Gas building pressure regulating box and using method thereof

A pressure regulating box and gas technology, which is applied in the direction of gas/liquid distribution and storage, pipeline system, mechanical equipment, etc., can solve the problems of difficult gas supply cost, large gas stop range and difficult replacement of the pressure regulating cabinet, so as to improve reliability Performance and stability, stable outlet pressure, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

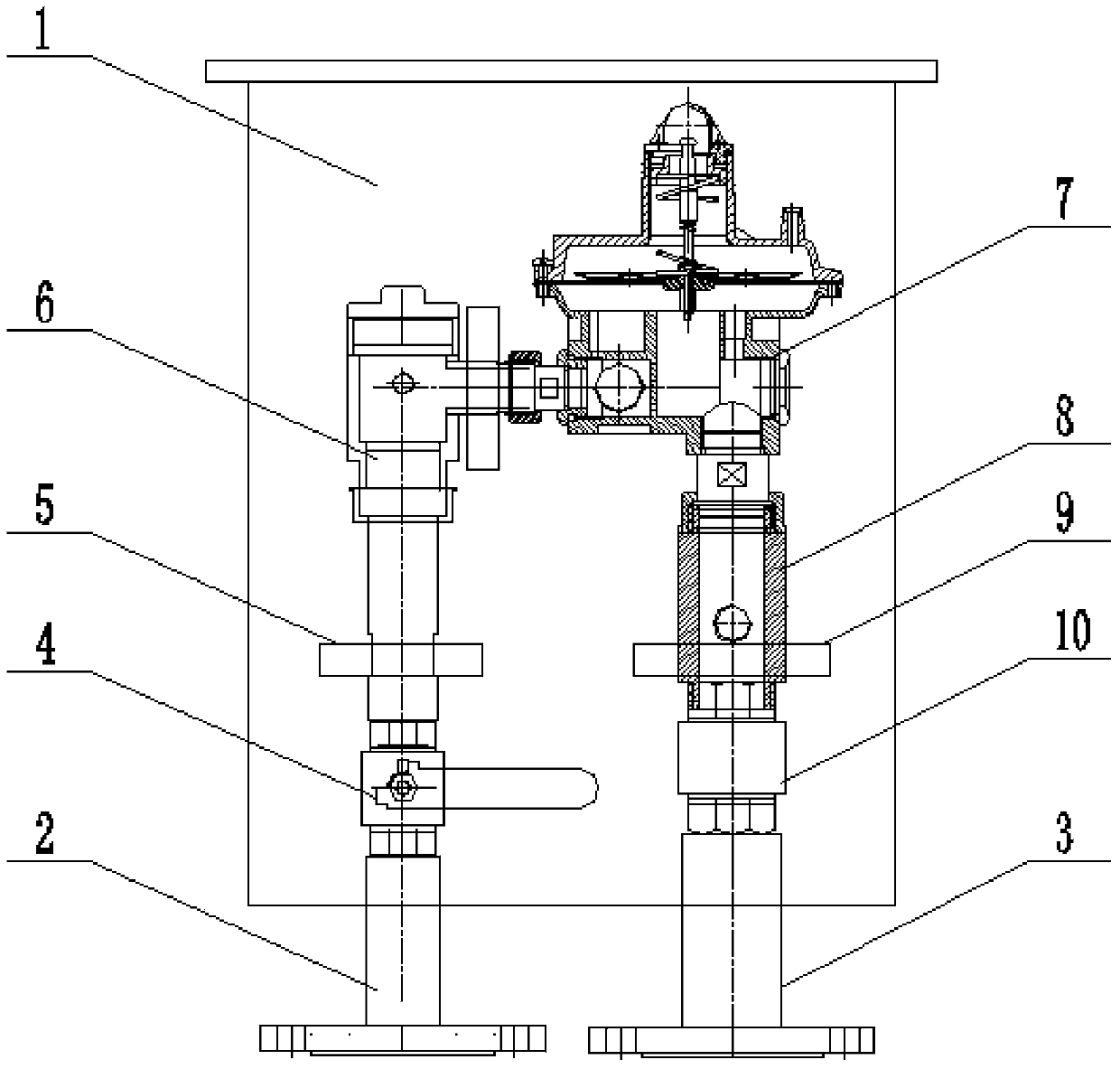

[0031] Such as figure 1 As shown, a gas building pressure regulating box provided in this embodiment includes a vertically arranged rectangular box body 1, and the box body 1 is equipped with a pressure regulator 7 and a filter 6 and the output port of the filter 6 Connected to the input port of the pressure regulator 7 in the horizontal direction, the lower input port of the filter 6 is connected to the inlet flange 2 through an inlet ball valve 4 in the vertical direction, and the inlet flange 2 passes through the box body 1 vertically downwards , the output port at the lower end of the pressure regulator 7 is connected to the outlet flange 3 through a deflation elbow ball valve 8 and an outlet ball valve 10 in the vertical direction, and the outlet flange 3 passes through the box body 1 in the vertical direction; wherein:

[0032] The inlet ball valve 4 is threadedly matched with the filter 6 and the inlet flange 2 respectively, between the deflation elbow ball valve 8 and ...

Embodiment 2

[0034] The structure of the gas building pressure regulating box in the present embodiment is the same as that in Embodiment 1, and the using method of the gas building building pressure regulating box of the present embodiment is carried out according to the following steps:

[0035] Step (1): Install the surge tank at the bottom of the box body 1 at a height of 1.0m from the ground;

[0036] Step (2): After the installation is completed, connect the pressure regulating box into the pipeline system through the inlet flange 2 and the outlet flange 3;

[0037] Step (3): Carry out the sealing performance test, enter the inert gas neon gas into the pipeline system at a pressure of 3Mpa, keep it for 30 minutes, if there is no leakage, then reduce the pressure to 0.05Mpa, keep it for 15 minutes, if there is no leakage If there is no gas phenomenon, continue to step (4);

[0038] Step (4): After completing the sealing performance test, open the inlet ball valve 4 at an opening of 5...

Embodiment 3

[0040] The structure of the gas building pressure regulating box in the present embodiment is the same as that in Embodiment 1, and the using method of the gas building building pressure regulating box of the present embodiment is carried out according to the following steps:

[0041] Step (1): Install the surge tank at the bottom of the tank 1 at a height of 1.2m from the ground;

[0042] Step (2): After the installation is completed, connect the pressure regulating box into the pipeline system through the inlet flange 2 and the outlet flange 3;

[0043]Step (3): Carry out the sealing performance test, enter the inert gas argon into the pipeline system at a pressure of 4Mpa, keep it for 40 minutes, if there is no leakage, then reduce the pressure to 1.0Mpa, keep it for 18 minutes, if there is no leakage If there is no gas phenomenon, continue to step (4);

[0044] Step (4): After completing the sealing performance test, open the inlet ball valve 4 at an opening of 8% / min, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com