A rapid steel pipe flaw detection device

A steel pipe, fast technology, applied in the direction of measuring devices, instruments, test and manufacturing objects, etc., can solve the problems of waste of human resources, increase labor costs, and consume physical strength of staff, so as to save labor, reduce labor intensity, and intuitive test results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] For a better understanding of the present invention, the present invention will be further described below with reference to specific embodiments and accompanying drawings.

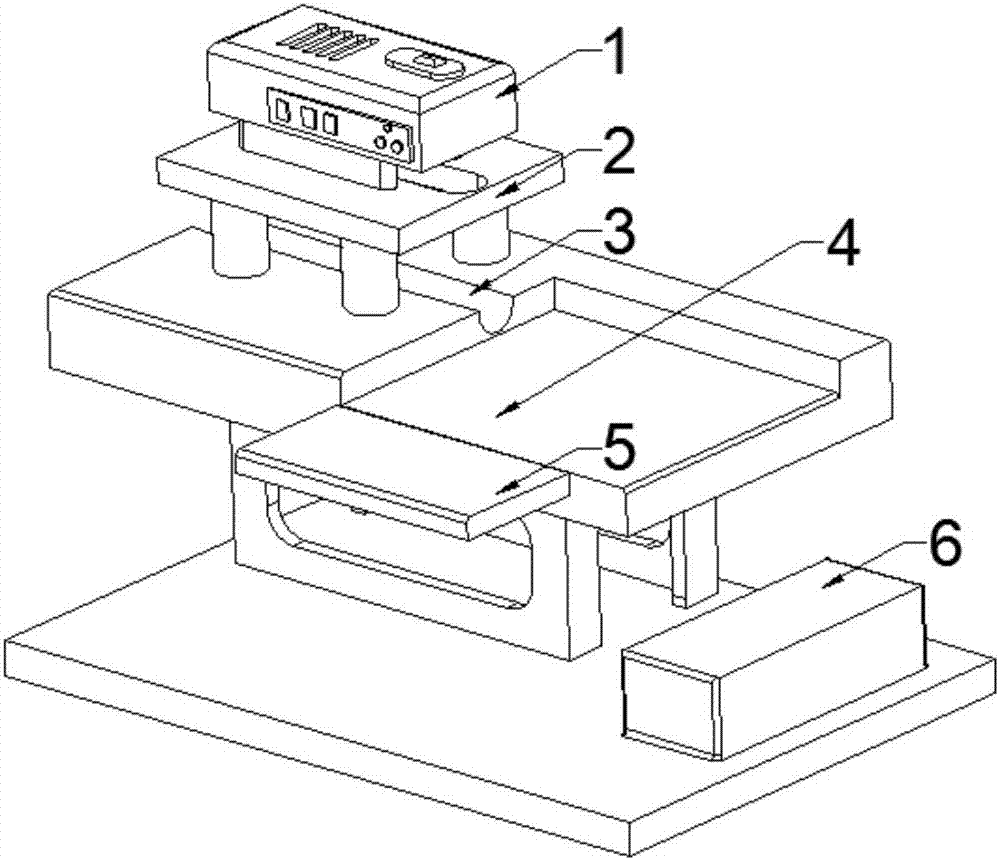

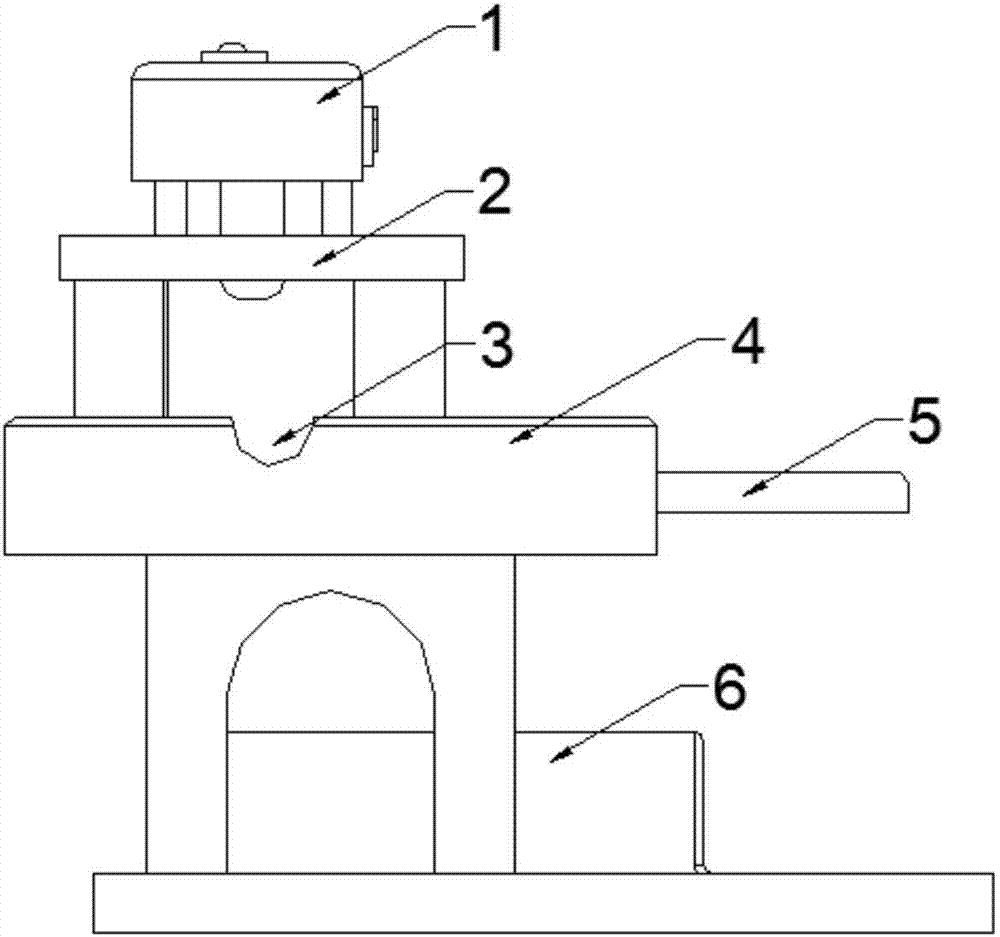

[0020] like Figure 1-2 As shown, a rapid steel pipe flaw detection equipment includes a flaw detection host 1, a bracket 2 is fixed on the lower end surface of the flaw detection host 1, and the bracket 2 is fixed on the upper end surface of a working platform 4, located between the brackets 2 The working platform 4 is provided with a fixing groove 3 for preventing steel pipes, the lower end of the flaw detection host 1 is provided with a probe, and the probe passes through the bracket 2 and points vertically to the fixing groove 3, and the working The side of the platform 4 is provided with an arrangement platform 5 for arranging defective steel pipes, the lower end surface of the working platform 4 is provided with a support plate, the lower end surface of the support plate is fixedly provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com