Method of simultaneously liquefying and saccharifying cirn starch

A technology of corn starch and maltose amylase, applied in fermentation and other directions, can solve the problem of low starch hydrolysis activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

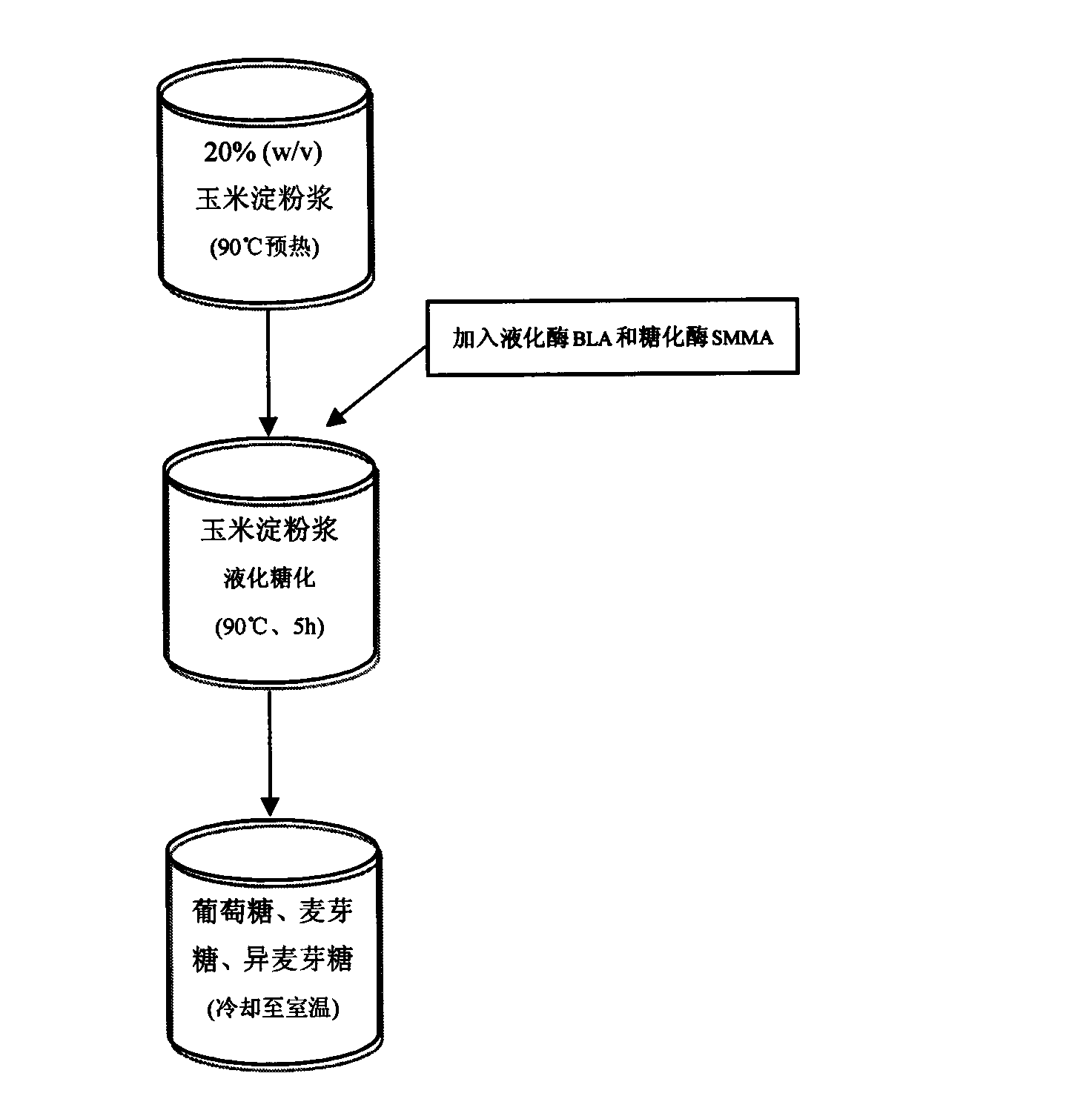

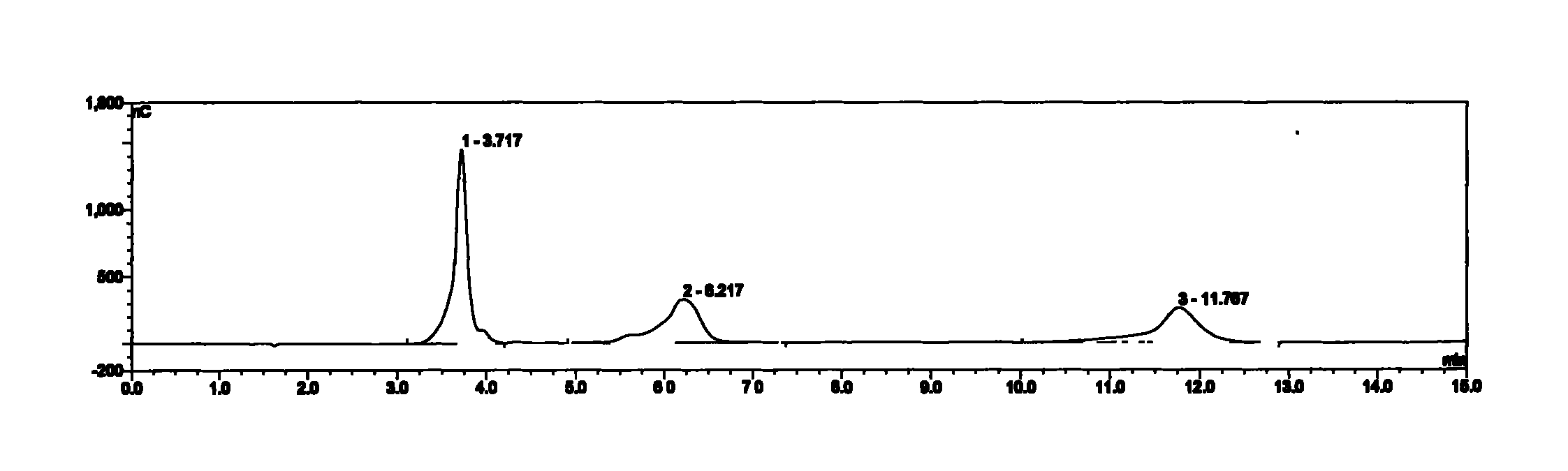

[0026] Mix 20mg of corn starch (Dacheng Industrial Group, Changchun City, Jilin Province) with 200μL buffer (50mM pH5.5 acetic acid-sodium acetate), preheat at 90°C for 3 minutes, then add 10U of Bacillus licheniformis (Bacillus licheniformis) alpha-amylase (BLA, 120, Novozymes, Denmark) and Staphylothermus marinus maltose amylase (SMMA) with an enzyme activity of 5U, after incubation at 90°C for 5h, and naturally cooled to room temperature, starch syrup was obtained. The components of the starch syrup were measured by high performance anion exchange chromatography, and the calculations were as follows: the yield of glucose was 38.92%, the yield of maltose was 39.87%, the yield of isomaltose was 31.83%, and the total yield was 110.62%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com