Air leakage control system and control method for air pre-heater

An air preheater and control system technology, applied in combustion methods, lighting and heating equipment, indirect carbon dioxide emission reduction, etc., can solve the problems of economic loss, non-adjustment, loss of function, etc. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

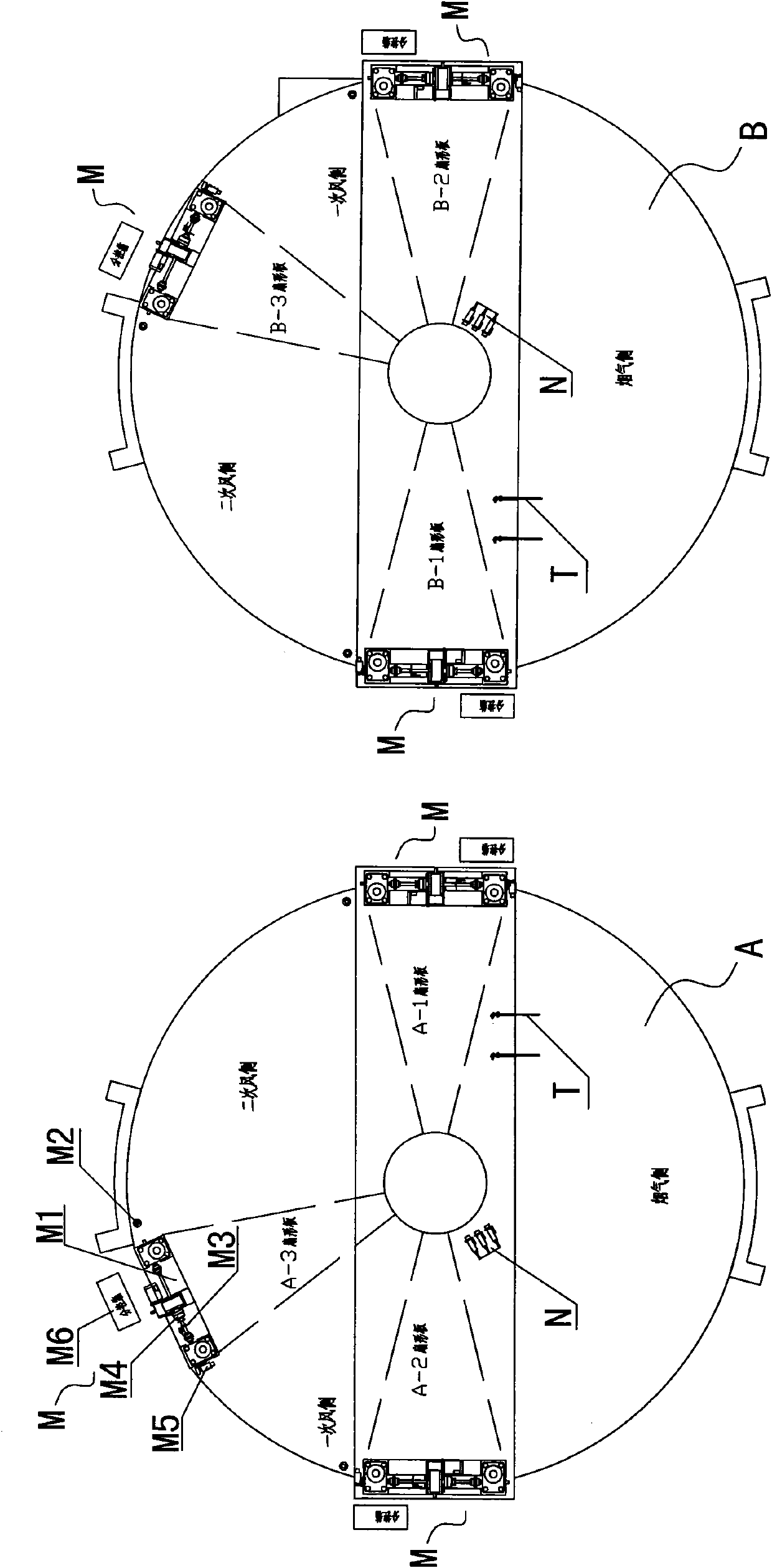

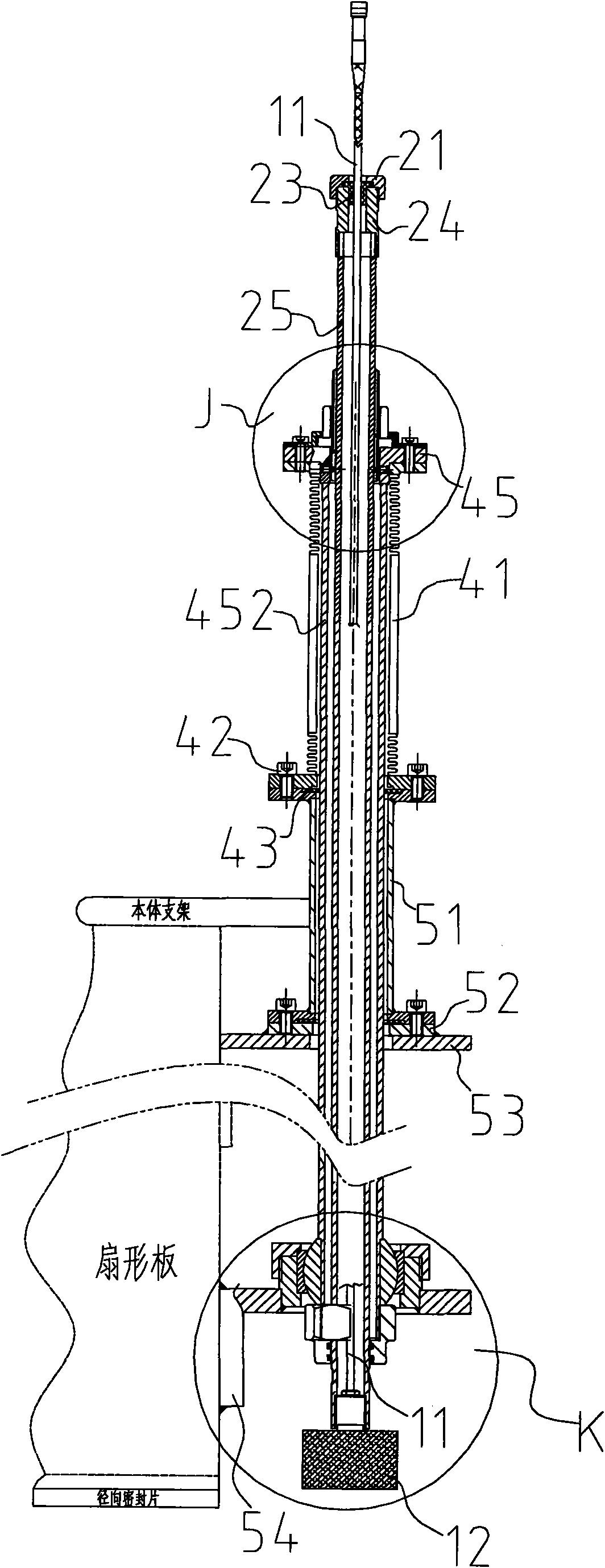

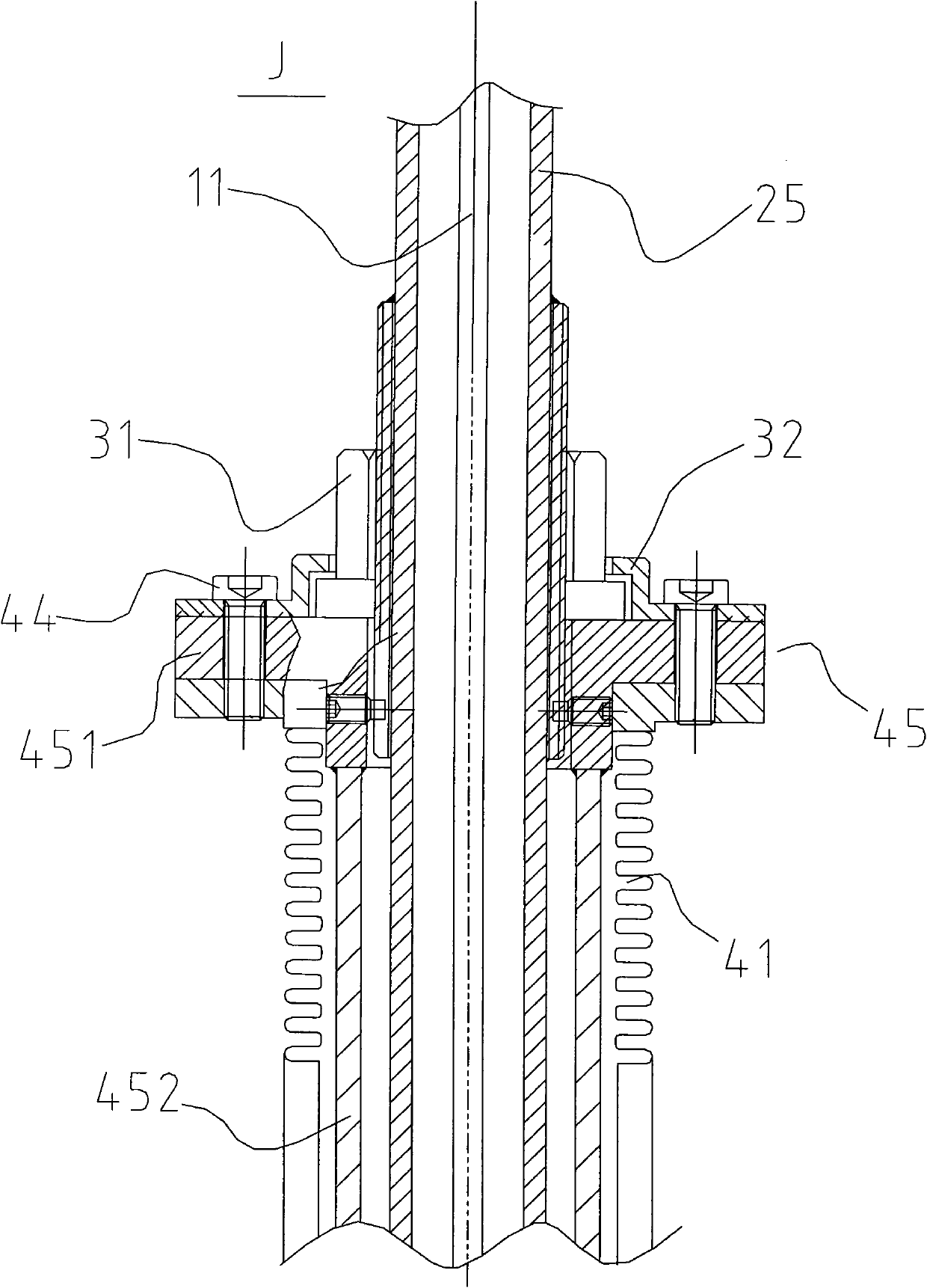

[0044] The air leakage control system includes a control unit, a fan-shaped plate execution unit M corresponding to the fan-shaped plate one-to-one, and a temperature detection device T corresponding to the air preheater one-to-one. The rotor speed measuring device N. Such as figure 1 As shown, in this embodiment, the generator set (boiler) is equipped with two air preheaters with three compartments, namely the first air preheater A and the second air preheater B, wherein the first air preheater Heater A is equipped with three fan-shaped plates, which are respectively fan-shaped plates A-1, A-2 and A-3, and the second air preheater B is equipped with three fan-shaped plates, which are respectively fan-shaped plates B-1, B-2 and B-3. Therefore, in this embodiment, the air leakage control system includes a control unit and six sets of fan-shaped plate execution units, and preferably also includes a rotor speed measuring device N installed on the first air preheater A and a te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com