Roller UT flaw detection mechanism and roller flaw detection method thereof

A technology of rollers and manipulators, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measuring devices. To solve problems such as the efficiency of sub-flaw detection, to reduce equipment investment and use costs, improve efficiency, and improve the efficiency of flaw detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

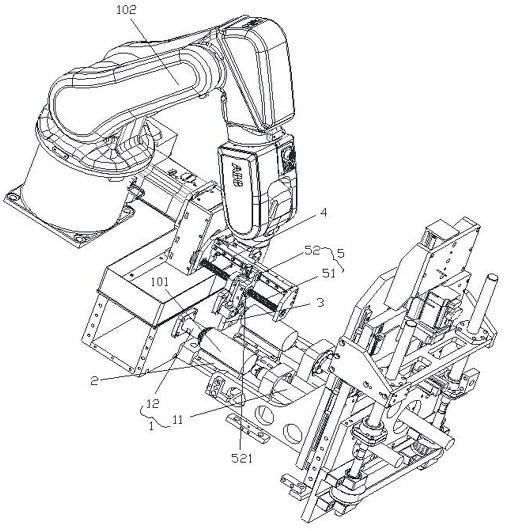

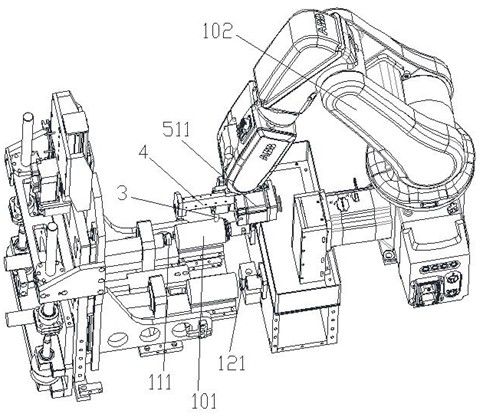

[0022] Such as Figure 1 to Figure 2 It is a specific implementation of this embodiment, applied to the flaw detection roller 101, and its structure includes a manipulator 102, and its structure also includes a clamping assembly 1 that clamps the roller 101 for rotation, a V-shaped groove 2 for placing the roller, and The UT probe 3 and the V-groove 2 can be moved up and down and arranged under the connecting line of the two clamping surfaces of the clamping component 1. The manipulator 102 is provided with a fixed frame 4, and the UT probe 3 is movably arranged on the fixed frame 4. The fixed frame 4 is provided with a drive assembly 5 that drives the UT probe 3 to move on the fixed frame 4. When the manipulator 102 drives the fixed frame 4 to move to the top of the V-shaped groove 2, the UT probe 3 is positioned at the positive end of the roller 101 in the longitudinal direction. Above, the driving assembly 5 drives the UT probe 3 to move on the fixed frame 4 along the lengt...

Embodiment 2

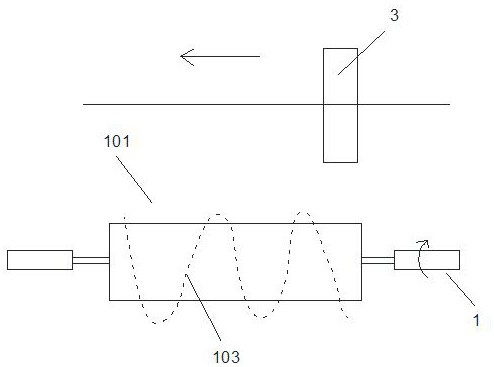

[0030] Such as image 3 As shown, this embodiment provides a roller UT flaw detection mechanism flaw detection roller method, using the principle of the roller UT eye mechanism flaw detection roller in Embodiment 1, the specific steps of the roller flaw detection are as follows: 1. Put the roller 101 Placed on the V-shaped groove 2, 2. The clamping component 1 clamps the roller 101, and moves the V-shaped groove 2 downward, so that the roller 101 is suspended and clamped on the clamping component 1. 3. The manipulator 102 drives The fixed frame 4 moves to the top of the V-shaped groove 2, and the spatial position of the UT probe 3 above the roller 101 is reasonably adjusted by moving the fixed frame 4. On the one hand, keep the bottom of the UT probe 3 and one end of the roller 101 in the length direction at 18mm-22mm. 4. When the clamping component 1 clamps the roller 101 for continuous rotation, the driving component 5 synchronously drives the UT probe 3 on the fixed frame 4...

Embodiment 3

[0033] Such as Figure 4 As shown, the present invention provides a roller UT flaw detection mechanism flaw detection roller method, using the roller UT eye mechanism flaw detection roller principle of embodiment 1, the specific steps of the roller flaw detection are as follows: 1. Place the roller 101 On the V-shaped groove 2, 2. The clamping component 1 clamps the roller 101, and moves the V-shaped groove 2 downward, so that the roller 101 is suspended and clamped on the clamping component 1. 3. The manipulator 102 drives and fixes it The frame 4 moves to the top of the V-groove 2, and the space position of the UT probe 3 above the roller 101 is reasonably adjusted by moving the fixed frame 4. On the one hand, the UT probe 3 is located directly above one end of the roller 101 in the length direction, and on the other hand Keep the bottom of the UT probe 3 and one end of the roller 101 in the length direction at 18mm-22mm. 4. When the clamping assembly 1 rotates the roller 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com