Fabricated concrete-filled steel tube combination column and splicing method

A technology for CFST column and CFST, which is applied to columns, piers, pillars, etc., can solve the problems of unfavorable promotion and application of CFST columns, the corrosion resistance of steel tubes is not as good as concrete, and the fire resistance is not as good as concrete, etc. Bearing capacity and deformation capacity, the effect of improving flexural rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

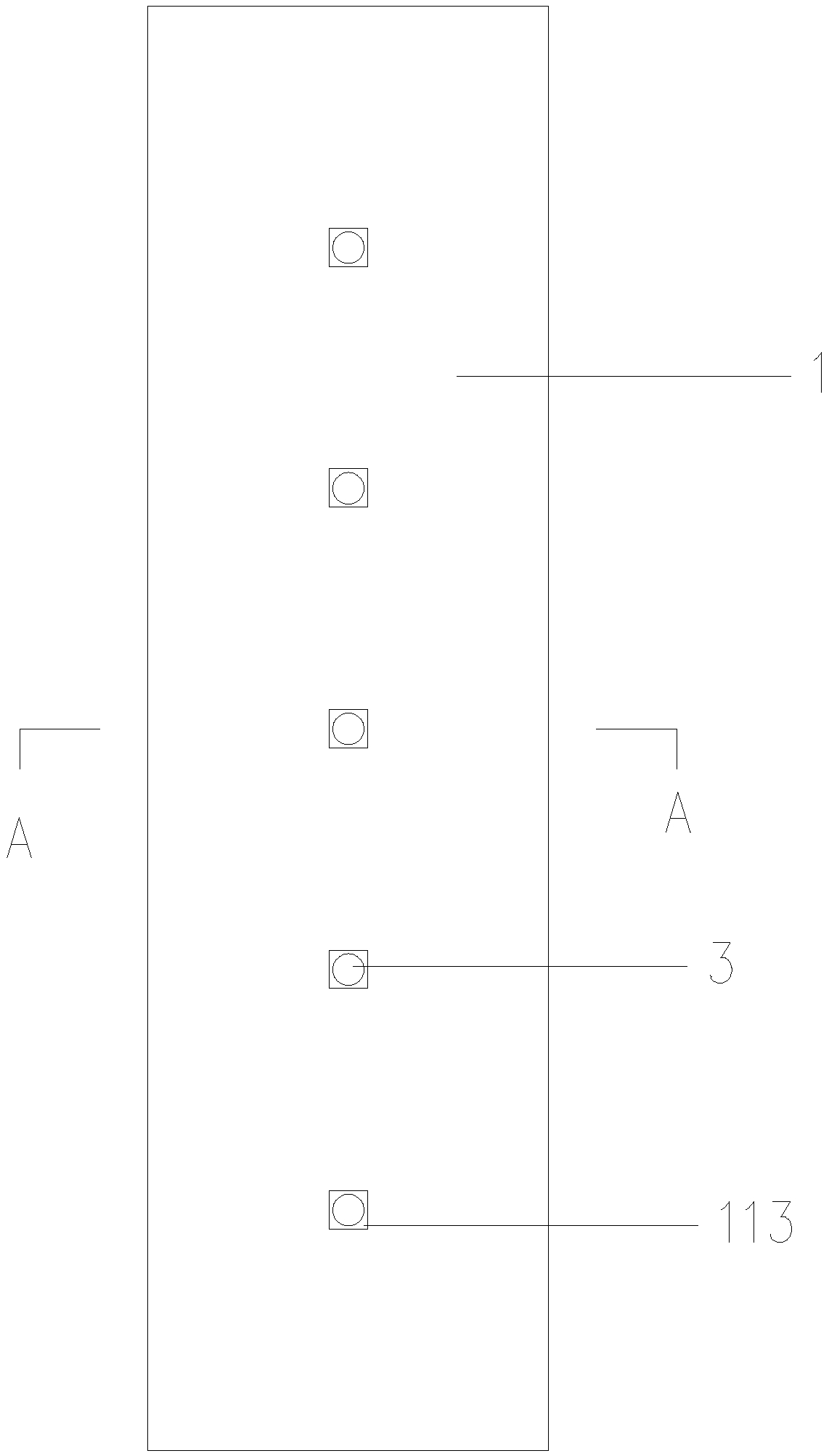

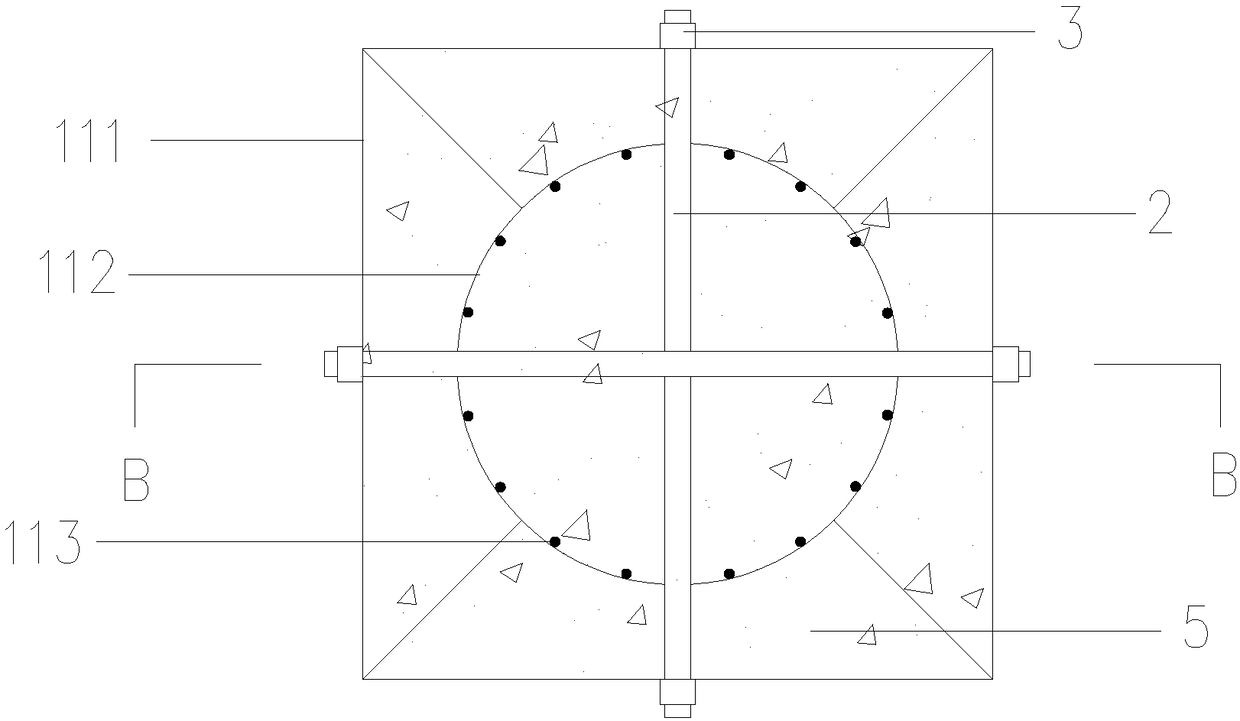

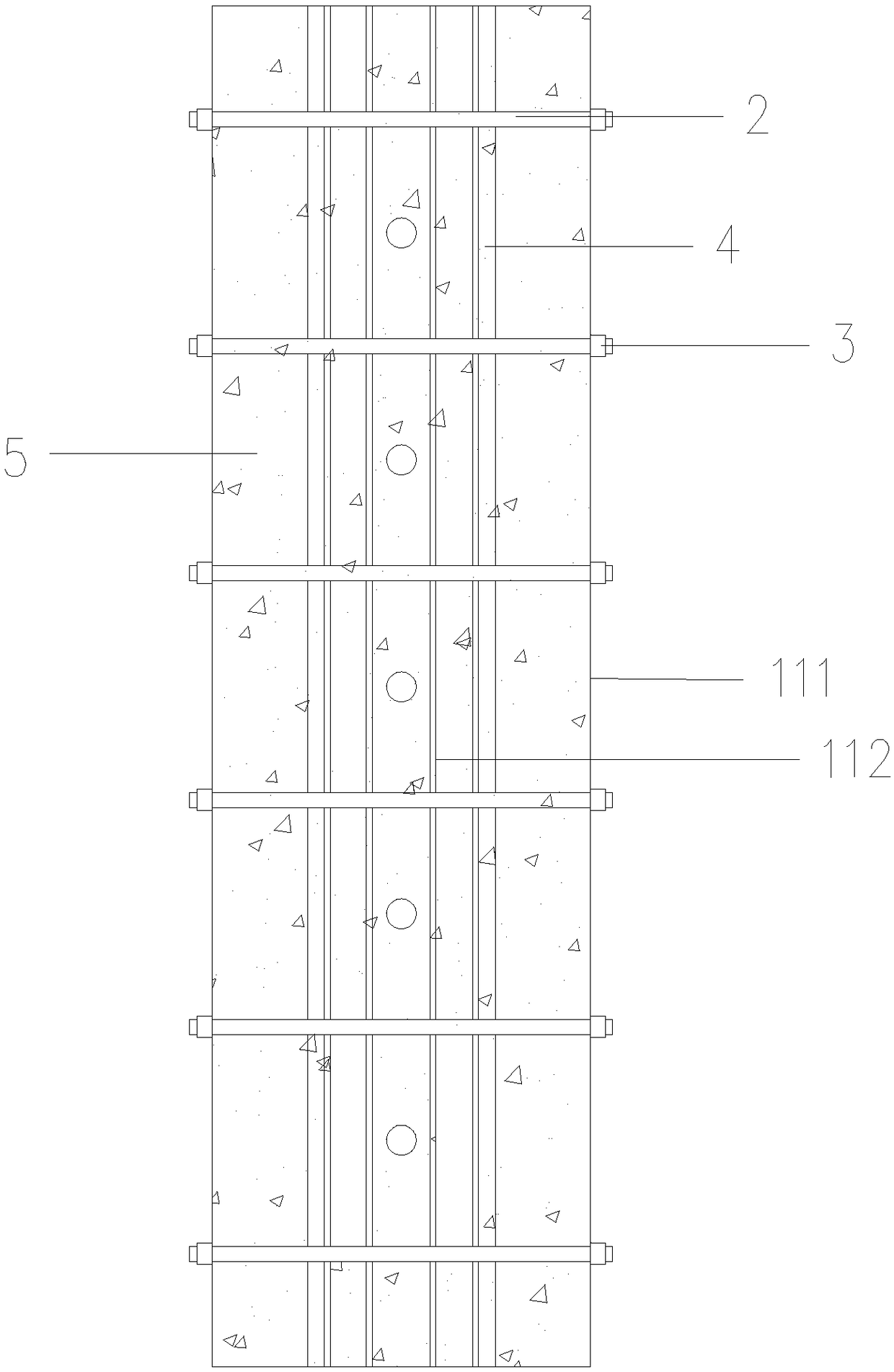

[0030] Please check Figure 1 to Figure 4 , a prefabricated steel tube concrete composite column, comprising a steel tube concrete prefabricated part 1 and a screw rod 2.

[0031] In this embodiment, the concrete-filled steel tube prefabricated part 1 is surrounded and spliced by two concrete-filled steel tube columns 11 to form a whole. After splicing, the curved steel plate 112 constitutes the inner wall of the steel pipe concrete prefabricated part, and the rectangular steel plate 111 constitutes the outer wall of the steel pipe concrete prefabricated part. Such as figure 2 and Figure 4 As shown, the arc-shaped steel plates of the two concrete-filled steel pipe columns 11 have a half circumference. After being enclosed and spliced, the inner wall section of the steel pipe concrete composite column is circular, and the outer wall section of the steel pipe concrete composite column is square. .

[0032] The rectangular steel plate 111 and the curved steel plate 112 ar...

Embodiment 2

[0043] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the concrete-filled steel pipe prefabricated part is surrounded by four concrete-filled steel pipe columns 11 and spliced into a whole, and the arc-shaped steel plates 112 of the four steel pipe concrete columns each have four One-half of the circumference, after enclosing and splicing, the cross section of the inner wall of the steel pipe concrete composite column is circular, and the cross section of the outer wall of the steel pipe concrete composite column is square.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com