Spinning machine bath

A spinning machine and bath technology, which is used in wet spinning, textile and papermaking, and complete sets of equipment for producing artificial threads, etc. Stable, long service life, and the effect of reducing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

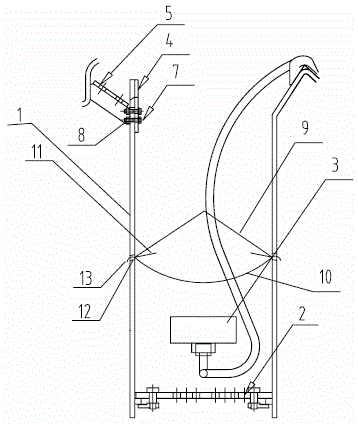

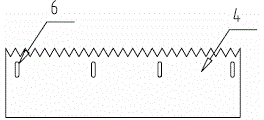

[0030] A spinning machine bath is characterized in that: it includes a bath body 1, a bottom of the bath body 1 is provided with a perforated plate 2, a spinneret 3 is arranged inside the bath body 1, and the inner wall of the bath body 1 is provided with a spinneret 3. A sawtooth plate 4 is arranged on the sawtooth plate 4, a strip hole 6 is arranged on the sawtooth plate 4, and a filter hole plate 5 is arranged on the outer wall of the bath body 1, and the filter hole plate 5 is arranged obliquely, and the filter hole plate 5 The lower end of the filter hole plate 5 is arranged below the top of the sawtooth plate 4, and the upper end of the filter orifice plate 5 is inclined outward relative to its lower end. The middle part of the bathtub body 1 is provided with a purification filter device, the purification filter device includes a conical upper filter screen 9 and an arc-shaped lower filter screen 10, and the conical direction of the upper filter screen 9 is upward. , the...

Embodiment 2

[0034] A spinning machine bath is characterized in that: it includes a bath body 1, a bottom of the bath body 1 is provided with a perforated plate 2, a spinneret 3 is arranged inside the bath body 1, and the inner wall of the bath body 1 is provided with a spinneret 3. A sawtooth plate 4 is arranged on the sawtooth plate 4, a strip hole 6 is arranged on the sawtooth plate 4, and a filter hole plate 5 is arranged on the outer wall of the bath body 1, and the filter hole plate 5 is arranged obliquely, and the filter hole plate 5 The lower end of the filter hole plate 5 is arranged below the top of the sawtooth plate 4, and the upper end of the filter orifice plate 5 is inclined outward relative to its lower end. The middle part of the bathtub body 1 is provided with a purification filter device, the purification filter device includes a conical upper filter screen 9 and an arc-shaped lower filter screen 10, and the conical direction of the upper filter screen 9 is upward. , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com