High pressure natural gas well slotting jacket sand prevention pipe

A slotted jacket and natural gas technology, applied in wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems of high pressure and high yield of fracture wall, low life of sand control pipe, sand plugging, etc., and the quality is easy to guarantee , complete testing means and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention takes a 3-1 / 2" (φ88.9mm) high-pressure, high-yield, highly corrosive natural gas well as an example,

[0029] Well depth 8050m

[0030] Formation pressure 100MPa

[0031] Flow pressure (bottomhole pressure) 95MPa

[0032] Flow 100×10 4 m 3 / day (standard conditions)

[0033] Temperature 170°C

[0034] h 2 S, CO 2 Content >3%

[0035] Sand median 0.10mm

[0036] Sand control particle size is required to be 0.08mm

[0037] Below, in conjunction with accompanying drawing, technical scheme of the present invention is described further:

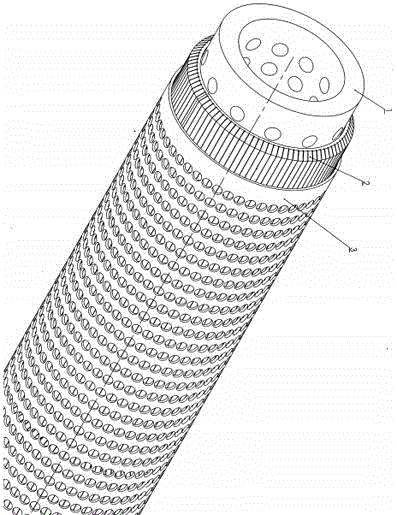

[0038]The utility model relates to a slotted jacket sand control pipe for high-pressure natural gas wells, which is used for well completion sand control of high-pressure, high-yield, high-corrosion natural gas wells. It is composed of a base pipe 1, a slotted jacket 2 and a circular hole-shaped spiral welded mesh pipe 3. The base pipe 1 adopts a circular flow-through hole pipe, and the base pipe 1 support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com