Filtering type bath of spinning machine

A spinning machine and filtering technology, which is applied in the spinning field, can solve the problems of non-adjustable bath depth and inability to guarantee the reaction time between the tow and the acid bath, and achieve stable molding, long service life, and improved product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

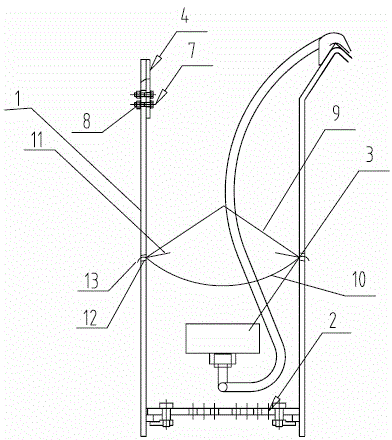

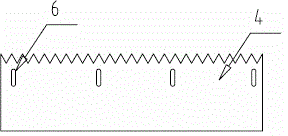

[0028] A filter type spinning machine bath, characterized in that: it includes a bath body 1, the bottom of the bath body 1 is provided with a perforated plate 2, the interior of the bath body 1 is provided with a spinneret 3, the bath body 1 A sawtooth plate 4 is provided on the inner wall, and a strip-shaped hole 6 is provided on the sawtooth plate 4 . The middle part of the bath body 1 is provided with a purification filter device, the purification filter device includes a conical upper filter screen 9 and an arc-shaped lower filter screen 10, and the tapered direction of the upper filter screen 9 is upward , the arc direction of the lower filter screen 10 is downward, a filter partition 11 is arranged between the upper filter screen 9 and the lower filter screen 10, and the side of the bath body corresponding to the end face of the filter partition 11 is opened There are notches 12. The filter partition 11 has a ring structure, and the filter partition 11 is formed by spl...

Embodiment 2

[0032] A filter type spinning machine bath, characterized in that: it includes a bath body 1, the bottom of the bath body 1 is provided with a perforated plate 2, the interior of the bath body 1 is provided with a spinneret 3, the bath body 1 A sawtooth plate 4 is provided on the inner wall, and a strip-shaped hole 6 is provided on the sawtooth plate 4 . The middle part of the bath body 1 is provided with a purification filter device, the purification filter device includes a conical upper filter screen 9 and an arc-shaped lower filter screen 10, and the tapered direction of the upper filter screen 9 is upward , the arc direction of the lower filter screen 10 is downward, a filter partition 11 is arranged between the upper filter screen 9 and the lower filter screen 10, and the side of the bath body corresponding to the end face of the filter partition 11 is opened There are notches 12. The filter partition 11 has a ring structure, and the filter partition 11 is formed by spl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com