Multi-function tunnel rock drilling and arching all-in-one machine

A multi-functional, all-in-one machine technology, applied in tunnels, tunnel linings, shaft linings, etc., can solve problems such as low efficiency, inability to realize the full working condition of tunnel arches, and restrictions on the use of arching machines, and achieve the effect of fast deployment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

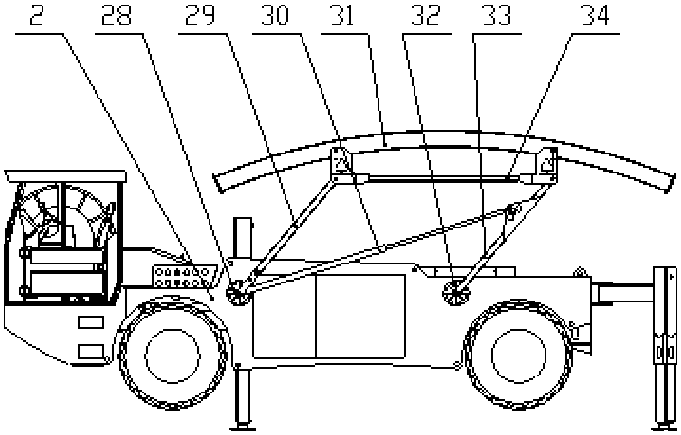

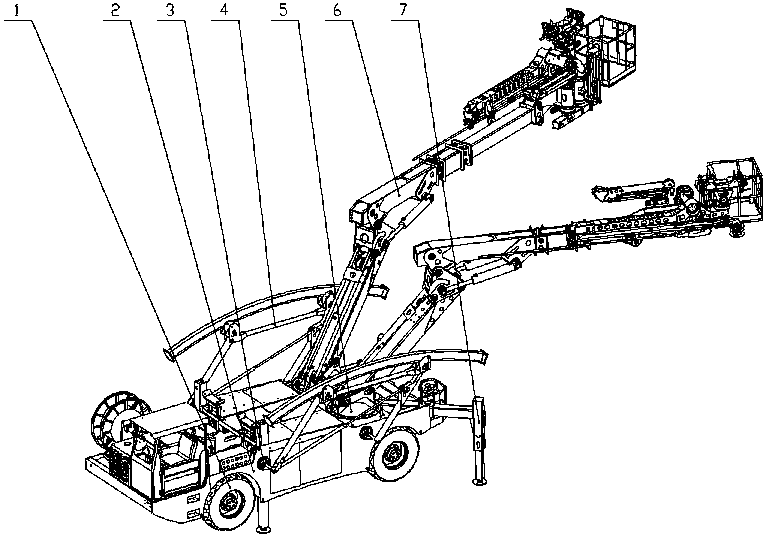

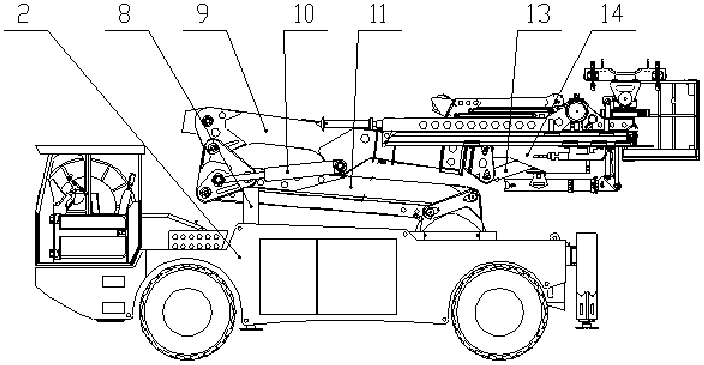

[0037] Such as figure 1 As shown, a multi-functional tunnel rock drilling frame-arch integrated machine provided by the present invention is mainly composed of a chassis 1, a host platform 2, a supporting arch device 4, a jib 6, and outriggers 7. Chassis 1 is a wheeled chassis, four-wheel drive, has faster traveling speed and better climbing ability. On the main engine platform 2, hydraulic pressure, electric control, power system and other auxiliary systems are arranged, and the main engine platform 2 is arranged with outriggers 7 to maintain the stability of the whole vehicle and avoid tipping during the construction of the arch machine. The arm frame 6 is installed on the host platform 2 through the swivel seat 5, and there are two arm frames 6 with similar structures, which are arranged at the rear of the host platform 2. The supporting arch devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com