A material lateral displacement device for a turning and throwing machine

A technology of lateral displacement and turning and throwing machines, applied in the field of turning and throwing machines, can solve the problems of uneven turning and throwing of the bottom layer of the stacking material, large single investment, and few expansion parts, etc., and achieves flexible and convenient use and strong adaptability. , to ensure the effect of flipping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

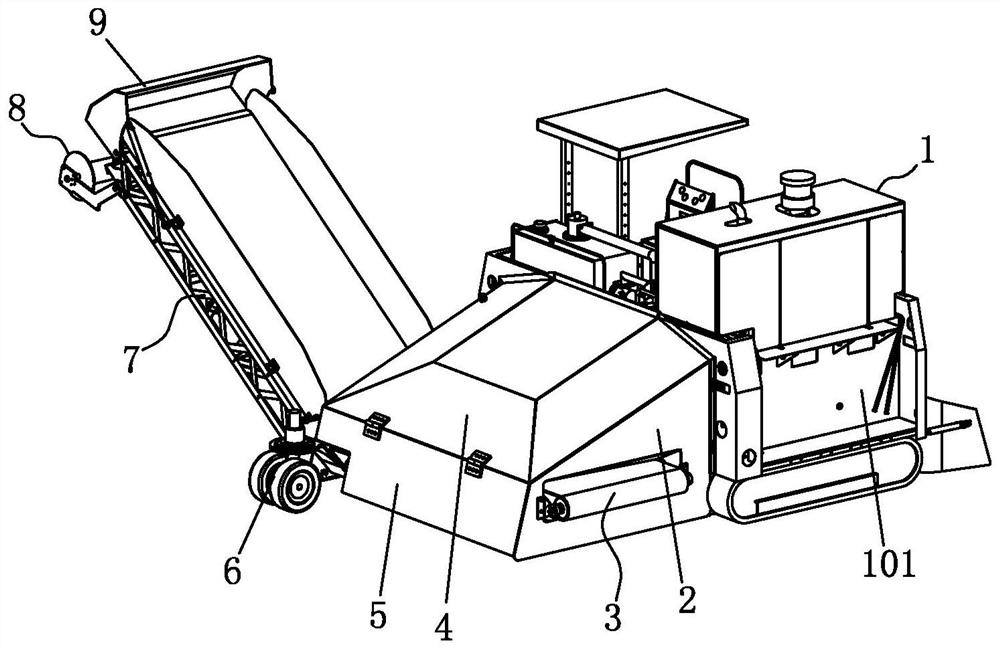

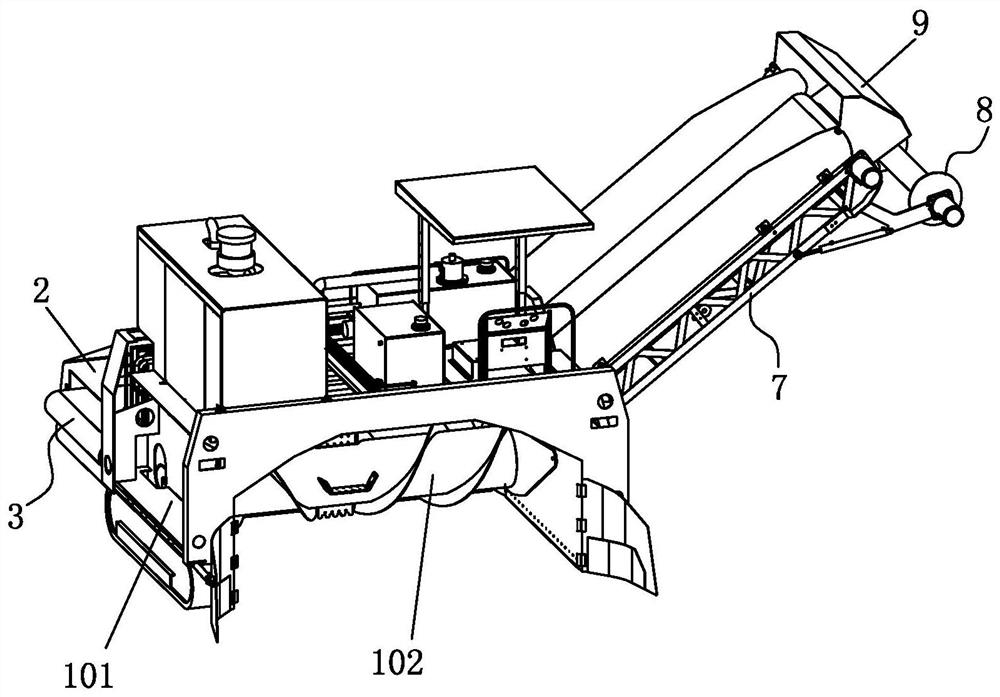

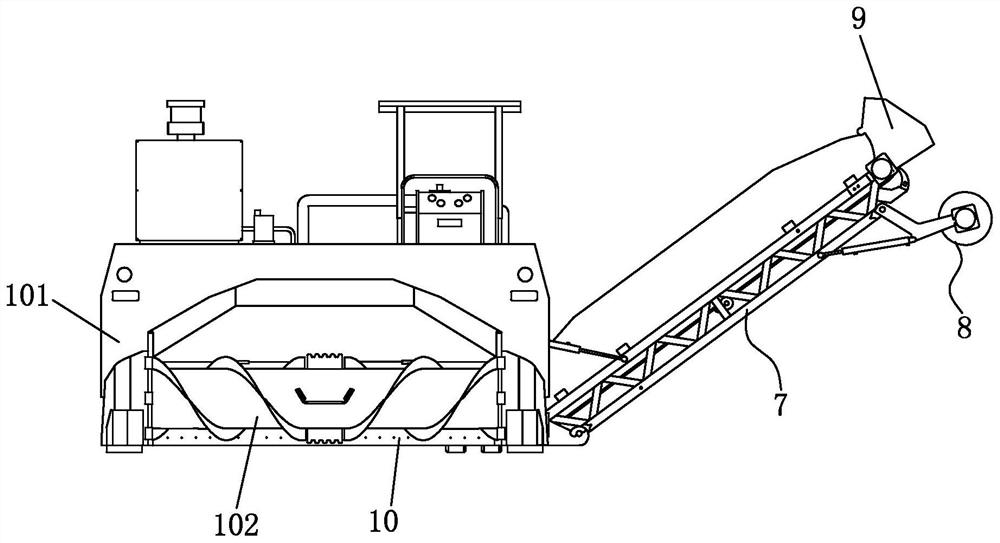

[0034] Such as Figure 1 to Figure 8 As shown, a material lateral displacement device for a turning machine of the present invention includes a turning machine 1 and a material displacement device connected to the rear of the turning machine 1; the turning machine 1 includes a turning machine main body 101 and a turning machine The turning and throwing drum 102 connected to the main body 101 of the machine, the material displacement device includes a shovel 10, a lateral conveying device 3, a pallet changing conveying device 7 and a walking wheel 6, and the lateral conveying device 3 is arranged horizontally, and passes through two mutual Parallel connection plates 2 are connected to the rear side of the main body 101 of the turning and polishing machine, and an inner support rod 11 is also connected between the two connection plates 2; the stack-changing conveying device 7 is connected to the outside of one of the connection plates 2 and is inclined upward; The shovel 10 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com