Method and apparatus for purifying zincilate

A purification method and technology of zinc slag, applied in furnaces, cooking furnaces, furnace types, etc., can solve the problem that the chemical composition only meets the 1# and 2# zinc standards, the vacuum distillation zinc smelting furnace burns, and the 0# zinc is not reached. Standards and other issues to achieve the effect of reducing energy consumption, low production costs, and avoiding extreme cold and heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

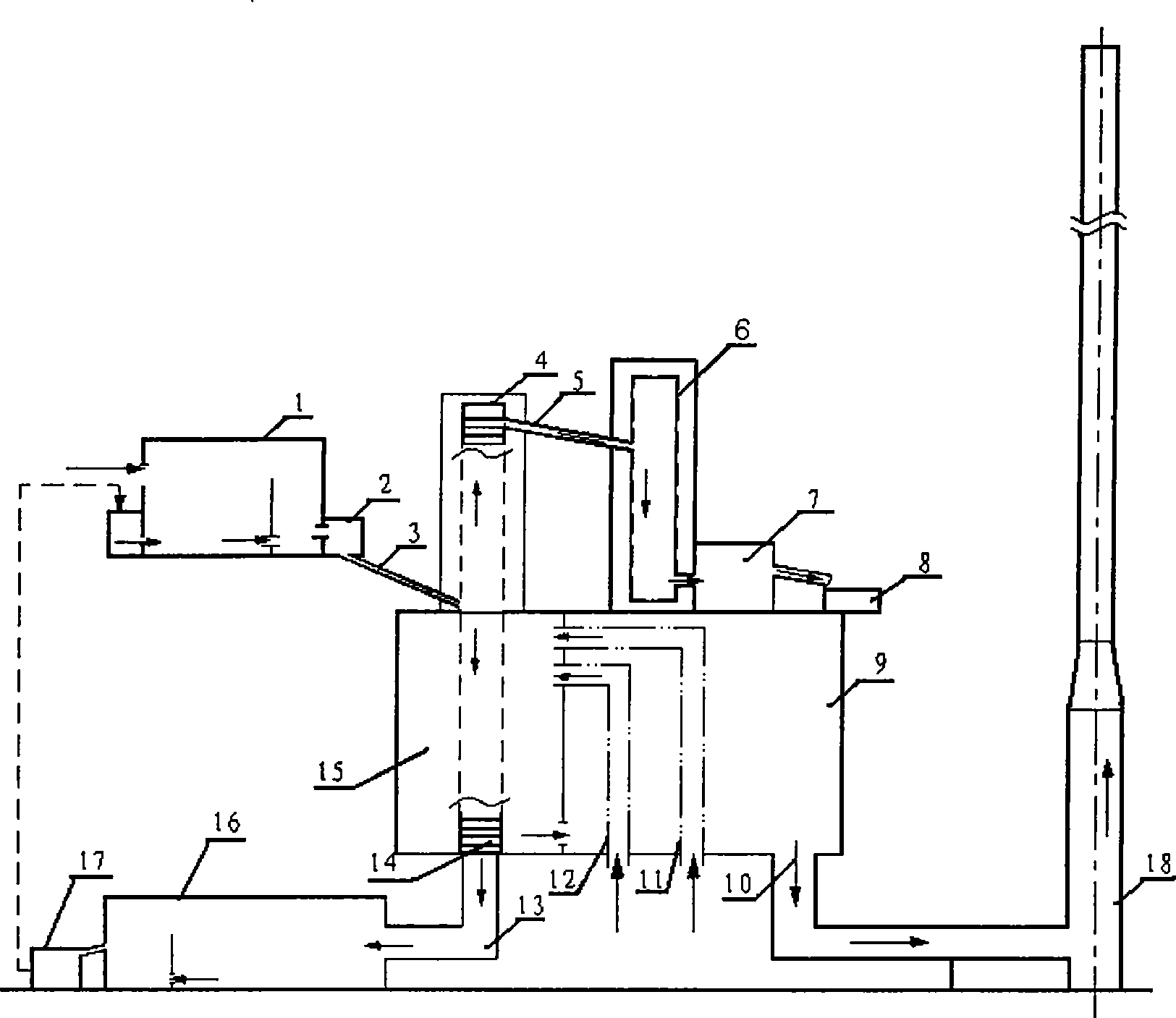

[0010] As can be seen from the accompanying drawings, the zinc slag purification device of the present invention is mainly composed of melting furnace 1, automatic feeder 2, feeding pipe 3, rectifying tower 4, evaporation chute 5, condenser 6, zinc storage tank 7, casting mold 8. It is composed of heat exchange chamber 9, descending part 13, combustion chamber 15, melting furnace 16, zinc ladle 17 and chimney 18. The zinc slag is firstly melted in the melting furnace 1, and the melting temperature of the melting furnace 1 is controlled at 500-750°C. The molten zinc slag is sent to the rectification tower 4 for distillation through the automatic feeding device 2 through the feeding pipe 3 . The rectification tower 4 is mainly composed of a tray group 14, which is connected with the combustion chamber 15 and the heat exchange chamber 9. The air 11 and the coal gas 12 are respectively sent to the combustion chamber 15 through the heat exchange chamber 9, and the exhaust gas 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com