Ultrasonic flaw detection apparatus

A flaw detection device and ultrasonic technology, which is applied to the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems of difficult manufacturing, poor economic benefits, huge cost, etc., and achieve the effects of low use cost, fast installation and disassembly, and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

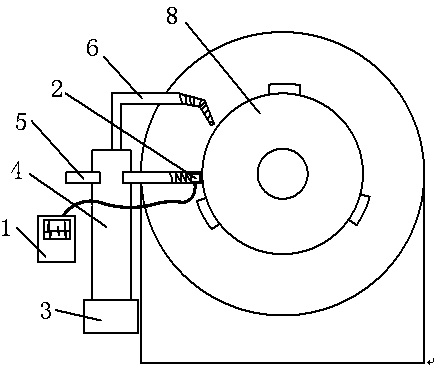

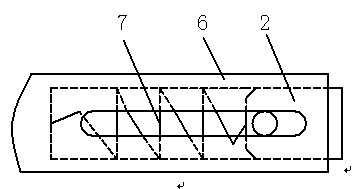

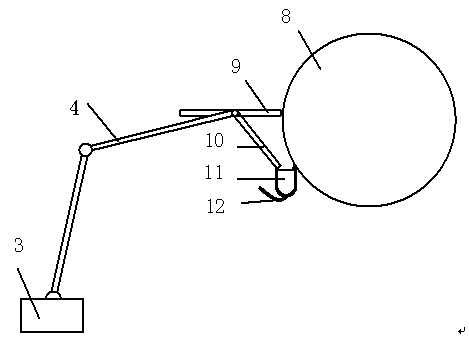

[0023] The invention discloses an ultrasonic flaw detection device, comprising a portable ultrasonic detector 1 and its detection probe 2, including a magnetic meter base 3 and a movable support 4 installed on its upper end surface, and a movable support 5 is installed at the free end of the movable support 4, One end of the detection probe 2 is installed in the chute at the end of the movable support 5 and connected to the adjustment spring 7, and some water spray pipes 6 are arranged around the working end of the detection probe 2, and the water spray pipe 6 is fixedly connected to the movable support 4 and Connected to the automatic water tank.

[0024] The present invention utilizes the machine tool to clamp and move the workpiece 8 and installs it on the machine tool to realize linear detection or spiral movement detection of the workpiece 8 . The magnetic switch can be realized through the switch by adopting the magnetic table base 3, so that the present invention can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com