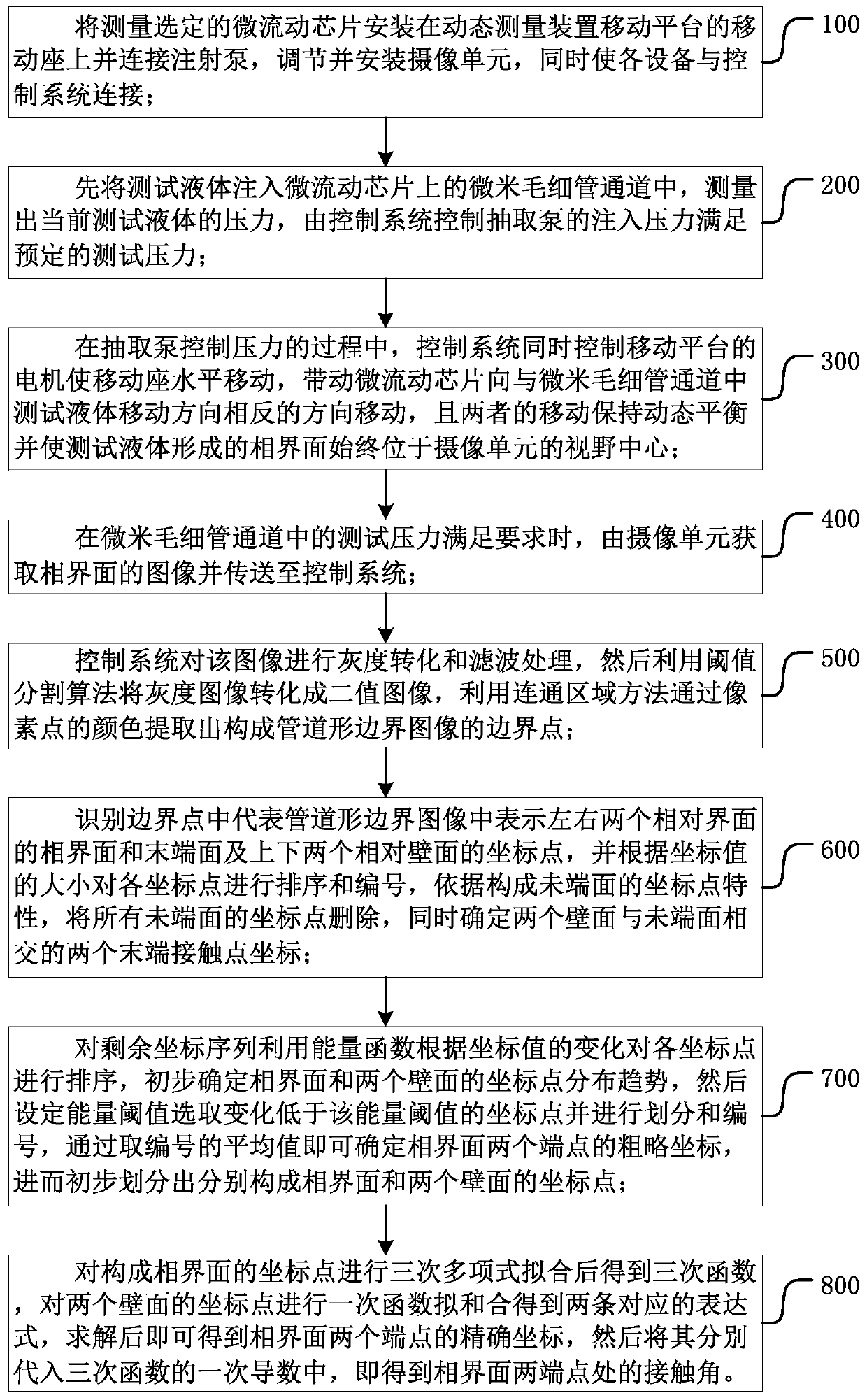

Method for obtaining gas-liquid phase interface in micron capillary channel

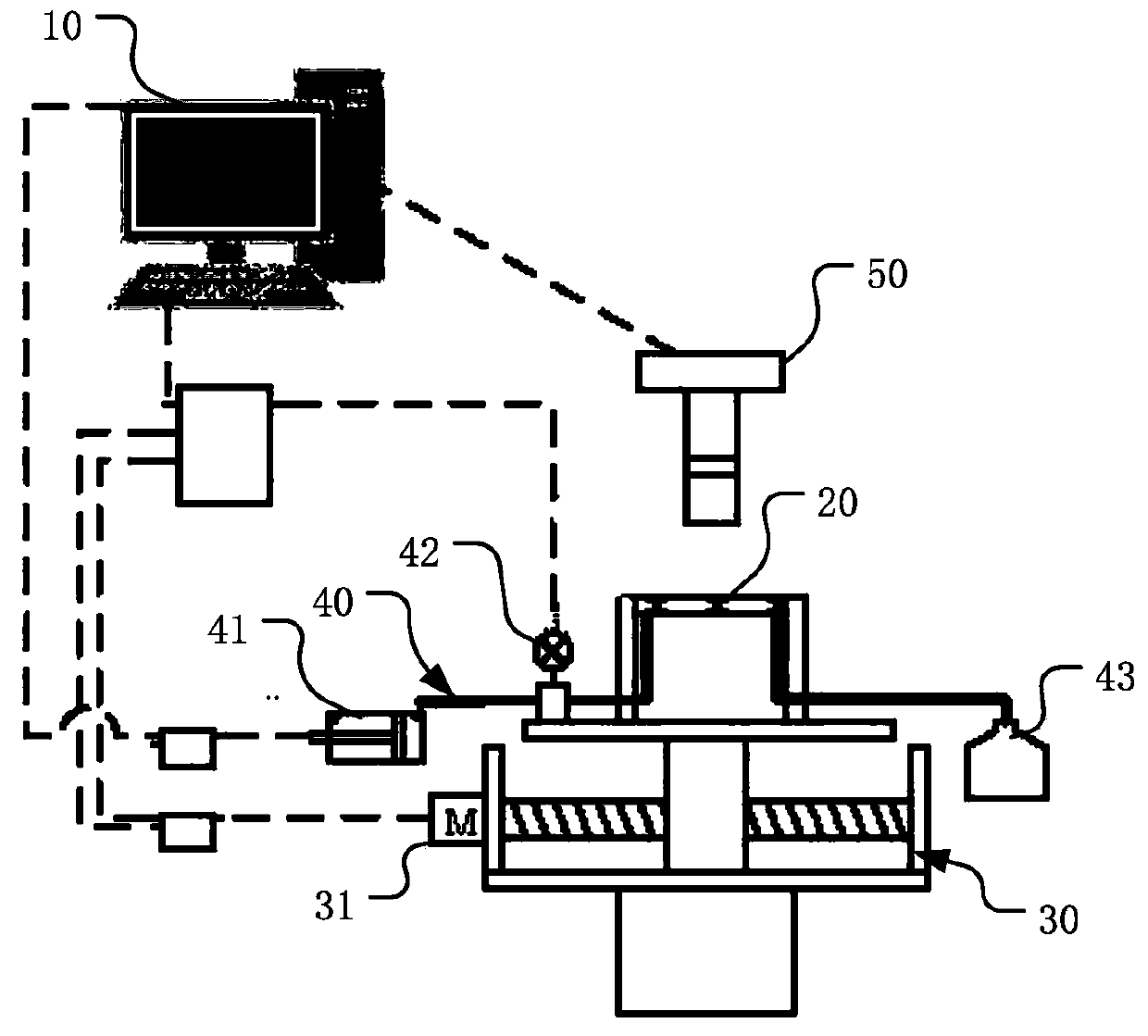

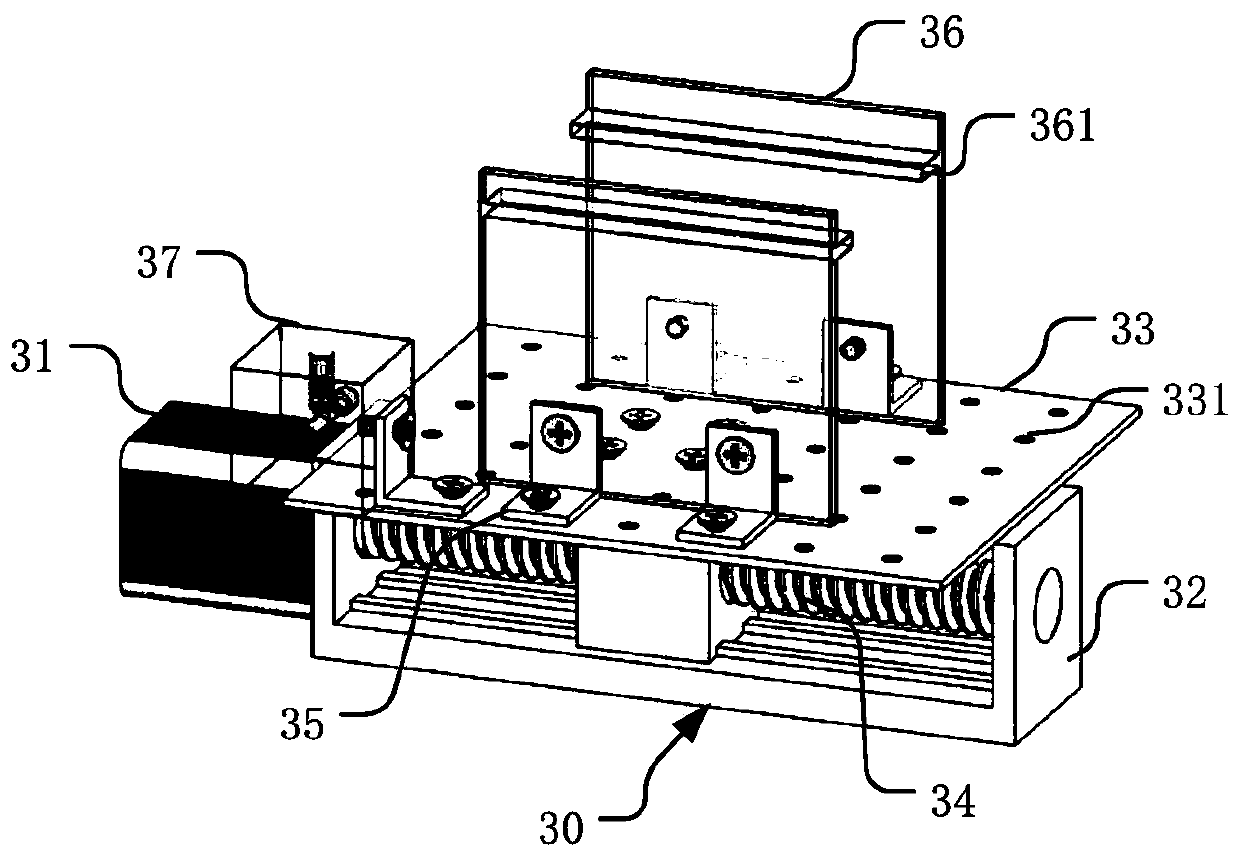

ActiveCN108827834AImprove efficiencyHigh measurement accuracyDiffusion analysisMicron scaleCapillary channel

The invention provides a method for obtaining a gas-liquid phase interface in a micron capillary channel. The pressure or flow velocity of the gas-liquid two-phase flow process in a micron-scale capillary channel guide is controlled by a dynamic testing device, and the phase interface shape is obtained under the conditions of low capillary number and low Bond number for the first time. Phase interface shape calculation based on an image processing method is adopted for the first time, and the data processing efficiency and measurement accuracy are greatly improved. The invention also providesa variety of algorithms for control of two-phase flow pressure control and electric platform speed control, and the flexibility of actual operation is improved to meet the requirements of various working conditions.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Axial-flow-type switch valve

InactiveCN103968092ASimple structureReasonable designOperating means/releasing devices for valvesLift valveEngineeringElastic matching

The invention discloses an axial-flow-type switch valve, and belongs to the technical field of valves. The axial-flow-type switch valve comprises a first flange connecting sleeve, an executing mechanism piston cylinder and a second flange connecting sleeve which are mutually connected. A piston-type driving mechanism is arranged in the executing mechanism piston cylinder, the piston-type driving mechanism comprises a valve element of a cylindrical structure and a piston connected with the outer side of the valve element in a sleeved mode, a piston is in elastic matching with a spring pad arranged in the executing mechanism piston cylinder, one end of the valve element is in sealing matching with the first flange connecting sleeve, and the other end of the valve element is matched with a valve seat arranged in the second flange connecting sleeve. According to the axial-flow-type switch valve, the mode that an executing mechanism, the piston, the valve element, the valve seat and the flange connecting sleeves are coaxially combined is adopted, the valve structure design concept that in the prior art, an executing mechanism can only be arranged outside a valve body is broken through, and the defects that an existing piston-type executing mechanism is large in friction force, low in response speed, low in adjusting precision and large in leakage rate are overcome.

Owner:HANGZHOU LIANGGONG VALVES

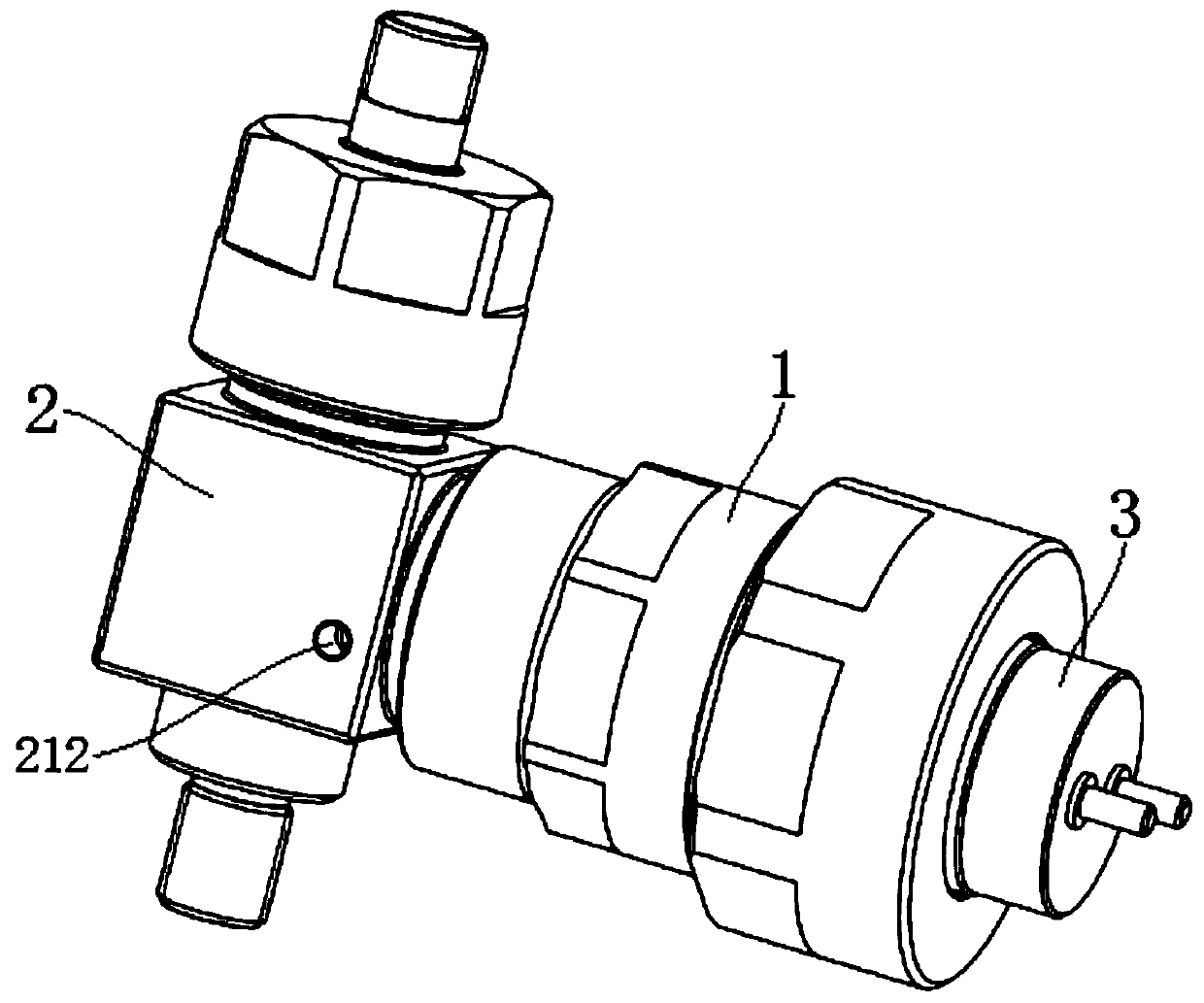

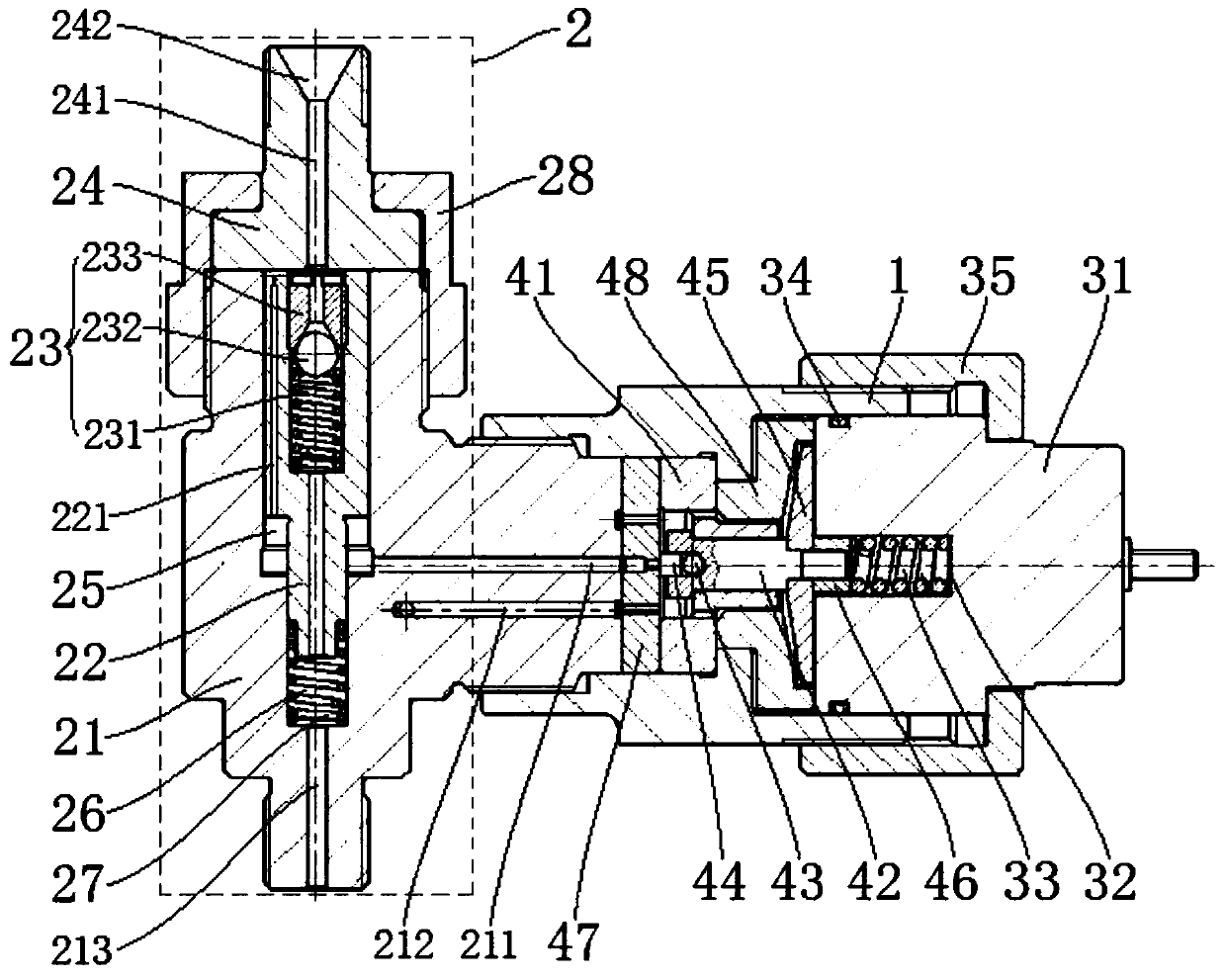

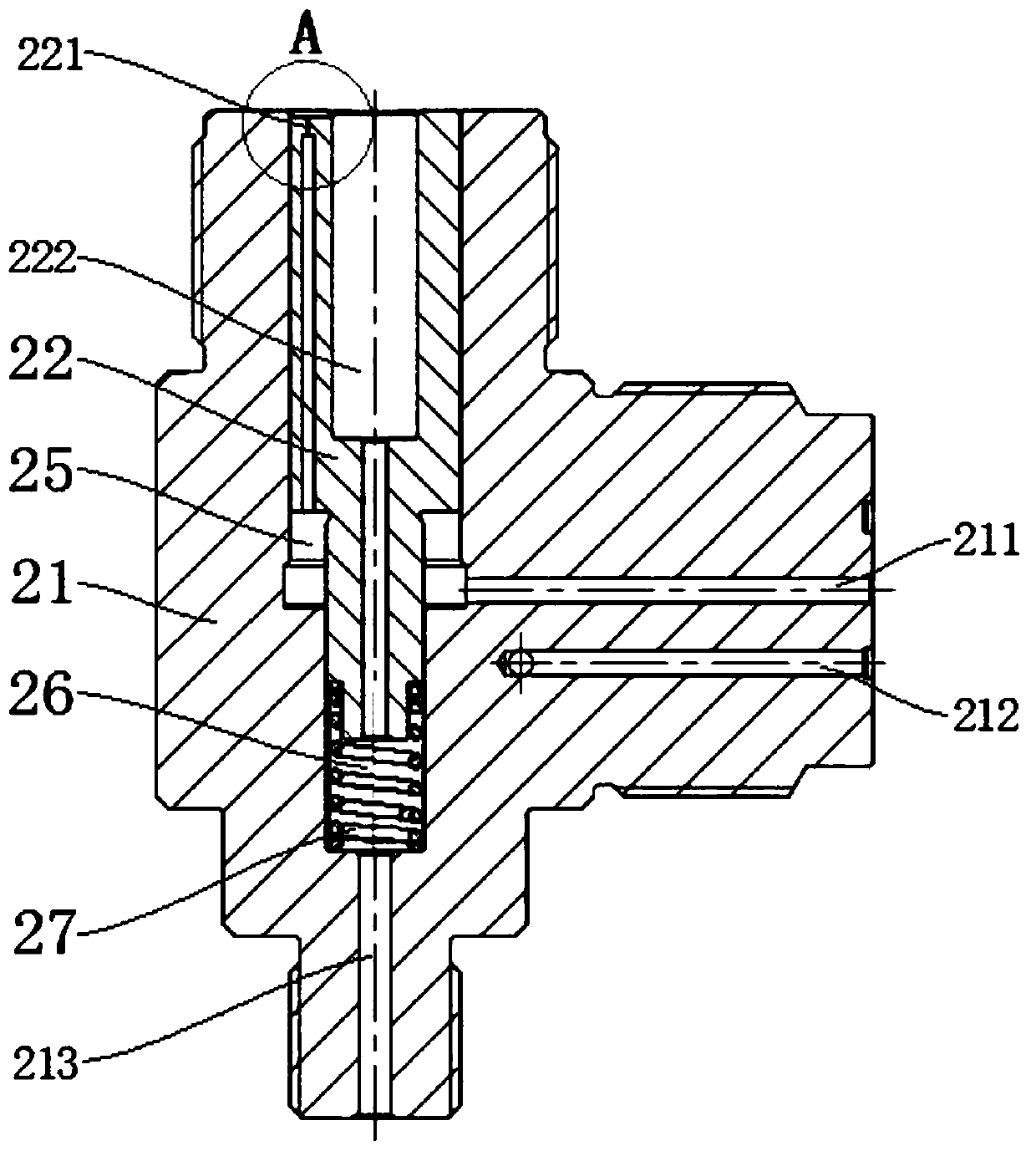

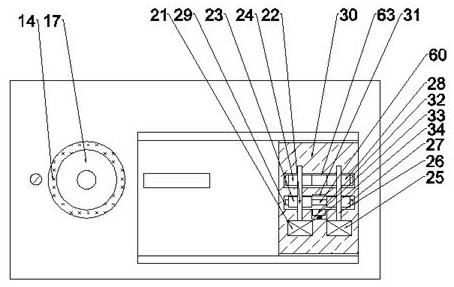

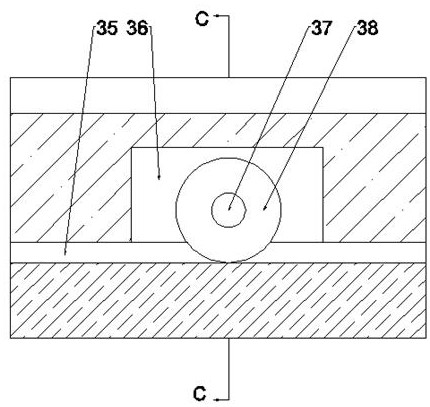

Diesel engine high-pressure fuel control booster pump

ActiveCN110397533AGuaranteed interchangeabilityReduce interchangeabilityMachines/enginesFuel injecting pumpsPressure differenceHigh pressure

The invention relates to a diesel engine high-pressure fuel control booster pump. The diesel engine high-pressure fuel control booster pump comprises a shell and is characterized by further comprisinga pressurizing coupling part, an electromagnetic valve assembly and a pressure relief assembly; the pressurization coupling part comprises a booster pump body, a pressurization plunger and a spring;a pressurization plunger cavity and a pressurization cavity which are mutually independent are formed between the pressurization plunger and the booster pump body, and the spring is positioned in thepressurization cavity; a pressure relief passage communicated with the pressurization plunger cavity and an oil return passage communicated with the outside of the booster pump body are arranged in the booster pump body; and the pressure relief passage is in communication with the oil return passage through the electromagnetic valve assembly through controlling the pressure relief assembly, and the pressurization plunger drives the pressurization cavity to realize fuel pressurization due to pressure differential motion. According to the diesel engine high-pressure fuel control booster pump, the fuel pressurization time and the frequency can be accurately controlled, the fuel injection laws of all the working conditions of the diesel engine can be matched, the fuel can be fully combusted, and the pollution can be reduced; the diesel engine high-pressure fuel control booster pump can be suitable for various high-pressure fuel systems with different supercharging ratios, and is compact instructure, good in reliability, flexible in control, fast in response and convenient and rapid to install.

Owner:CHONGQING HONGJIANG MACHINERY

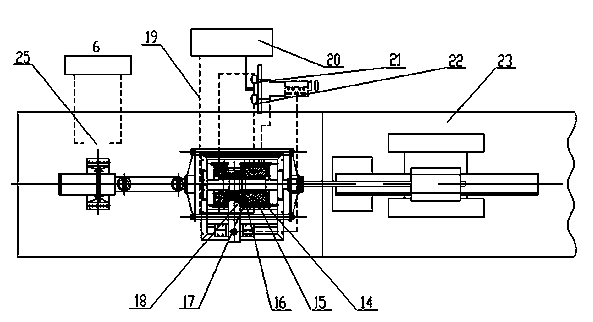

Overall test and data testing device for large-tonnage horizontal directional drilling machine

InactiveCN104236945AQuality improvementIncrease speedStructural/machines measurementPull forcePush pull

The invention discloses an overall test and data testing device for a large-tonnage horizontal directional drilling machine. The overall test and data testing device comprises a basic connecting plate, a power input connector, a carriage, a dynamometer, a computer torsion control circuit, a computer torsion control operating table, a computer push-pull force control operating table, a computer push-pull force control circuit, a push-pull force sensor and a hydraulic damping system. The hydraulic damping system is composed of a damping oil cylinder, a hydraulic pipeline and a hydraulic station. The torque, the rotating speed and the power of the dynamometer are connected to the computer torsion control operating table through the computer torsion control circuit, and signals of the push-pull force sensor of the hydraulic damping system are input in the computer push-pull force control operating table through the computer push-pull force control circuit. After power is input in the overall test and data testing device for the large-tonnage horizontal directional drilling machine by the horizontal directional drilling machine, overall tests and testing can be conducted on push force and pull force of the horizontal directional drilling machine and the output torque, the rotating speed and the power of a power head of the horizontal directional drilling machine.

Owner:XUZHOU XUGONG FOUND CONSTR MACHINERY

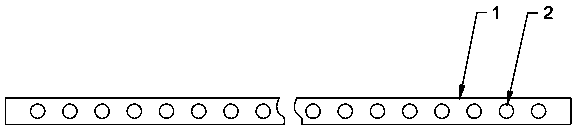

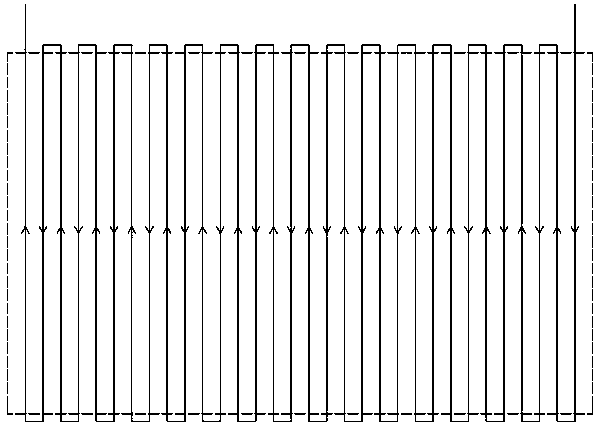

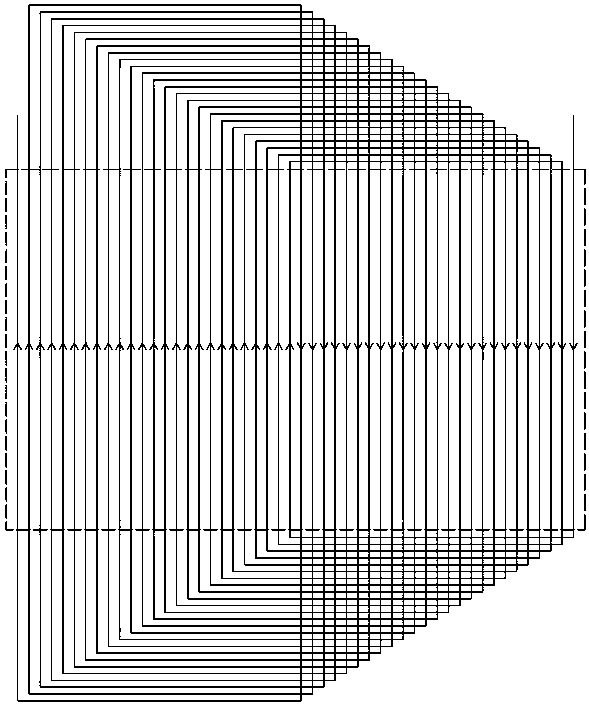

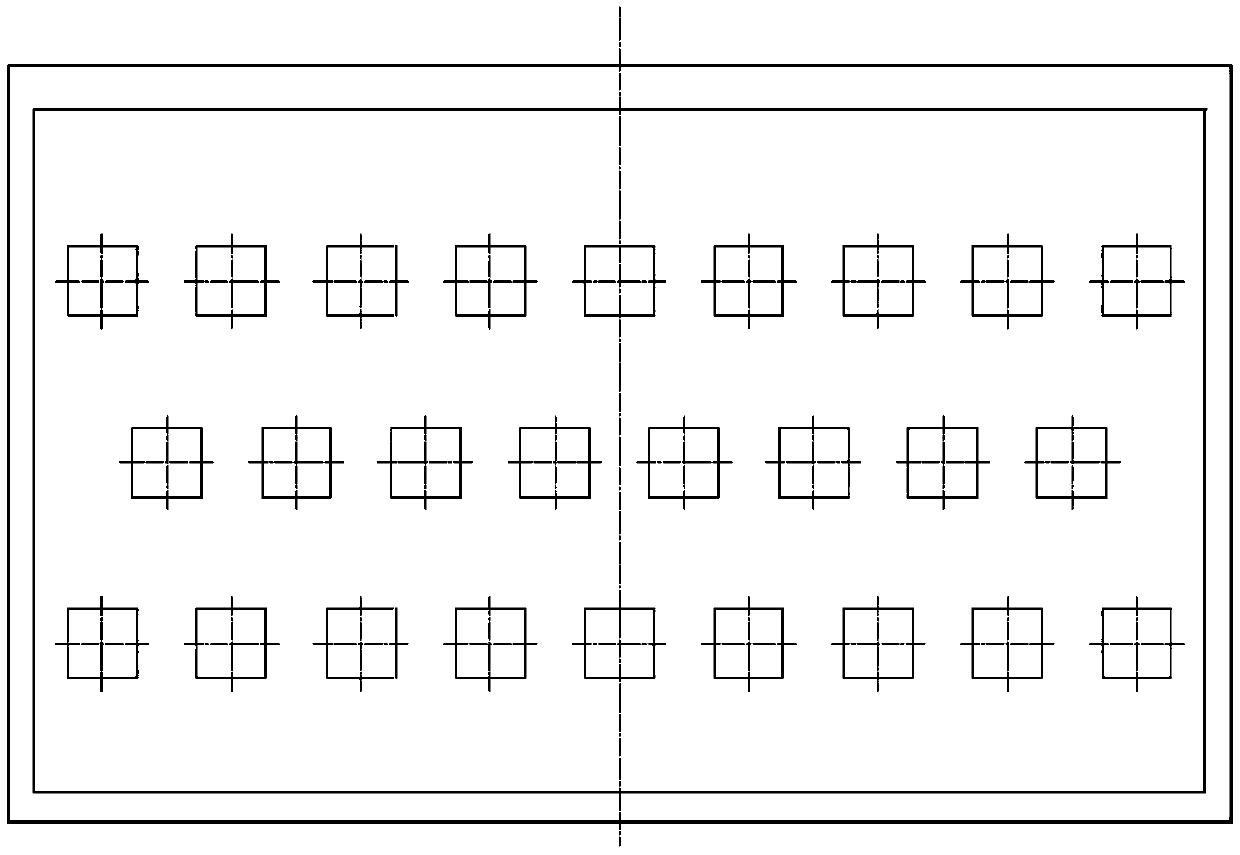

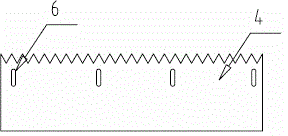

High-frequency electromagnetic induction straight hot press heating plate

PendingCN111203945AEven distribution of coilsHeating evenlyPlywood pressesLaminationPhysicsSteel plates

The invention discloses a high-frequency electromagnetic induction straight hot press heating plate. The high-frequency electromagnetic induction straight hot press heating plate comprises a steel plate and a high-temperature electromagnetic wire; a row of wire holes penetrating through the steel plate are formed in the positions, parallel to the upper surface and the lower surface, of the middleof the steel plate and are distributed at equal intervals, and the distance between centers of every two adjacent wire holes is 5-10 cm; when the distance between centers of every two adjacent wire holes is 5-8 cm, the high-temperature electromagnetic wire is threaded through the wire hole according to the principle that the current direction of every two adjacent holes is consistent as much as possible, and the two ends of the high-temperature electromagnetic wire are connected with a high-frequency heating power source and a controller. According to the high-frequency electromagnetic induction straight hot press heating plate, through the wire hole forming mode, the self structure of the steel plate is not changed as much as possible, and it is ensured that the mechanical property of thesteel plate is not changed; and meanwhile, it can be ensured that electromagnetic energy is absorbed by the steel plate sufficiently and converted into heat energy, the whole steel plate is uniform in heating, and an existing flat hot pressing plate is transformed advantageously.

Owner:湖南宏润科技发展有限公司

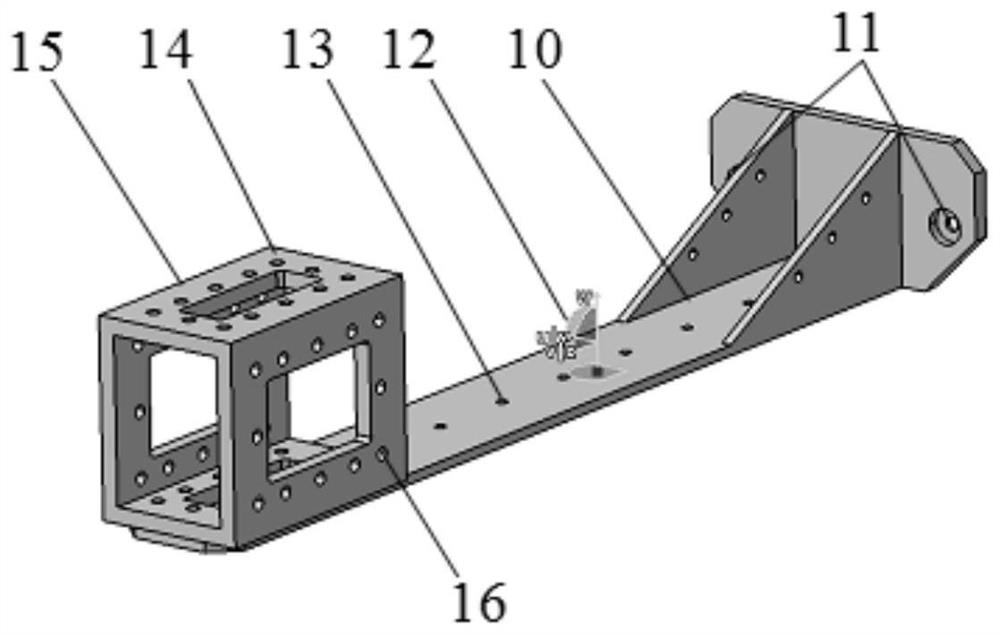

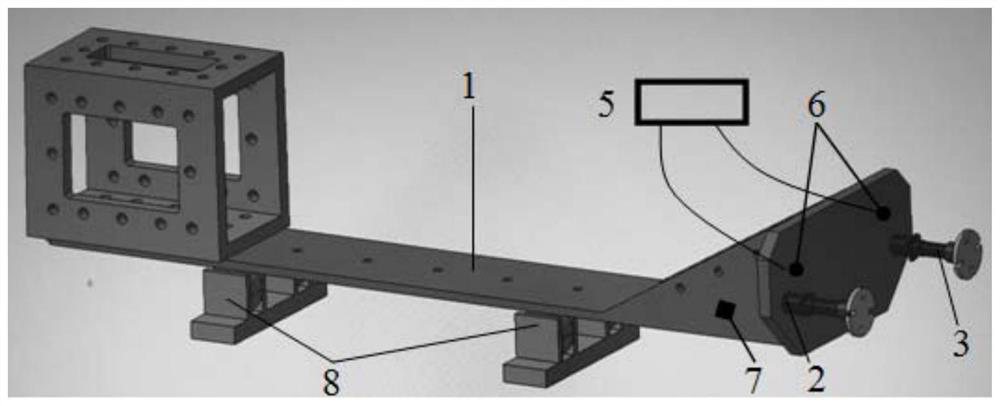

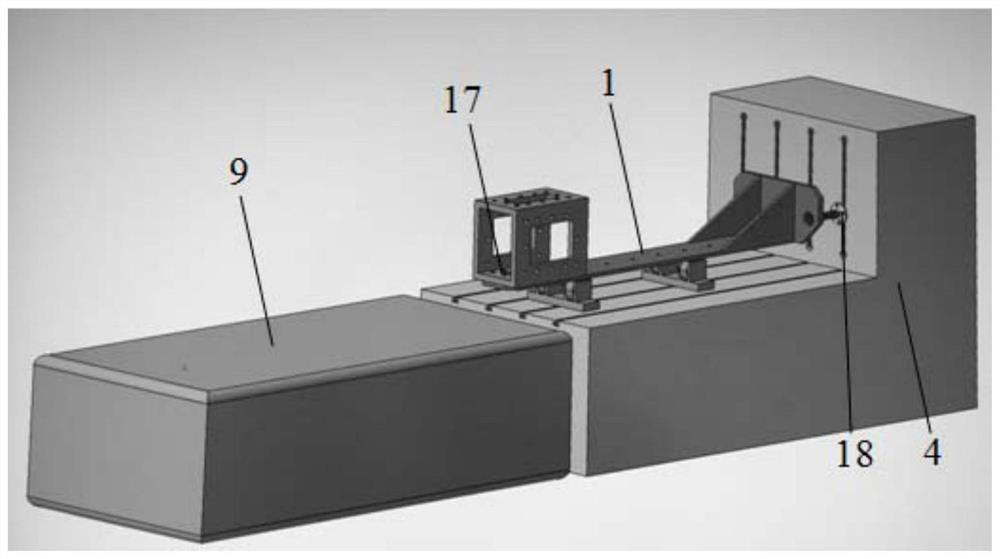

Test method for verifying ejection separation of cruise aircraft assembly

InactiveCN111746823AWell formedLarge adjustment rangeAircraft components testingFlight vehicleControl theory

The invention relates to a test method for verifying ejection separation of a cruise aircraft assembly. The test method comprises the steps of S1, simulating an actual aircraft by adopting an aircraftmass characteristic simulation tool; S2, adjusting the position of the mass center of the aircraft mass characteristic simulation tool relative to an ejection point to be consistent with that of an actual aircraft; S3, installing a catapult to the position of a connecting interface of the aircraft mass characteristic simulation tool, and applying pre-tightening force the same as that of installation of the actual aircraft; and S4, installing a thrust sensor at the other end of the catapult, then placing the aircraft mass characteristic simulation tool on four pulleys, and installing the thrust sensor on an ignition test bed. According to the method, the specially designed aircraft mass characteristic simulation tool is concise in form and large in adjustable range, and can meet the requirements of multiple working conditions; adopted instruments and equipment are measuring tools commonly used in a laboratory; the test method is very easy to implement, so that the test method has relatively high popularization and application values.

Owner:BEIJING SPACE TECH RES & TEST CENT

Integrated technique of hard alloy brazing and heat treatment for cutting pick

The invention discloses an integrated technique for hard alloy brazing and heat treatment for a cutting pick. The technique is characterized by including the steps of A, feeding; B, die forging; C, machining; D, hard alloy brazing; E, heat treatment; F, surface treatment. The technique has the advantages that brazing quality is improved greatly, technical indexes of heat treatment meet the condition requirements, productivity is improved effectively, production cost is reduced, work environment is improved, and environmental pollution is reduced greatly.

Owner:SHAANXI AOBANG FORGING

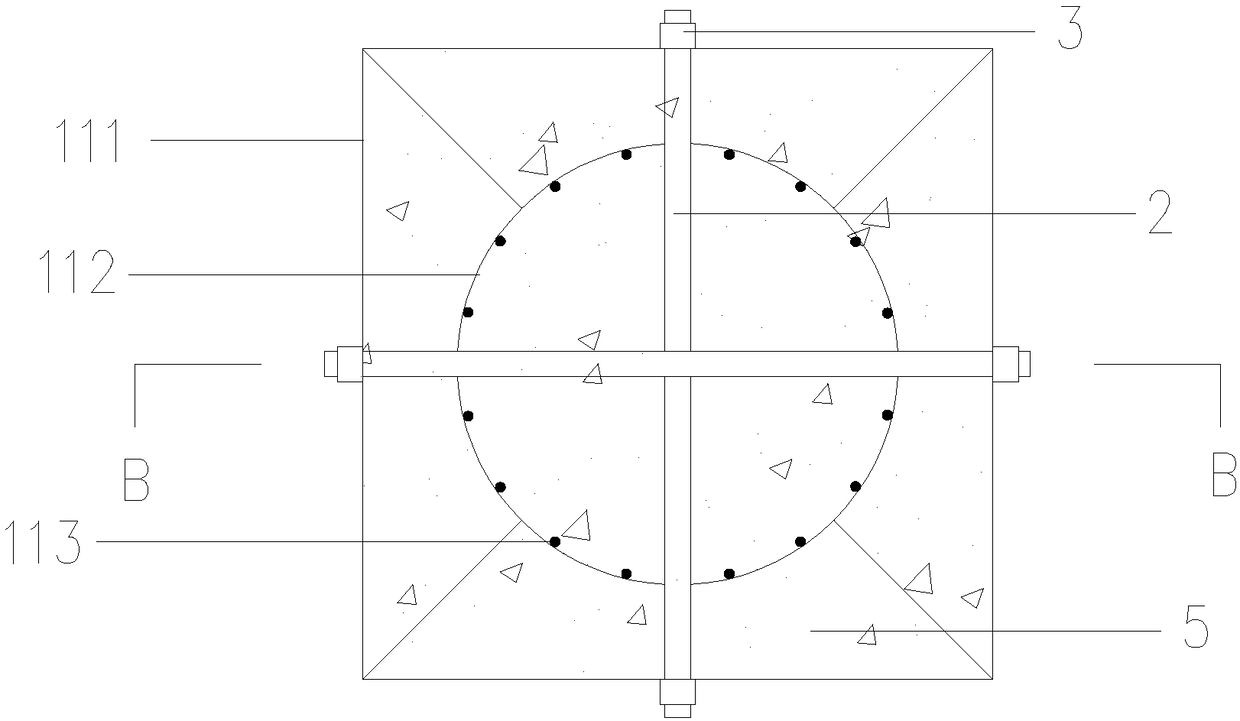

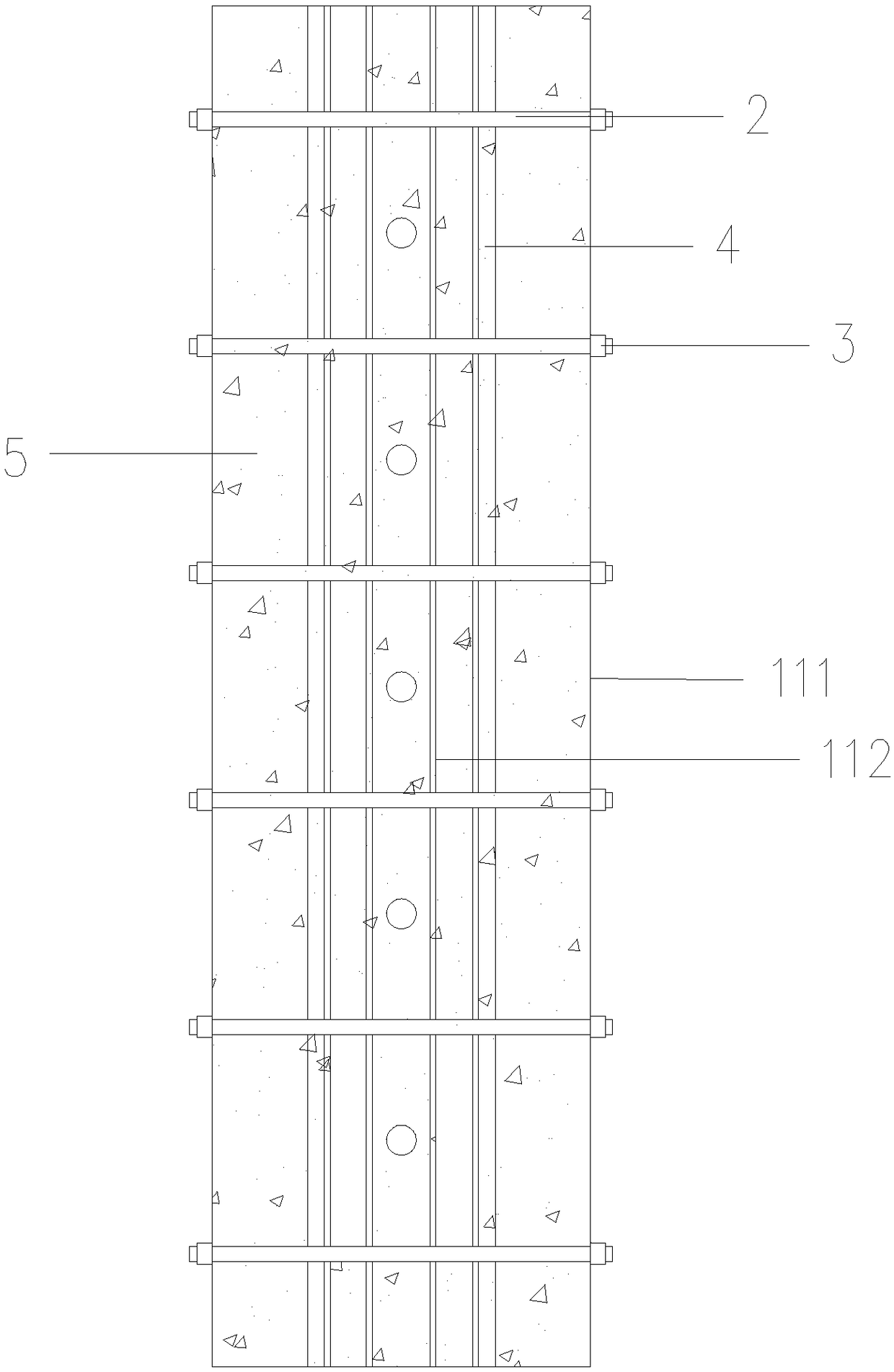

Fabricated concrete-filled steel tube combination column and splicing method

PendingCN108222371AGuaranteed binding effectIncreased bending stiffnessStrutsPillarsSheet steelRebar

The invention discloses a fabricated concrete-filled steel tube combination column and a splicing method. The fabricated concrete-filled steel tube combination column comprises a concrete-filled steeltube prefabricated part which is spliced into a whole by means of being defined by at least two concrete-filled steel tube columns, and after defining and splicing, the section of the concrete-filledsteel tube prefabricated part is externally square and internally circle. Through holes are formed in a rectangular steel plate and an arc-shaped steel plate, the rectangular steel plate and the arc-shaped steel plate are formed through welding, and then reinforcements are welded to the internally-sunken side of the arc-shaped steel plate. The multiple concrete-filled steel tube columns forms theconcrete-filled steel tube prefabricated part with the section being externally square and internally circle in defined and spliced modes, and then screws are connected into the through holes formedin the rectangular steel plate and the arc-shaped steel plate in an inserted mode to be fixed. A pouring material is injected into the concrete-filled steel tube prefabricated part. According to the fabricated concrete-filled steel tube combination column, the constraint effect of internal circular steel tubes on the pouring material in a core area can be ensured, and the advantage of the rectangular section on building arrangement can also be developed.

Owner:HUAQIAO UNIVERSITY

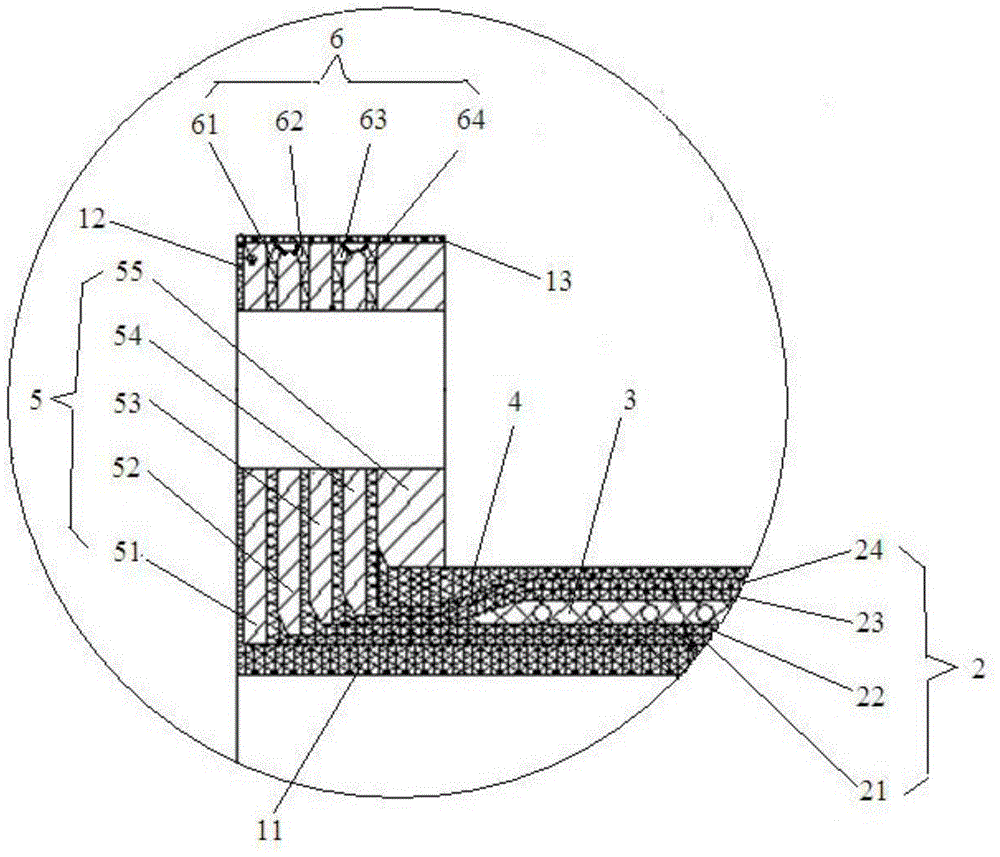

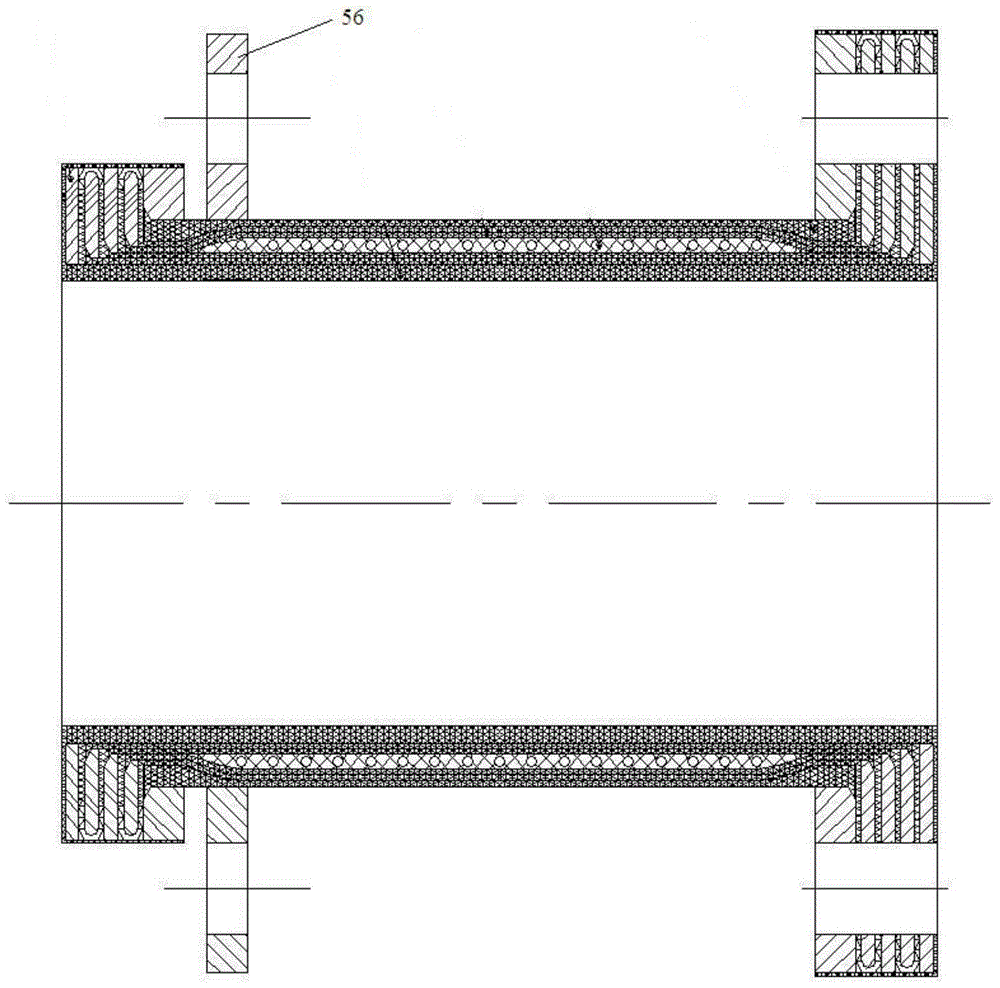

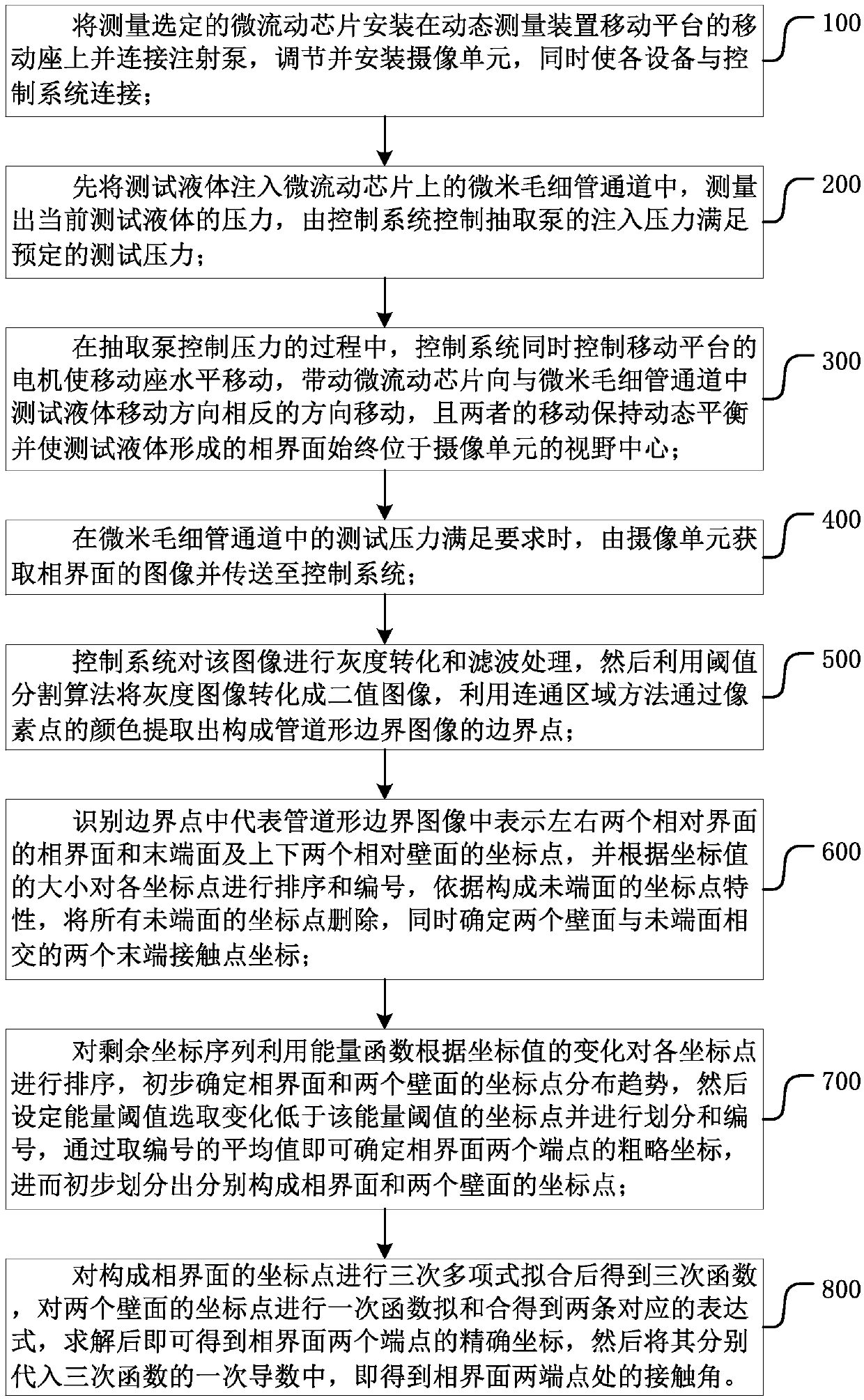

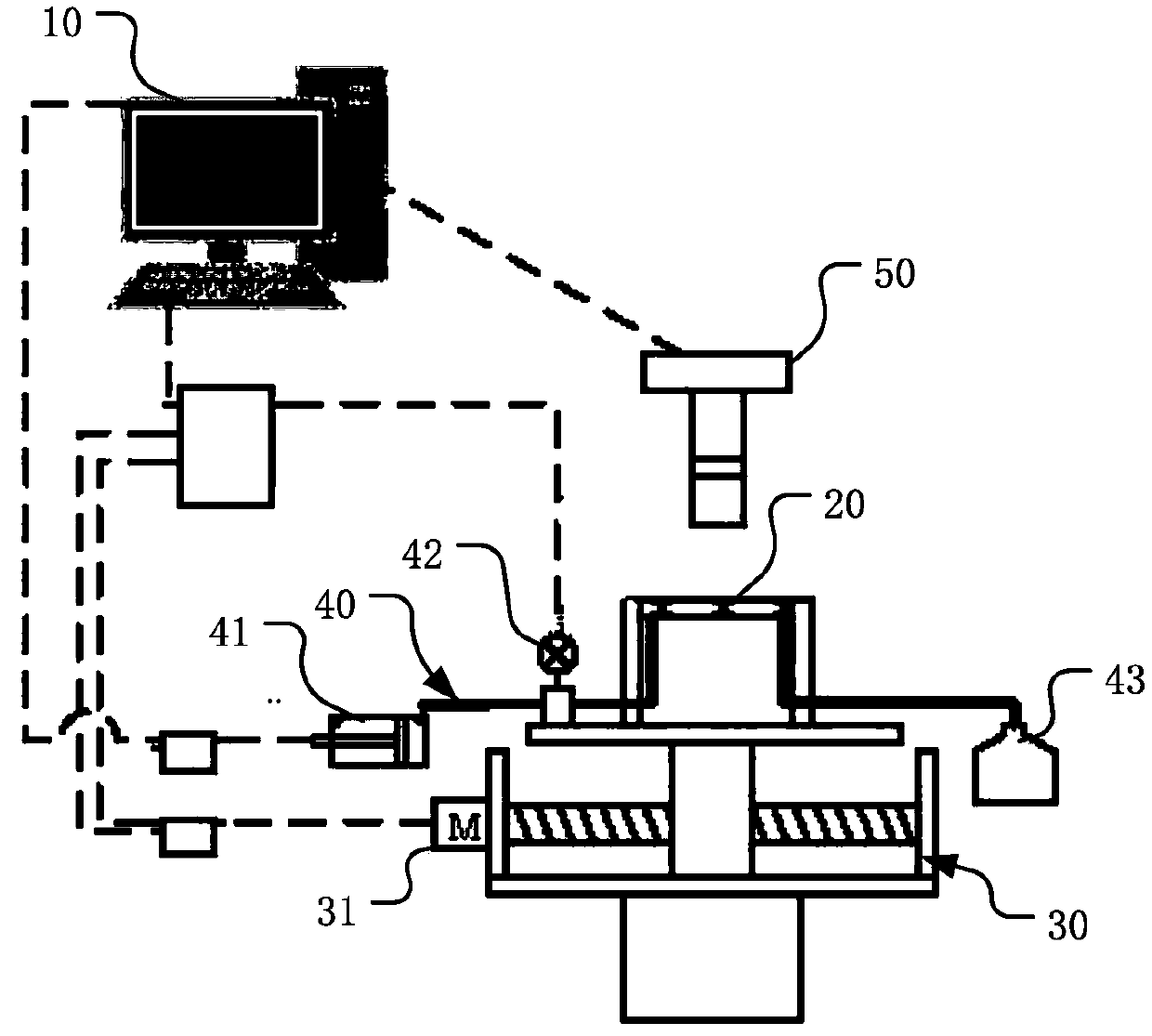

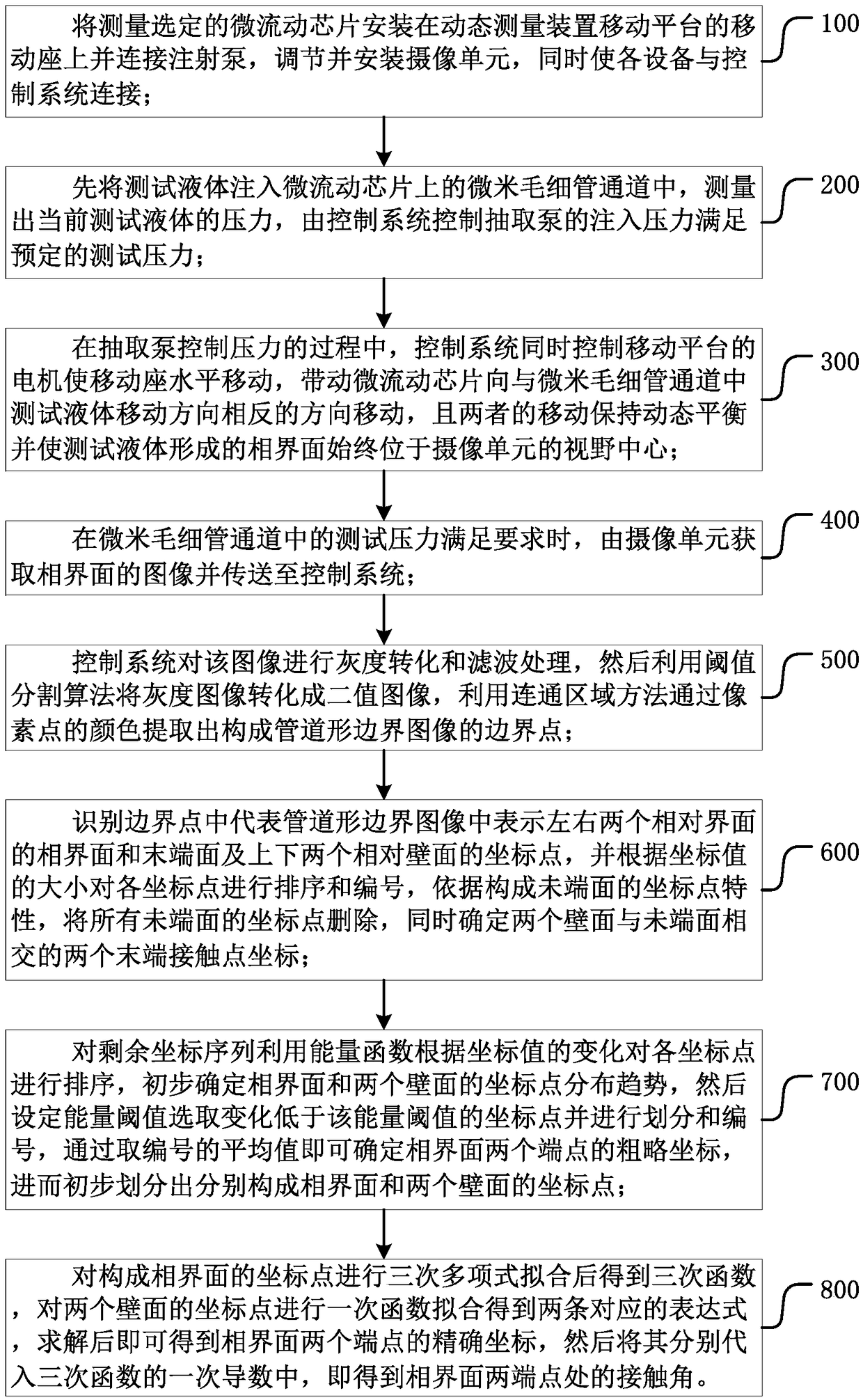

Measuring method for contact angle of gas-liquid phase interface in micrometer capillary passage

ActiveCN109187278AImprove efficiencyHigh measurement accuracySurface/boundary effectBond numberImaging processing

The invention provides a measuring method for a contact angle of a gas-liquid phase interface in a micrometer capillary passage. The pressures or flow speeds of flowing processes of a gas phase and aliquid phase in a micrometer-scale capillary are controlled by using a dynamic testing device, and the dynamic contact angle measurement in the states of small capillary number and small Bond number is realized for the first time. The measurement for the contact angle and phase interface speed based on an image processing method is firstly adopted, so that the data processing efficiency and the measuring precision are greatly improved. The invention further provides various algorithms for controlling the pressure of a two-phase flowing process and the speed of an electric platform, so that theflexibility during actual operation is improved, and furthermore, demands under various working conditions are met.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Method for determining relationship between pressure and flow in micron capillary channel

ActiveCN109000883AImprove efficiencyHigh measurement accuracyHydrodynamic testingCapillary channelDynamic testing

The invention provides a method for determining the relationship between pressure and flow in a micron capillary channel. According to the method in the invention, control on the pressure or the flowspeed in a gas-liquid two-phase flow process in a micron capillary is realized by utilization of a dynamic test device; a method for obtaining a phase interface and phase interface displacement is provided; obtaining of the phase interface shape under the states of low capillary number and low bond number is realized for the first time; phase interface shape calculation and speed calculation basedon an image processing method are adopted for the first time; therefore, the data processing efficiency and the measurement precision are greatly increased; due to determination on the speed, the contact angle and the displacement of the phase interface, the relationship between the pressure and the test liquid flow in the micron capillary channel can be determined; therefore, a control system directly controls and adjusts pressure change according to the flow; an experimental process and a speed control algorithm of a movable base are simplified; the actual operation flexibility is improved;and requirements of all kinds of working conditions can be satisfied.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

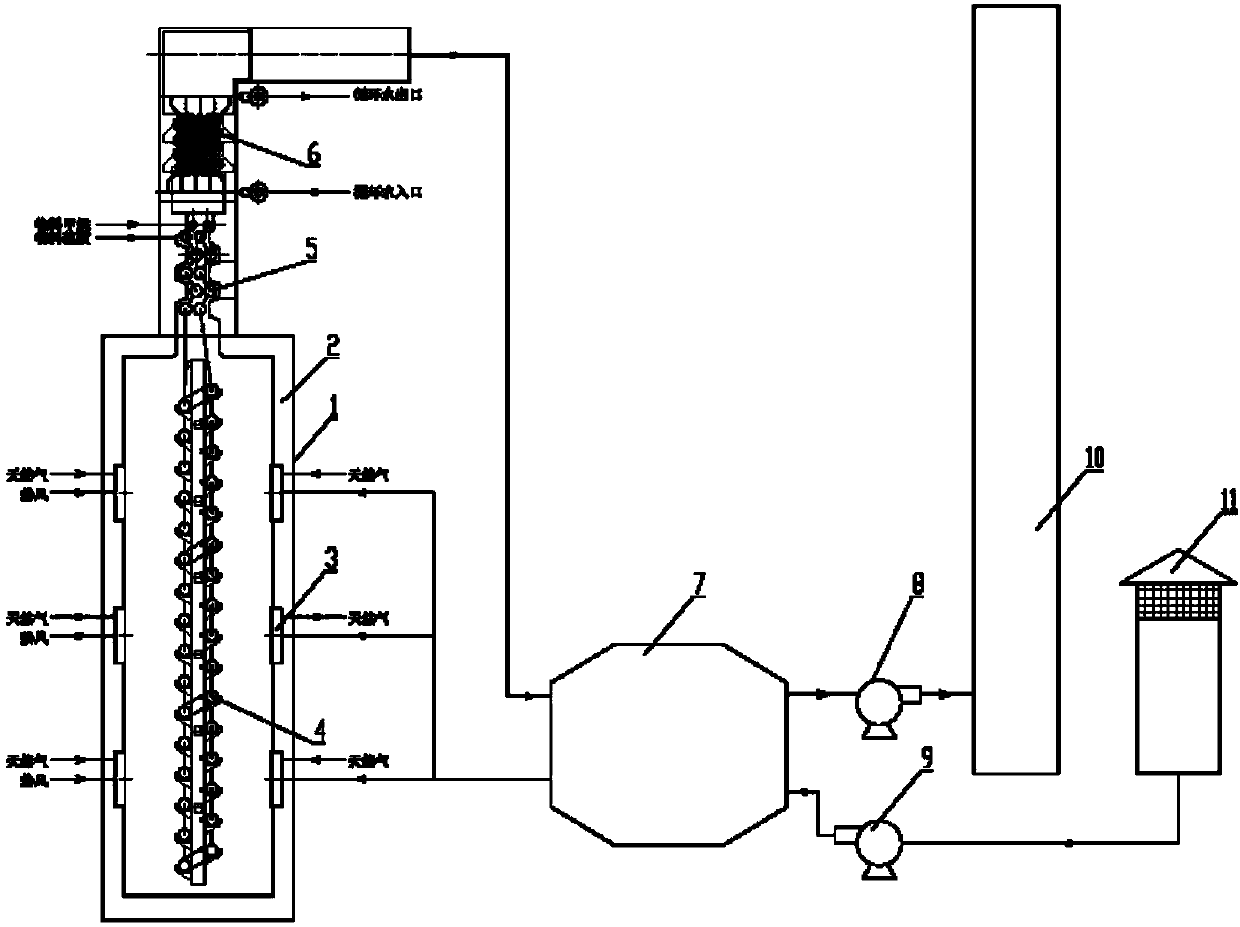

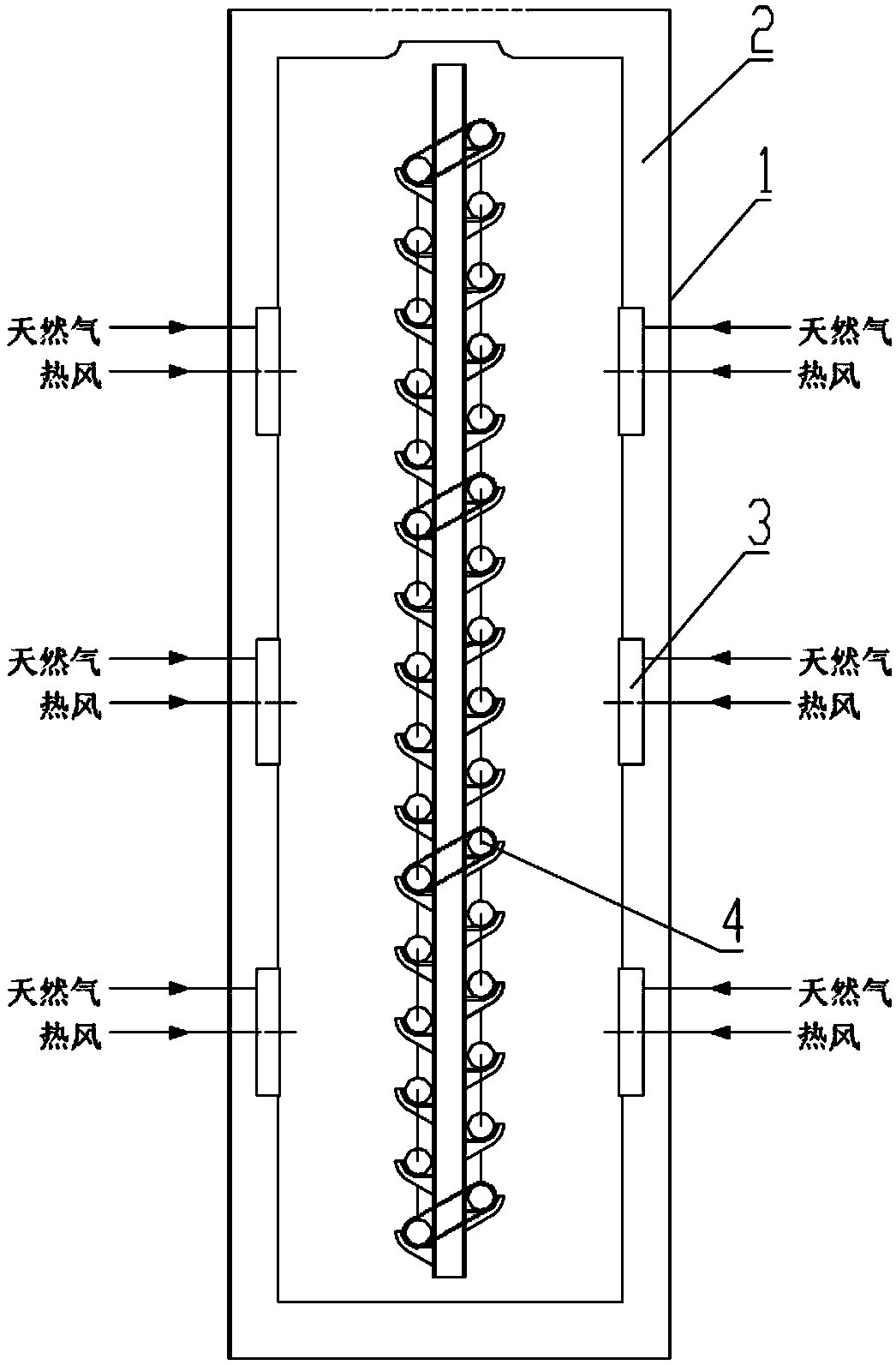

Novel reaction furnace for preparing carbon disulfide

PendingCN109650390AUniform and stable temperature distributionImprove purityCarbon disulfideCombustorEngineering

Disclosed is a novel reaction furnace for preparing carbon disulfide. The novel reaction furnace comprises a reaction furnace body and the like, the reaction furnace body is a radiation section of thereaction furnace, and connected with an impact section, the impact section is connected with a convection section, and a lining is installed in the reaction furnace body, the impact section and the convection section; a plurality of burners are installed on the side wall of the reaction furnace body, a furnace pipe of the radiation section is installed in the reaction furnace body, a furnace pipein the impact section is connected with the furnace pipe of the radiation section, and a material enters the furnace pipe in the impact section; the convection section is connected with a preheater through a flue duct, and the preheater is connected with a chimney through an induced draft fan; an air inlet tower is connected with a burner blower which is connected with the preheater; the preheater is connected with the burners through a pipeline and provides hot air for the burners, and the hot air and natural gas entering the burners are mixed for burning. The novel reaction furnace is usedfor preparing carbon disulfide, on the premise of meeting process performance requirements, the heat distribution of a temperature field is more uniform, the quality of the carbon disulfide product ishigher, the exhaust smoke temperature and the heat dissipation loss are reduced, and the overall thermal efficiency of the reaction furnace is improved.

Owner:BEIJING HANGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

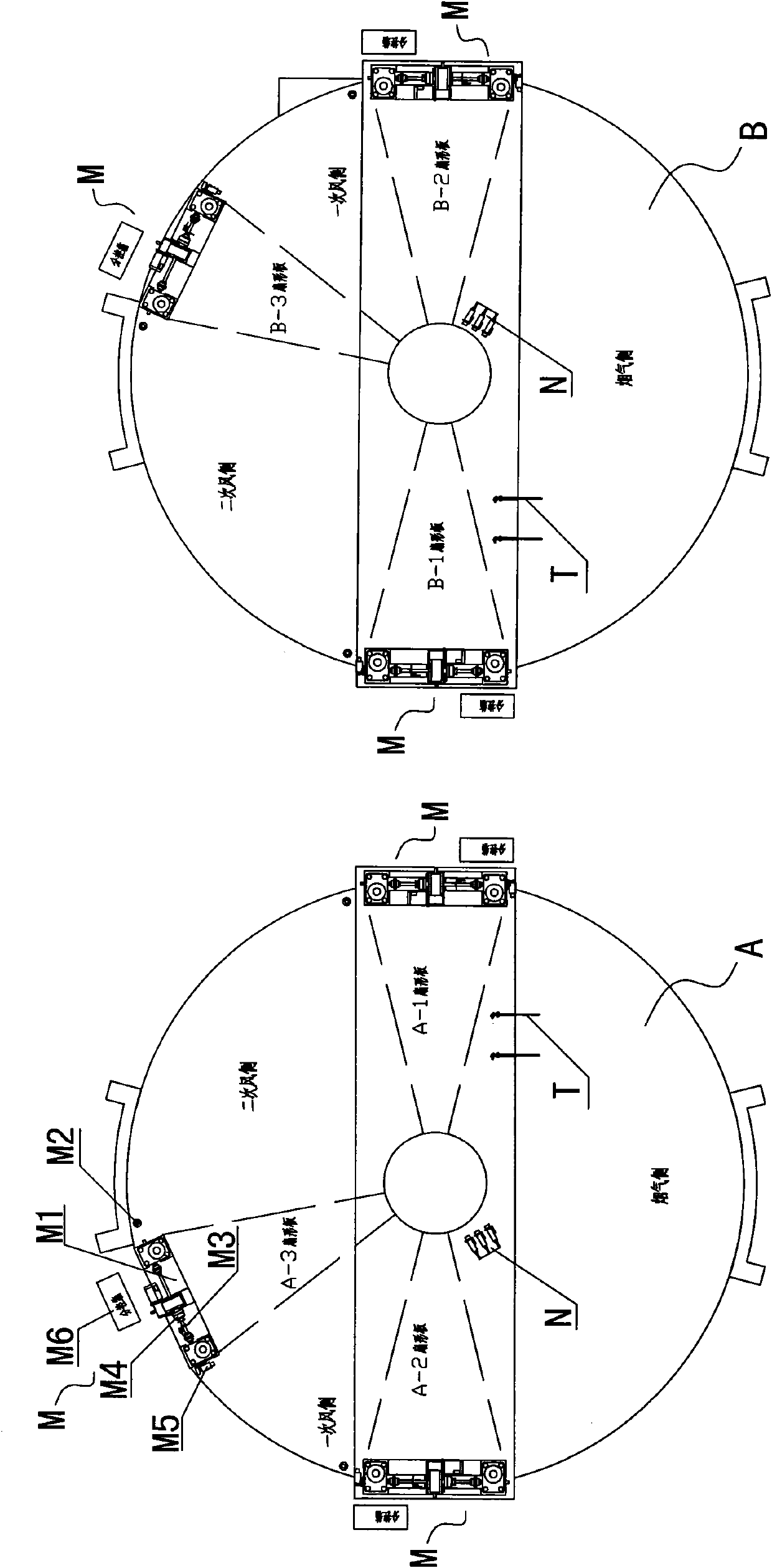

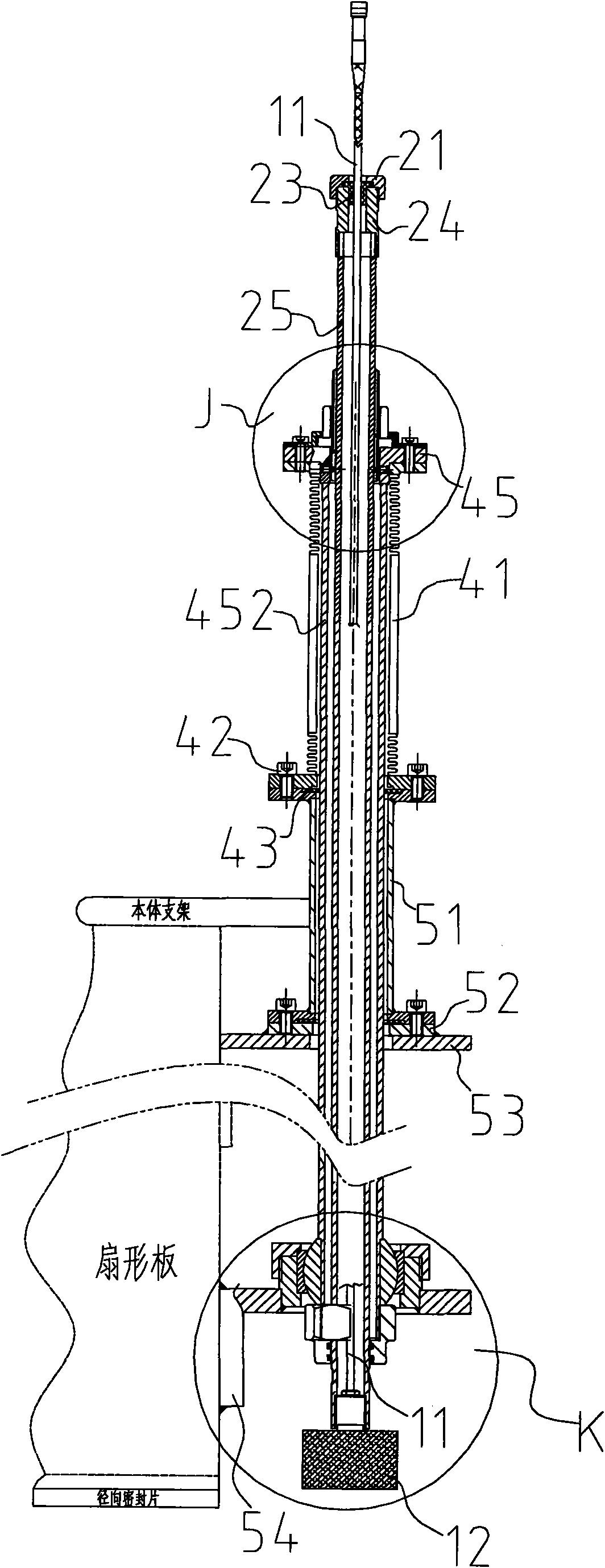

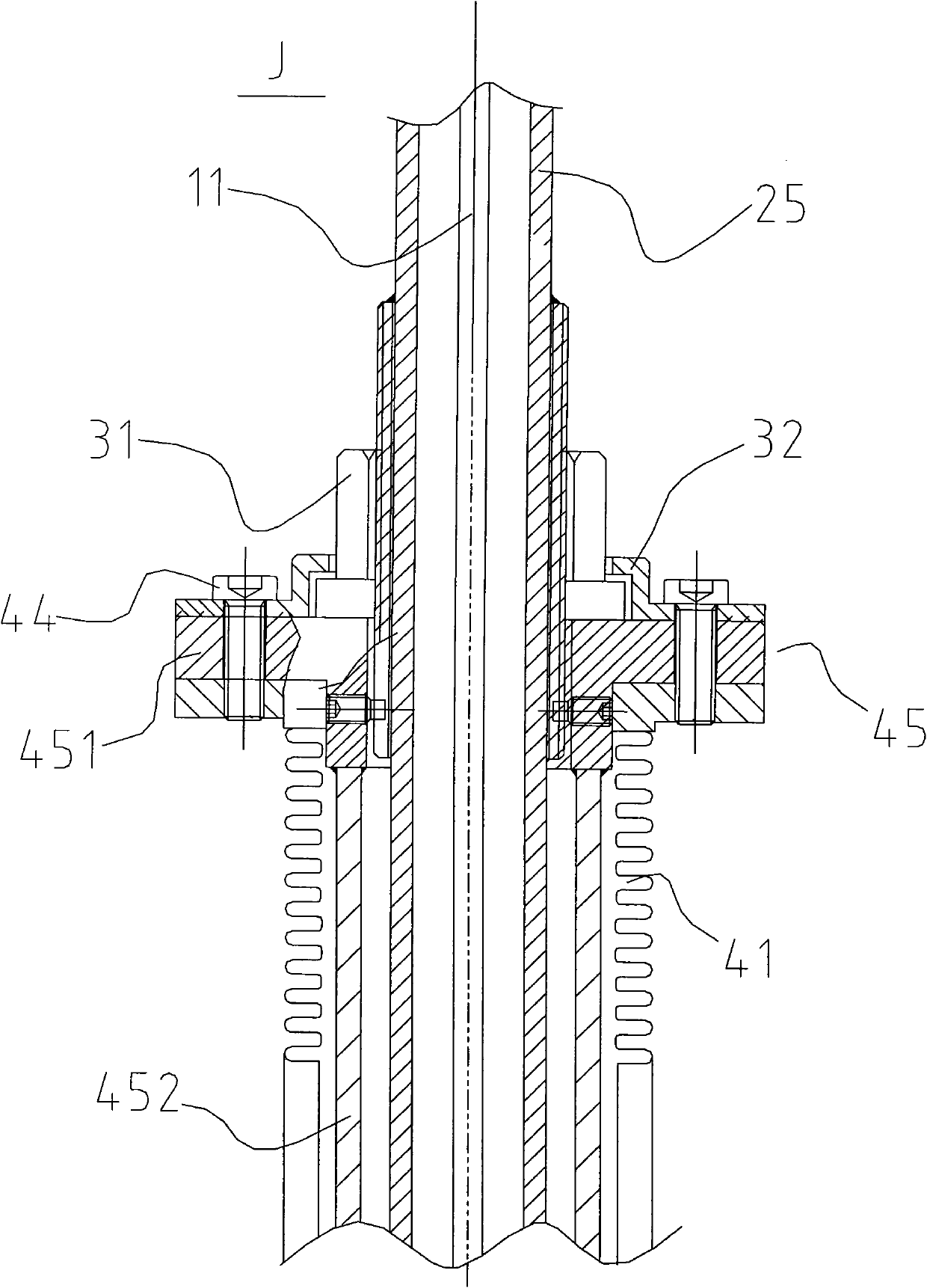

Air leakage control system and control method for air pre-heater

ActiveCN102278767BLower levelReduce the overall heightCombustion processIndirect carbon-dioxide mitigationAir preheaterTemperature control

The invention discloses an air leakage control system and an air leakage control method for an air pre-heater. The system comprises a main control unit, a fan-shaped plate execution unit and a temperature detection device; a sensor device of the fan-shaped plate execution unit transmits the acquired current signals for reflecting gaps of respectively corresponding fan-shaped plates and radial sealing sheets to the control unit; the temperature detection device transmits the acquired temperature signals to the control unit; and the control unit selectively controls a lifting mechanism of the execution unit according to the current signals or the temperature signals to drive the fan-shaped plates to move up and down. According to the air leakage control system, when the sensor device fails,the control unit can regulate the positions of the fan-shaped plates through the temperature signals acquired by the temperature detection device, and an operator can overhaul and regulate the sensordevice in the temperature control process or the air pre-heater does not need to work, so the system is very important in the field, for abnormal halt produces huge loss.

Owner:SHANGHAI ORIENTAL MARITIME ENG TECH CO LTD

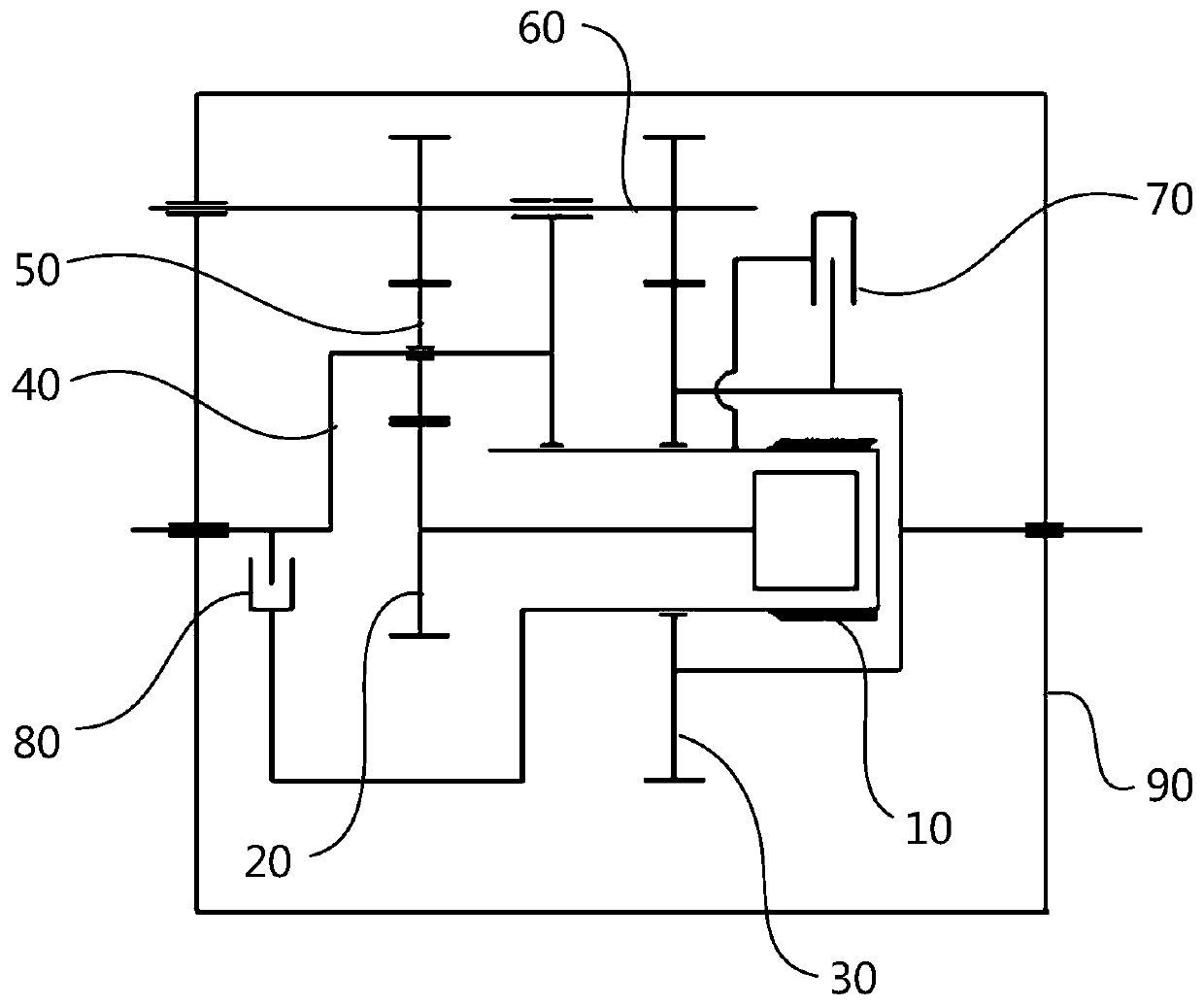

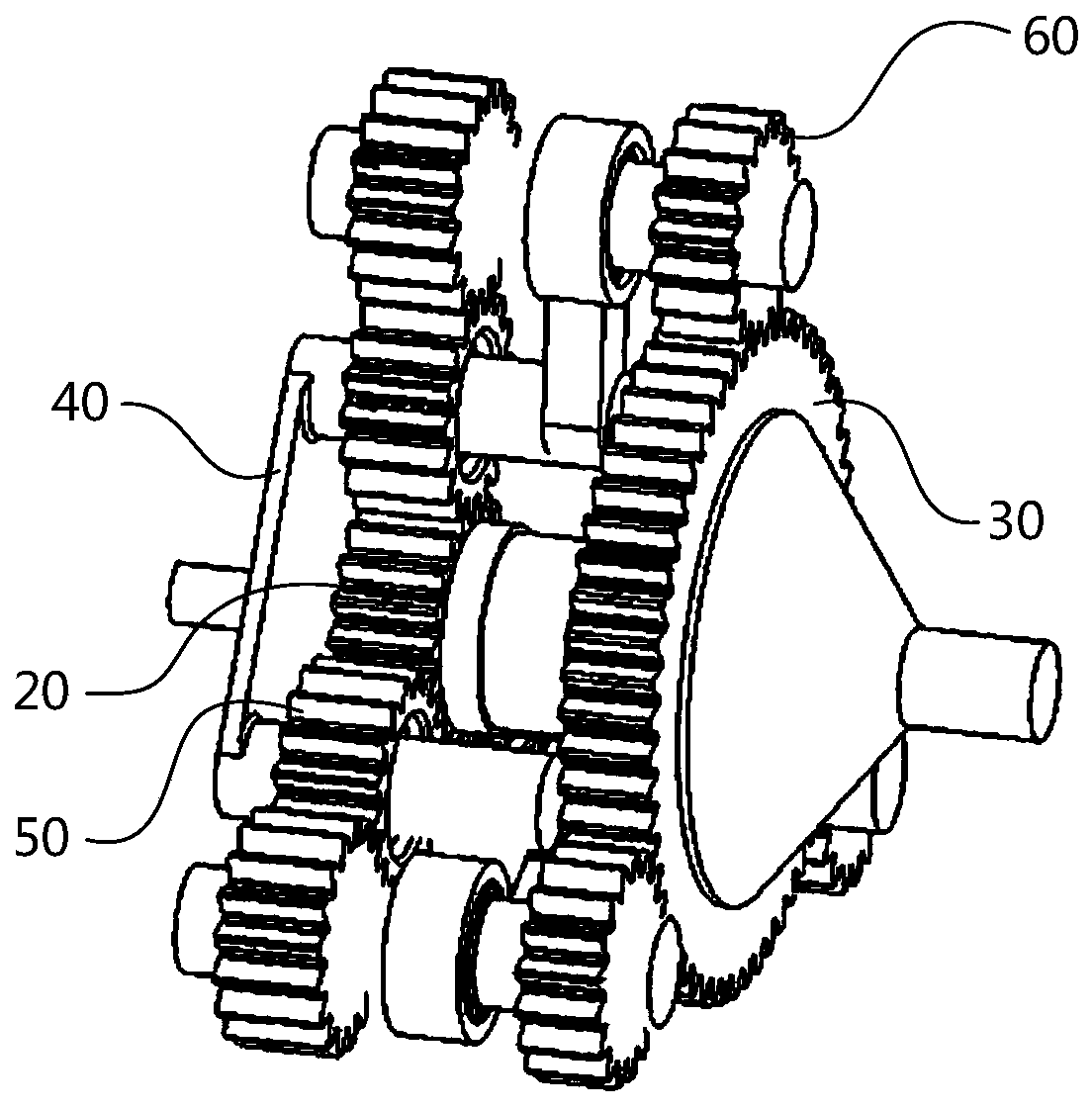

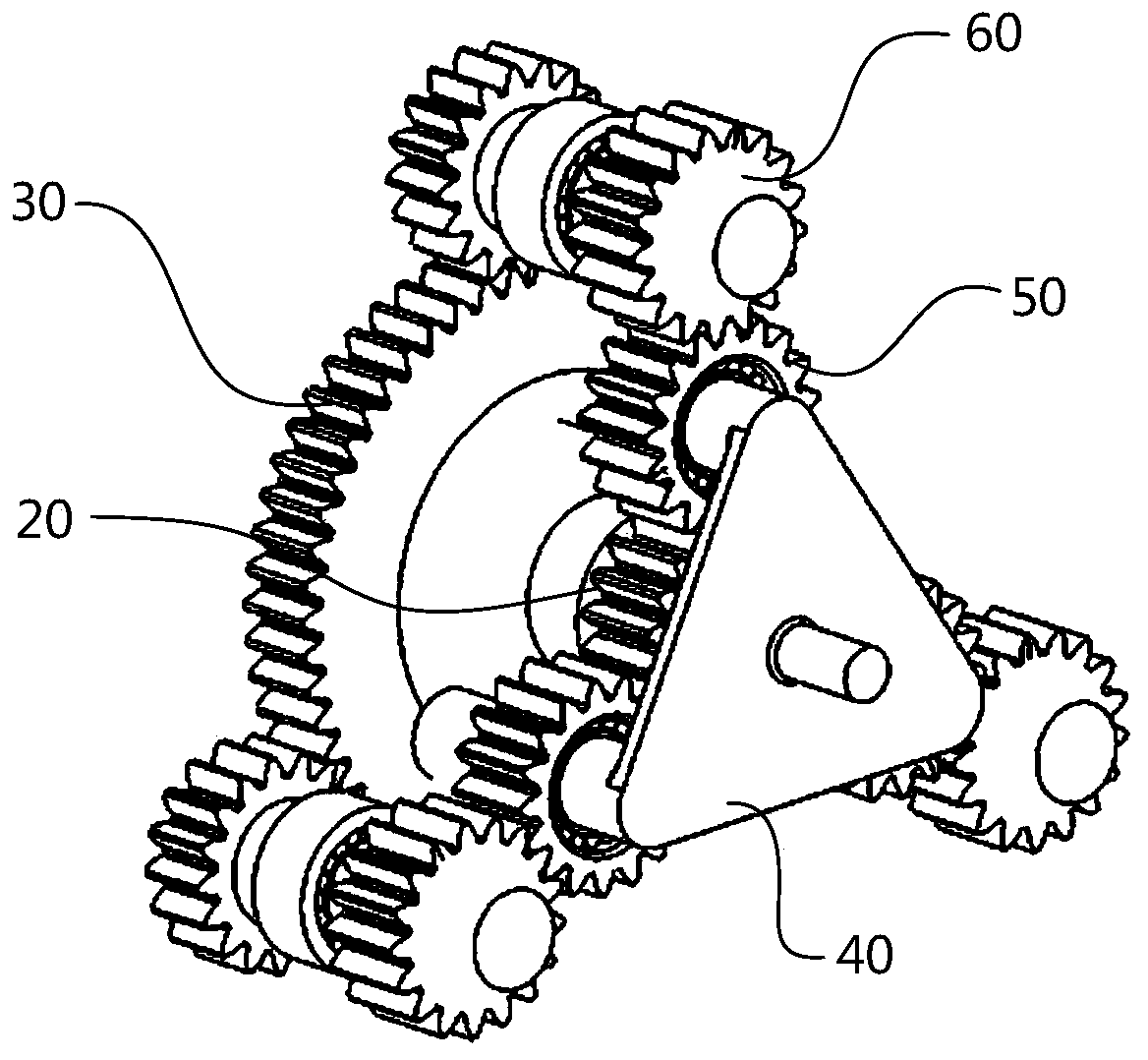

Transmission device and transmission

PendingCN110725909AChange output stateChange the number of output terminalsToothed gearingsGearing detailsEngineeringMechanical engineering

The invention relates to a transmission device and a transmission. The transmission device comprises a basal body, a rotating body, a first transmission mechanism, a second transmission mechanism anda middle transmission mechanism; the rotating body can be rotated relative to the basal body; the first transmission mechanism is selectively connected or disconnected with the basal body; part of thesecond transmission mechanism is selectively connected or disconnected with the basal body; the middle transmission mechanism is arranged between the first transmission mechanism and the second transmission mechanism; when the first transmission mechanism is connected with the basal body, and part of the second transmission mechanism is disconnected with the basal body, power obtained by the rotating body is output through the second transmission mechanism under the limiting effect of the first transmission mechanism and the middle transmission mechanism; and when the first transmission mechanism is disconnected with the basal body, and part of the second transmission mechanism is connected with the basal body, the power obtained by the rotating body is transferred to the first transmission mechanism and the middle transmission mechanism through the second transmission mechanism, and is output through the first transmission mechanism and the middle transmission mechanism.

Owner:XCMG CONSTR MACHINERY

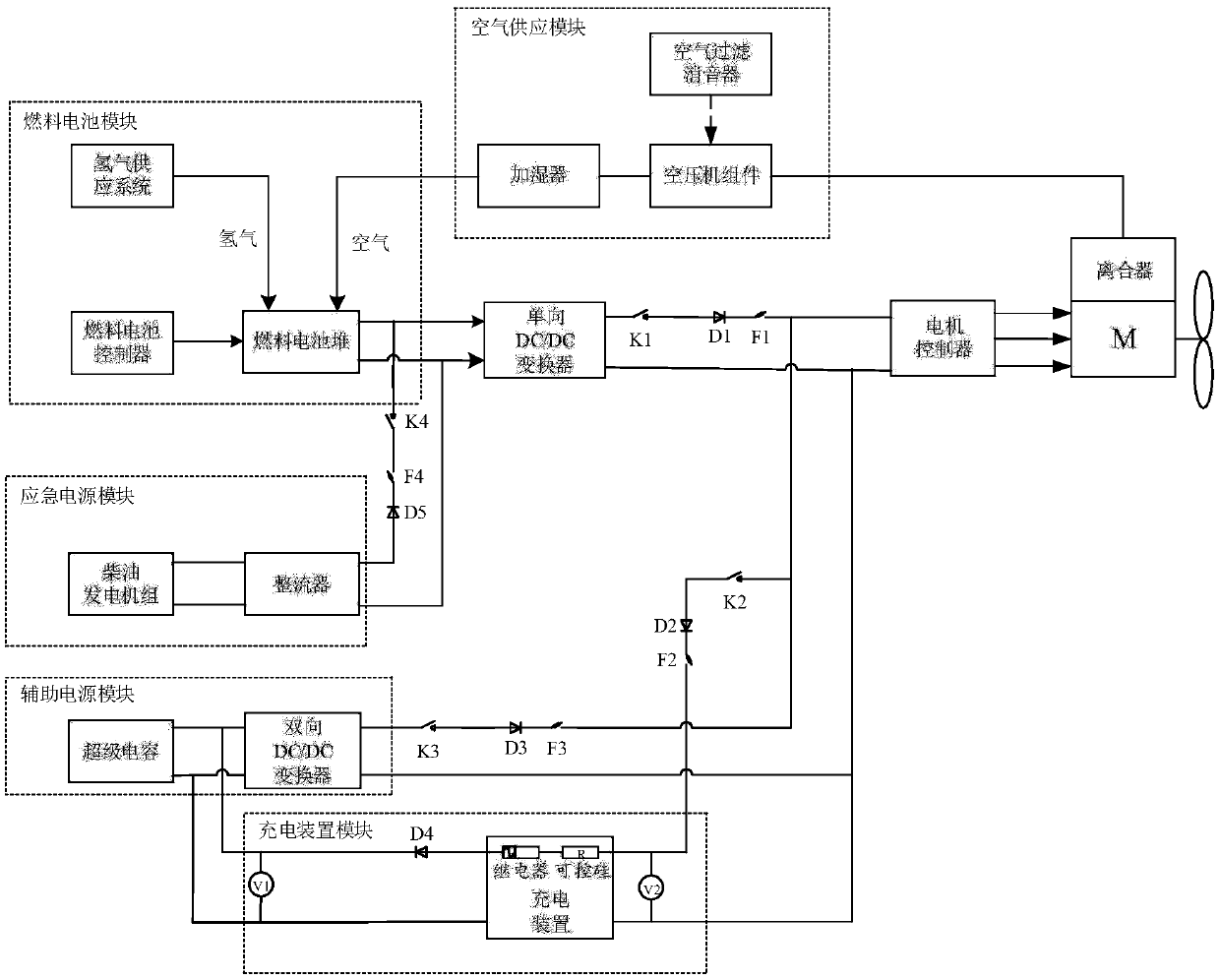

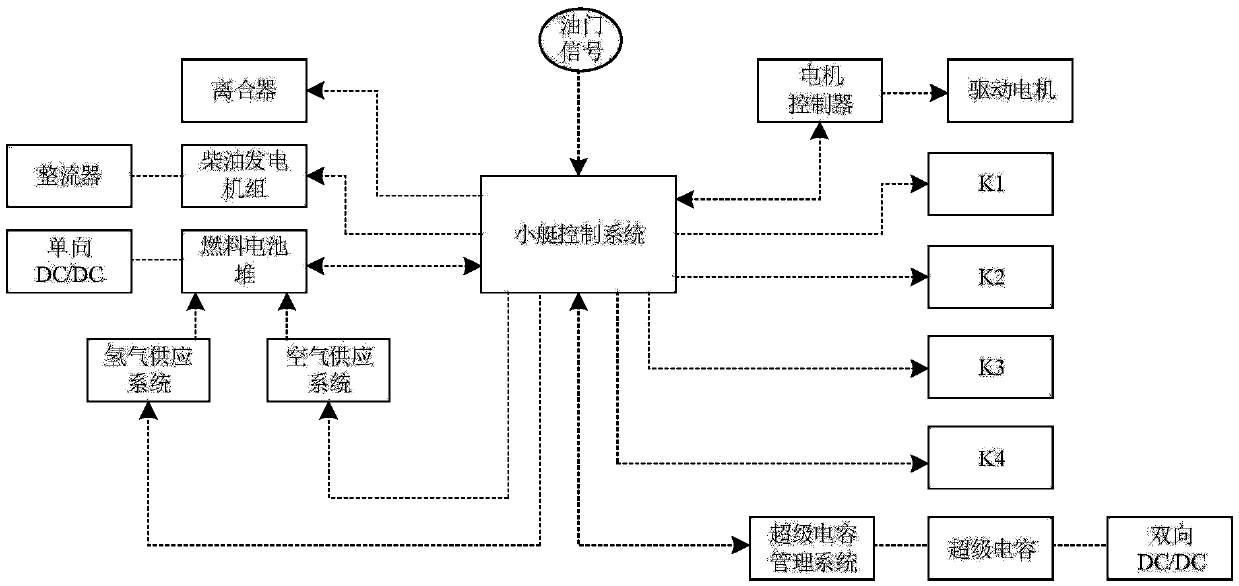

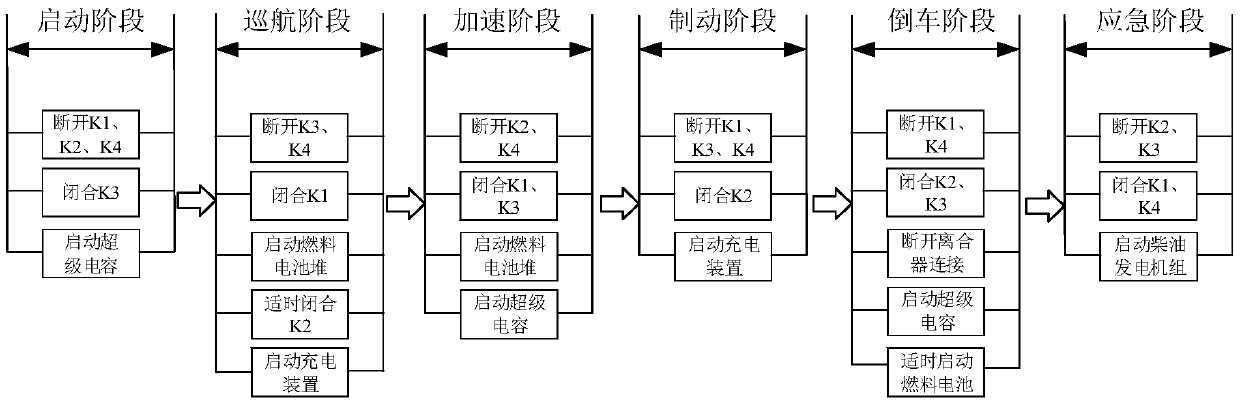

Fuel cell hybrid power system for small inland river boat

InactiveCN109649624ALong sailing timeGuaranteed safety and reliabilityPower plants using propulsion unit combinationsPropulsive elementsSpecific gravityCapacitance

The invention discloses a fuel cell hybrid power system for a small inland river boat. By parallel output of a fuel cell and a supercapacitor, when one power source is in performance decline, the other one can provide energy required by the small inland river boat. The output voltage of a fuel cell stack passing through a single-way DC / DC converter is higher than the full voltage of the supercapacitor. When the small inland river boat requires low output power, the fuel cell provides energy and charges the supercapacitor until the supercapacitor is fully charged, and then charging is stopped.When the output power required by the small inland river boat exceeds capacity of the fuel cell, the fuel cell and the supercapacitor operate simultaneously to provide power for the small inland riverboat. Once fuel cell faults or fuel exhausting occur in a navigation process of the small inland river boat, a diesel generating set starts to provide electric energy for the small inland river boatto return. Therefore, navigation time of the small inland river boat can be prolonged to the greatest extent, an air power system is simplified, a proportion of a power system is decreased, and systemenergy consumption is reduced.

Owner:WUHAN UNIV OF TECH

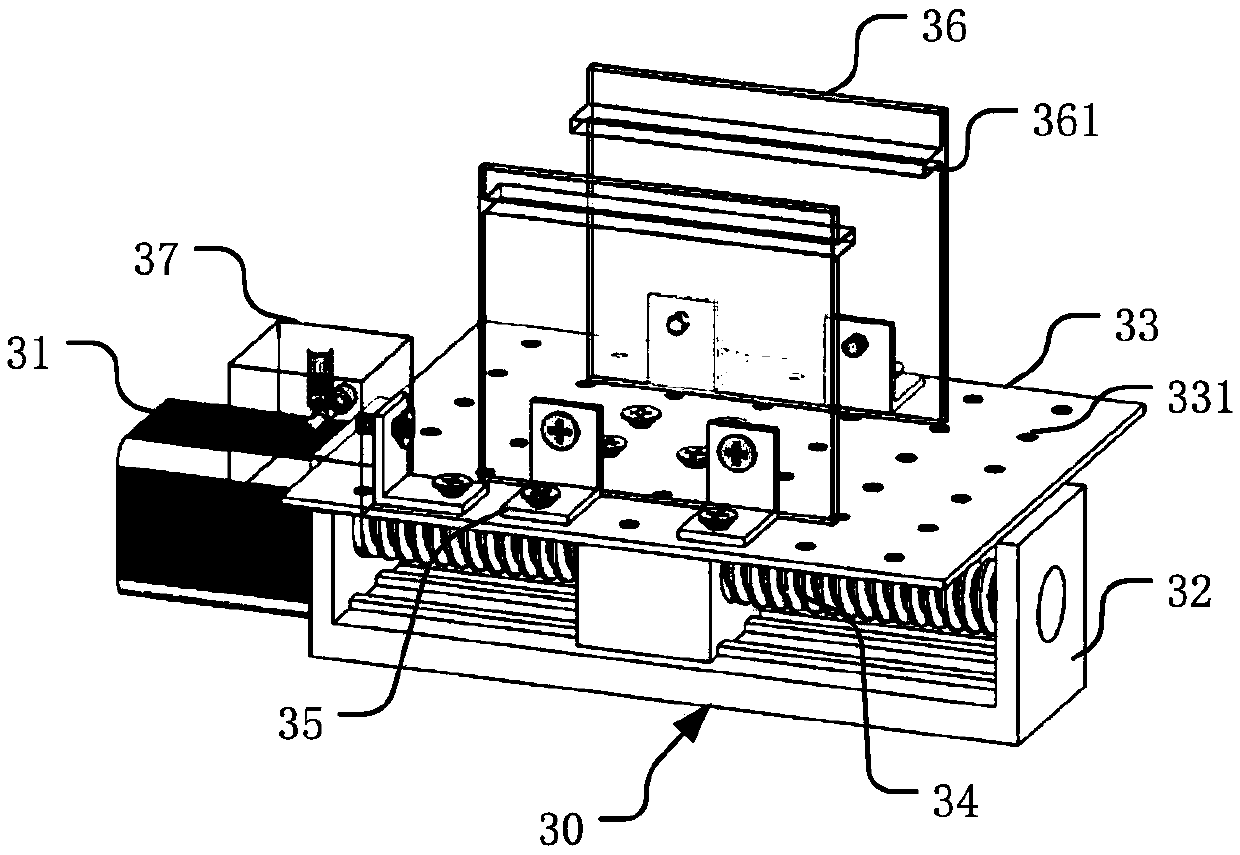

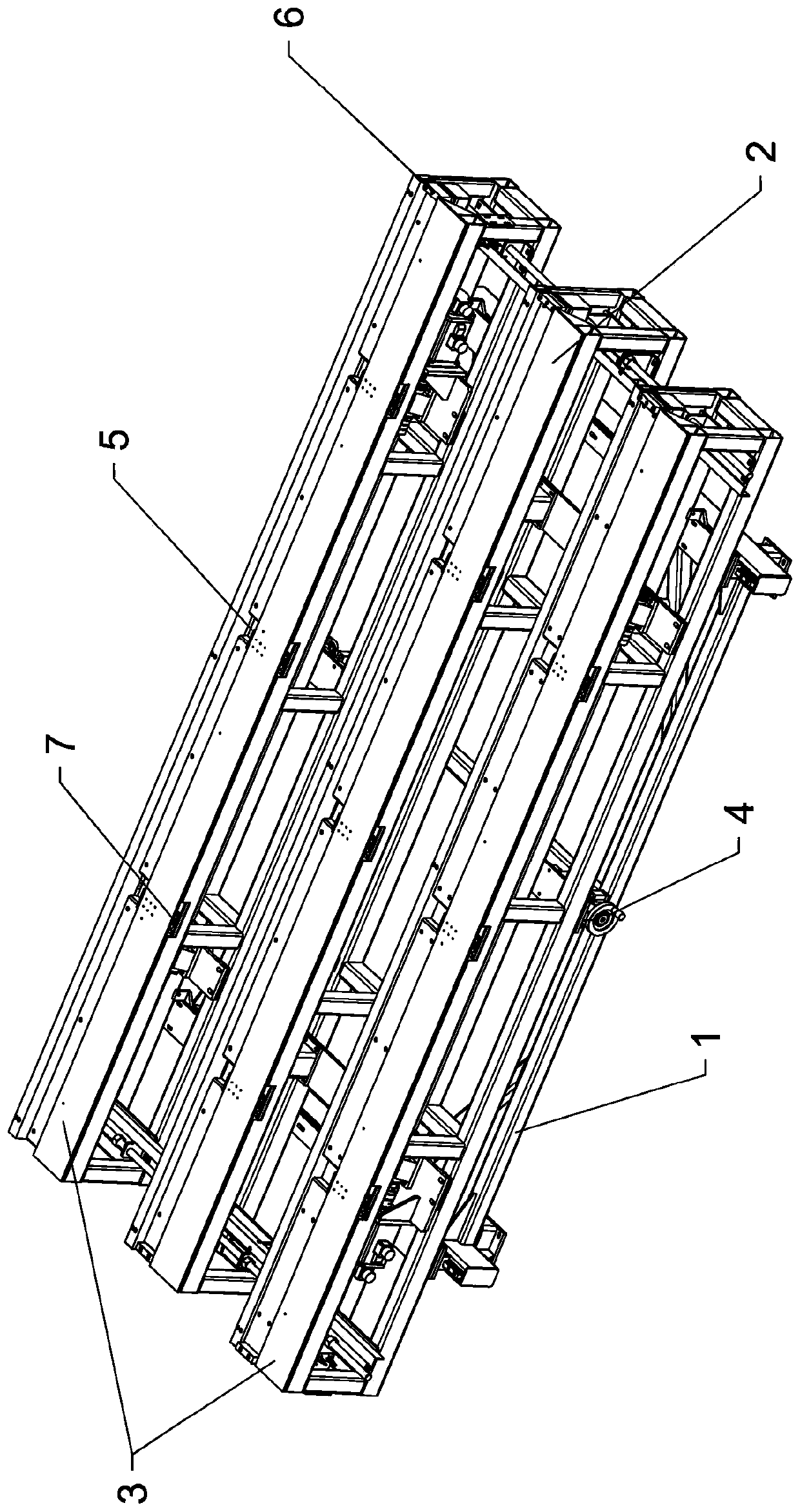

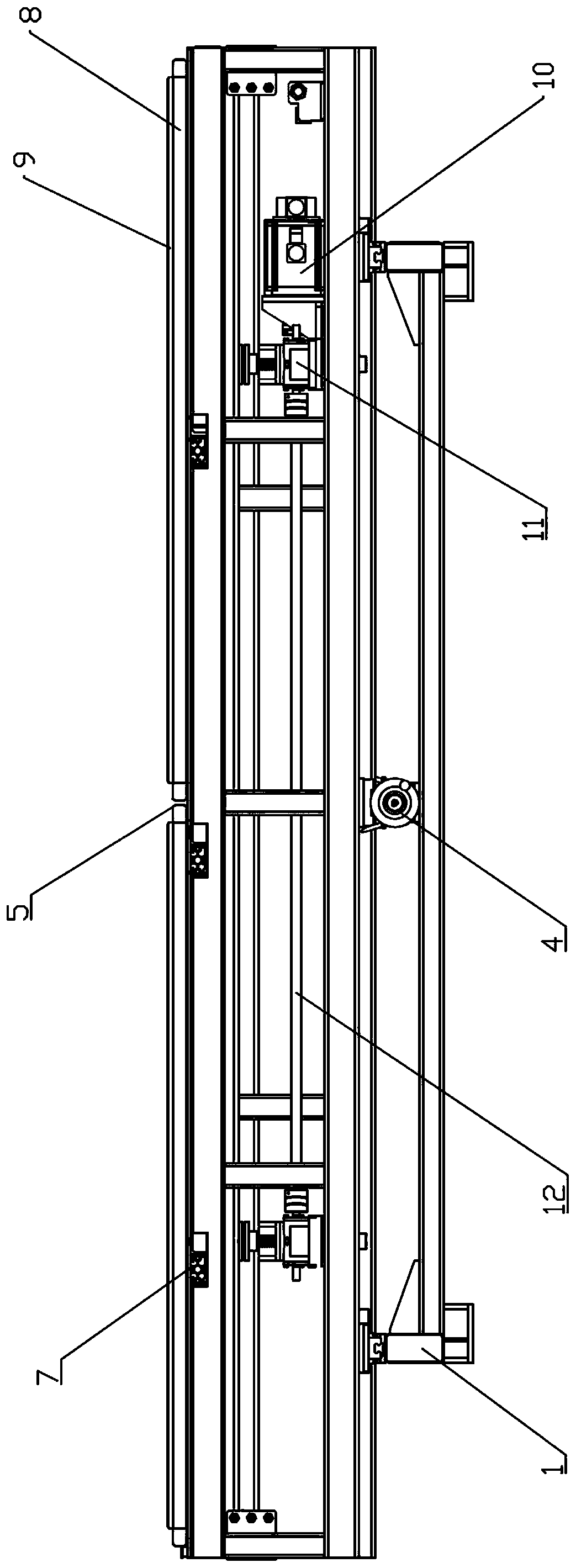

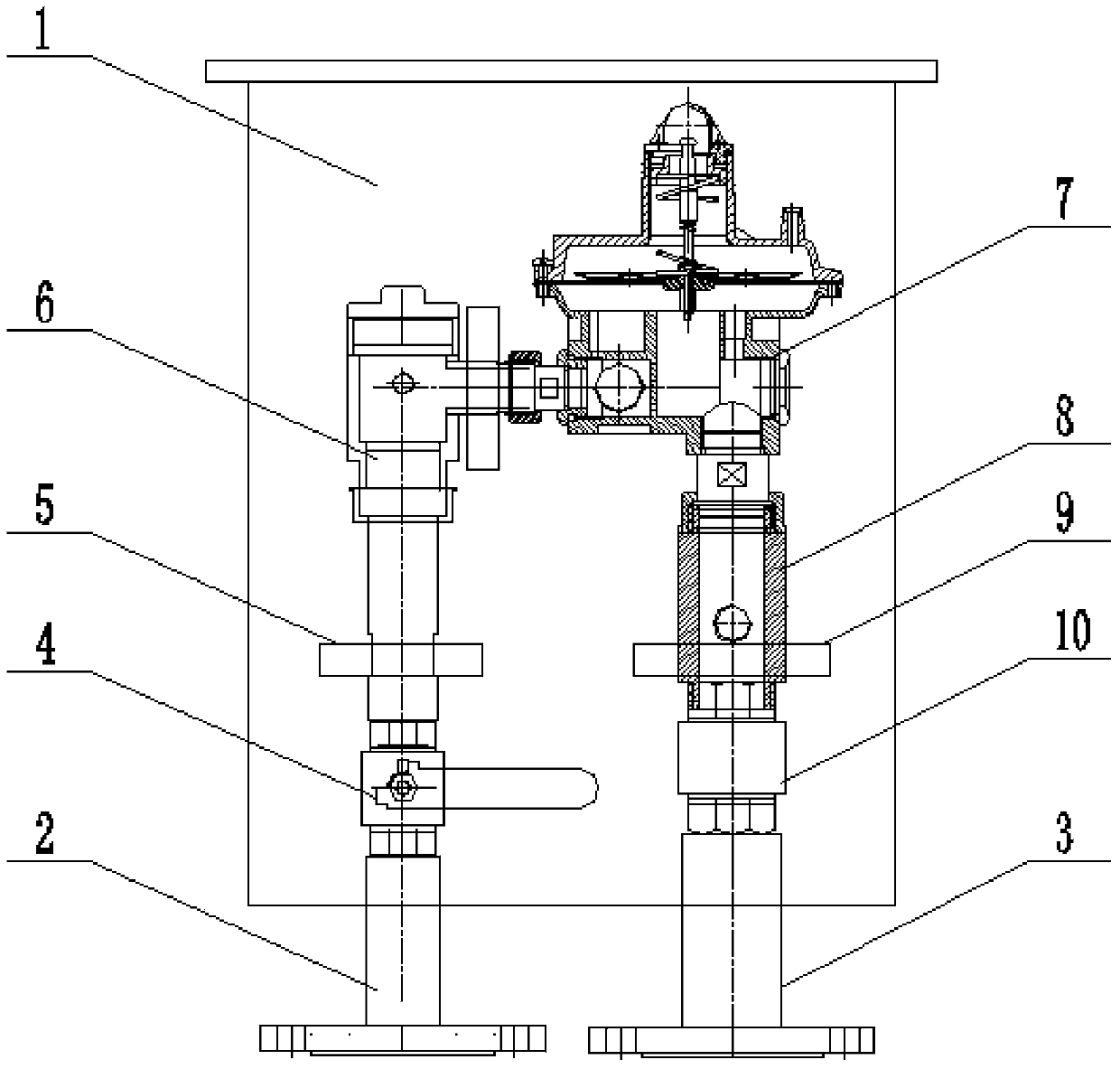

Mechanism for adjusting position of fabricated wall frame

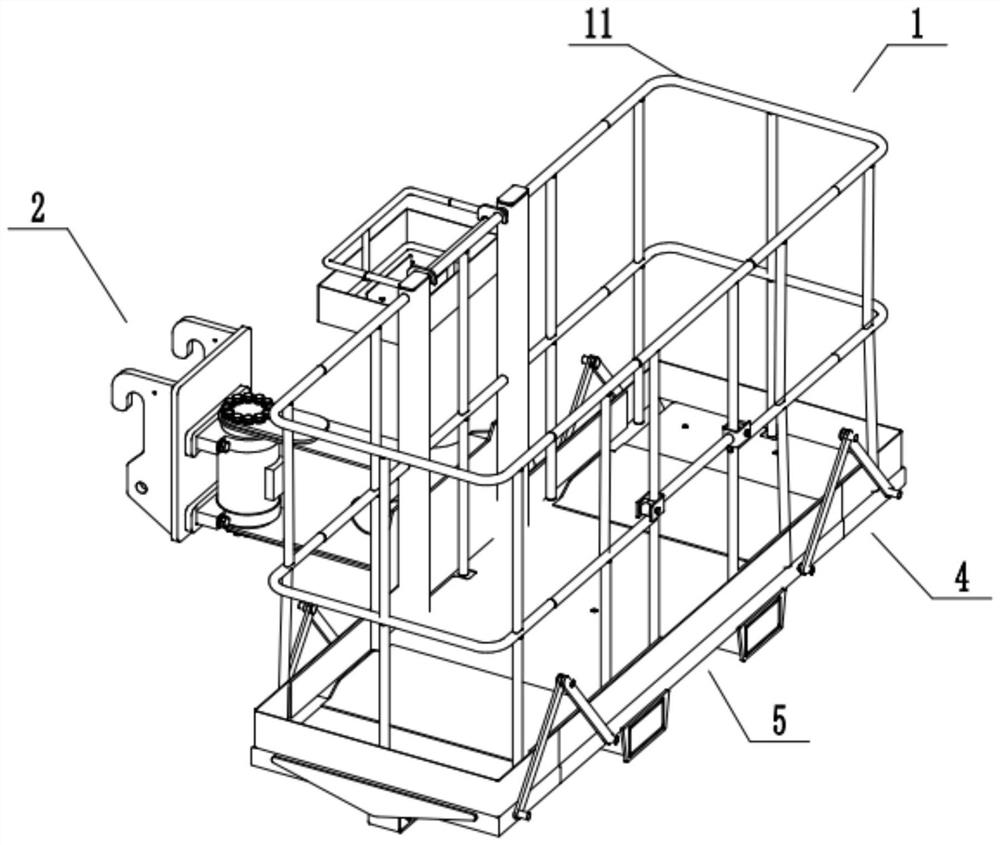

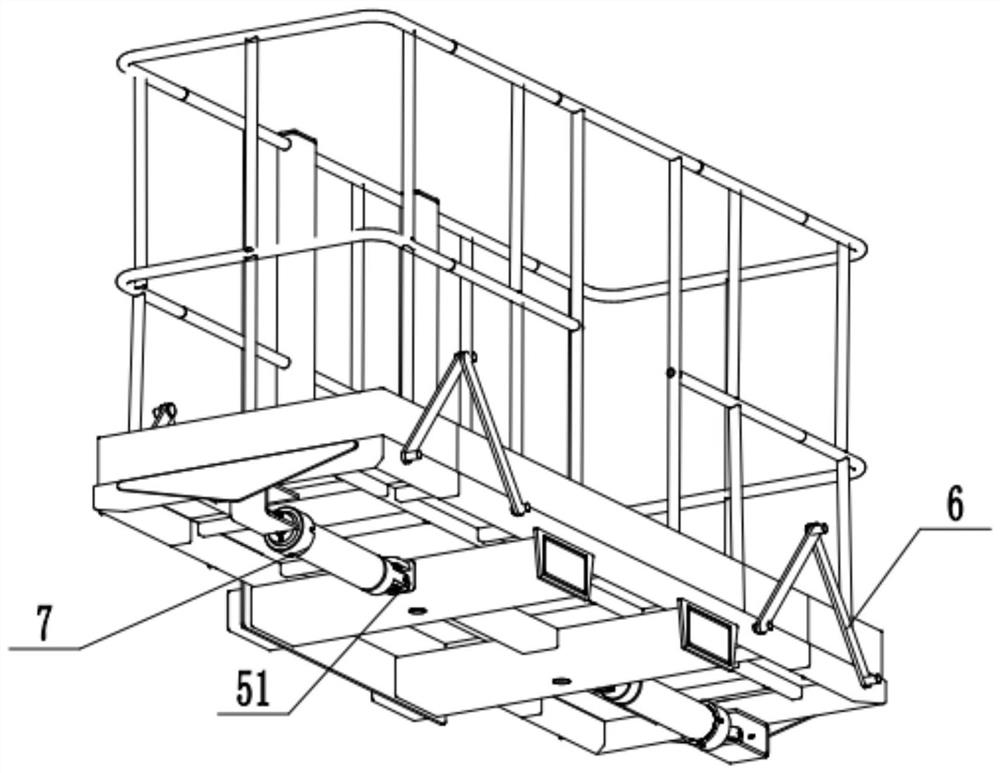

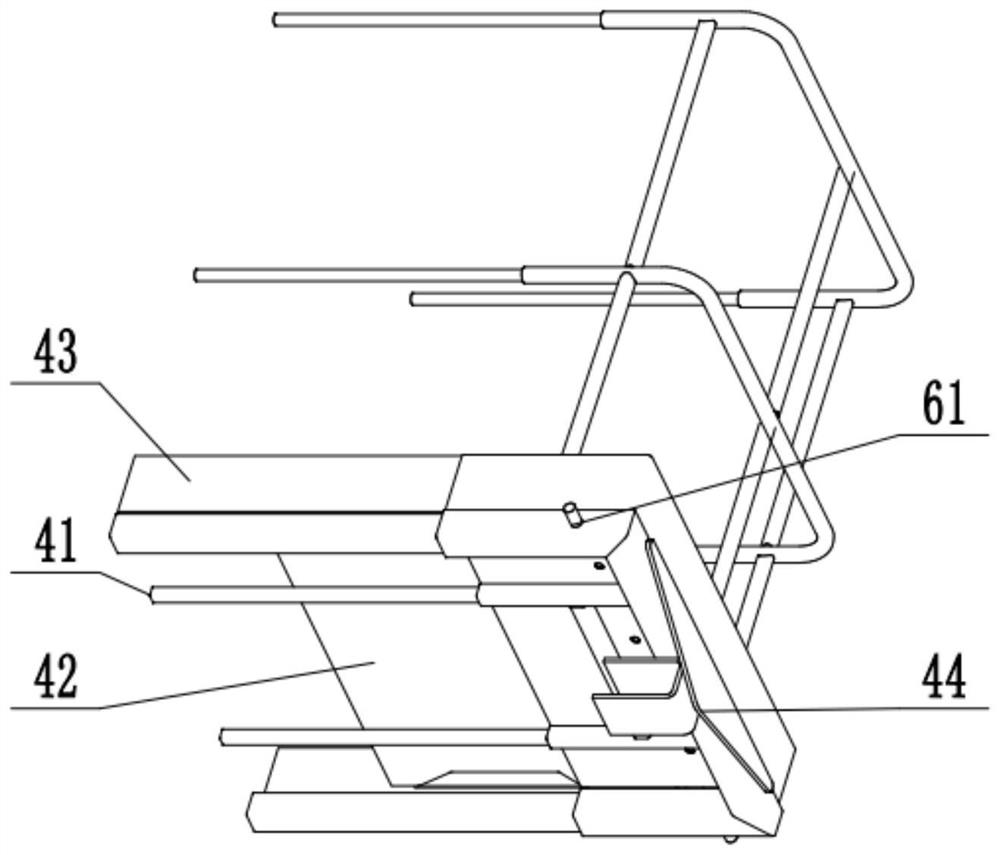

PendingCN109736490AAchieve regulationMeet the needs of working conditionsWallsComputer moduleEngineering

The invention relates to a mechanism for adjusting position of a fabricated wall frame. The mechanism comprises a cross beam module, a frame positioning and lifting module, and a base, wherein the frame positioning and lifting module is arranged on the base, each frame is placed on each cross beam in the cross beam module, and then each cross beam is adjusted through the frame positioning and lifting module, so that the distribution positions of the frames are adjusted, and the requirements of working conditions are met. By the adoption of the mechanism, the frame distribution position in thefabricated wall can be adjusted according to the specification and process change of the fabricated wall, the production efficiency is improved, the labor intensity of workers is reduced, the safety coefficient is high, and the applicability is good.

Owner:CNBM TRIUMPH ROBOTICS SHANGHAI CO LTD +1

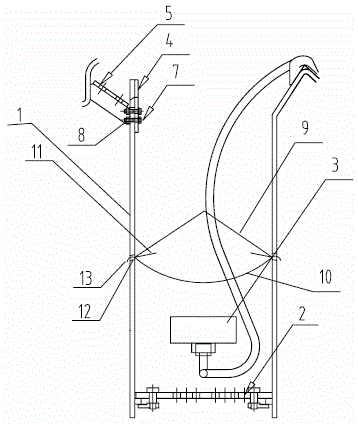

Spinning machine bath

ActiveCN104451913AAdequate responseMeet production requirementsArtificial thread manufacturing machinesWet spinning methodsPulp and paper industrySpin speed

The invention relates to the technical field of spinning, in particular to a spinning machine bath. The spinning machine bath comprises a bath body, a perforated plate is arranged at the bottom of the bath body, a spinning jet is arranged inside the bath body, a sawtooth plate is arranged on the inner wall of the bath body, stripped holes are arranged in the sawtooth plate, an obliquely-arranged filter-hole plate is arranged on the outer wall of the bath body, a purification filter unit is arranged in the middle of the bath body and comprises an upper filter screen and a lower filter screen, the upper filter screen is upwardly conical, the lower filter screen is downwardly arced, a filter partition is arranged between the upper filter screen and the lower filter screen, and a notch is formed in the side face, corresponding to the end face of the filter partition, of the bath body. Corresponding bath depth is acquired by reasonably adjusting sawtooth plate according to production yield and spinning speed, impurities in acid bath are reduced, and production and process requirements are met.

Owner:CHENGDU GRACE FIBER

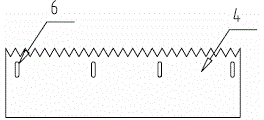

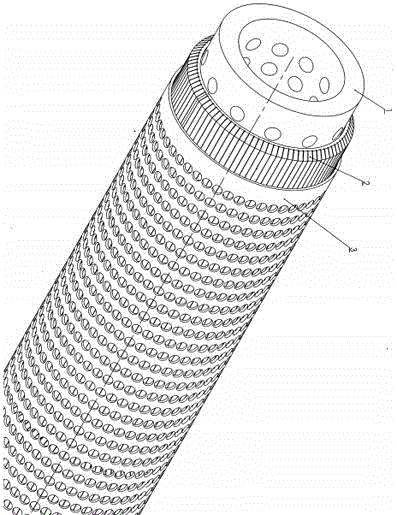

High pressure natural gas well slotting jacket sand prevention pipe

InactiveCN104033135AMeet the needs of working conditionsAffect circulationFluid removalNumerical controlWear resistant

The invention relates to a high pressure natural gas well slotting jacket sand prevention pipe. The high pressure natural gas well slotting jacket sand prevention pipe is formed by a base pipe, a slotting jacket and a circular hole helical welding mesh pipe and is characterized in that the base pipe is provided with a circular overflowing through hole and is served as an interior support for the slotting jacket; the circular hole helical welding mesh pipe is served as a protective sleeve for the slotting jacket. According to the high pressure natural gas well slotting jacket sand prevention pipe, synthesis technologies such as the powder metallurgy, the electric spark numerical control machining and material control deformation are adopted to manufacture a high density, high accuracy, high wear resistant washing and high corrosion resistant well completion sand prevented micro-gap overflowing channel for a natural gas well, the overflowing channel is guaranteed not being blocked during the long time production process and having functions of automatically loosening well cylinder blocked sand and enabling the natural gas to flow from the well cylinder to the full length range of the base pipe in a balanced mode, and a set system and complete solution for well completion and sand prevention of a high pressure, high yield and high corrosion natural gas well is provided.

Owner:兰州正丰石油化工技术装备有限责任公司

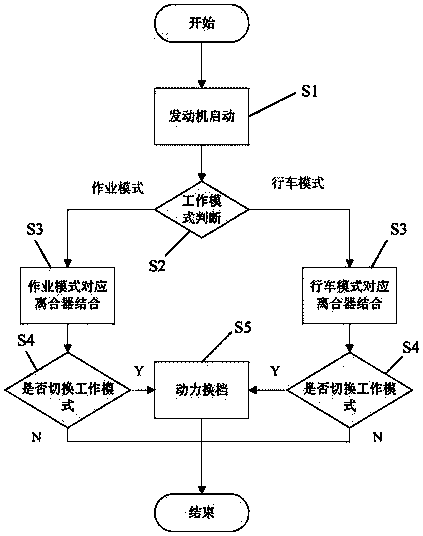

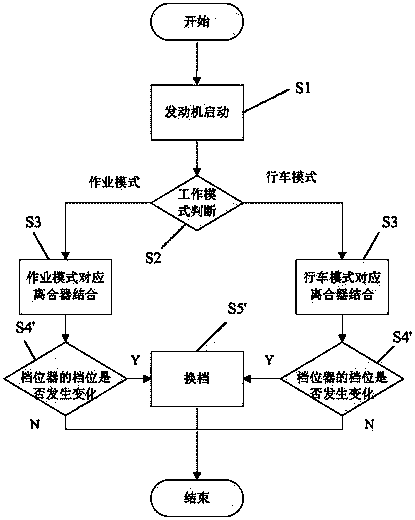

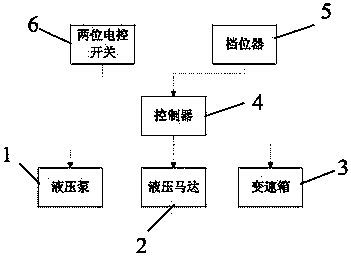

Land leveler, and gear shift control method and gear shift control system for land leveler

ActiveCN103883724AReduce the number of shiftsReduce lossMechanical machines/dredgersGearing controlTravel modeControl system

The invention discloses a gear shift control method for a land leveler. The gear shift control method includes starting an engine; judging a working mode to determine whether the land leveler is in a travel mode or an operation mode and selecting a corresponding gear of a gearbox according to different working modes; monitoring operation, and specifically, monitoring the working mode of the land leveler in a land leveler working procedure; performing power gear shift, in other words, actuating power gear shift if the working mode does not change, or executing power gear shift if the working mode changes. The gear shift control method has the advantages that gear shift is only carried out on the gearbox when the working mode changes, so that the gear shift frequency of the land leveler in the working procedure can be reduced, loss of friction plates of a clutch in the gearbox can be decreased, the service lives of the friction plates can be prolonged, the number of actual gears can be increased, and requirements of large quantities of working conditions can be met. The invention further provides the land leveler and a gear shift control system for the land leveler.

Owner:HUNAN SANY ROAD MACHINERY

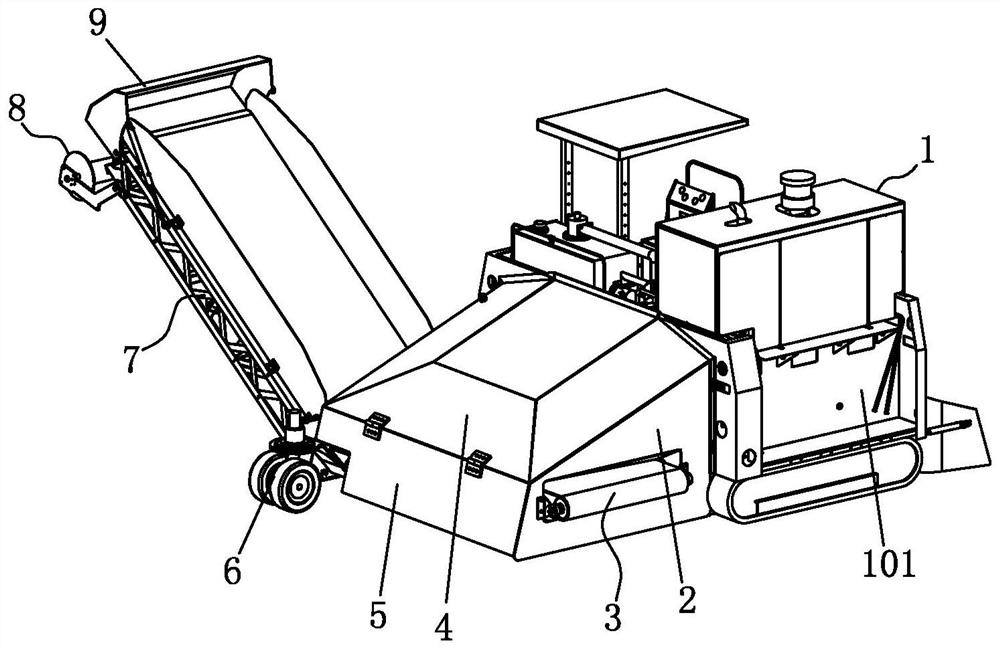

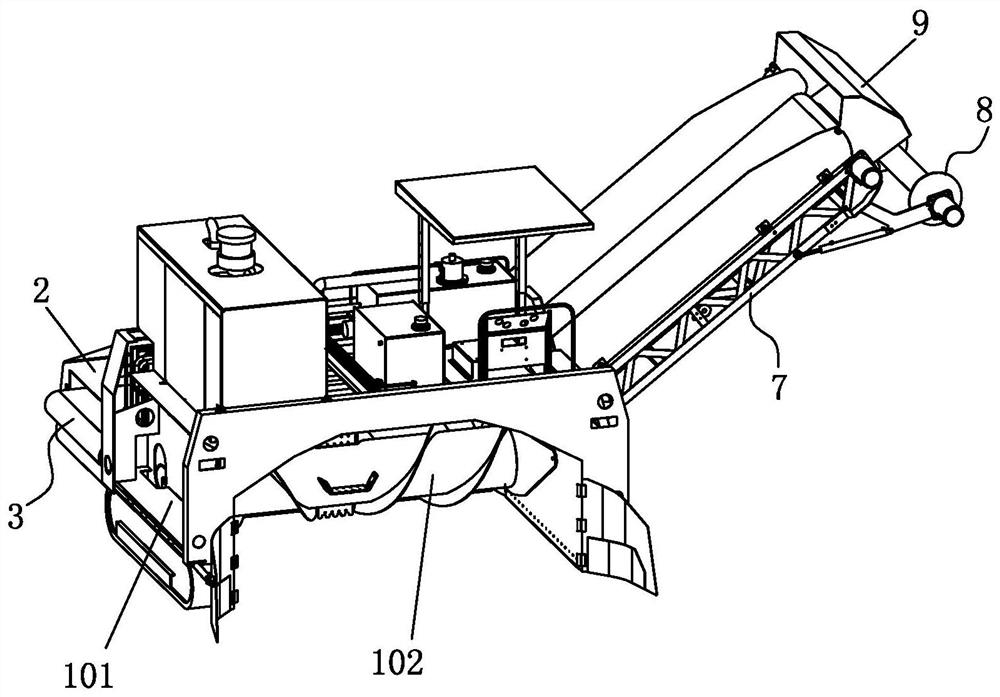

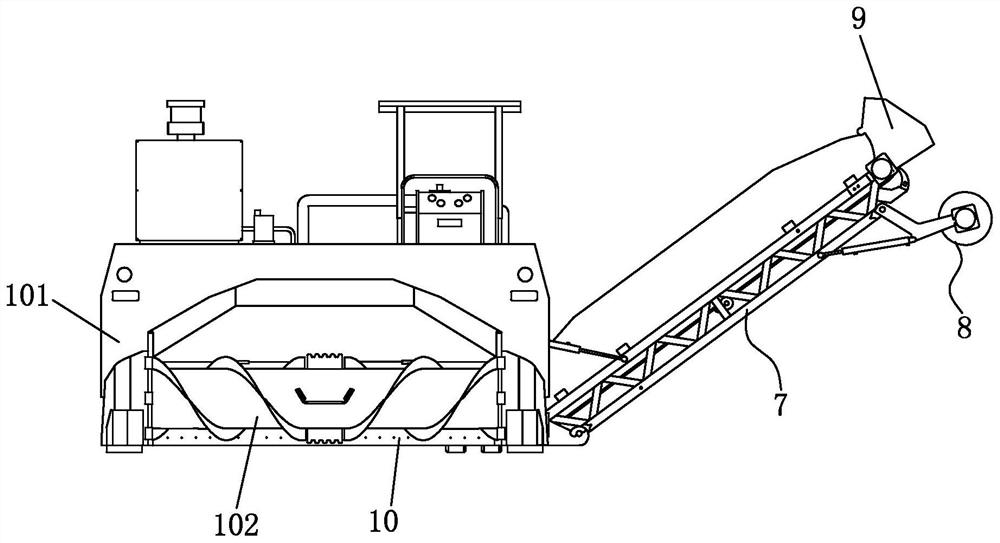

A material lateral displacement device for a turning and throwing machine

ActiveCN110668100BTo achieve the effect of side-turning throwing machineTo achieve the purpose of changing stampsThrowing machinesCleaningEngineeringConveyor belt

The invention discloses a material lateral displacement device for a turning machine, which comprises a turning machine and a material displacement device connected behind the turning machine. The device is installed horizontally and connected to the rear side of the turning and throwing machine through the connecting plate; the pallet changing conveying device is connected to the outside of the connecting plate and is installed inclined upward; the blade is located between the transverse conveying device and the turning and throwing drum; Rear: The horizontal conveyor belt conveys the material to the side where the palletizing conveyor is located, and the palletizing conveyor belt conveys the material upwards. As an extended part of the turning machine, the invention is connected to the tail end of the turning machine, so that the ordinary ride-on type turning machine can achieve the effect of a side-turning turning machine, the structure is simple, and the walking efficiency and production efficiency of the turning machine can be effectively improved. efficiency.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Gas building pressure regulating box and using method thereof

ActiveCN104197200AMeet the needs of working conditionsEasy to operatePipeline systemsControl theoryScrew thread

The invention discloses a gas building pressure regulating box which comprises a vertically arranged rectangular box body. A pressure regulator and a filter are arranged in the box body in a hidden mode. An output port of the filter and an input port of the pressure regulator are connected in a communicated mode in the horizontal direction. A lower-end input port of the filter is connected with a suction flange through an inlet ball valve in the vertical direction. The suction flange penetrates through the box body vertically and downwardly. A lower-end output port of the pressure regulator is connected with a discharge flange through a deflation curved spit ball valve and an outlet ball valve sequentially in the vertical direction. The discharge flange penetrates through the box body in the vertical direction. The inlet ball valve is in screw-thread fit with the filter and the suction flange respectively. The deflation curved spit ball valve is in screw-thread fit with the pressure regulator and the outlet ball valve. The outlet ball valve is in screw-thread fit with the discharge flange. The invention further provides a using method of the gas building pressure regulating box. The pressure regulator is arranged in the gas building pressure regulating box, so that the pressure at an outlet is stable, and reset is more convenient; maintenance is convenient, dismantling is simple, and cost is lowered.

Owner:江苏大昌燃气设备有限公司

Operation platform and control method thereof and telescopic boom forklift

ActiveCN113135535AAccurate judgmentEnsure safetySafety devices for lifting equipmentsTotal factory controlControl engineeringControl theory

Owner:SANY MARINE HEAVY IND

Lifter device capable of controlling transportation direction and feeding distance

InactiveCN111825015AOperation, driving the continuous upward transportation of goods is easy and convenientEasy to transportConveyorsLifting framesGear wheelElectric machinery

The invention discloses a lifter device capable of controlling a transportation direction and a feeding distance. The lifter device comprises a base, wherein a belt storage cavity with an upward opening is arranged in the base; the upper side of the belt storage cavity communicates with a slide plate cavity with an upward opening; a lifting motor which is positioned at the left side of the belt storage cavity is fixedly connected in the base; the upper end surface of the lifting motor is fixedly connected to a rotary shaft which upwards extends; the upper end surface of the base is fixedly connected to a sleeve which is positioned at the left side of the slide plate cavity; the upper end surface of the base is fixedly connected to a folding column which extends upwards; a motor is rotatedto match with a gear rack, so that a workbench of the lifter is foldable, and therefore, occupied space is reduced; and through the rotatable base and a liftable supporting column, the lifter can realize lifting and rotating on different positions according to difference of working conditions, so that needs of each working condition are met; and meanwhile, a conveyor belt operates to drive goods to continuously transport upwards, so that transportation of goods is very easy and convenient, and work efficiency is greatly improved.

Owner:东阳格盘机械科技有限公司

Filtering type bath of spinning machine

ActiveCN104451915AAdequate responseEfficient separationArtificial thread manufacturing machinesWet spinning methodsImpurityWaste management

The invention relates to the technical field of spinning, in particular to a filtering type bath of a spinning machine. The filtering type bath of the spinning machine comprises a bath body, wherein a perforated plate is arranged on the bottom of the bath body; a spinning nozzle is arranged in the bath body; a purifying and filtering device is arranged in the middle of the bath body and comprises an upper conical filter screen and a lower arc-shaped filter screen; the conical direction of the upper filter screen is upward; the arc-shaped direction of the lower filter screen is downward; a filtering partition is arranged between the upper filter screen and the lower filter screen; and a notch is formed in a side surface, which corresponds to an end surface of the filtering partition, of the bath body. When entering the bath, bathing acid flows through the upper filter screen and the lower filter screen sequentially; after the bathing acid is filtered twice, most of impurities in the bathing acid can be stopped by the filtering partition; the filtering partition is taken out and cleaned by a worker; and the impurities in the filtering partition are reduced greatly.

Owner:CHENGDU GRACE FIBER

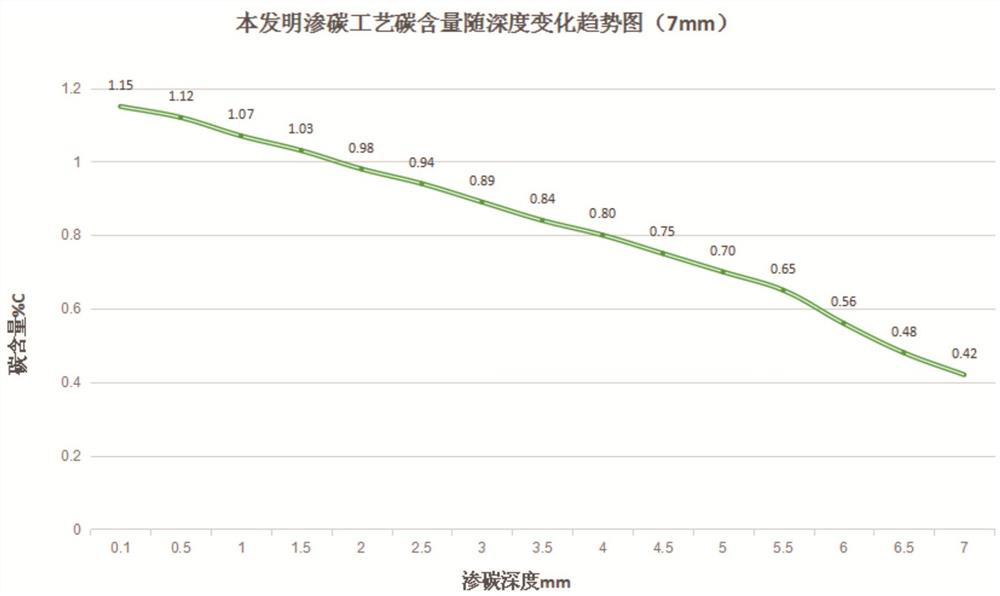

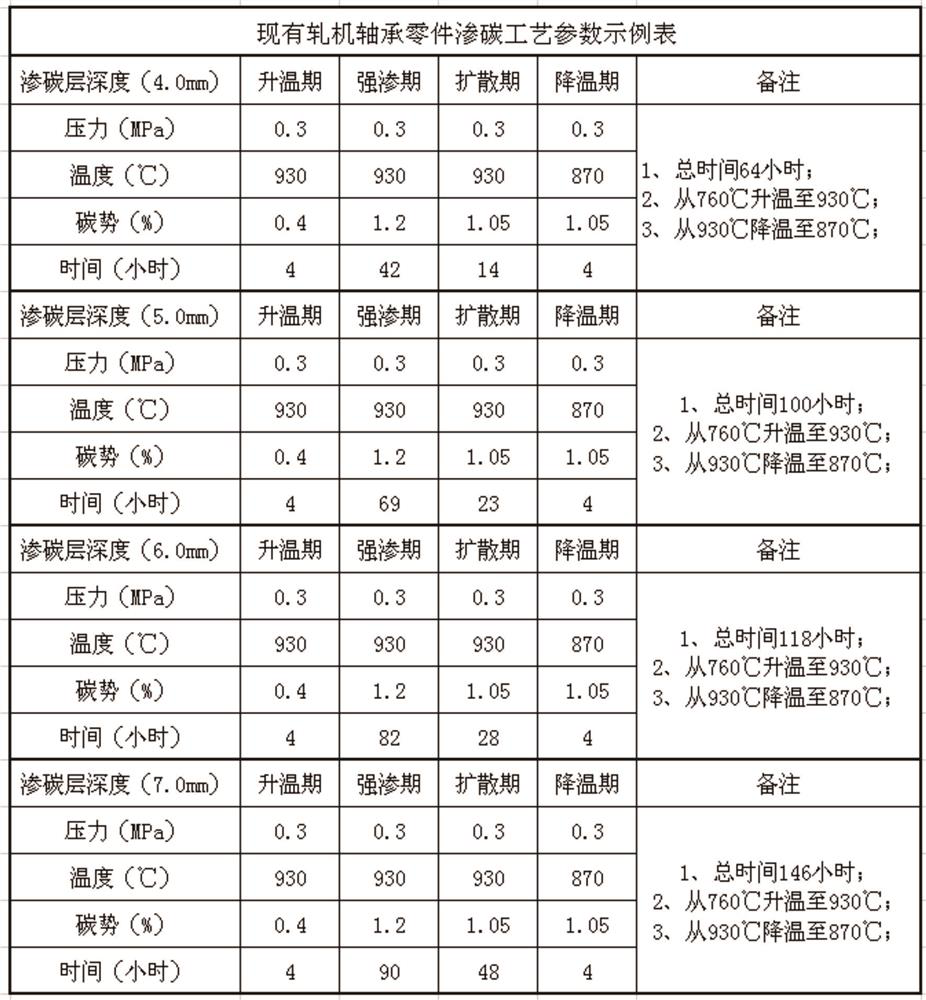

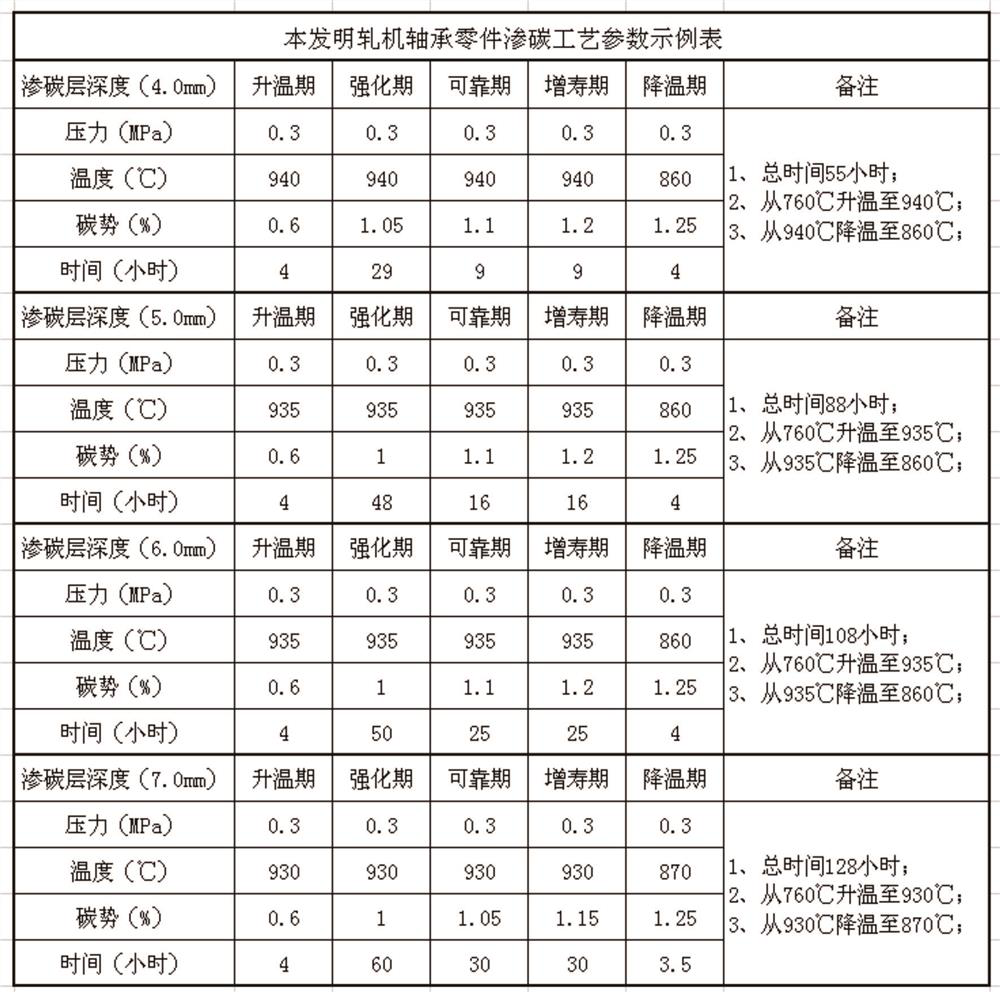

Carburizing heat treatment process for rolling mill bearing part

PendingCN114836709ACarburizing depth is sufficientEnough carbonSolid state diffusion coatingFurnace typesCarbon potentialCarbide

A rolling mill bearing part carburizing heat treatment technology is characterized in that the rolling mill bearing part is sequentially divided into a surface layer, a secondary surface layer and a core layer from outside to inside according to the carburizing depth, and the carburizing technology is divided into a heating period, a strengthening period, a reliable period, a life prolonging period and a protection period according to the depth and carbon content requirements of the surface layer, the secondary surface layer and the core layer; wherein the carbon potential in the heating period is set to be 0.6%, the carbon potential in the strengthening period, the carbon potential in the reliable period, the carbon potential in the life prolonging period and the carbon potential in the protection period are all set to be maintained to be 1.0% or above and are sequentially increased stage by stage, and the highest carbon potential is not higher than 1.25%; in the carburizing process, by adjusting the carbon potential of each period, it is ensured that the rolling mill bearing part has enough carburizing depth and corresponding carbon content while it is ensured that no thick and large carbide structure is formed on the surface layer; according to actual use inspection, the rolling mill bearing produced after the carburizing heat treatment process is implemented completely meets the use condition requirements of the high-end plate strip rolling mill bearing, the service life and the reliability of the rolling mill bearing exceed international famous brands, and the quality of domestic rolling mill bearings reaches the international advanced level.

Owner:LUOYANG HUIGONG BEARING TECH

A method for obtaining the gas-liquid phase interface in a micron capillary channel

ActiveCN108827834BImprove efficiencyHigh measurement accuracyDiffusion analysisMicron scaleCapillary channel

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com