Semi-steel can permanent layer castable

A permanent layer and castable technology, which is applied in the field of blast furnace ironmaking, can solve the problems of castable strength reduction, permanent layer drop, peeling, etc., achieve good application prospects, increase service life, and improve heat storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The raw material formula shown in Table 3 is used for batching. After the raw materials pass the test, they are sampled and tested after weighing, stirring, and packaging. The physical and chemical indicators are as shown in Table 4:

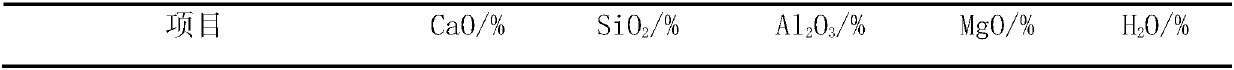

[0060] Raw material proportioning that table 3 embodiment 1 adopts

[0061]

[0062]

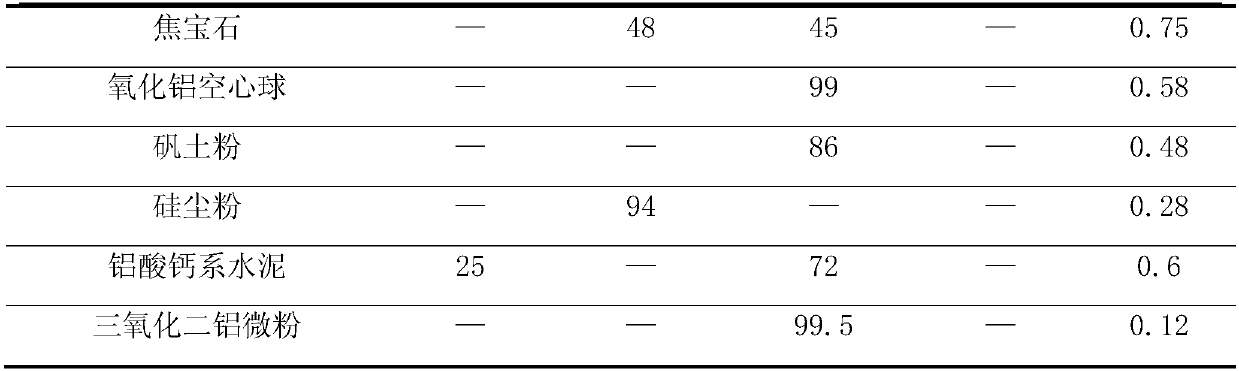

[0063] Table 4 The physical and chemical testing results of the semi-steel tank permanent layer castable made in Example 1

[0064]

[0065] Example 1 The castable for the permanent layer of the semi-steel tank was used as the refractory integral castable material for the permanent layer of the semi-steel tank. This time, 45 tons of the castable for the permanent layer of the semi-steel tank were sent to the cold repair area of the semi-steel tank, and 3 semi-steel tanks were collected. The data after an overall overhaul was compared with the overhaul data of the original castables. The pouring performance of the three test half-steel tanks w...

Embodiment 2

[0067] The raw material formula shown in Table 5 is used for batching. After the raw materials pass the test, they are sampled and tested after weighing, stirring, and packaging. The physical and chemical indicators are as shown in Table 6:

[0068] Raw material proportioning that table 5 embodiment 2 adopts

[0069]

[0070] Table 6 The physical and chemical testing results of the semi-steel tank permanent layer castable made in Example 2

[0071]

[0072] Example 2 The castable for the permanent layer of the semi-steel tank was used as the refractory integral castable material for the permanent layer of the semi-steel tank. This time, 45 tons of the castable for the permanent layer of the semi-steel tank were sent to the cold repair area of the semi-steel tank, and 3 semi-steel tanks were collected. The data after an overall overhaul was compared with the overhaul data of the original castables. The pouring performance of the three test half-steel tanks was better th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com