A light rail flaw detection trolley

A flaw detection vehicle and trolley technology, which is applied to railway inspection vehicles, railway car body parts, railway vehicle shape measuring instruments, etc., can solve the problems of expensive equipment, less road station configuration, inconvenient access to and from the road, etc., and achieve accurate flaw detection results. , The effect of large carrying weight and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The relevant features of this patent will be further described in detail below in conjunction with the accompanying drawings.

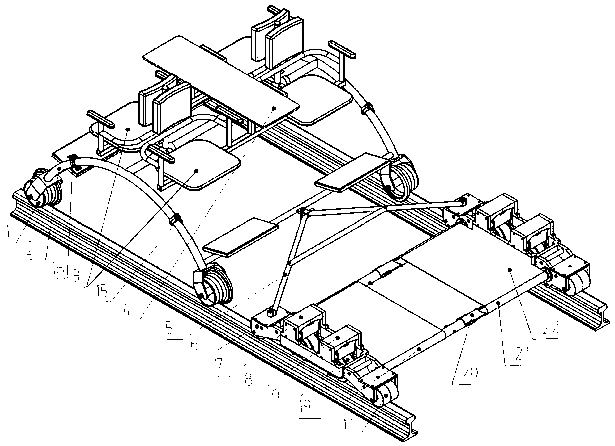

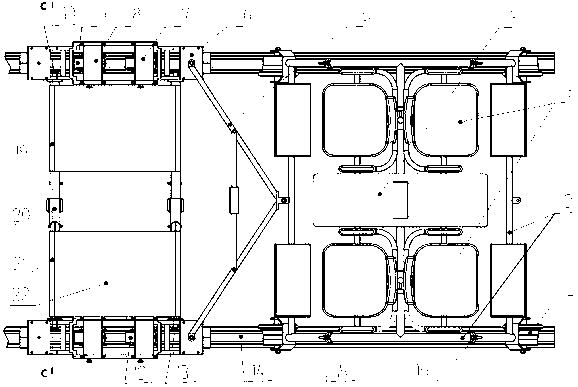

[0017] like figure 1 As shown, the light-duty rail flaw detection trolley consists of two parts: the driving trolley and the flaw detection trolley. The driving trolley includes the driving wheel 1, the trolley body 2, the seat 3, the working platform 4, two folding mechanisms 15 and 16 and an electrical system. Wheel 1 is four aluminum alloy wheels, and hub motors are arranged in the wheels to provide power to make the dolly run on the track. The flaw detection trolley includes connecting bracket 5, flaw detection car body 6, flaw detection mechanism 7 and 8, flaw detection wheel 9, left elastic telescopic rod 19 and right elastic telescopic rod 21, telescopic mechanism 20, flaw detection trolley platform 22, etc. The flaw detection trolley and the driving trolley pass through The connection bracket 5 is connected.

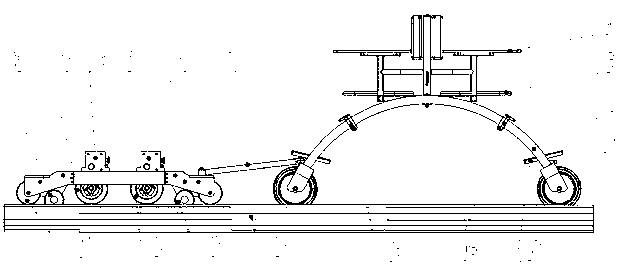

[0018] like figure 2 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com