Control device for automatic continuous speed transforming transmission

A technology of variable speed transmission and control device, which is applied in the direction of transmission device control, transmission device, and components with teeth, etc., can solve the problem of shifting control of transmission device that cannot be continuously changed, and achieve the effect of improving the operation feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

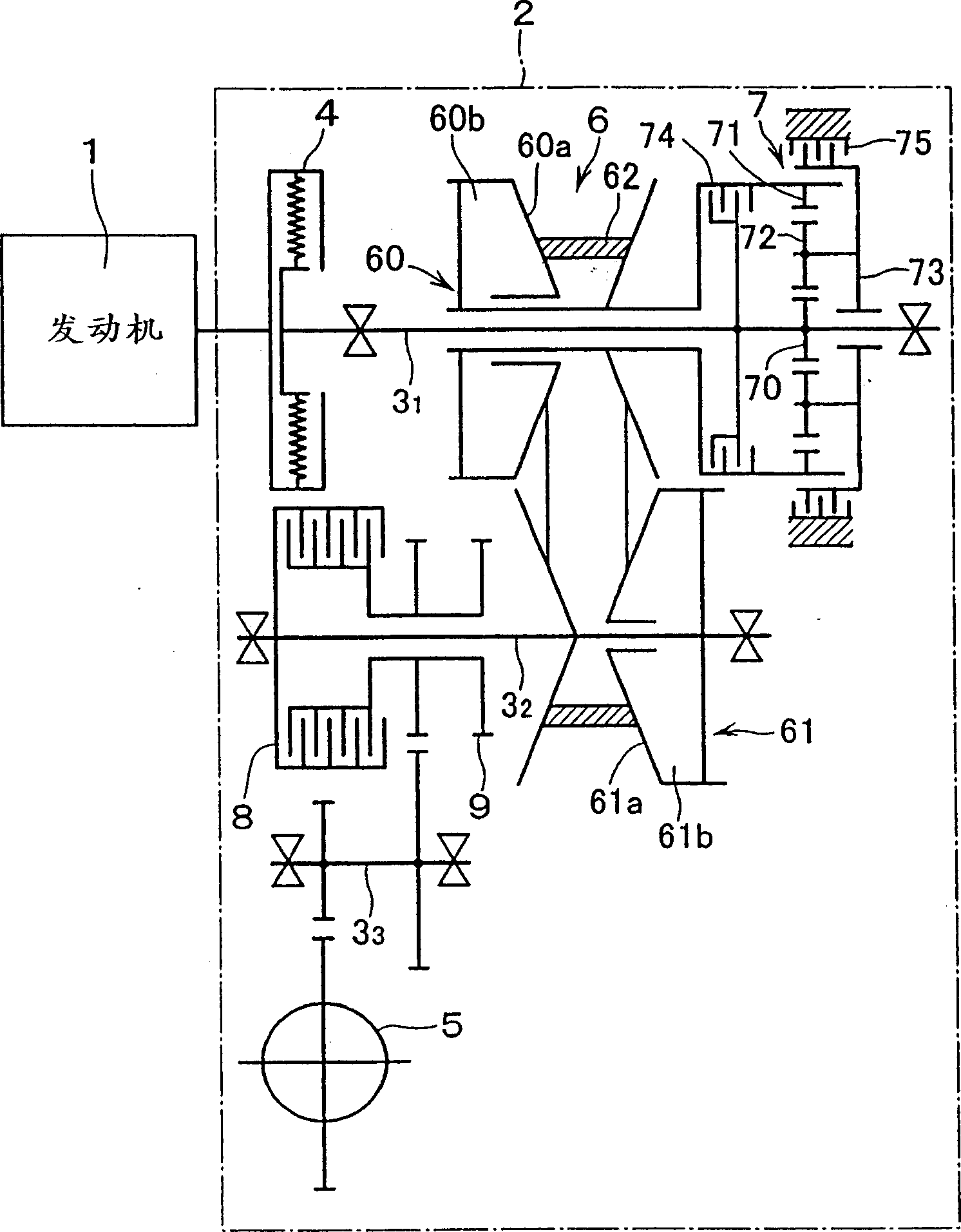

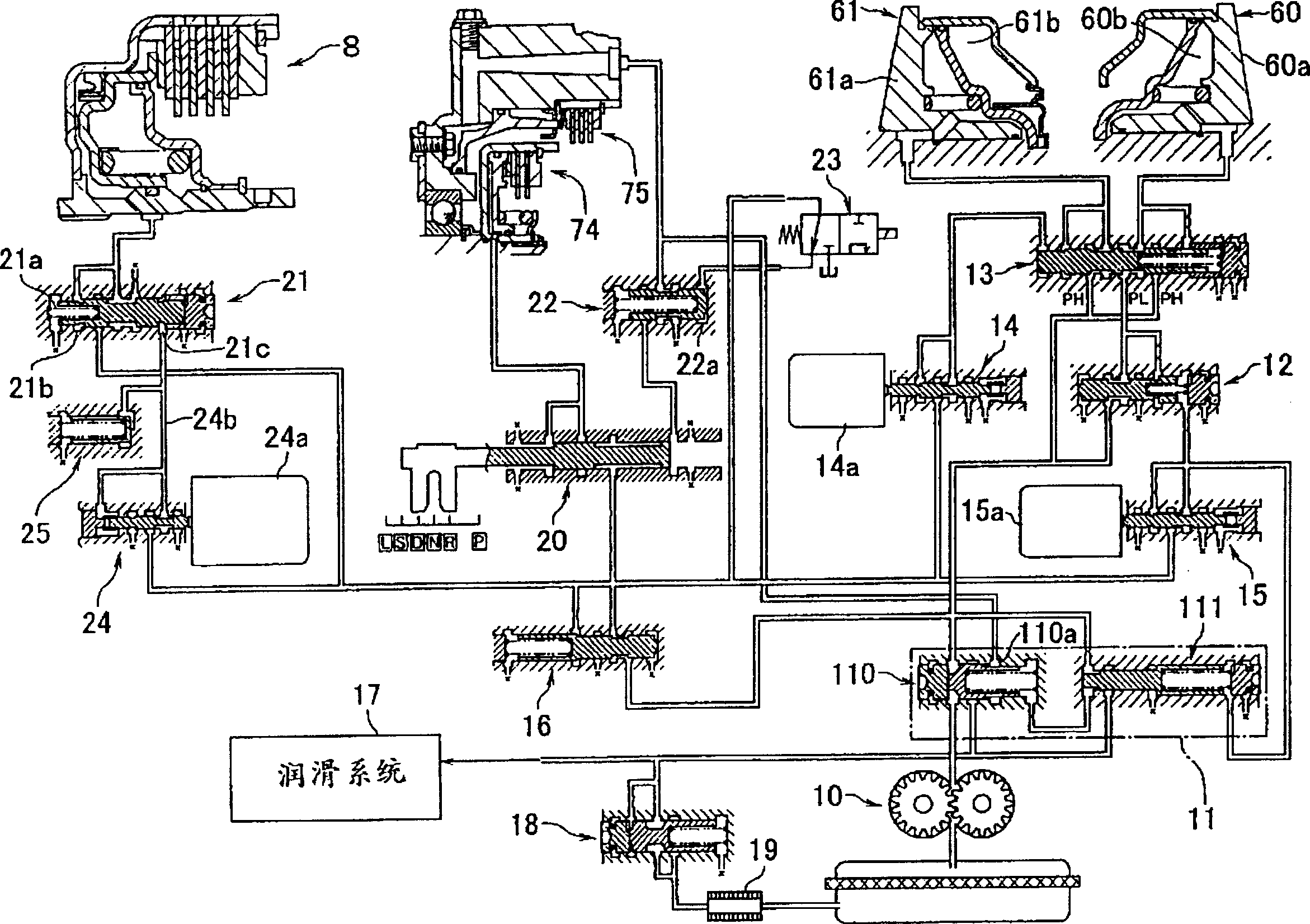

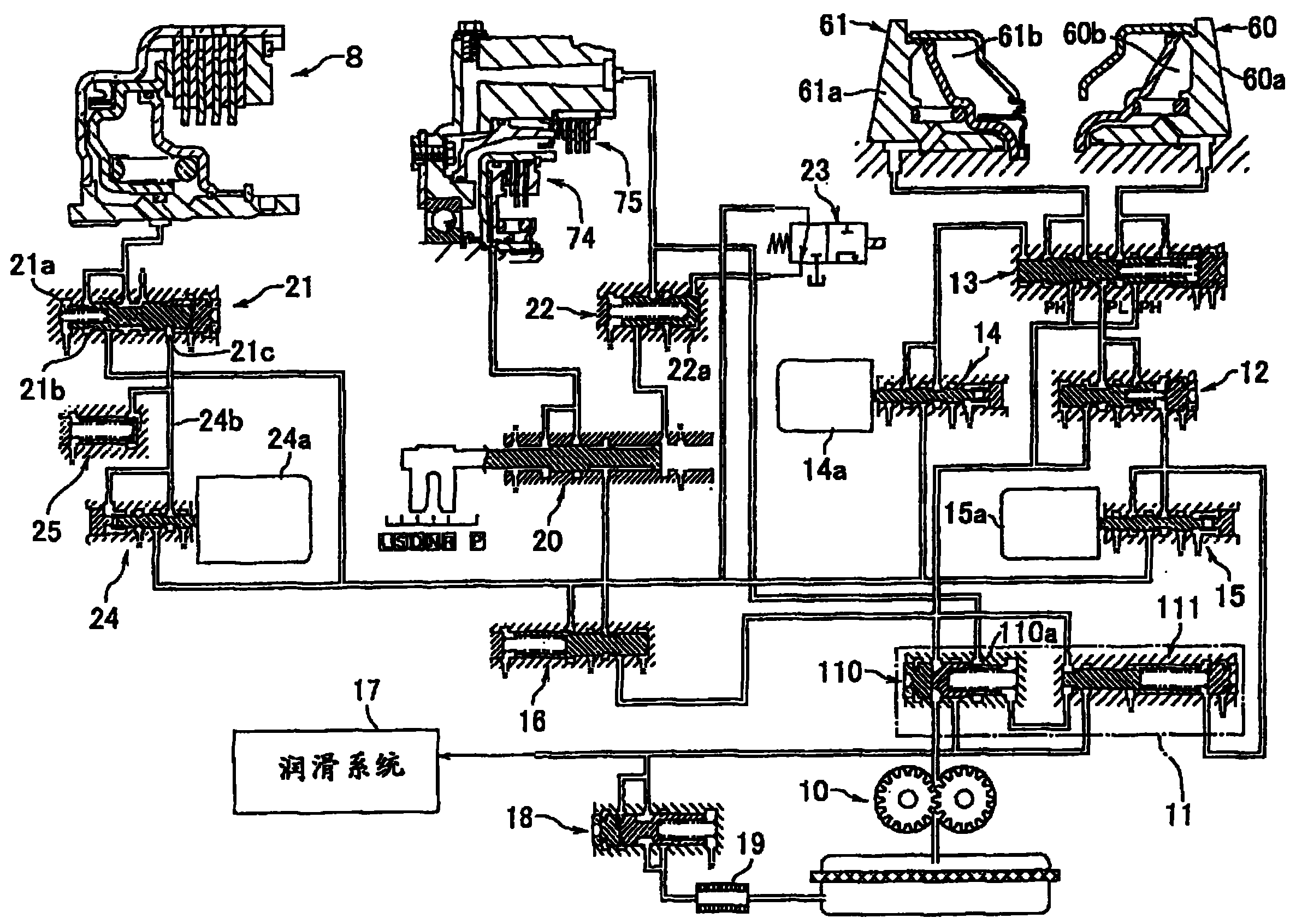

[0013] Reference attached figure 1 , reference numeral 1 denotes an engine, and reference numeral 2 denotes a continuously variable transmission, which includes three first to third shafts 3 arranged parallel to each other 1 、3 2 and 3 3 . first axis 3 1 is connected to the engine 1 through a shock absorber 4, while the third shaft 3 3 It is connected to the drive wheels (not shown) of the locomotive through a differential gear 5 .

[0014] in the first axis 3 1 and third axis 3 3 There is a continuously variable transmission mechanism 6 between them. The continuously variable transmission mechanism 6 is rotatably supported on the first shaft 3 1 The driving wheel 60 on the top is fixed on the second shaft 3 2 The upper driven wheel 61 and the drive belt 62 extending between the two wheels 60,61 constitute. The mechanism 6 controls the internal pressure of the hydraulic cylinders 60b, 61b to press the movable pulleys 60a, 61a to change the diameter of the transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com