Patents

Literature

36results about How to "Excellent low friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

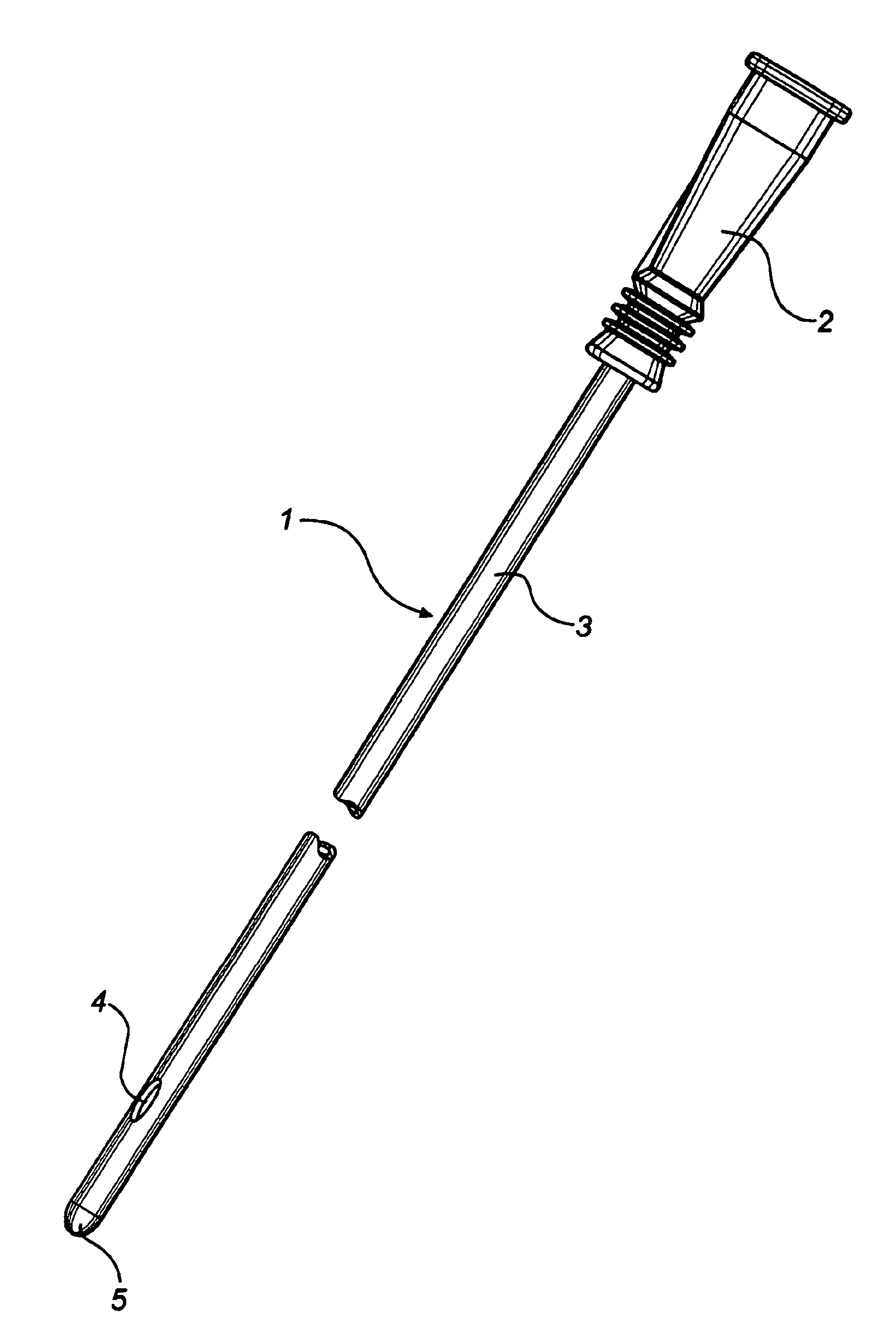

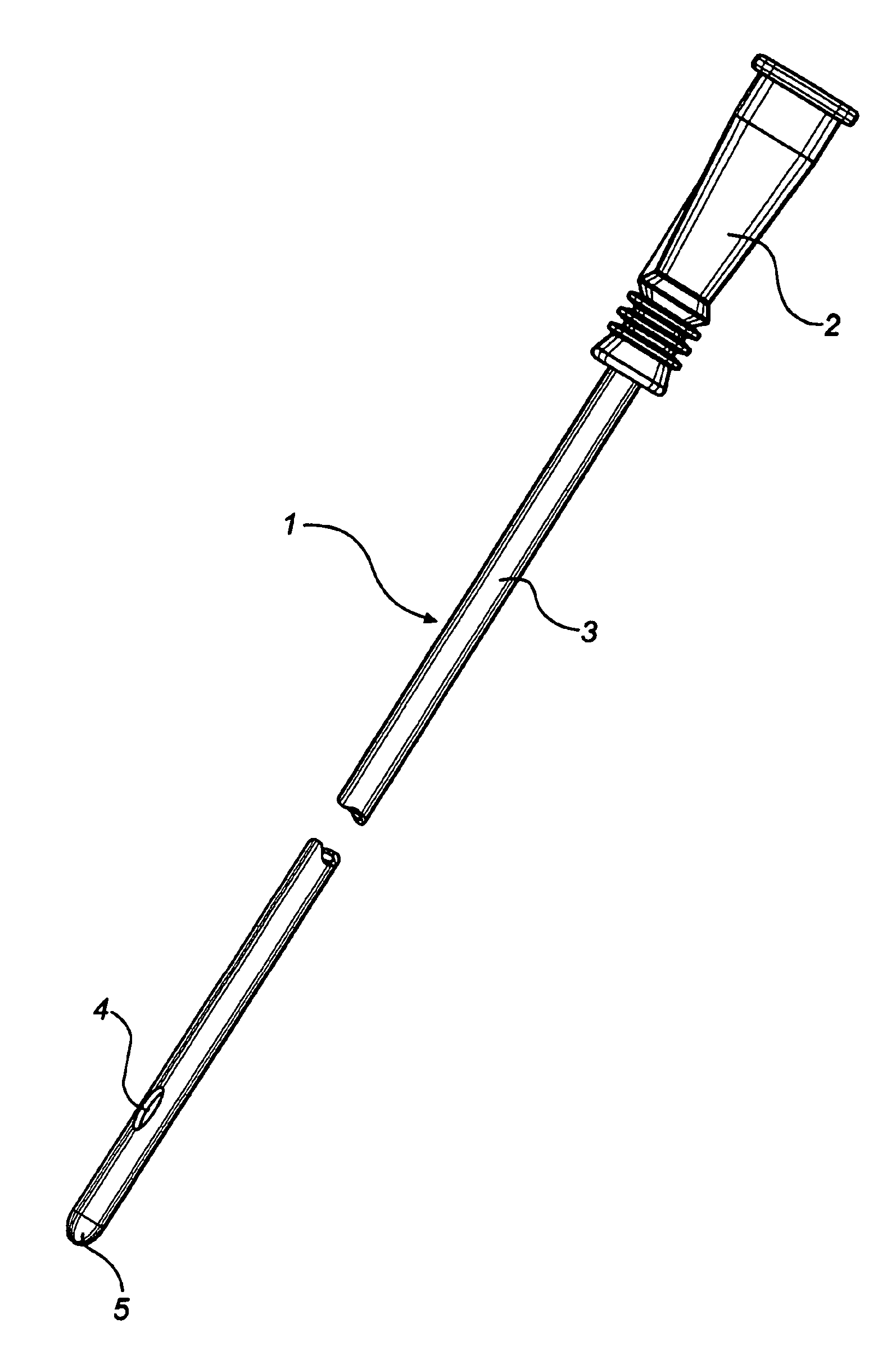

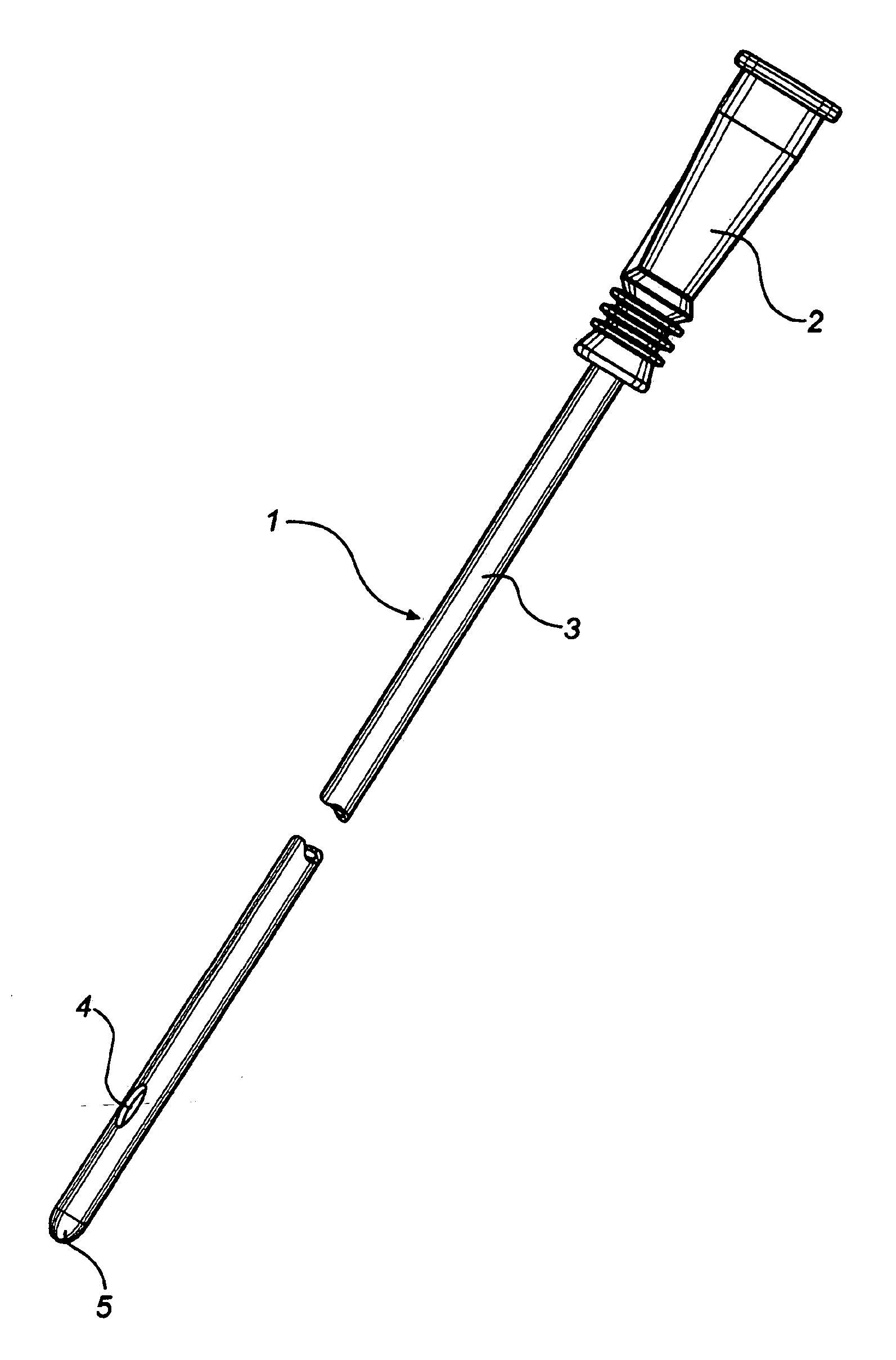

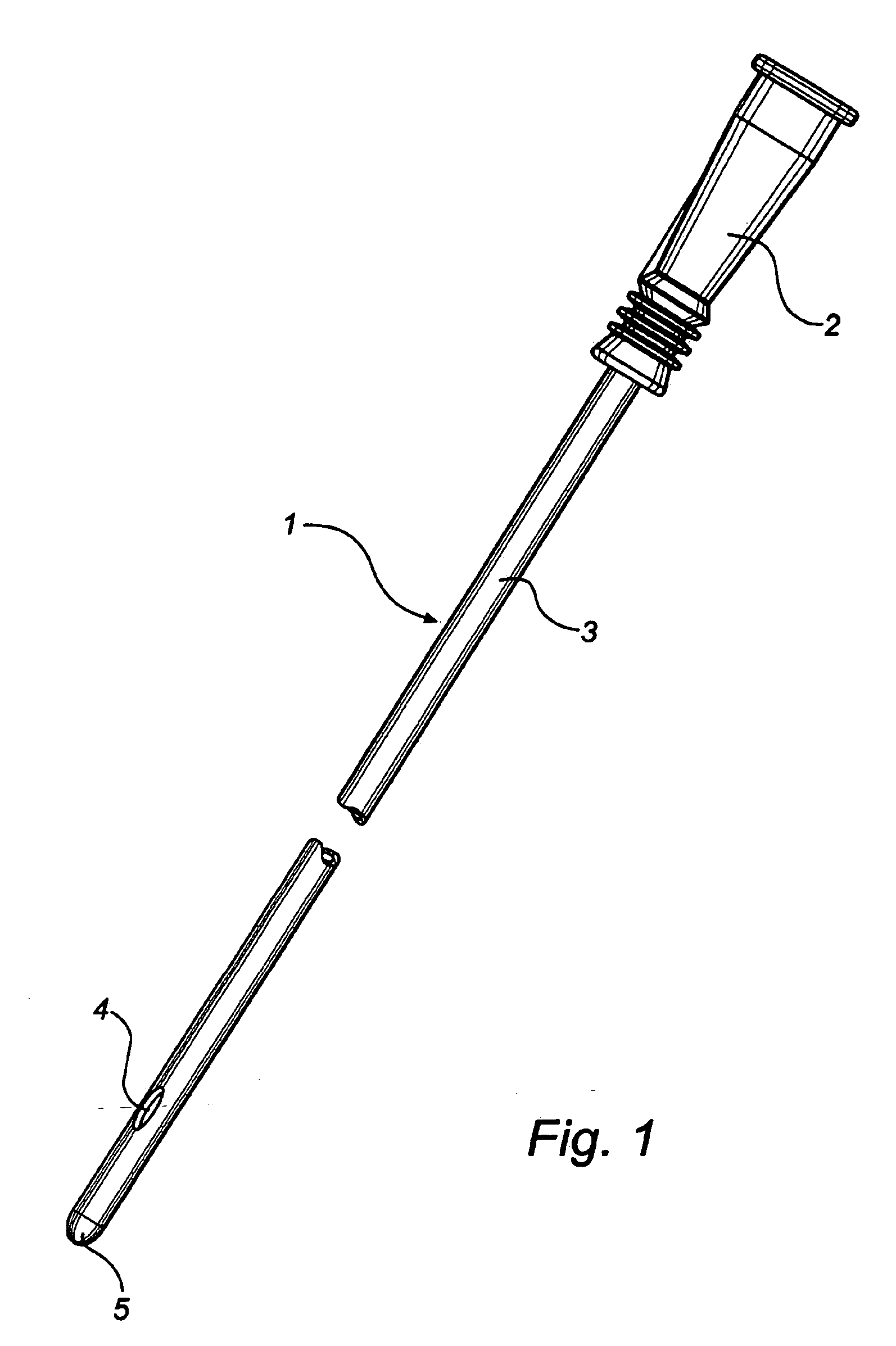

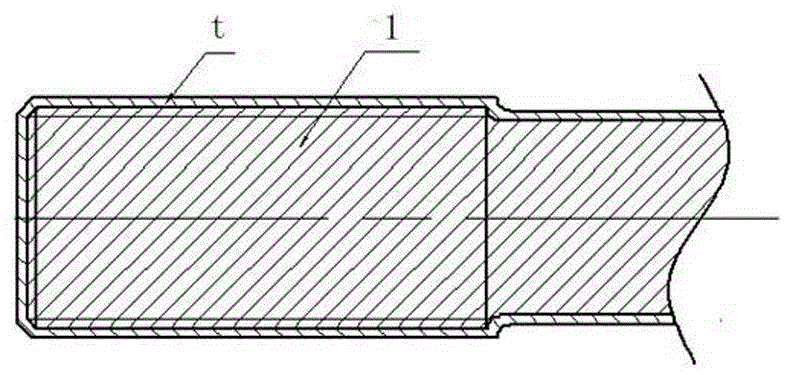

Urinary catheter

ActiveUS8168249B2Improve mechanical propertiesImprove adhesionWound drainsGlovesUrinary catheterPolyolefin

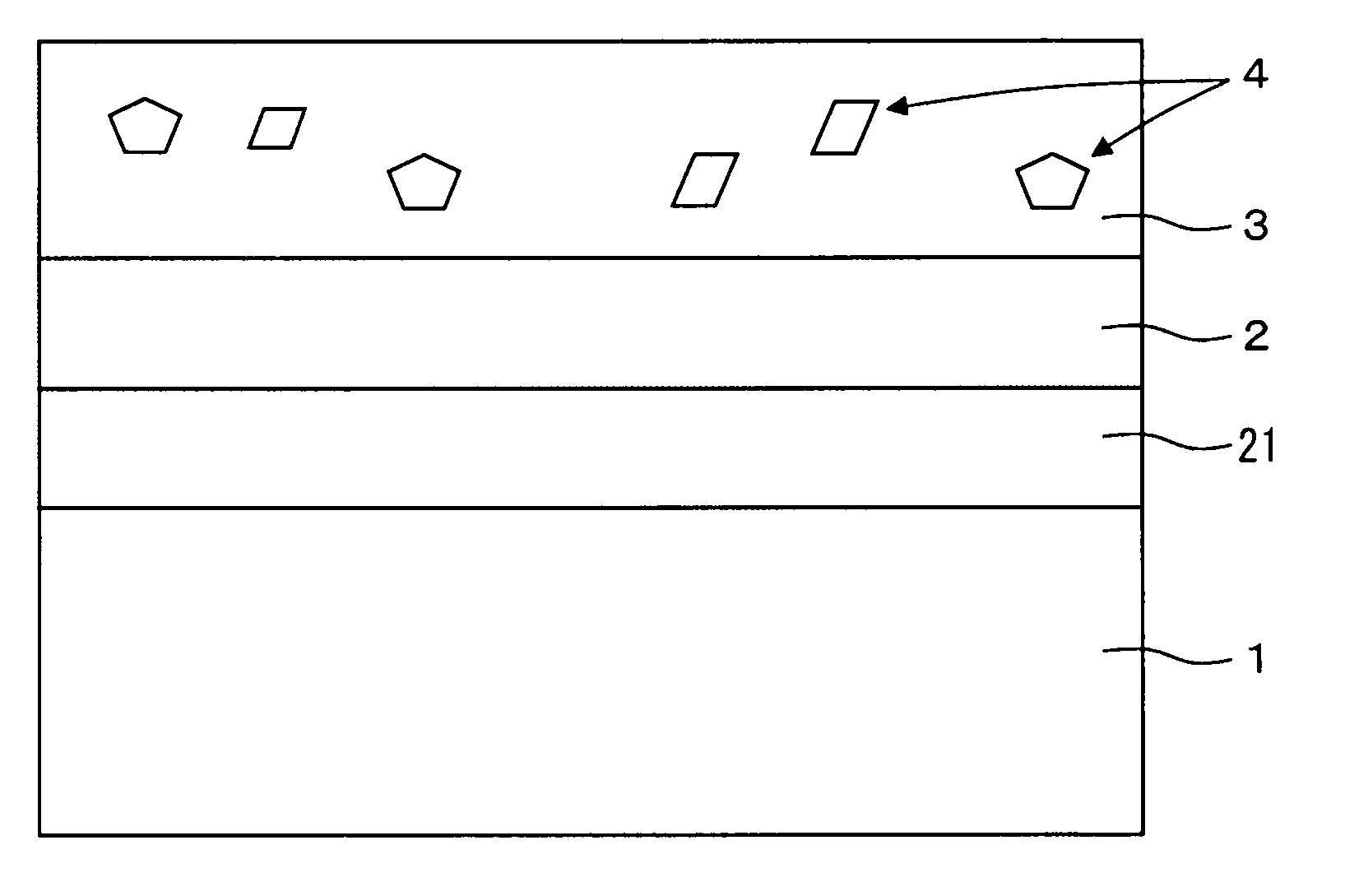

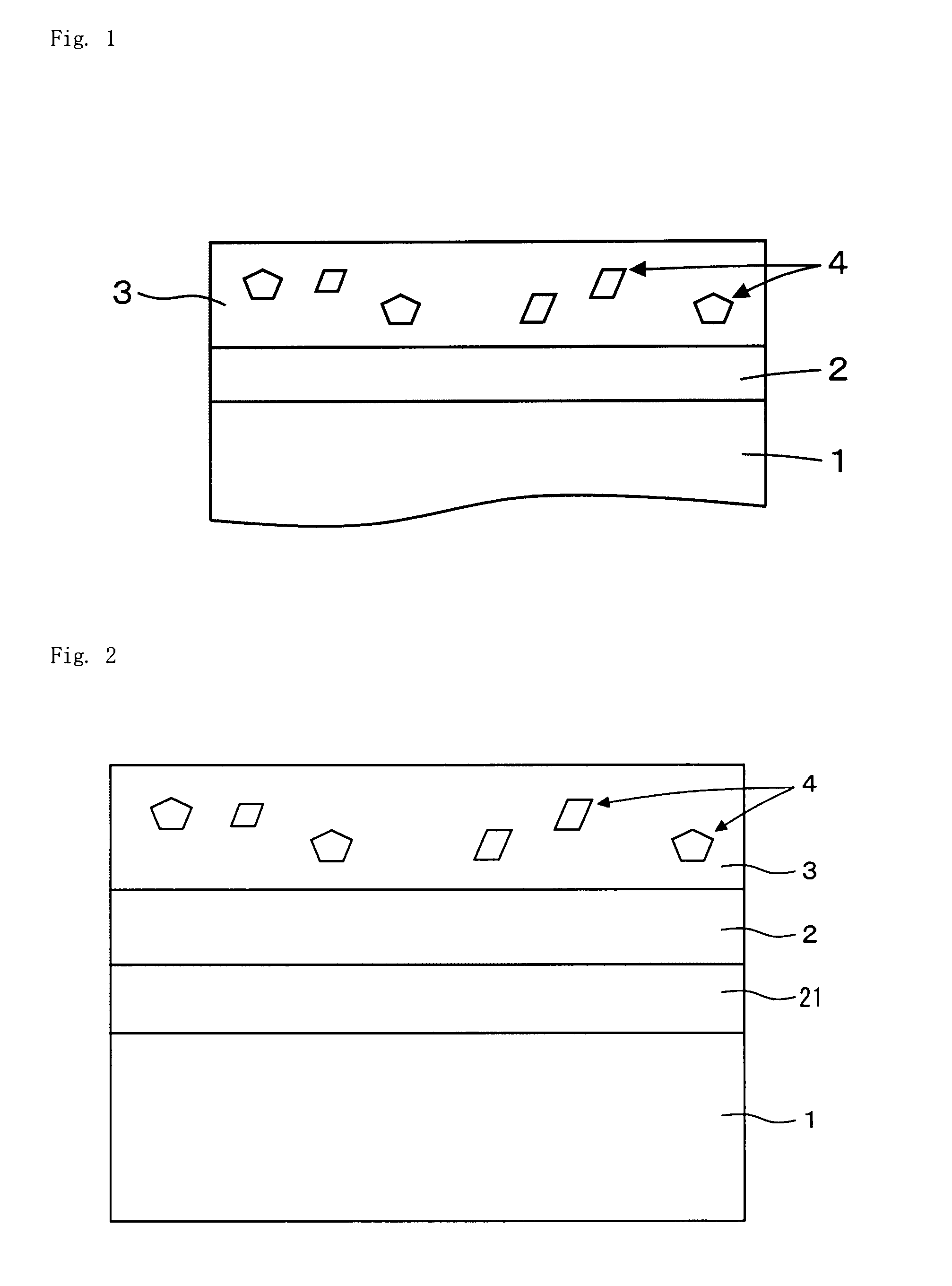

A medical device is disclosed, comprising a substrate, having on its surface, on at least a part thereof, a hydrophilic surface layer providing low-friction surface character of the medical device when wetted by a wetting fluid. The substrate is made of a polymer blend comprising a polyolefin and a composition having molecules with active hydrogen(s), such as polyamide or polyurethane. The hydrophilic surface layer is preferably adhered to the substrate by a polyurea network, whereby said polyurea network forms a covalent bond to said active hydrogen(s) in the substrate. The new substrate material is environmentally acceptable and cost effective, has adequate mechanical and chemical properties and enables the hydrophilic coating to be adequately adhered.

Owner:ASTRA TECH SE

Urinary catheter

ActiveUS20070016169A1Improve mechanical propertiesMaintain good propertiesGlovesWound drainsUrinary catheterPolyolefin

A medical device is disclosed, comprising a substrate, having on its surface, on at least a part thereof, a hydrophilic surface layer providing low-friction surface character of the medical device when wetted by a wetting fluid. The substrate is made of a polymer blend comprising a polyolefin and a composition having molecules with active hydrogen(s), such as polyamide or polyurethane. The hydrophilic surface layer is preferably adhered to the substrate by a polyurea network, whereby said polyurea network forms a covalent bond to said active hydrogen(s) in the substrate. The new substrate material is environmentally acceptable and cost effective, has adequate mechanical and chemical properties and enables the hydrophilic coating to be adequately adhered.

Owner:ASTRA TECH SE

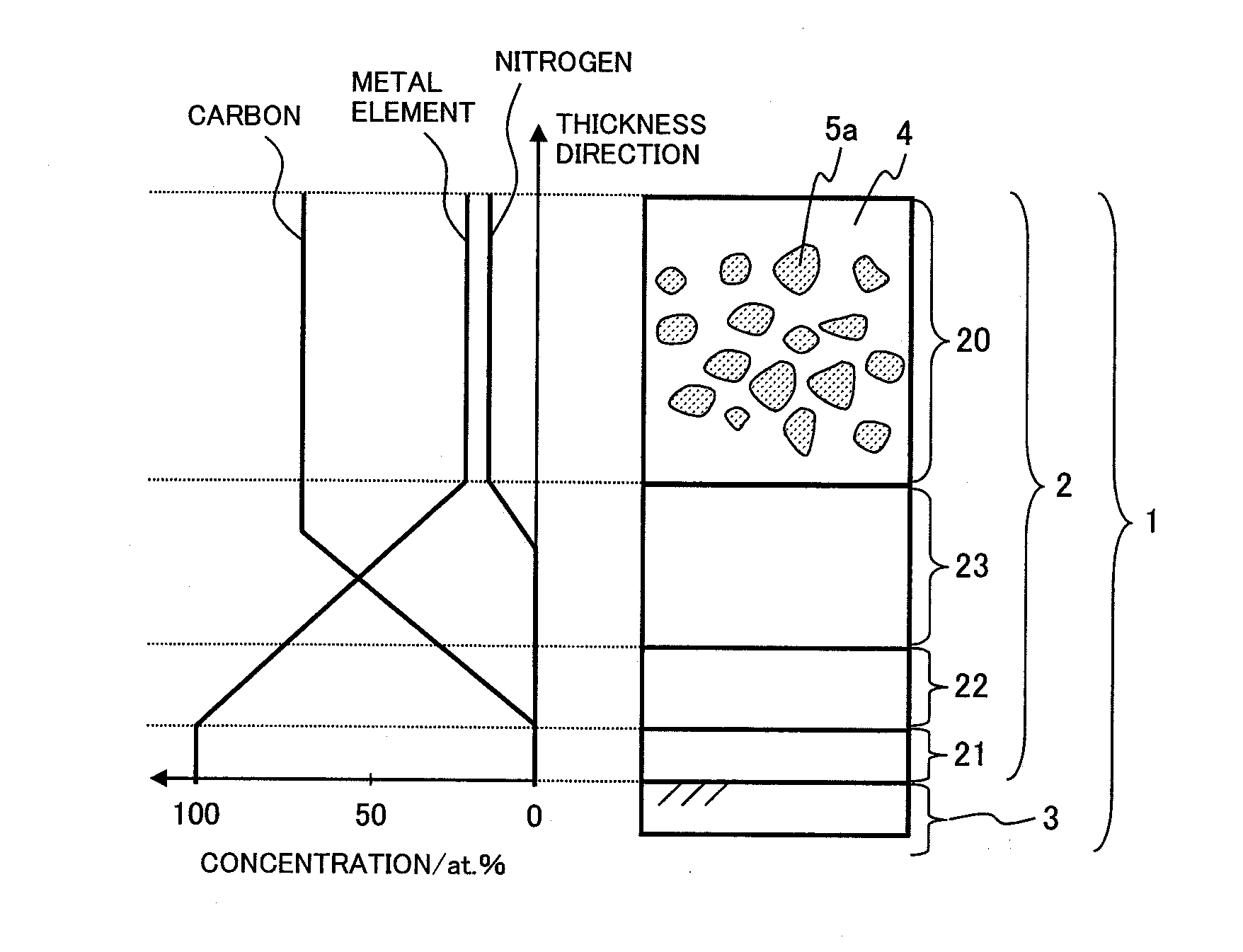

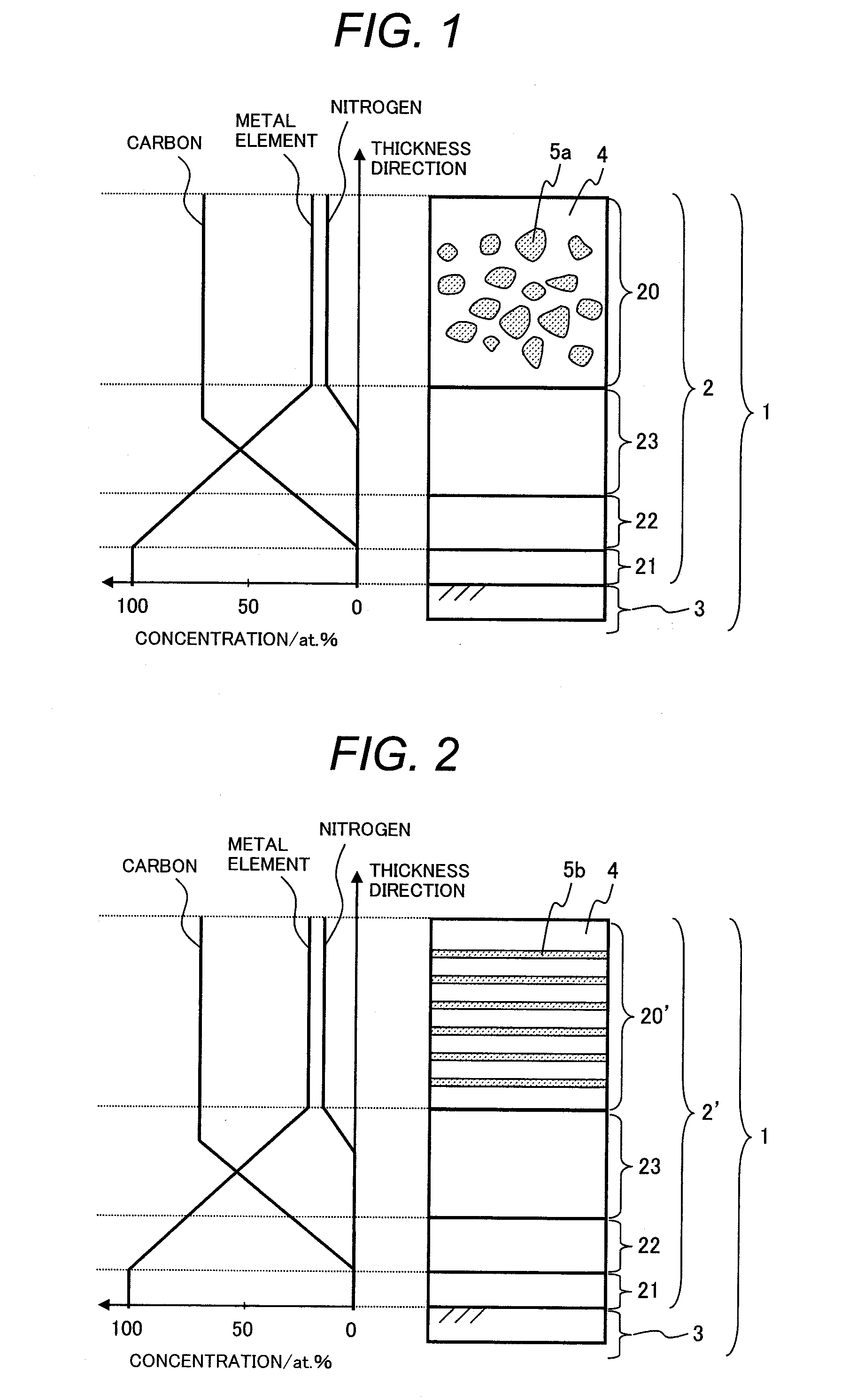

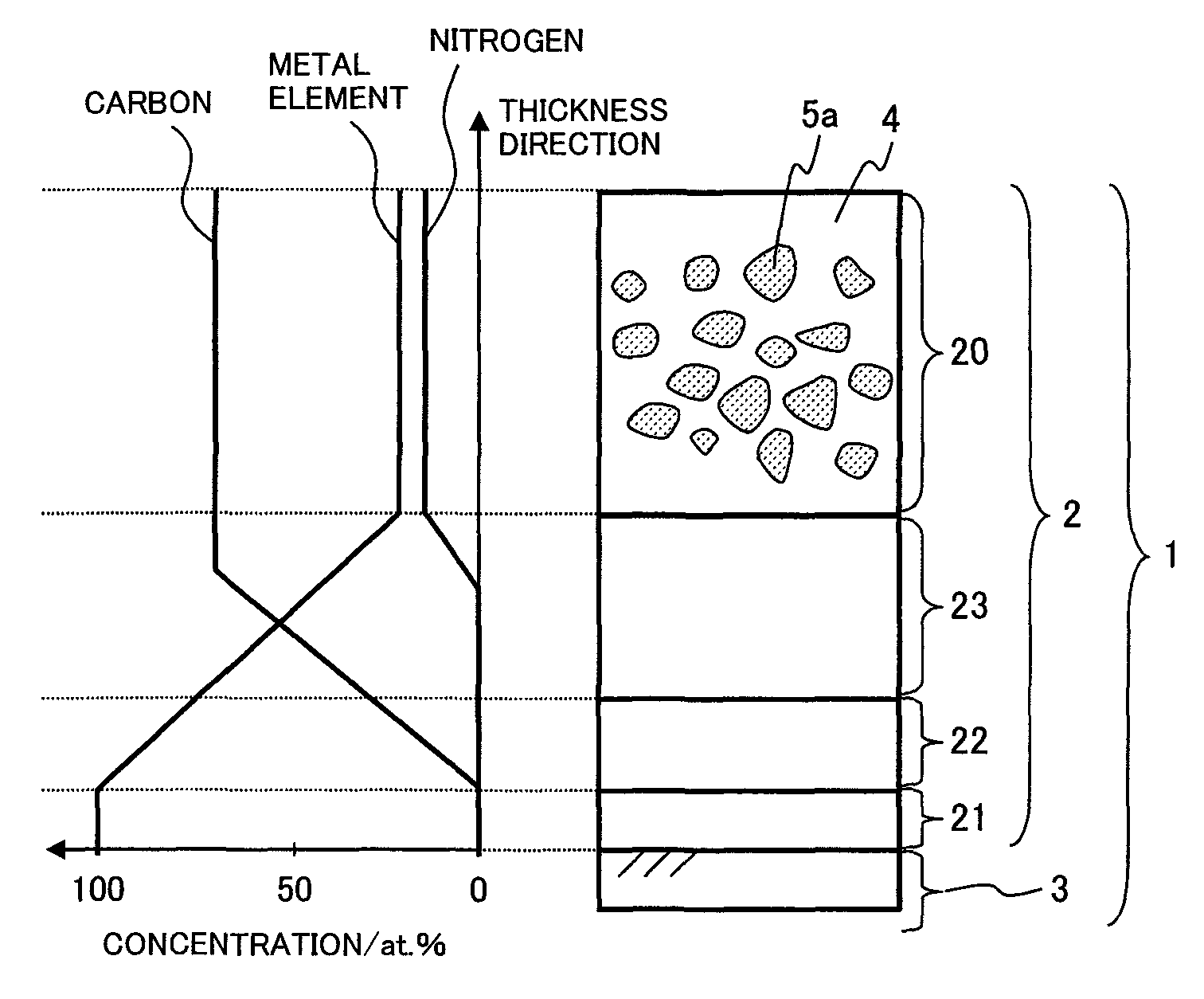

Slide part

ActiveUS20110052934A1Low in its friction propertyImprove wear resistancePiston ringsPlungersCarbideNitrogen

Owner:HITACHI METALS LTD

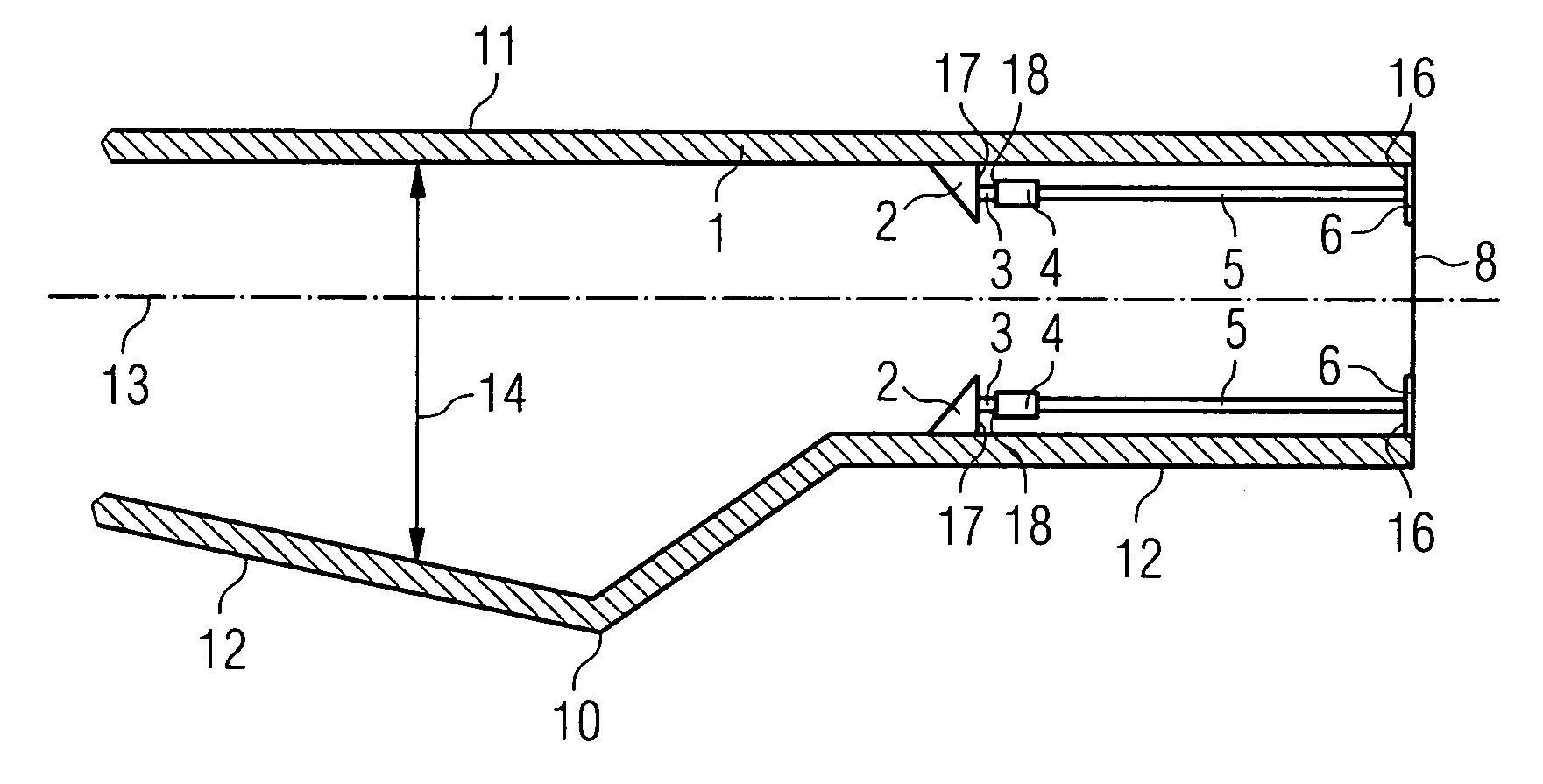

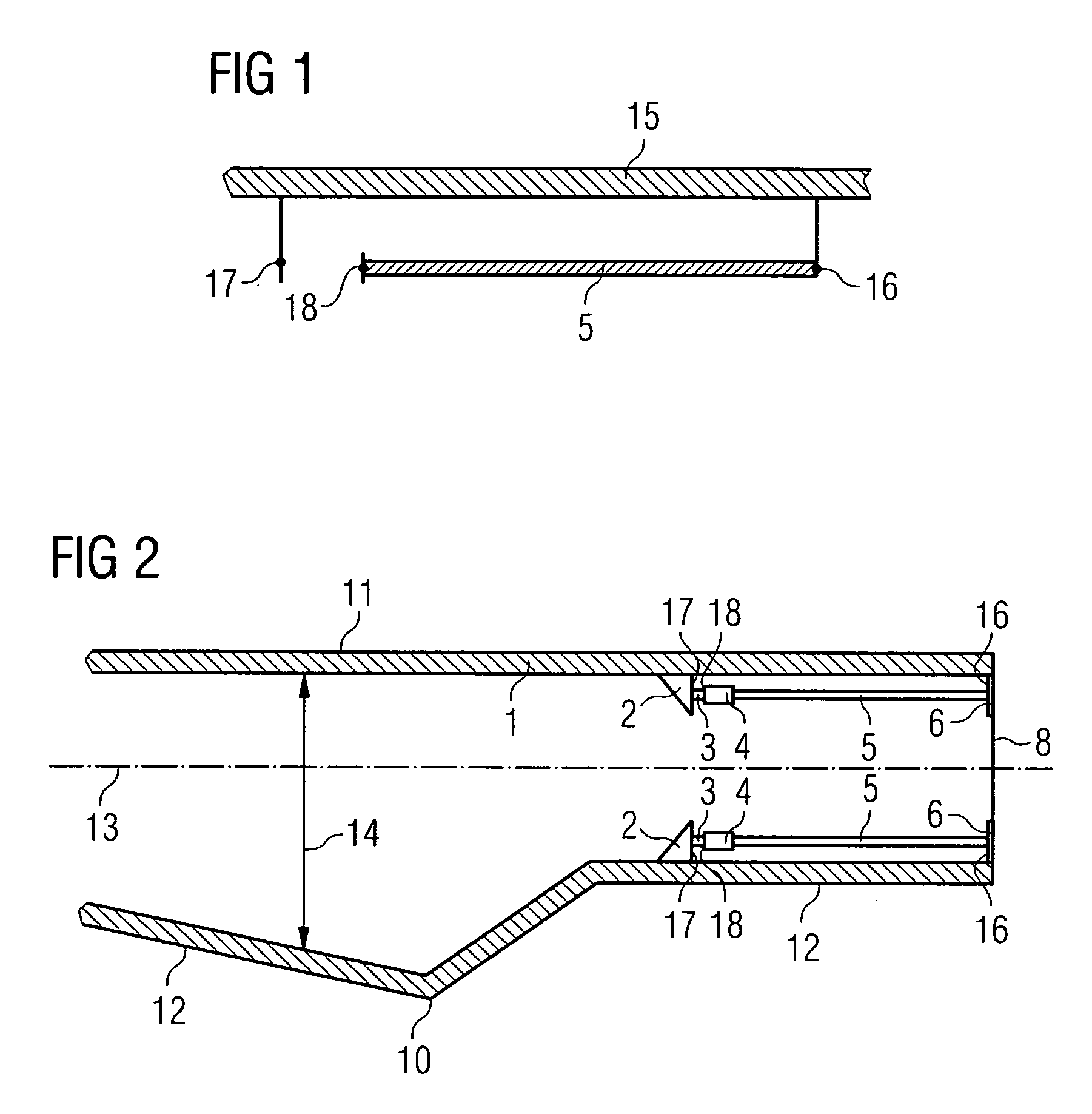

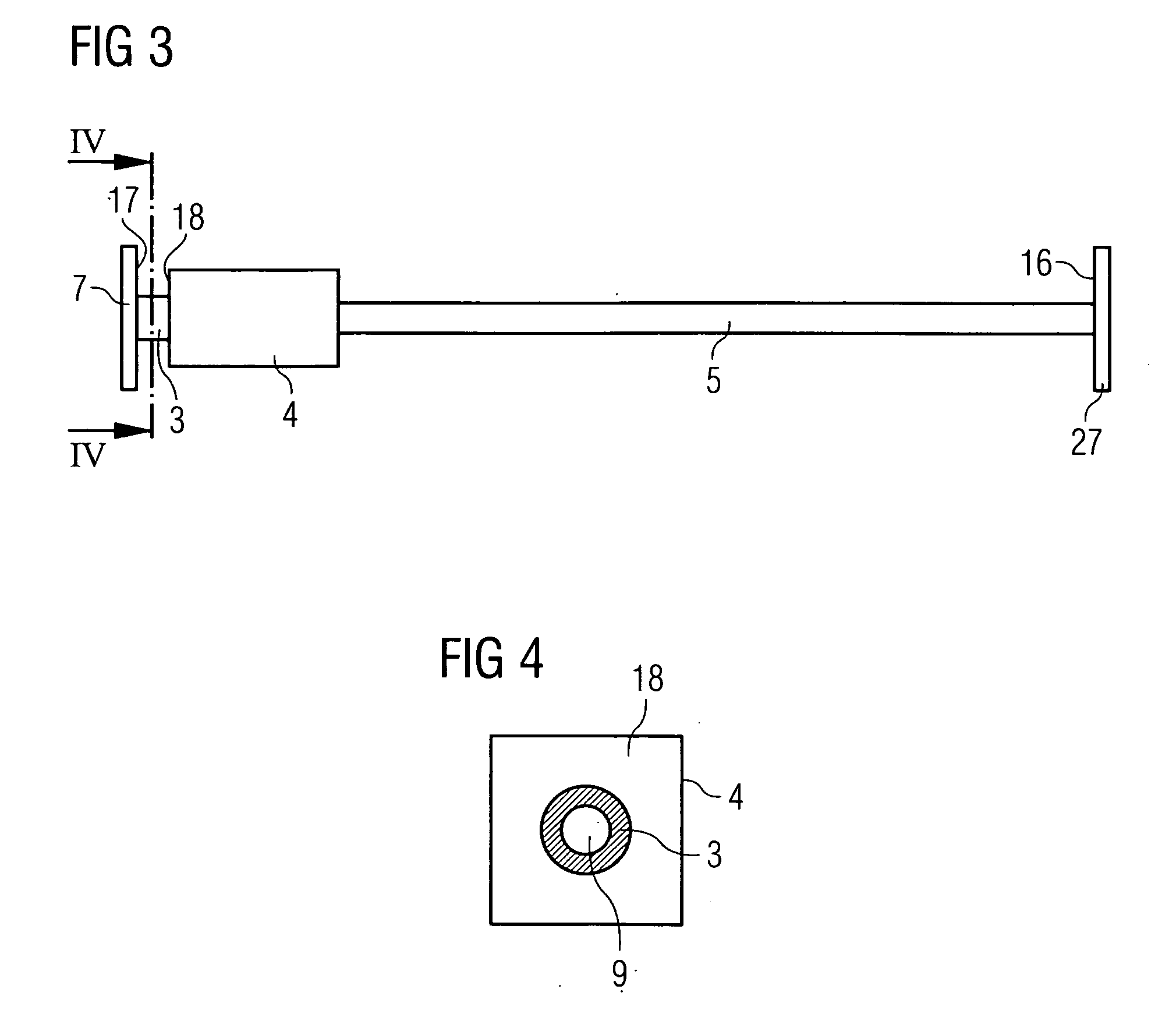

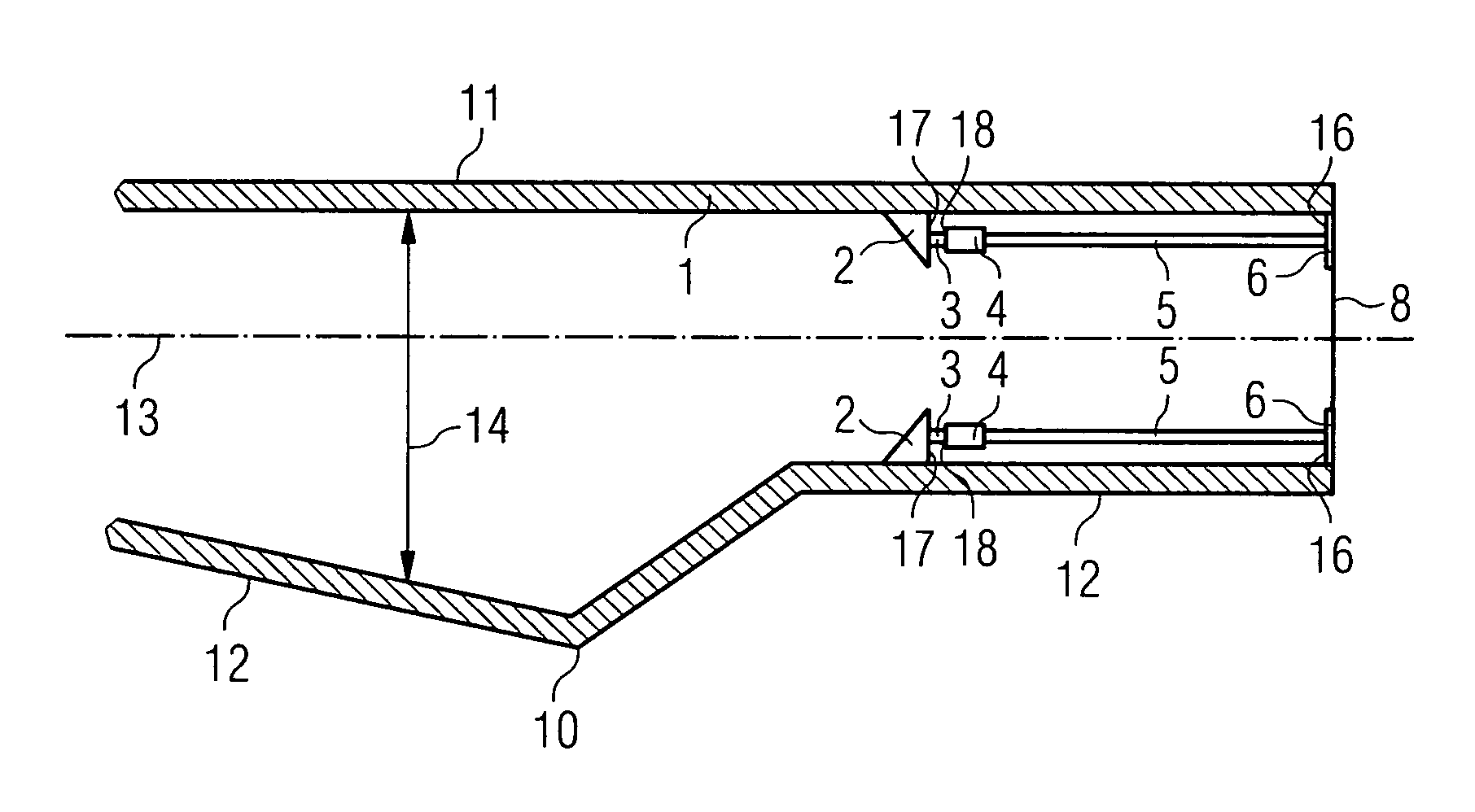

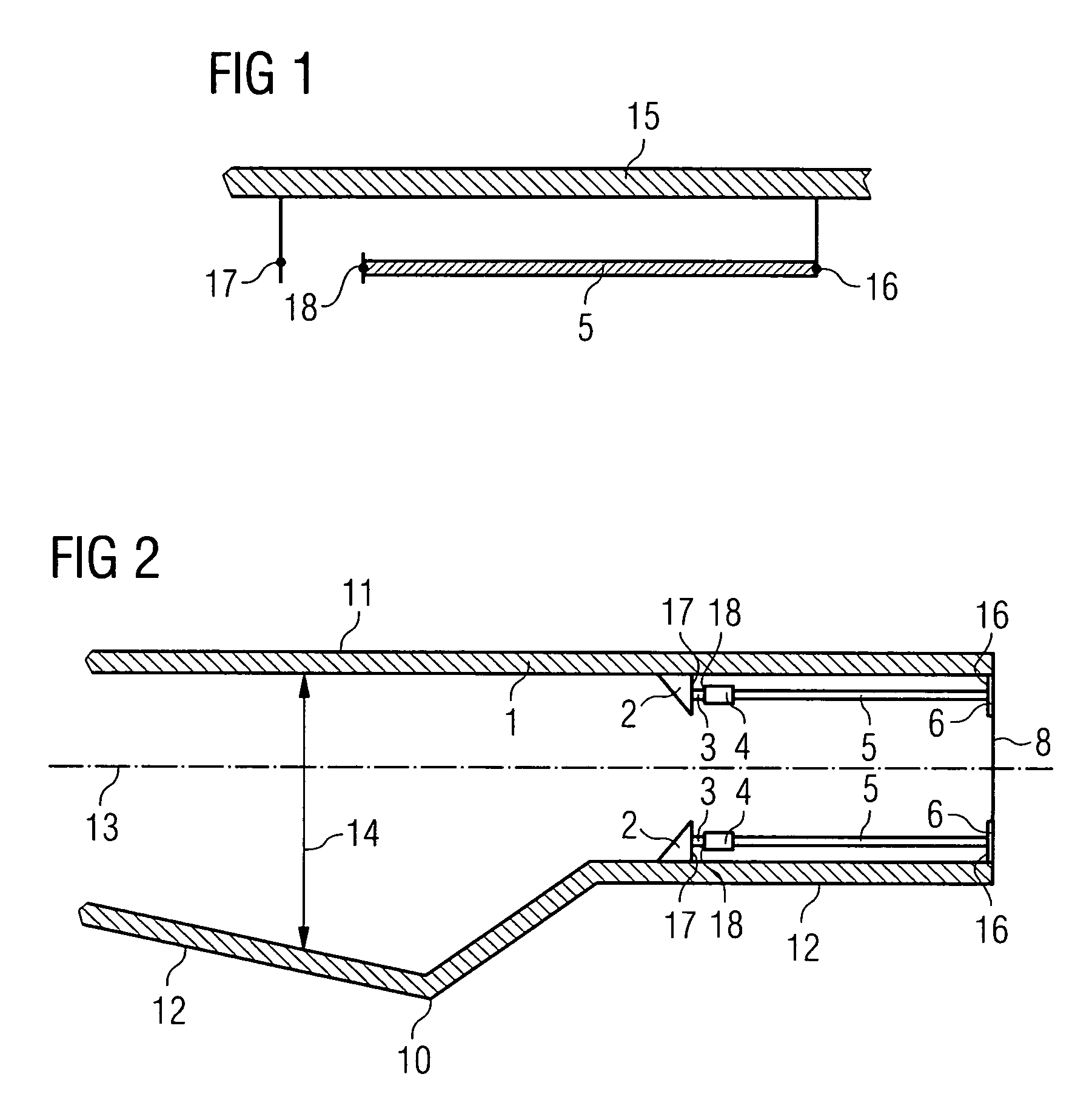

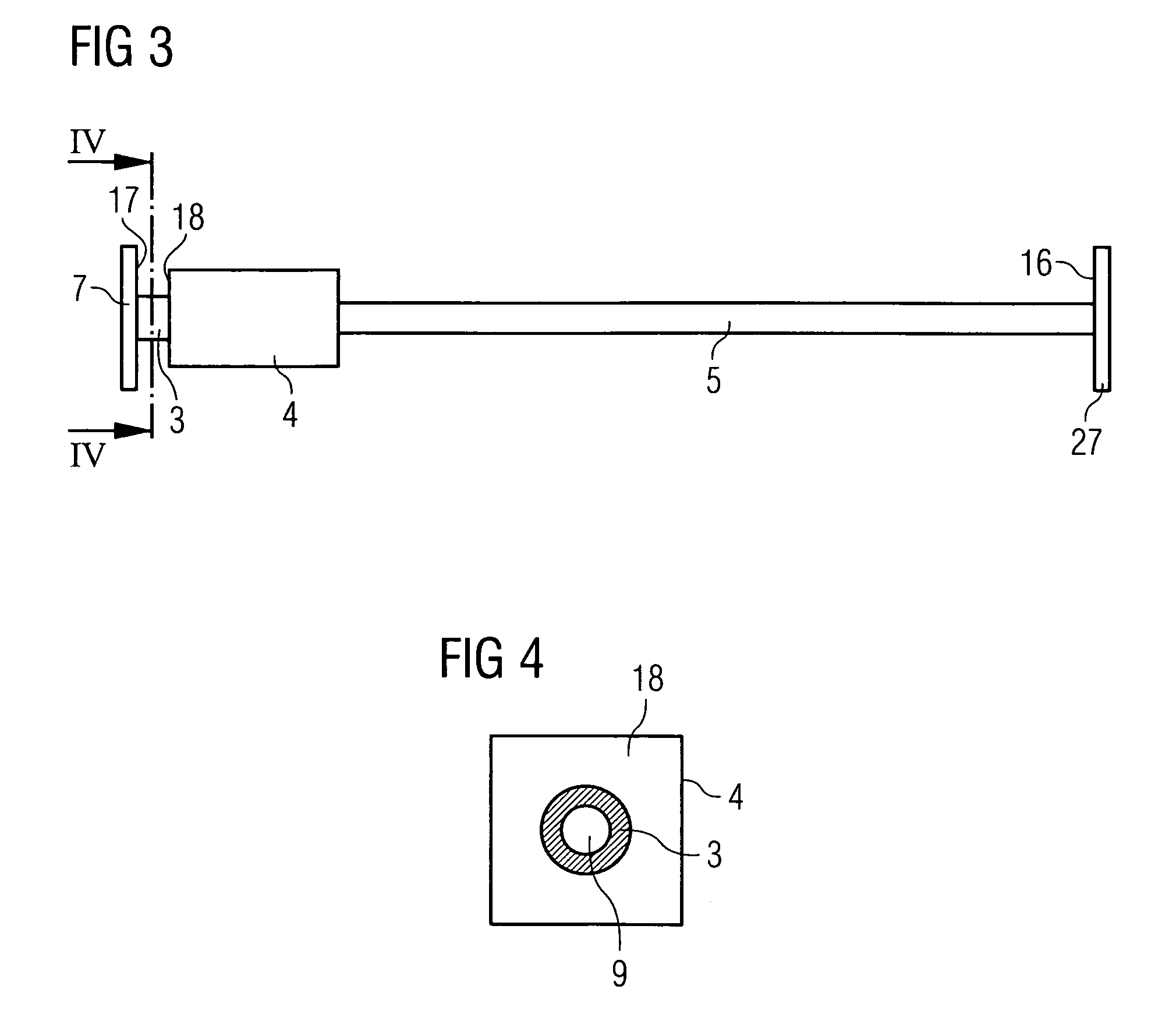

Sensor setup for determination of deflection and/or strain

InactiveUS20090068014A1Reduce quality problemsMeasurement is robustPropellersWind motor controlProximity sensorEngineering

An elongated member of a wind turbine is disclosed which is potentially subject to strain and which comprises a sensor unit for determining the deflection and / or strain of the elongated member between a first point and a second point, which are assigned to the same side of the elongated member, and the sensor unit comprises a proximity sensor for determining the distance between the second point and a third point, the third point being connected to the first point by an inflexible support, the distance between the first point and the third point being considerably longer than the distance between the second point and the third point, wherein the sensor unit comprises a compressible and / or stretchable element located between the second point and the third point. Moreover, a wind turbine rotor blade and a tower of a wind turbine, each comprising a previously described elongated member, are disclosed.

Owner:SIEMENS AG

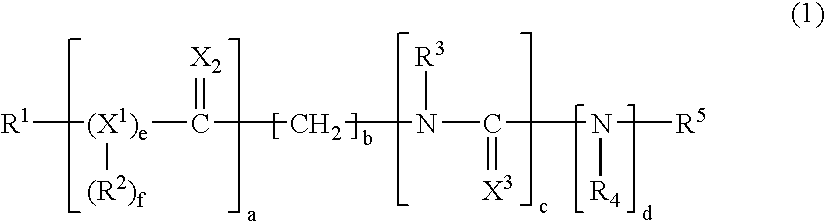

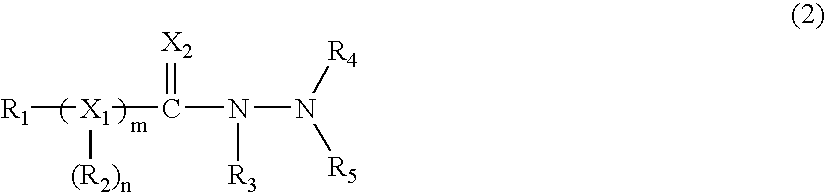

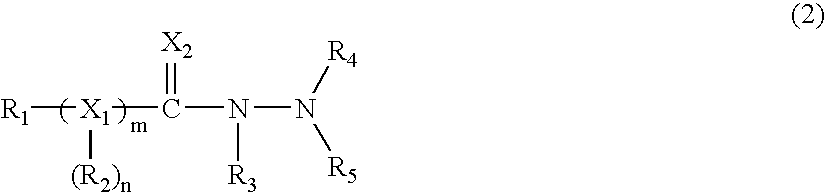

Lubricating oil additive and lubricating oil composition

InactiveUS20060172900A1Easy to handleShorten production timeOrganic chemistryLiquid carbonaceous fuelsCombustionOil additive

Lubricating oil compositions have low friction properties and anti-wear properties and are excellent in long drain capability. The lubricating oil compositions are particularly suitable for use as a fuel efficient type lubricating oil for internal combustion engines. The lubricating oil compositions contain a lubricating oil additive comprising one or more compounds selected from a specific nitrogen-containing compound, an acid-modified derivative thereof, and an oil soluble metal complex obtained by mixing the nitrogen-containing compound and / or acid-modified derivative thereof with an organic metal salt and / or organic metal complex.

Owner:NIPPON OIL CORP

Coating Composition, Coating Film, and Method of Reducing Underwater Friction

ActiveUS20070272119A1Excellent low frictionReduce performanceFireproof paintsAntifouling/underwater paintsSolubilityOragene

It is an object of the present invention to provide a coating composition which can attain low friction performance without impairing the functions of a conventional coating composition, a coated film formed by using the same and a method of reducing friction in water. A coating composition containing an organic polymer particle, wherein said organic polymer particle has the solubility at 23° C. in the artificial seawater specified in ASTM D1141-98 of 15 g / liter or less, the water-absorbing amount for the artificial seawater specified in ASTM D1141-98 of 0.01% by mass or more and a particle diameter of 0.05 to 100 μm.

Owner:NIPPON PAINT CO LTD

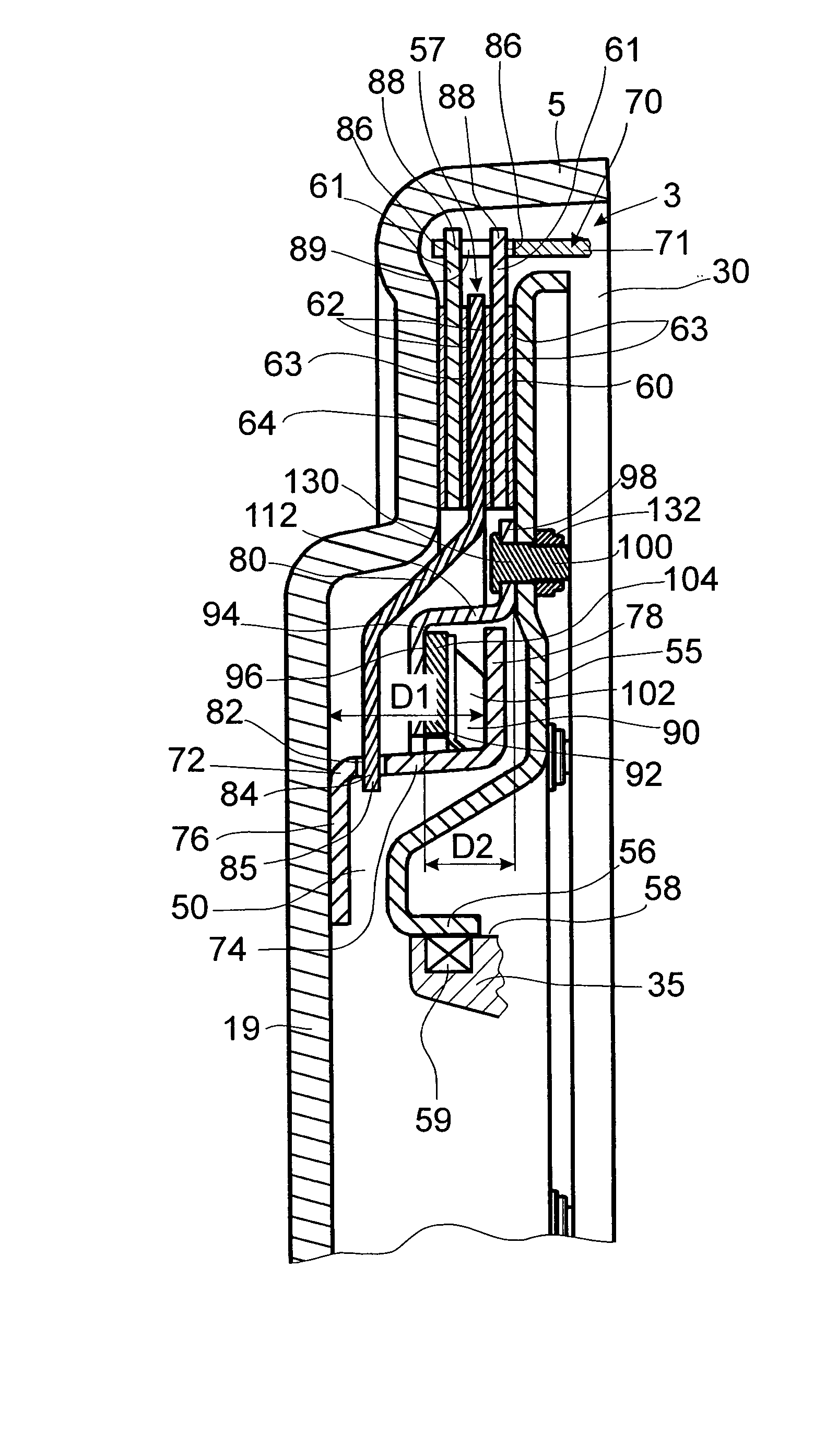

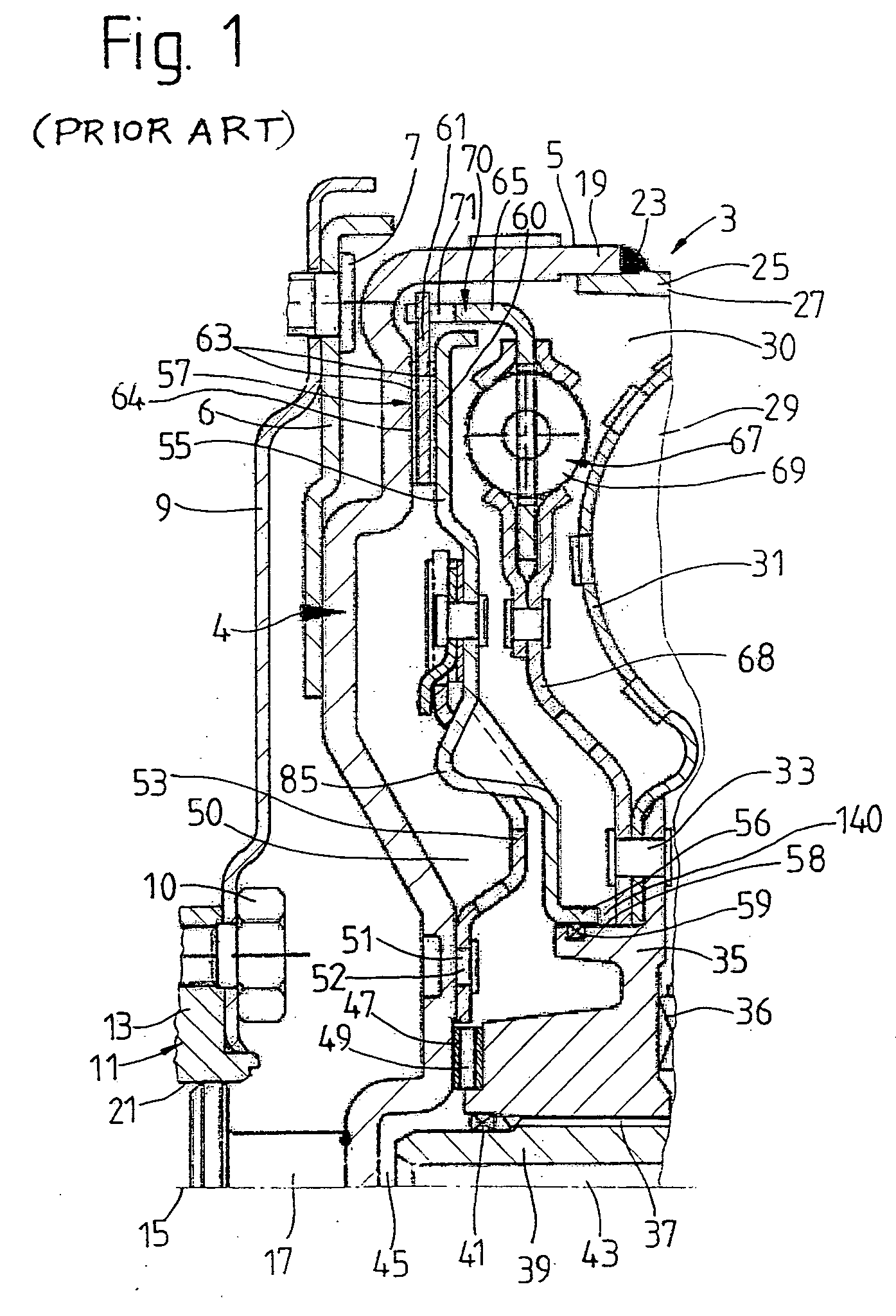

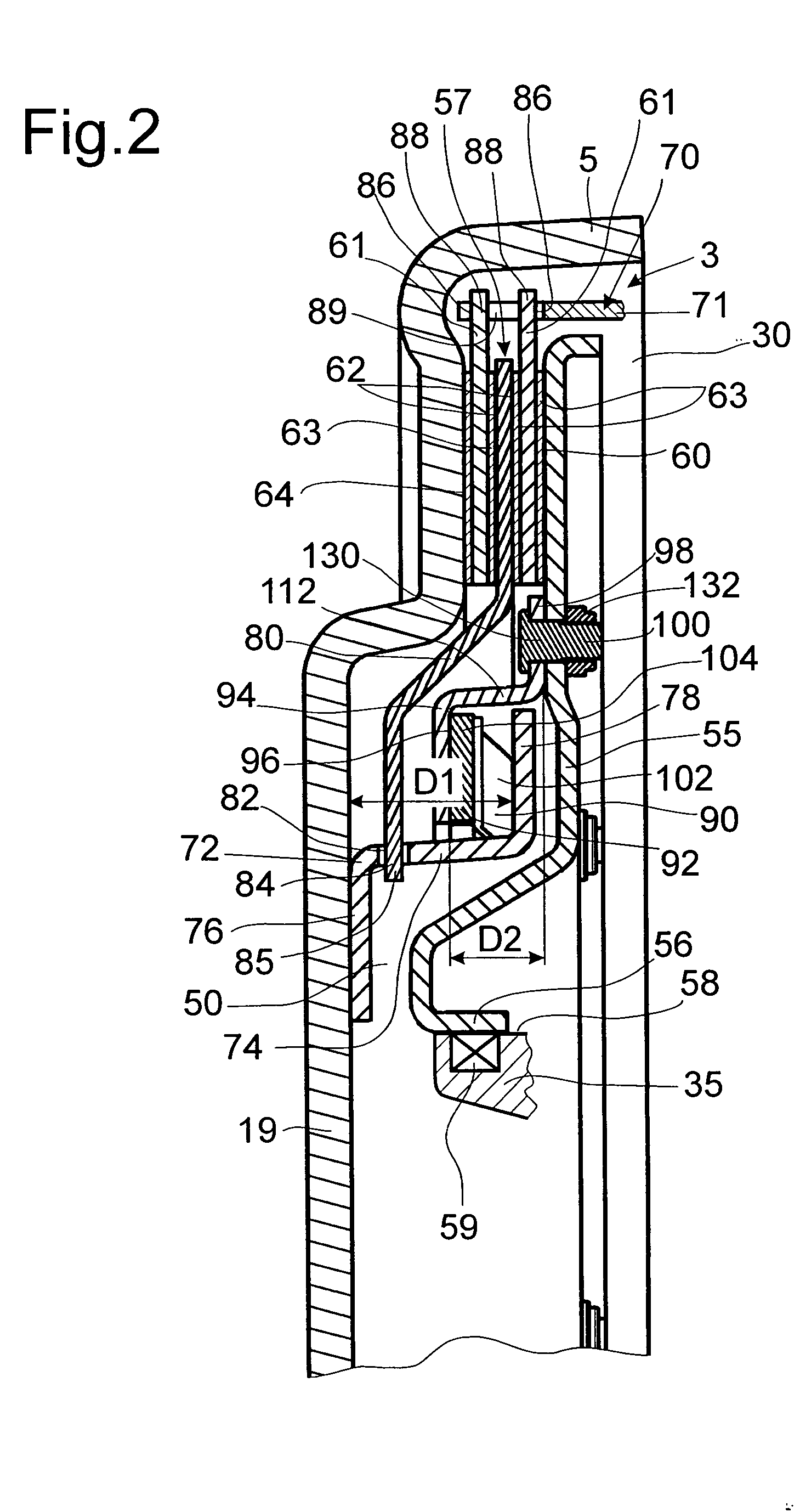

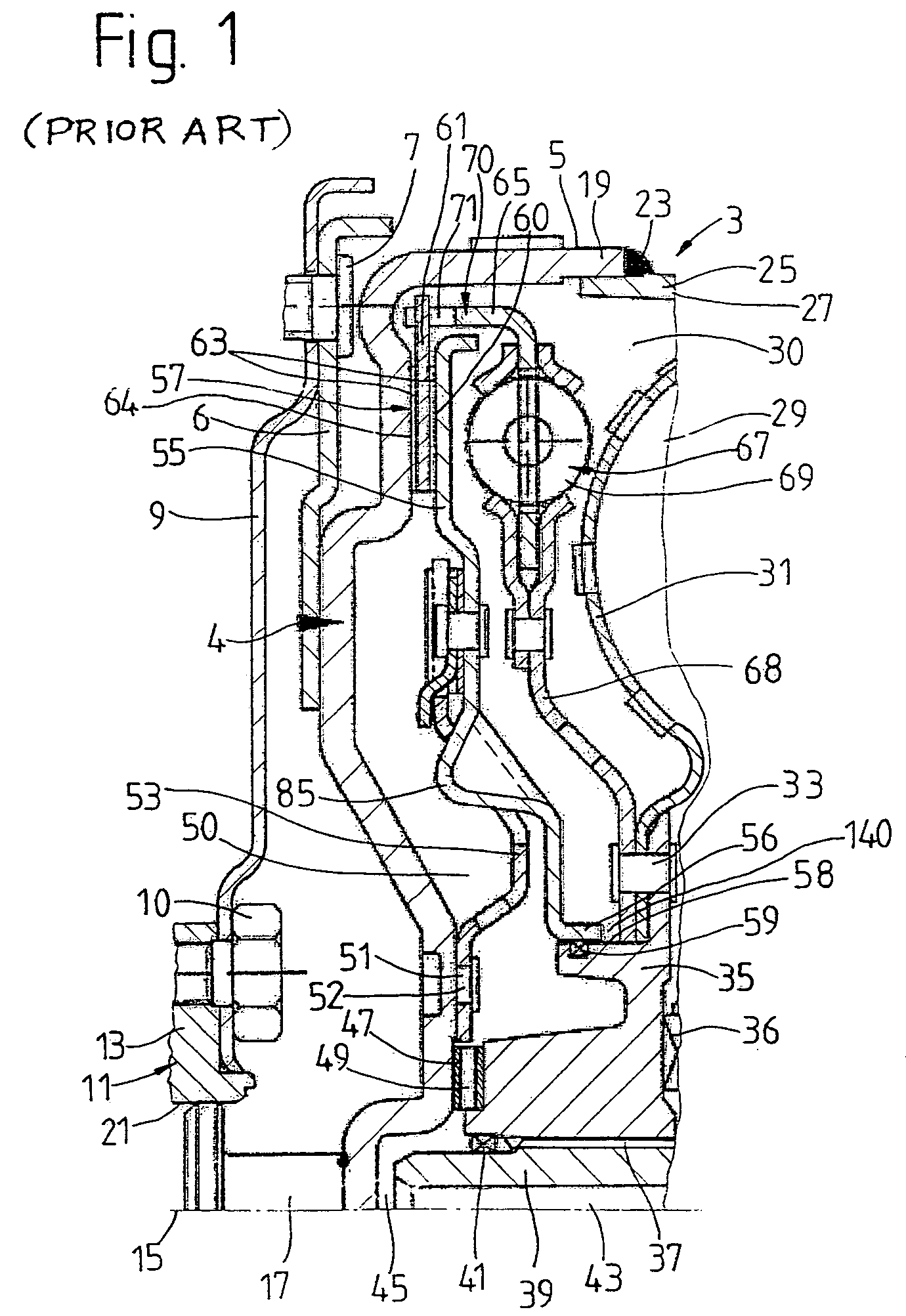

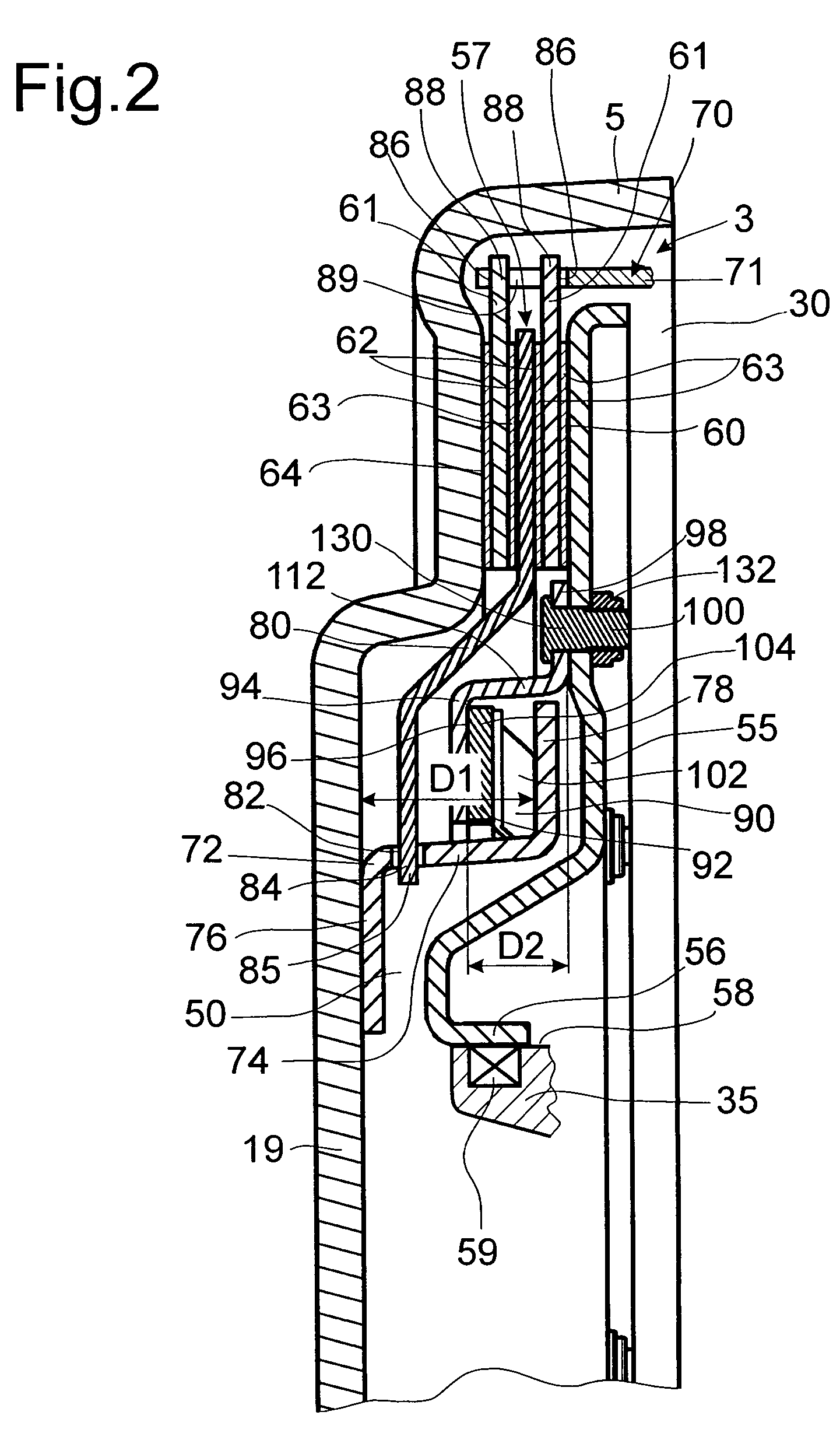

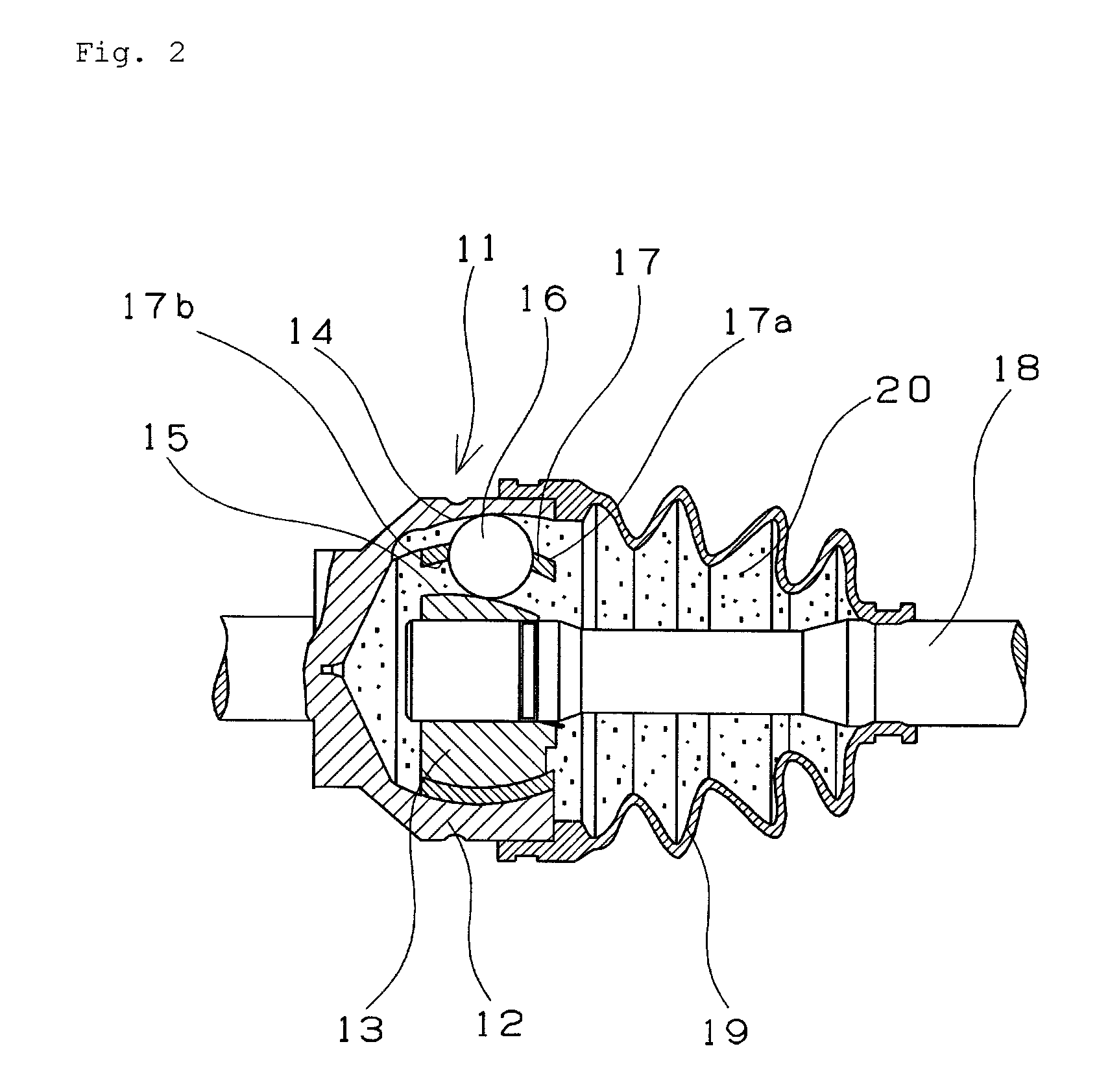

Bridging clutch for a hydrodynamic clutch device enclosed by a housing

InactiveUS20050199461A1Increase the number ofExcellent low frictionRotary clutchesFluid gearingsEngineeringPiston

A bridging clutch for a hydrodynamic clutch device includes a housing comprising a cover having a friction surface; a piston which can move axially with respect to the housing, the piston having a friction surface which faces the friction surface of the cover; a first pretensioning element mount fixed to the cover and having a first support section; a second pretensioning element mount fixed to the piston and having a second support section; and a pretensioning element supported axially between the first and second support sections for actuating the piston in a predetermined axial direction. A slide device located between the pretensioning element and the second support section permits sliding movement of the pretensioning element with respect to the second pretensioning element mount.

Owner:ZF FRIEDRICHSHAFEN AG

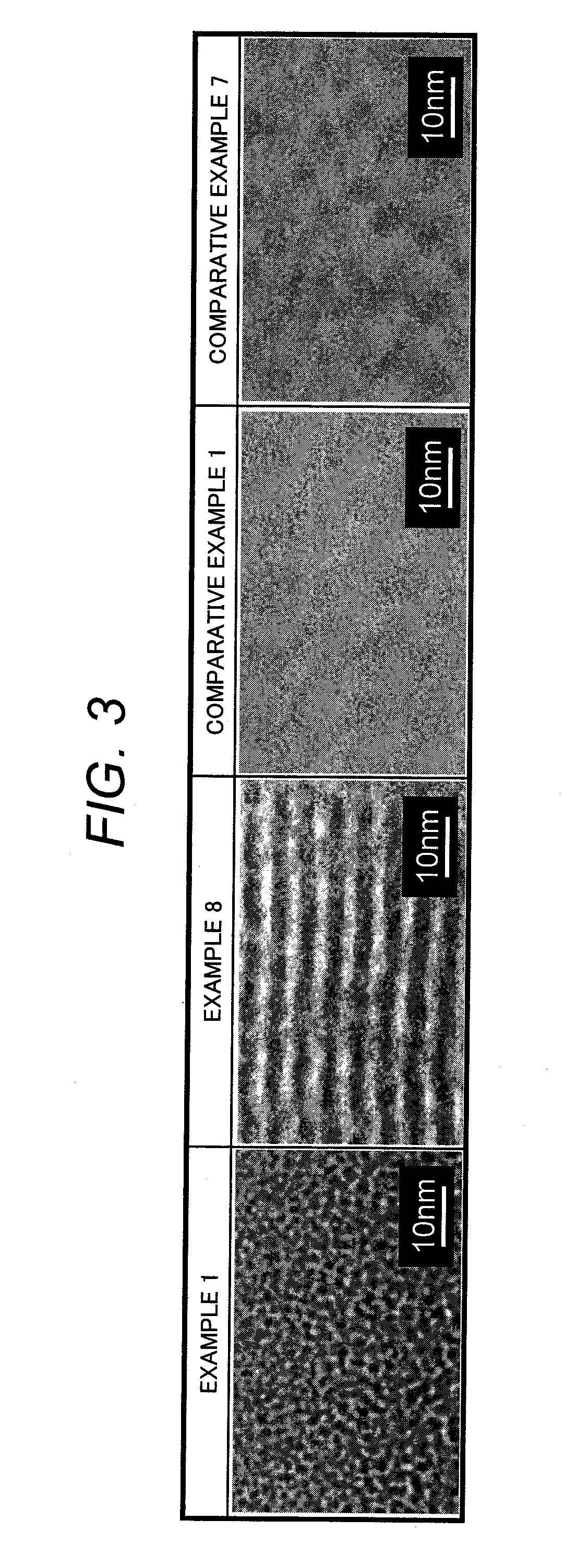

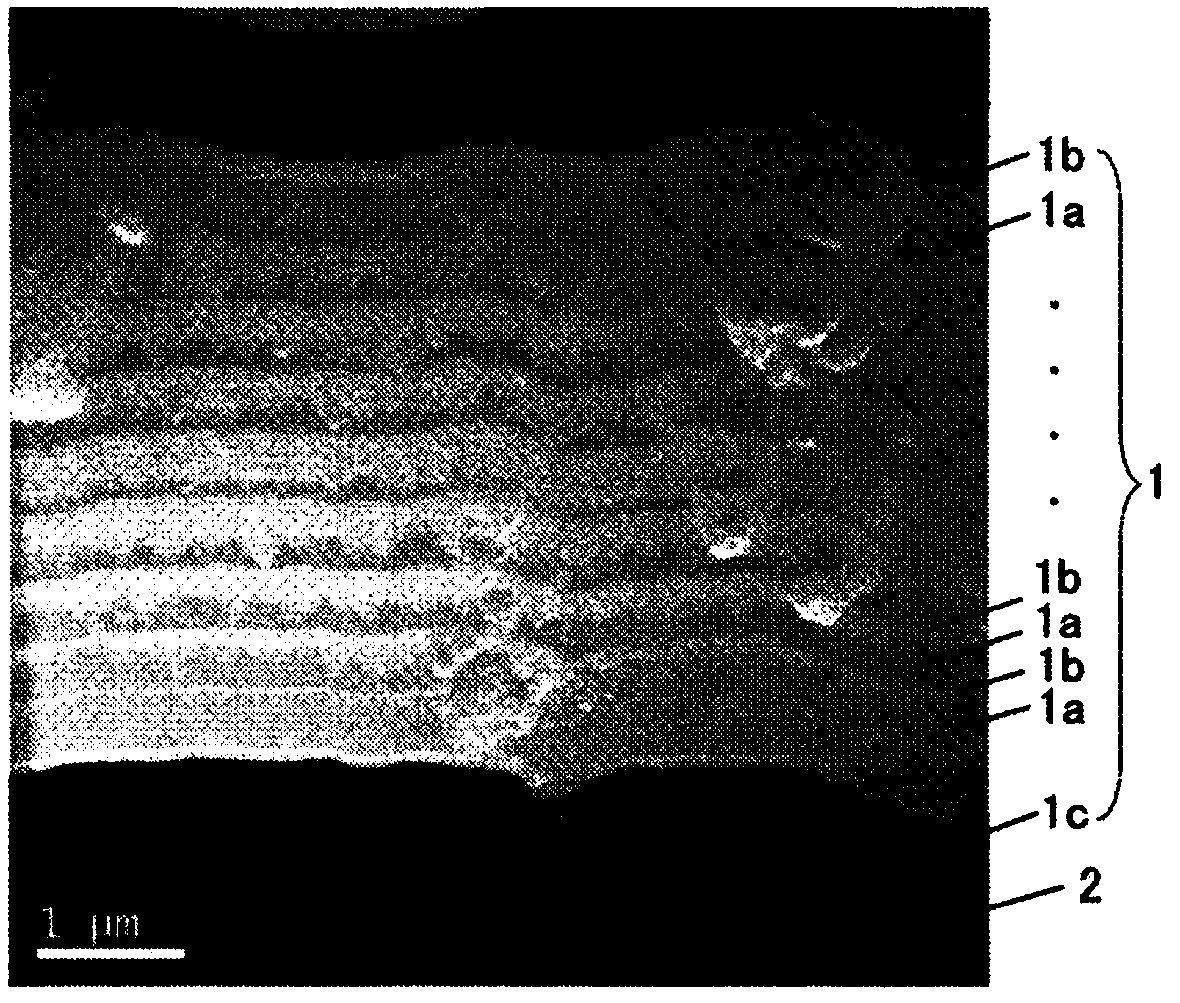

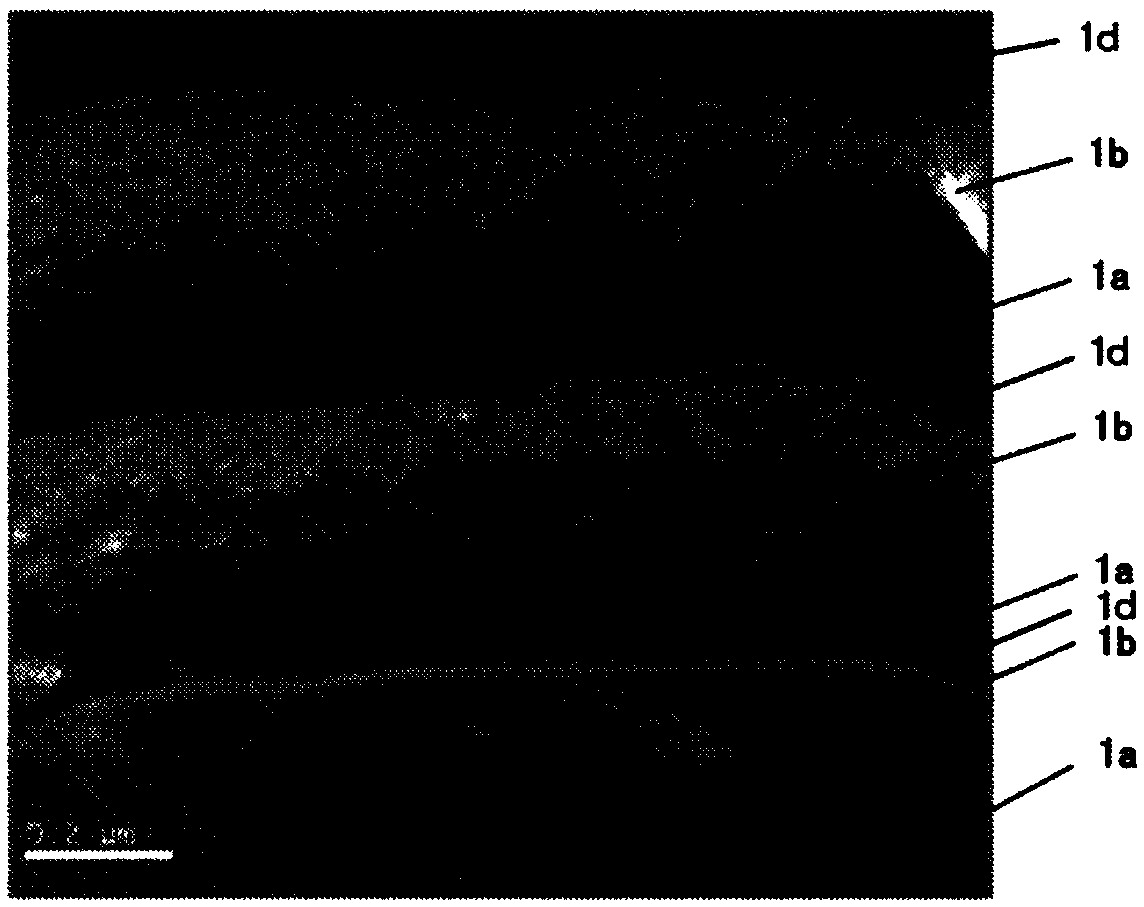

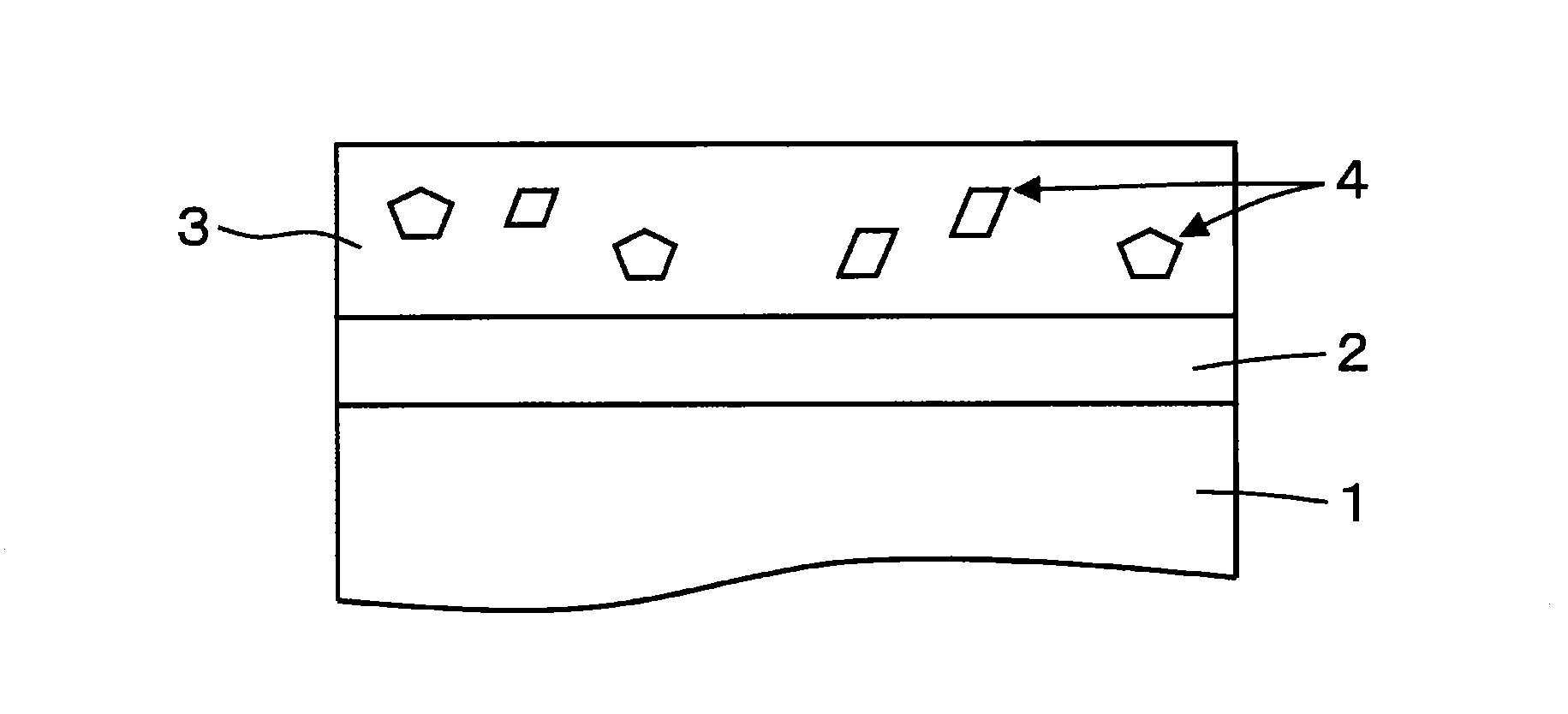

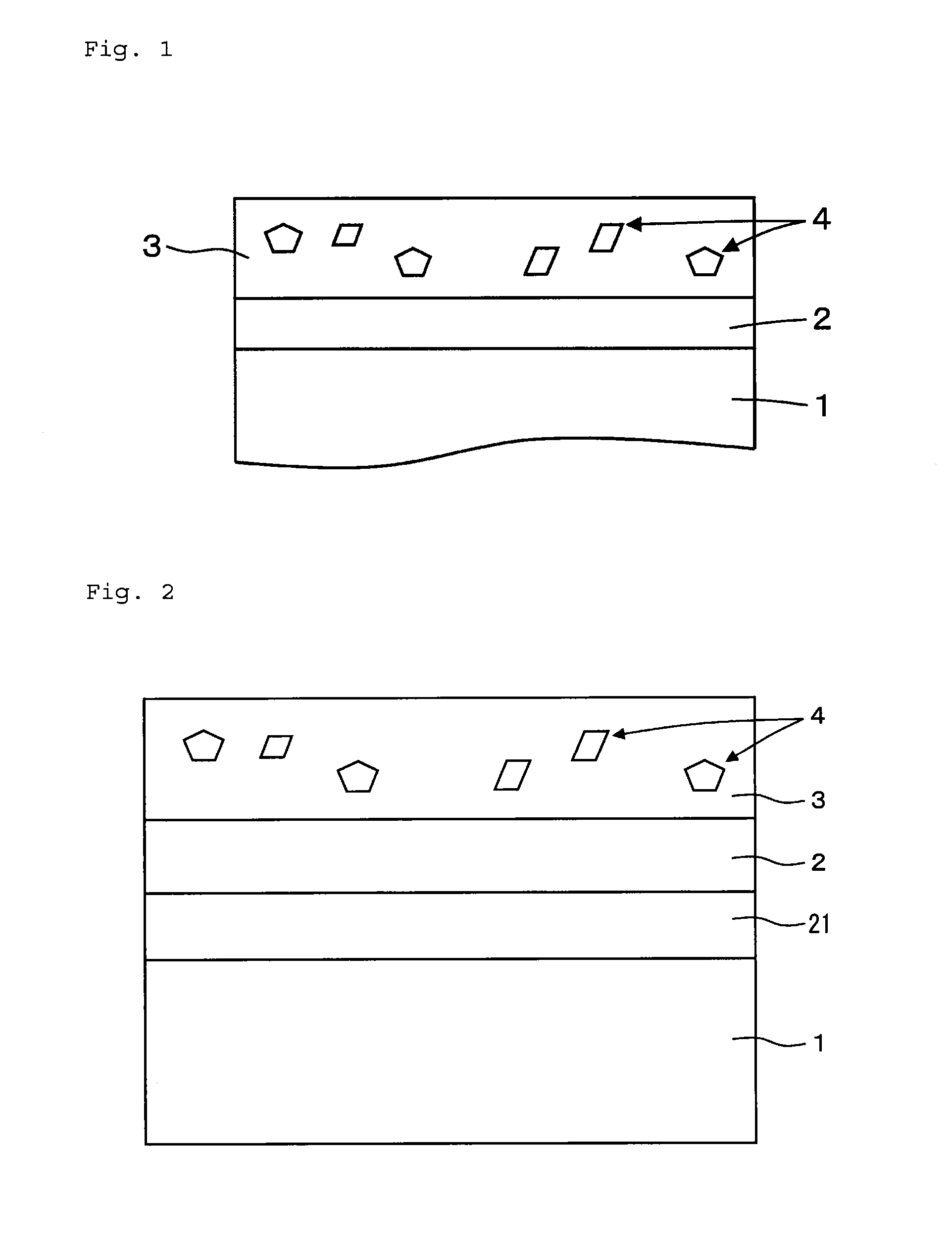

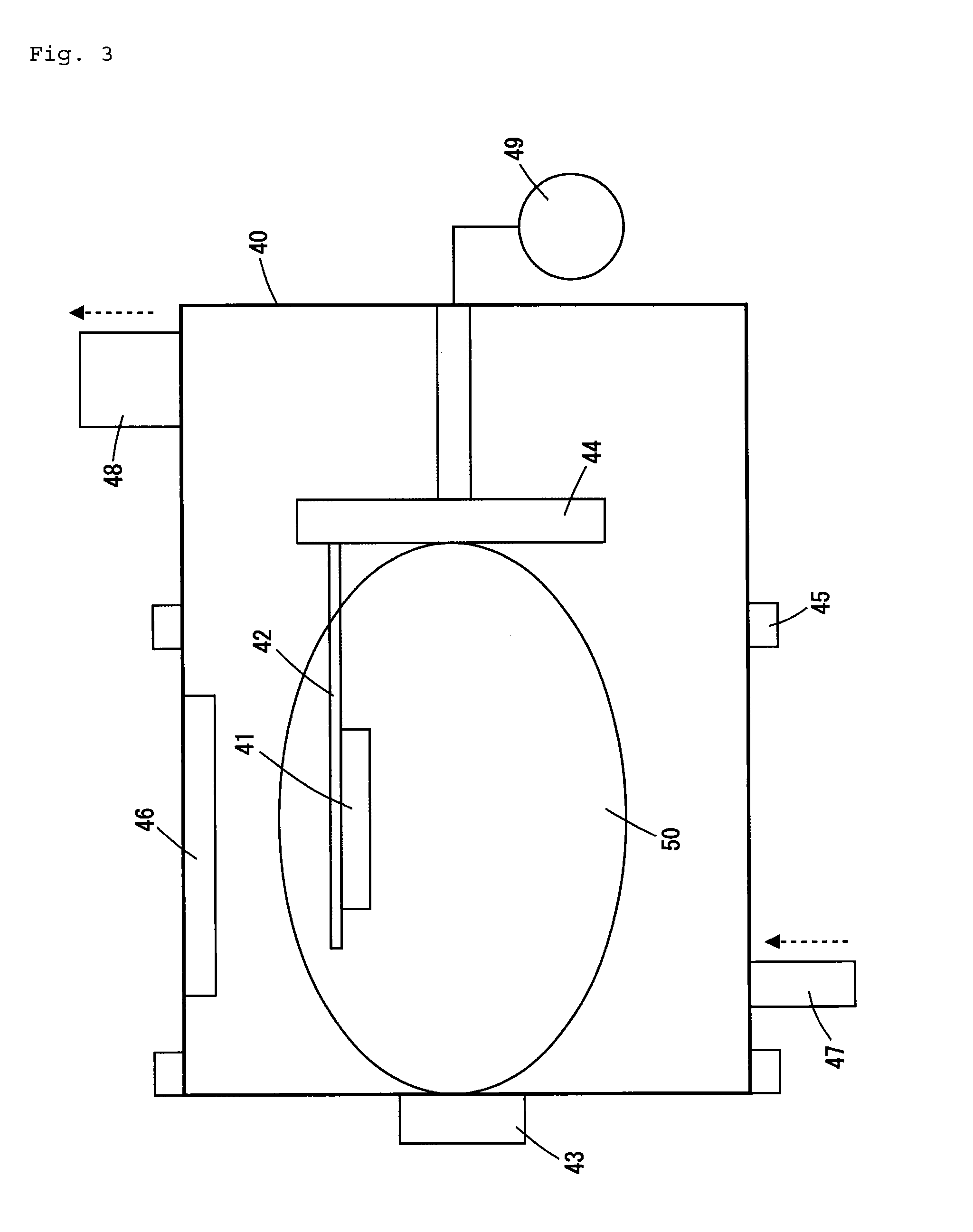

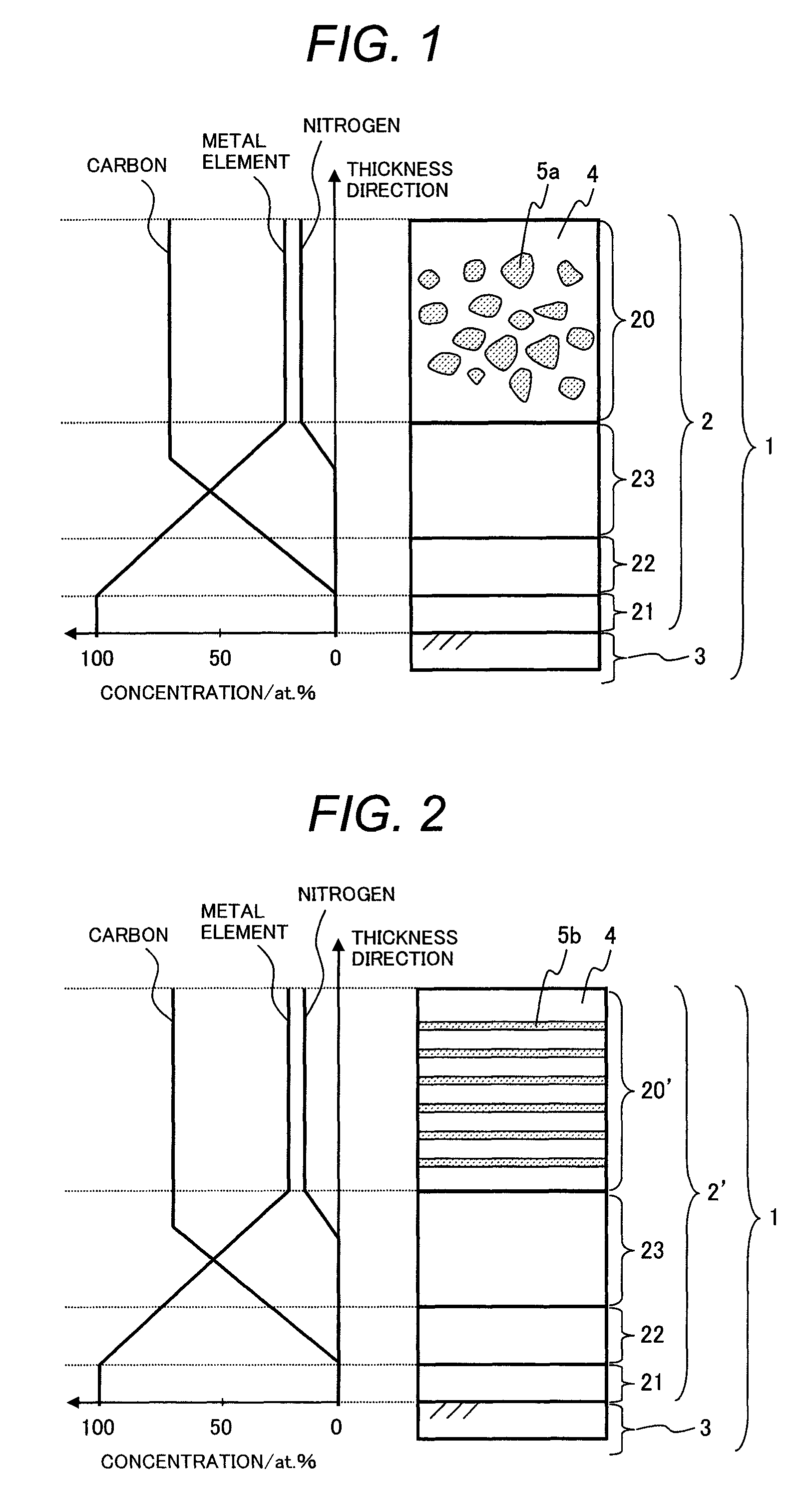

Coating film, manufacturing method therefor, and PVD apparatus

ActiveCN108368602AIncreased durabilityExcellent low frictionPiston ringsLayered productsCarbon filmCarbon layer

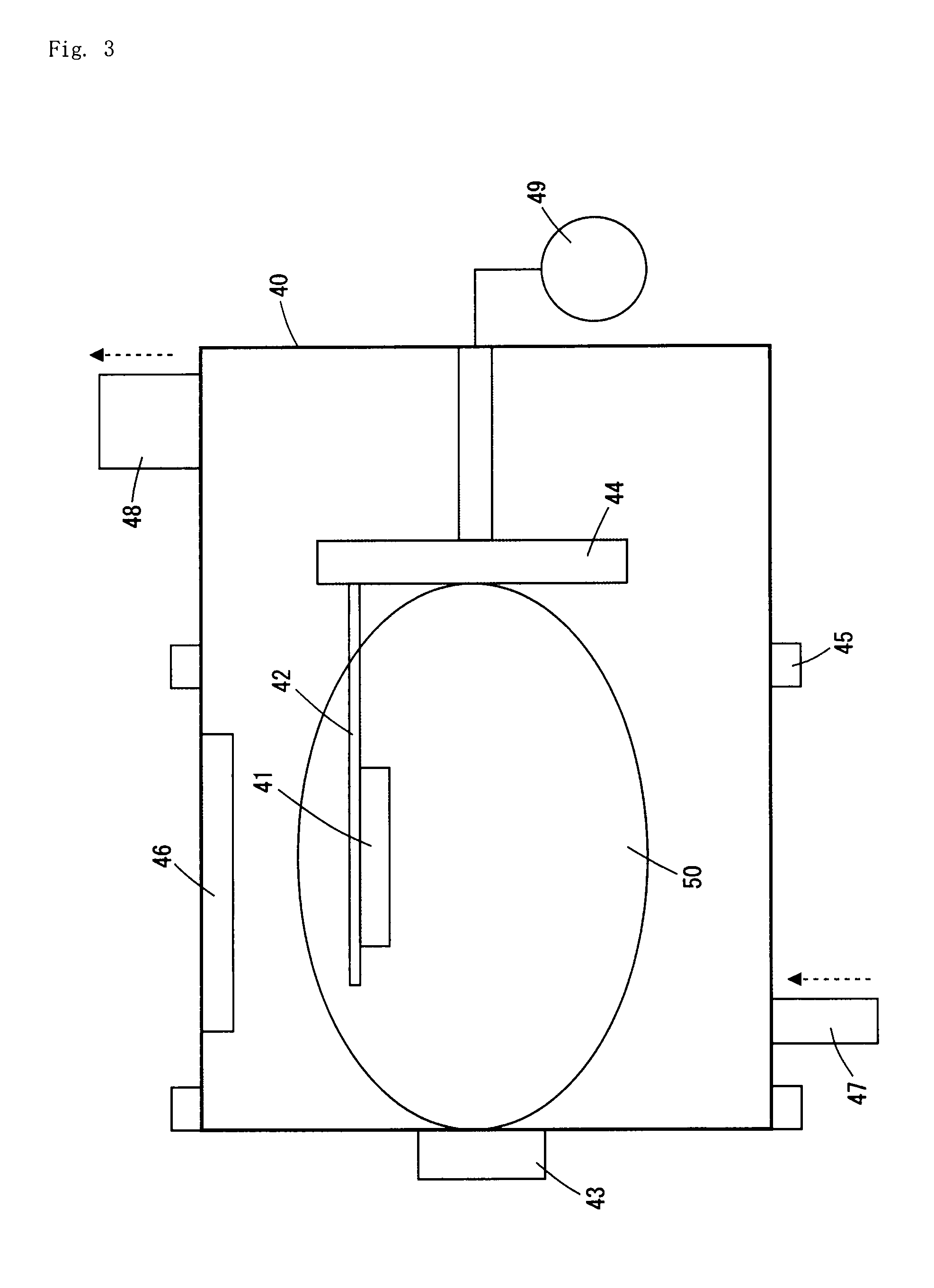

The purpose of the invention is to provide technology, which, in addition to being capable of forming thick hard carbon films of excellent durability even using PVD, is able to establish both chippingresistance and abrasion resistance in the formed hard carbon film and able to improve low friction properties and peeling resistance. Provided is a coating film to coat the surface of a substrate, the coating film having a total film thickness of greater than 1 [mu]m to 50 [mu], wherein: when a cut surface is observed using bright field TEM images, white hard carbon layers that are shown as relatively white and black hard carbon layers that are shown as black are alternately laminated in the thickness direction; and the white hard carbon layers have regions that have grown in a fan-shape in the thickness direction. Provided is a coating film manufacturing method for forming the coating film on the surface of a substrate using PVD, wherein conditions for film formation on the substrate arecontrolled so that the substrate repeatedly alternates temperature increase and temperature decrease between a low temperature range of greater than 50 DEG C to 200 DEG C and a high temperature rangeof greater than 200 DEG C to 300 DEG C, and the substrate is rotated and / or made to revolve.

Owner:NIPPON ITF +1

Sensor setup for determination of deflection and/or strain

InactiveUS8123480B2Improve accuracyRobustnessPropellersWind motor controlProximity sensorEngineering

An elongated member of a wind turbine is disclosed which is potentially subject to strain and which comprises a sensor unit for determining the deflection and / or strain of the elongated member between a first point and a second point, which are assigned to the same side of the elongated member, and the sensor unit comprises a proximity sensor for determining the distance between the second point and a third point, the third point being connected to the first point by an inflexible support, the distance between the first point and the third point being considerably longer than the distance between the second point and the third point, wherein the sensor unit comprises a compressible and / or stretchable element located between the second point and the third point. Moreover, a wind turbine rotor blade and a tower of a wind turbine, each comprising a previously described elongated member, are disclosed.

Owner:SIEMENS AG

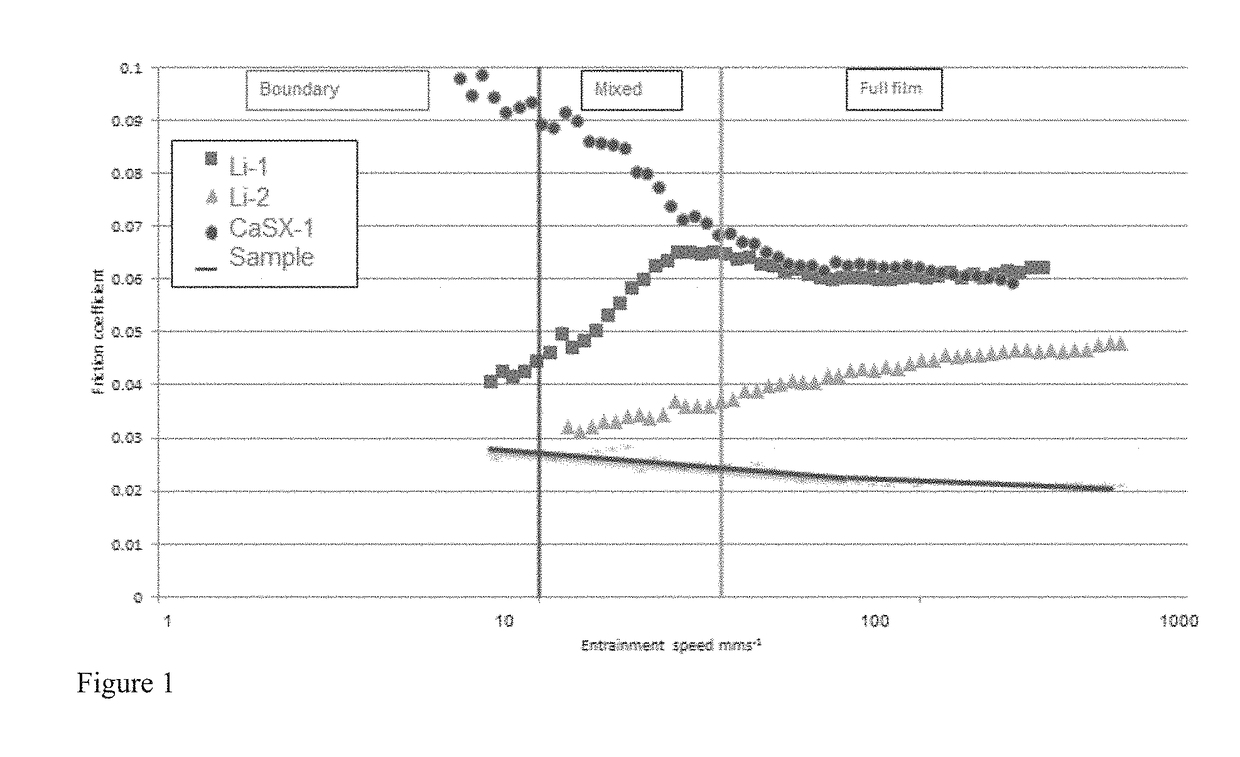

Lubricant composition and sliding mechanism using the lubricant composition

InactiveUS20120177915A1Excellent low friction propertyReduce coefficient of frictionOrganic chemistryRecord information storageTungstenSulfur containing

Provided by the present invention is a lubricating oil composition showing a very low frictional coefficient when used as a lubricating oil for a low friction sliding material prepared by blending with an additive selected from a specific phosphorus-zinc-containing compound and a specific sulfur-containing compound, and a sliding mechanism having an excellent low frictional property in which a DLC film containing 5 to 50 atom % of hydrogen is formed or a sliding mechanism having an excellent low frictional property in which 1 to 30 atom % of tungsten (W) or molybdenum (Mo) is contained is provided by combining the above lubricating oil composition with a sliding member having a film of a specific low frictional sliding material on a sliding face.

Owner:IDEMITSU KOSAN CO LTD +1

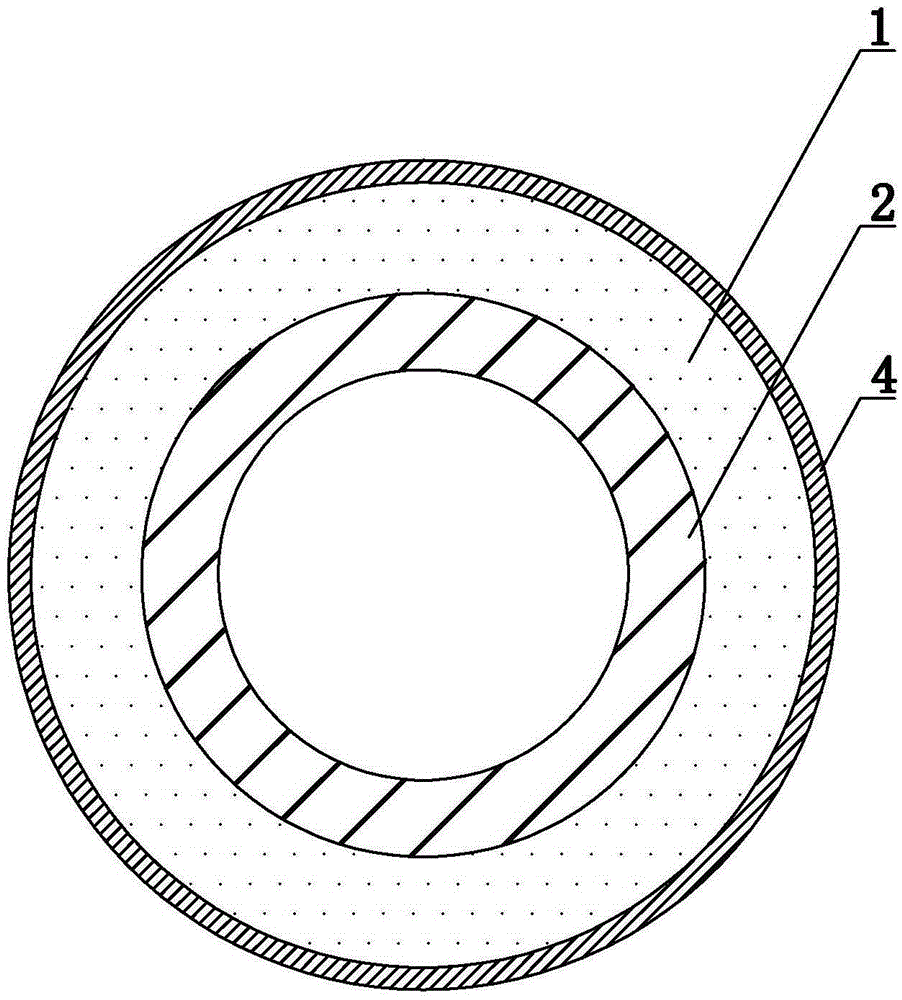

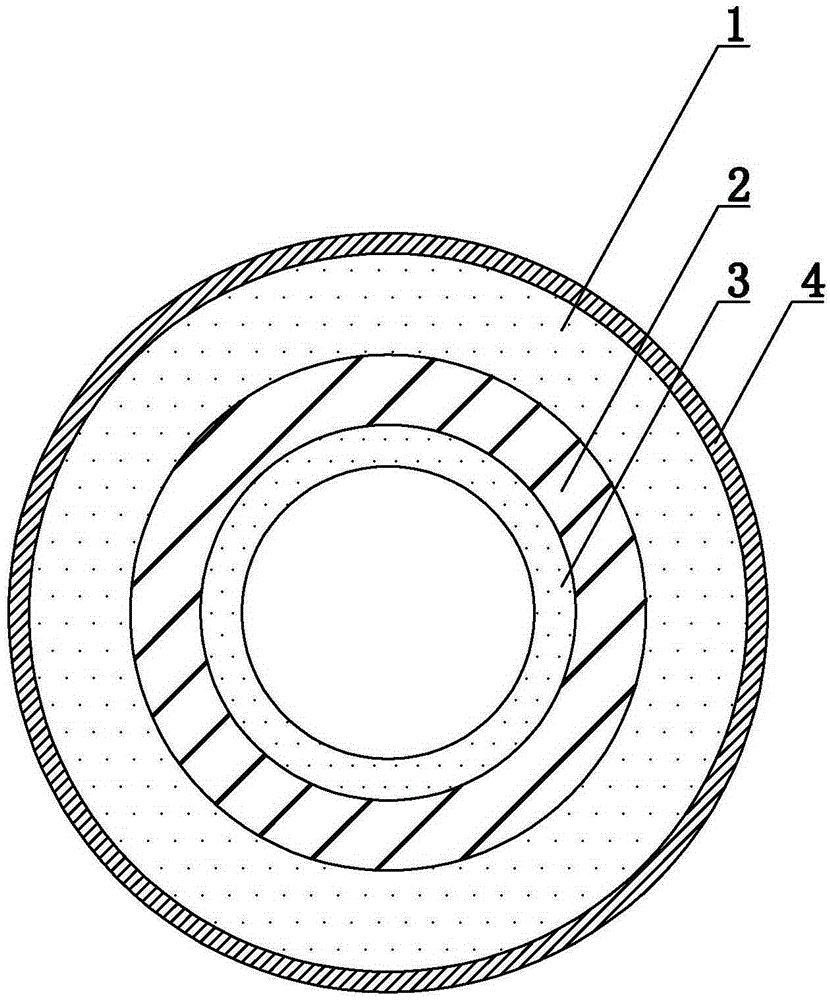

Hydrophilic type super-lubricity urinary catheter and preparation method thereof

The invention relates to a hydrophilic type super-lubricity urinary catheter and a preparation method thereof, and belongs to the technical field of medical product processing. The hydrophilic type super-lubricity urinary catheter consists of a hydrophilic type super-lubricity coating, a polyurethane polymer outer layer and a pipe main body layer, wherein the hydrophilic type super-lubricity coating is arranged on the polyurethane polymer outer layer; the pipe main body layer is positioned at the inner side of the polyurethane polymer outer layer, and is integrally formed with the polyurethane polymer outer layer; and the hydrophilic type super-lubricity coating, the polyurethane polymer outer layer and the pipe main body layer form a concentric layer structure. The hydrophilic type super-lubricity urinary catheter provided by the invention is applied to clinical infusion and has the advantages of being integrally formed, strong in adhesive force, good in wetting property, good in water retention property, low in friction coefficient, high in mechanical strength, excellent in safety and the like.

Owner:SHAOXING XINYUANLI TECH CO LTD

Lubricating oil composition, and sliding mechanism using lubricating oil composition

ActiveUS20150036962A1Reduce coefficient of frictionExcellent low frictionShaftsBearing componentsSulfonateAlkaline earth metal

Disclosed is a lubricating oil composition for low-friction sliding materials, which is used in a sliding mechanism where a DLC film containing hydrogen in an amount of from 5 atom % to 50 atom % is formed on at least one sliding surface.The lubricating oil composition contains, in the lubricant base oil therein and based on the total amount of the composition, (A) an organic zinc dithiophosphate in an amount of from 0.005% by mass to 0.12% by mass in terms of the phosphorus concentration therein, (B) an amide-based friction-reducing agent in an amount of from 0.05% by mass to 5.0% by mass, and (C) an alkaline earth metal salicylate-based detergent and / or an alkaline earth metal sulfonate-based detergent in an amount of from 0.05% by mass to 0.5% by mass in terms of the alkaline earth metal concentration therein.

Owner:IDEMITSU KOSAN CO LTD

Bridging clutch for a hydrodynamic clutch device enclosed by a housing

InactiveUS7201261B2Increase the number ofExcellent low frictionRotary clutchesFluid gearingsEngineeringPiston

A bridging clutch for a hydrodynamic clutch device includes a housing comprising a cover having a friction surface; a piston which can move axially with respect to the housing, the piston having a friction surface which faces the friction surface of the cover; a first pretensioning element mount fixed to the cover and having a first support section; a second pretensioning element mount fixed to the piston and having a second support section; and a pretensioning element supported axially between the first and second support sections for actuating the piston in a predetermined axial direction. A slide device located between the pretensioning element and the second support section permits sliding movement of the pretensioning element with respect to the second pretensioning element mount.

Owner:ZF FRIEDRICHSHAFEN AG

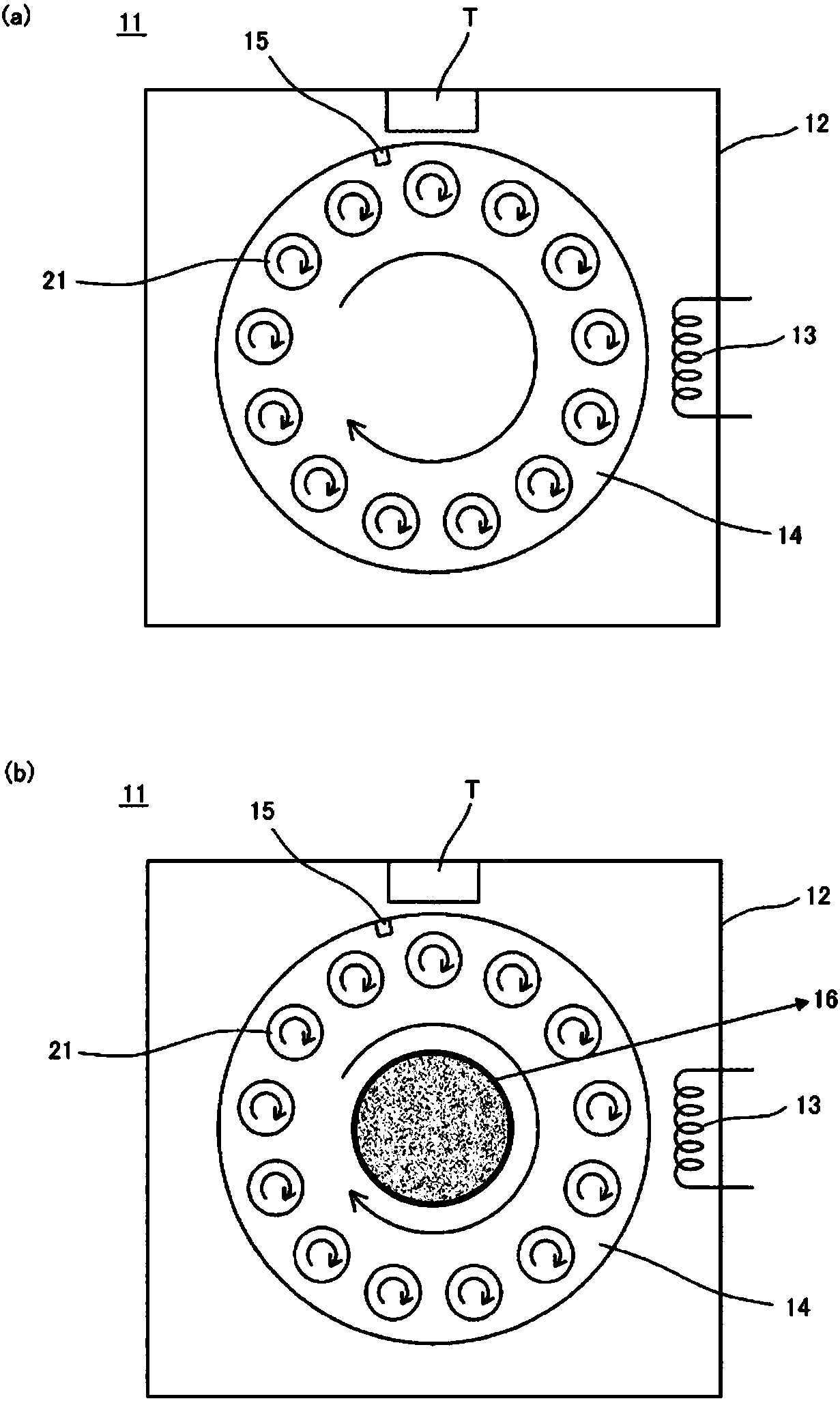

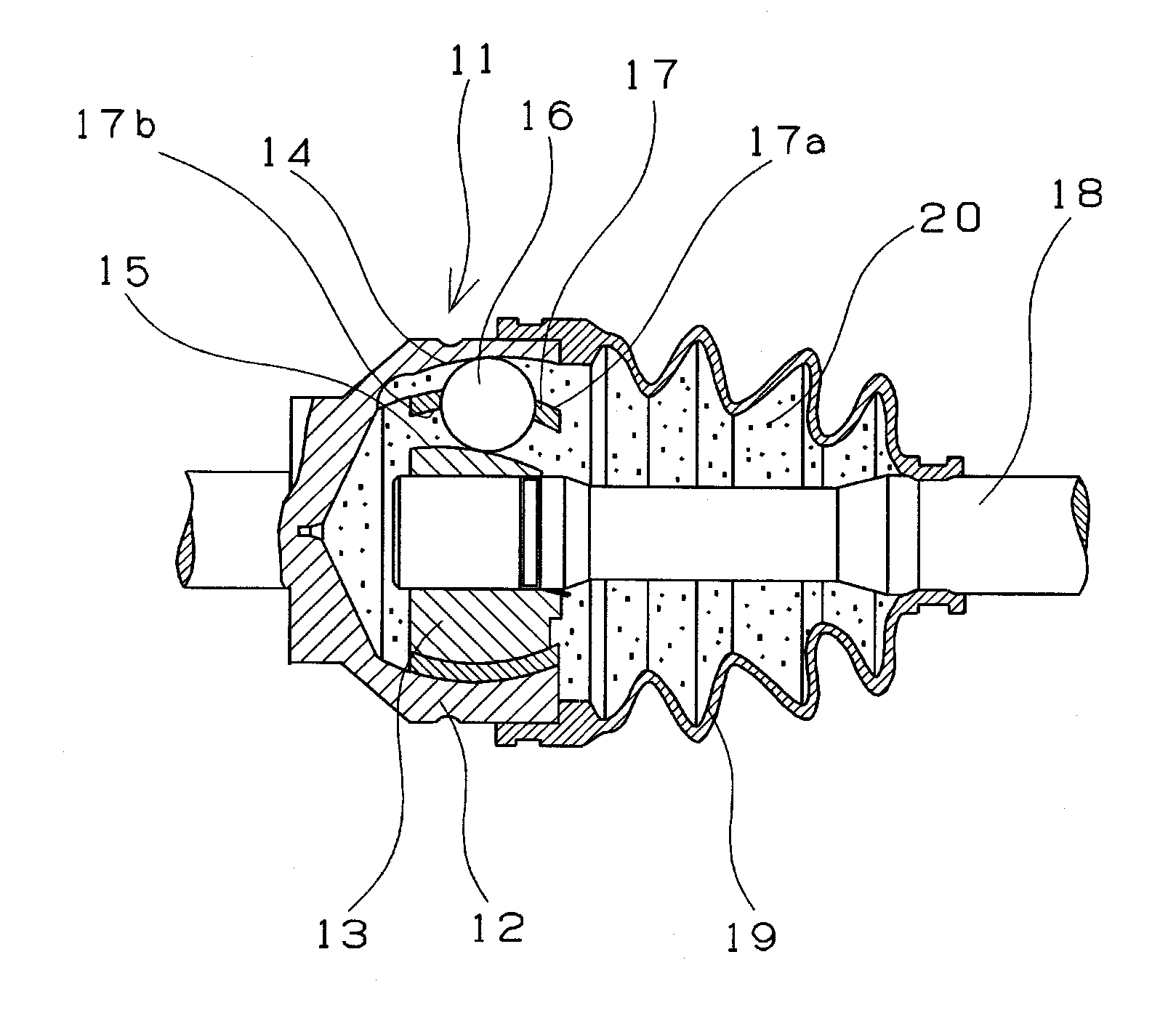

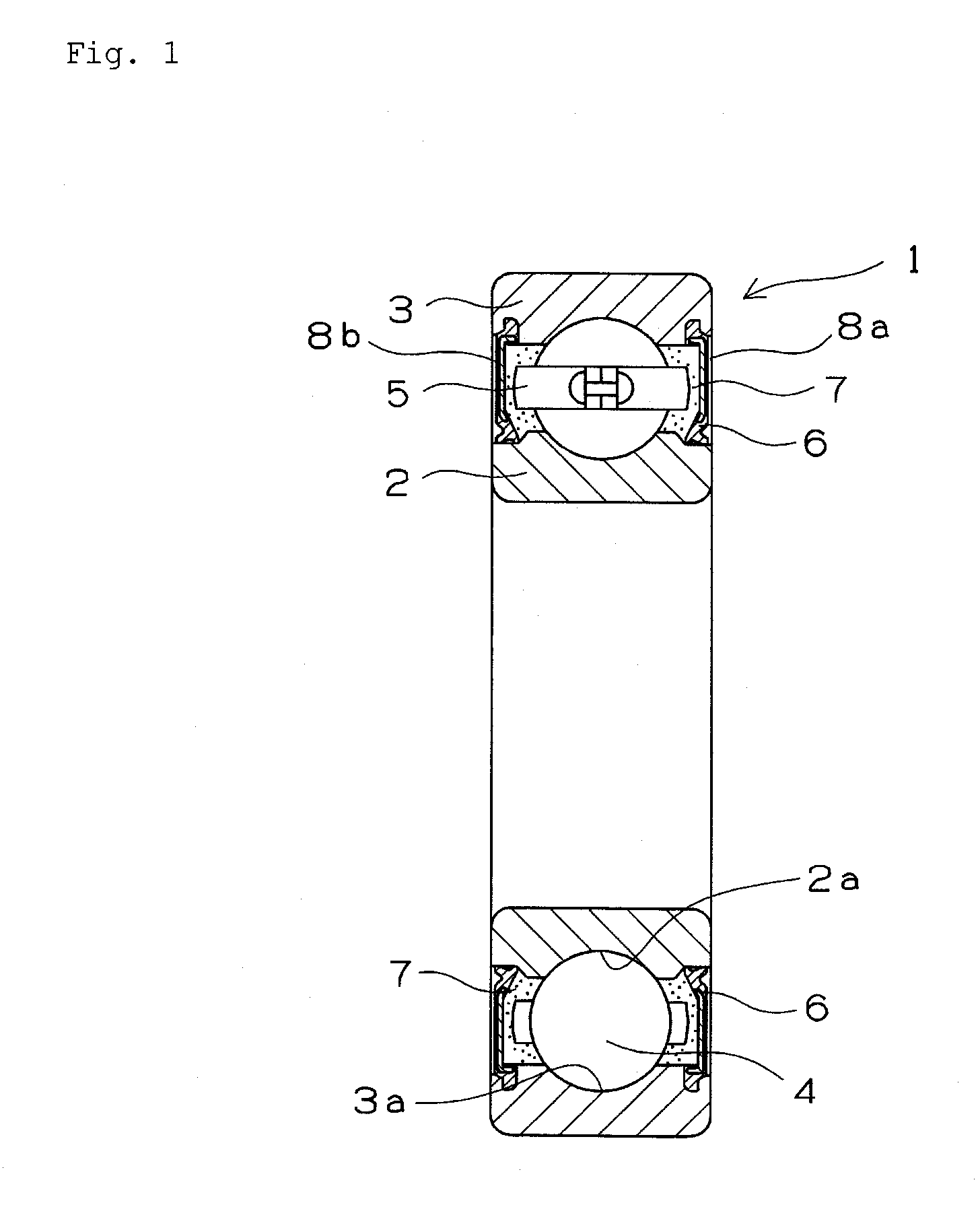

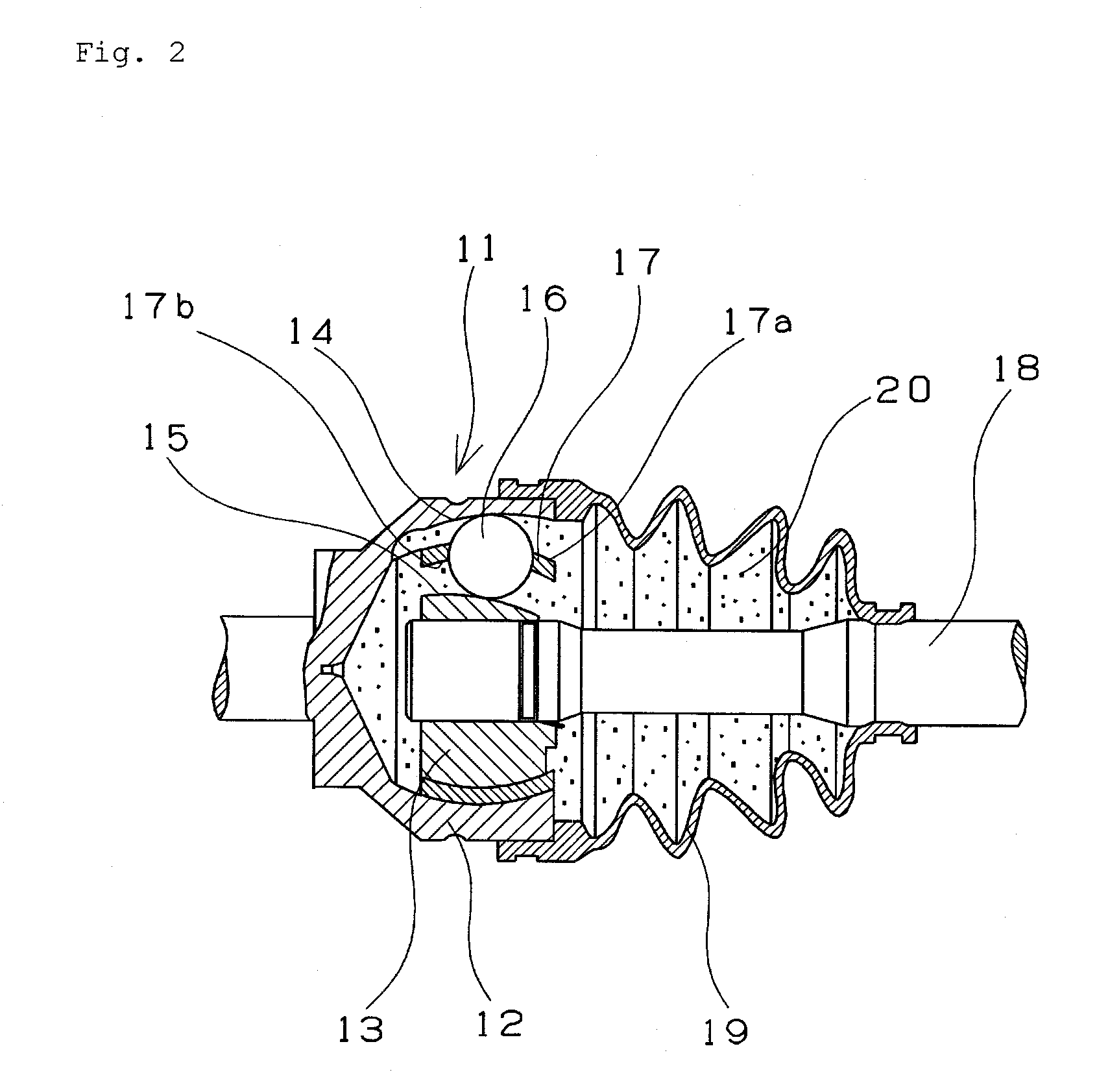

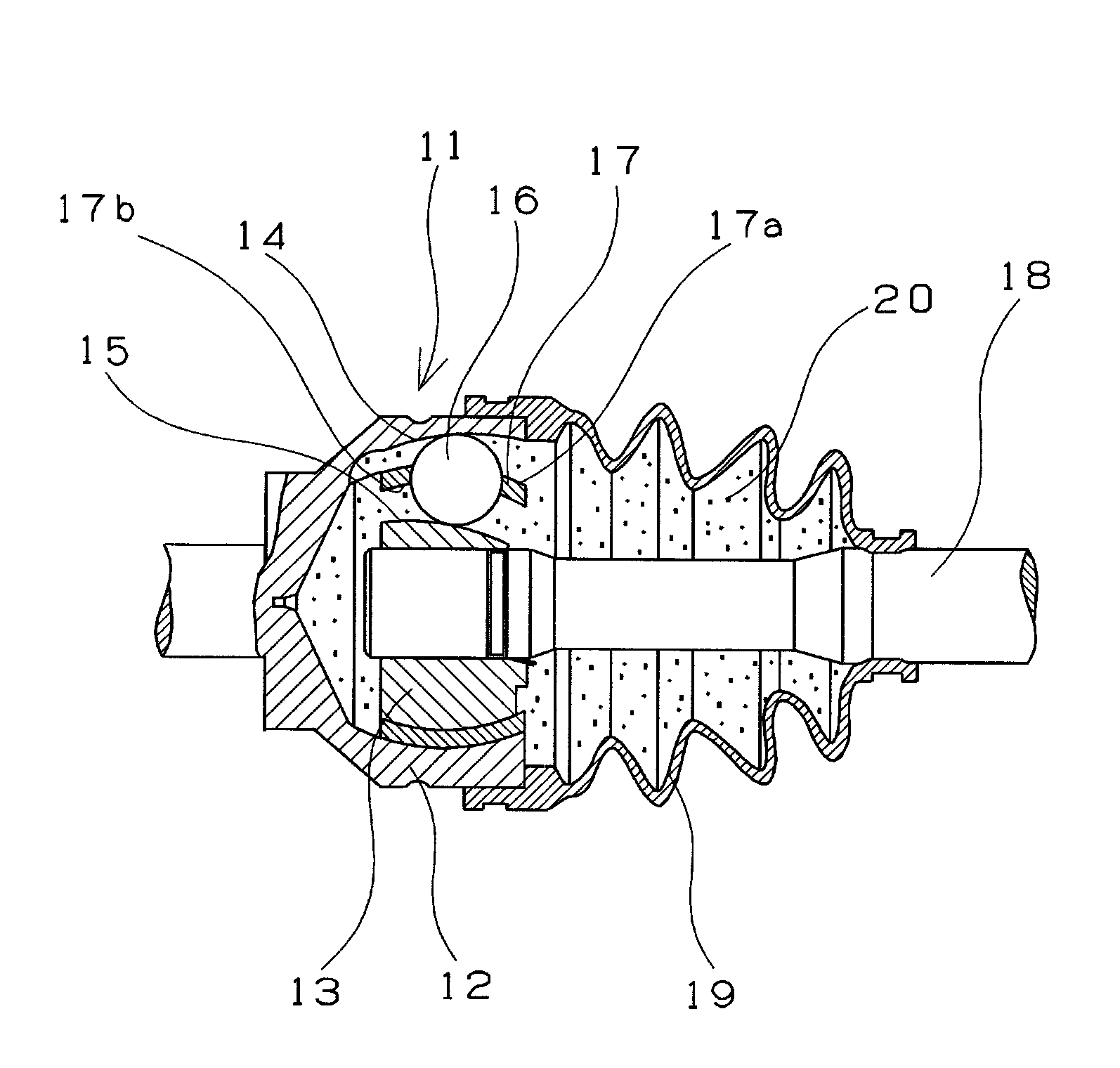

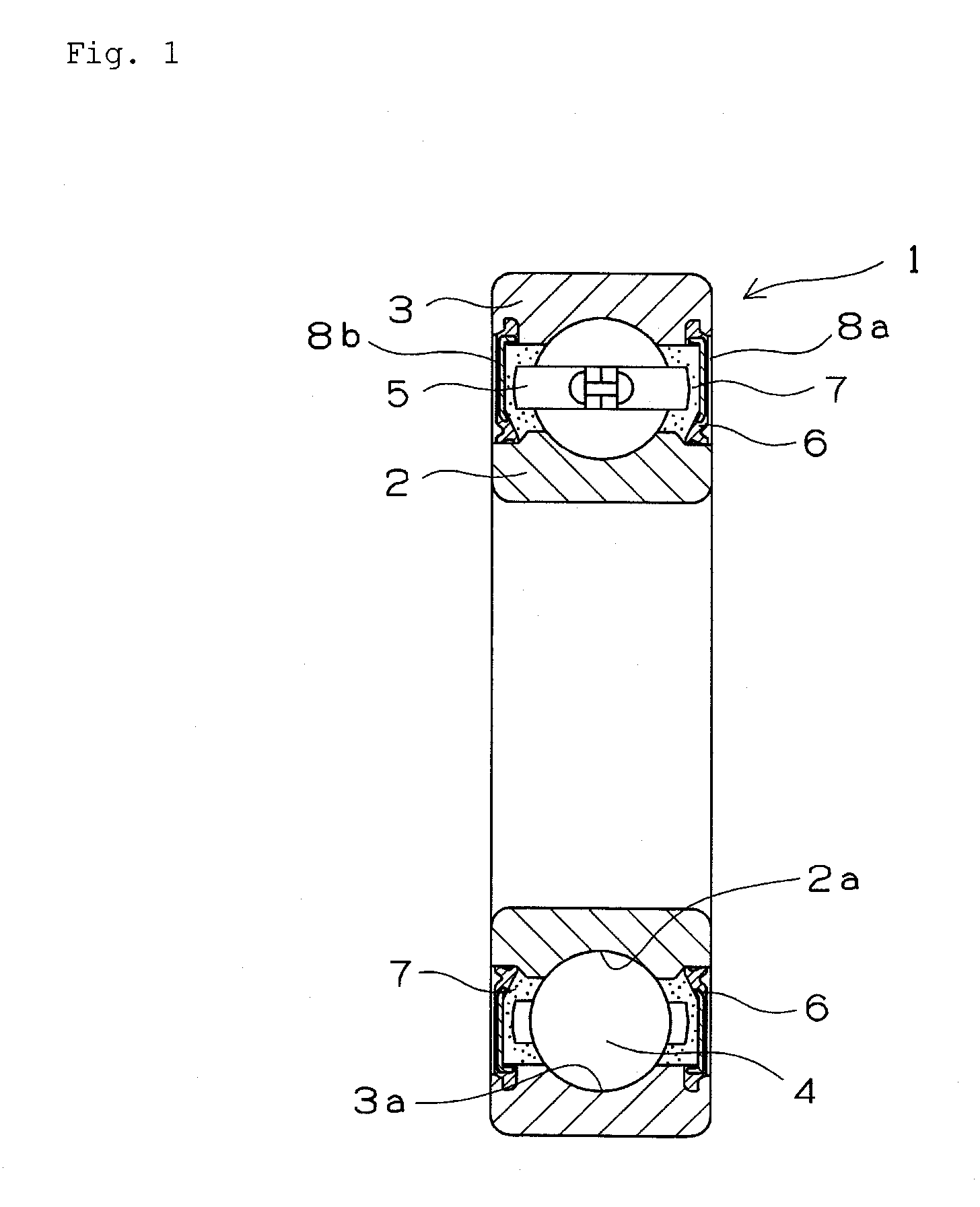

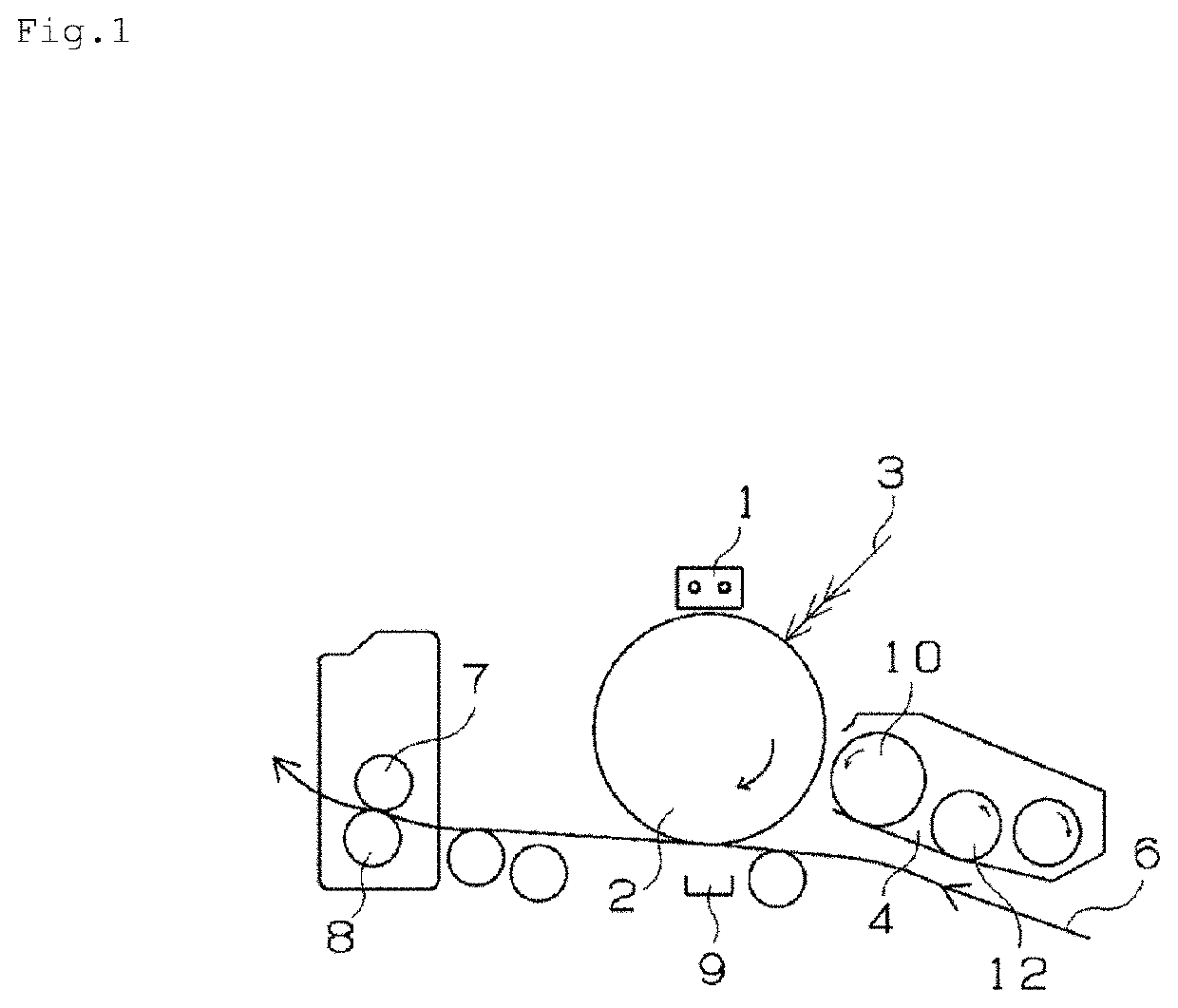

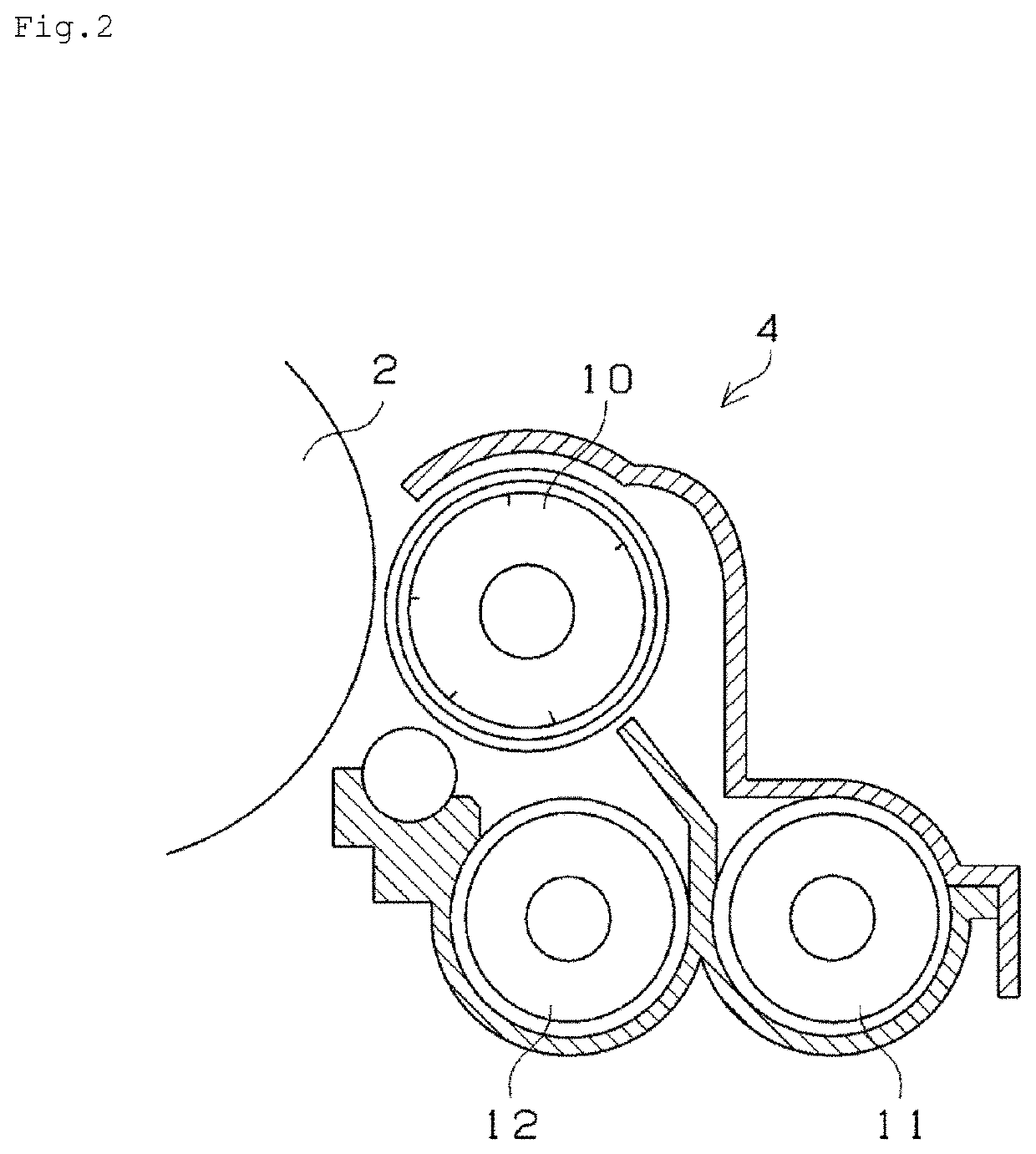

Grease composition, grease-packed bearing, universal joint and linear motion device

ActiveUS20130276563A1Improve the lubrication effectImprove wear resistanceToothed gearingsBearing componentsLinear motionContact pressure

The present invention provides a grease composition which contains a small amount (not more than 0.06 wt %) of molybdenum and yet is capable of achieving an excellent low friction property when mechanical parts in which the grease composition has been packed are operated under a severe sliding condition in which they are subjected to a high speed and a high contact pressure. The present invention also provides a bearing, a universal joint, and a linear motion device in which the grease composition of the present invention is packed. A grease composition (7) is packed inside a grease-packed bearing (1) in such a way that the grease composition (7) is applied to at least the circumference of each rolling element (4). The grease composition (7) contains base oil, a thickener, and an additive. The additive includes molybdenum dithiocarbamate and sodium dithiocarbamate. The content of the molybdenum for the whole weight of the grease composition (7) is set to not more than 0.06 wt %.

Owner:NTN CORP

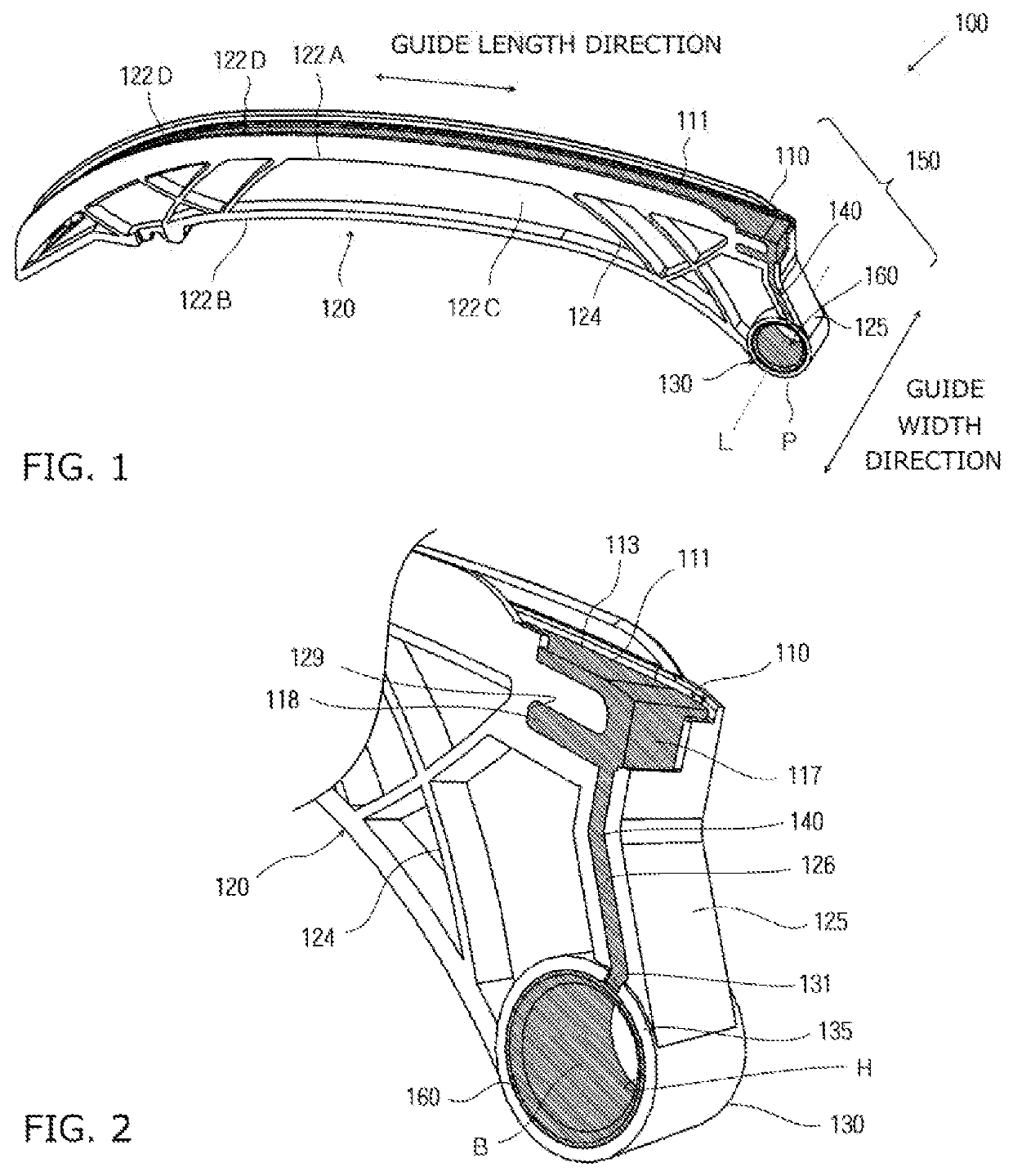

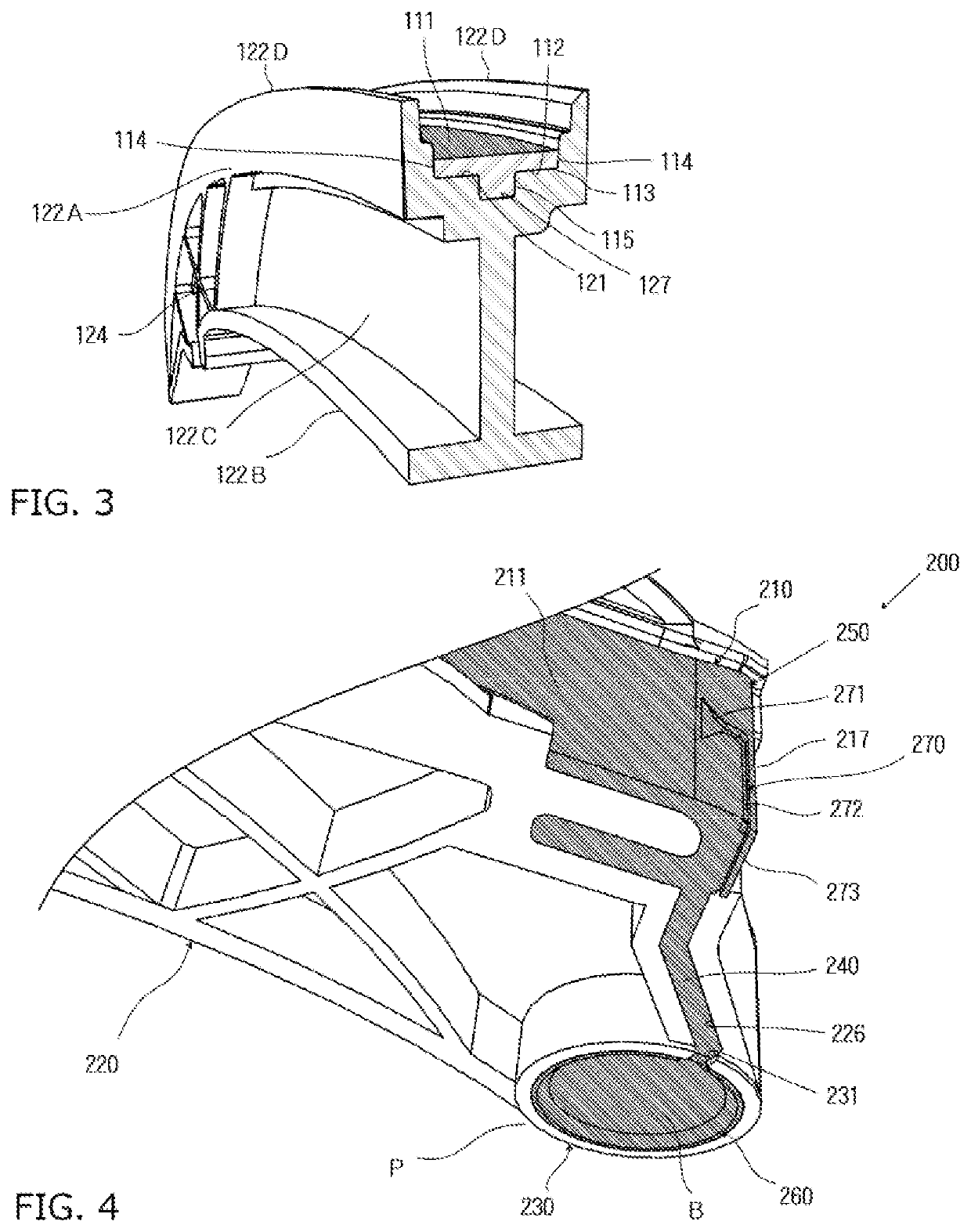

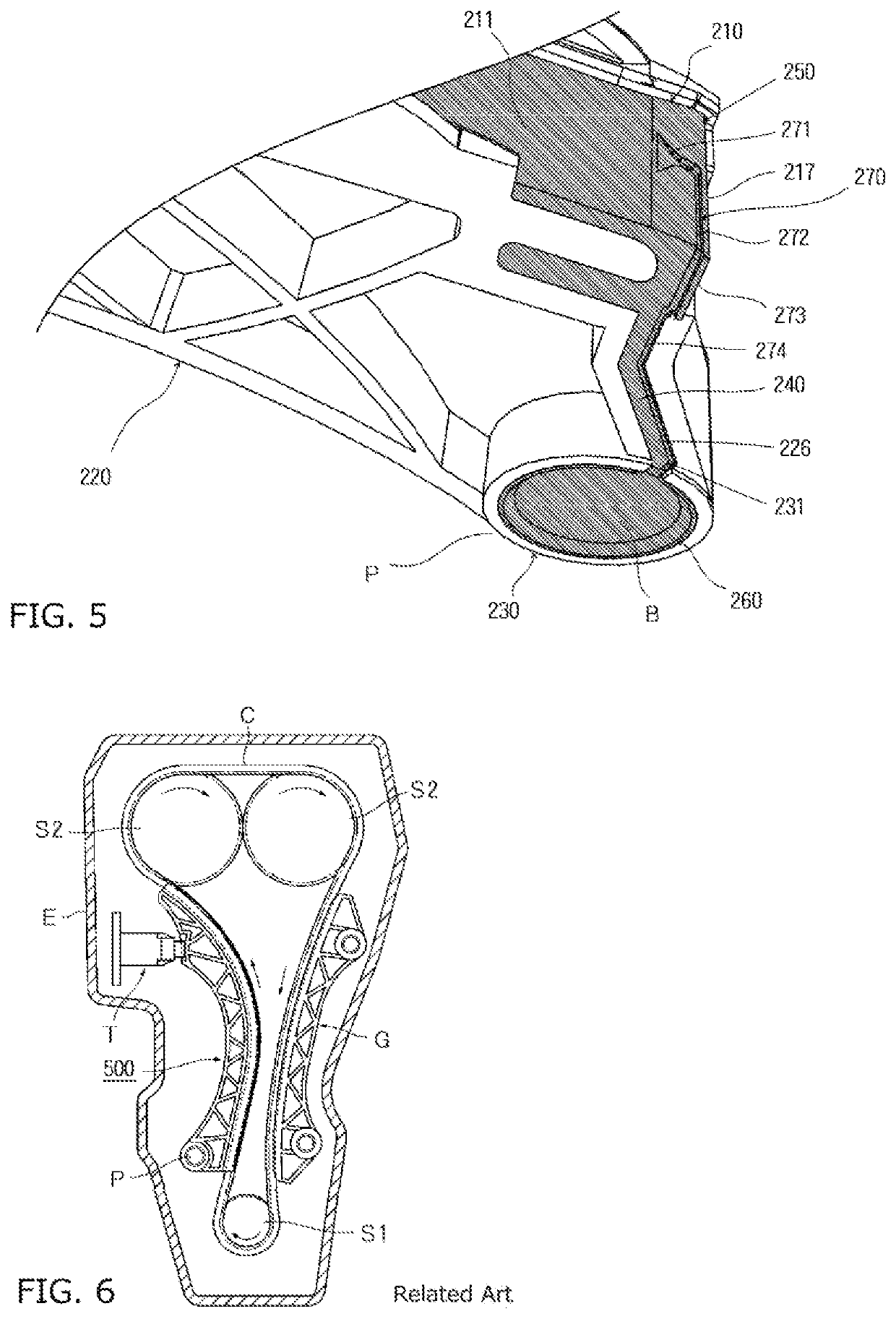

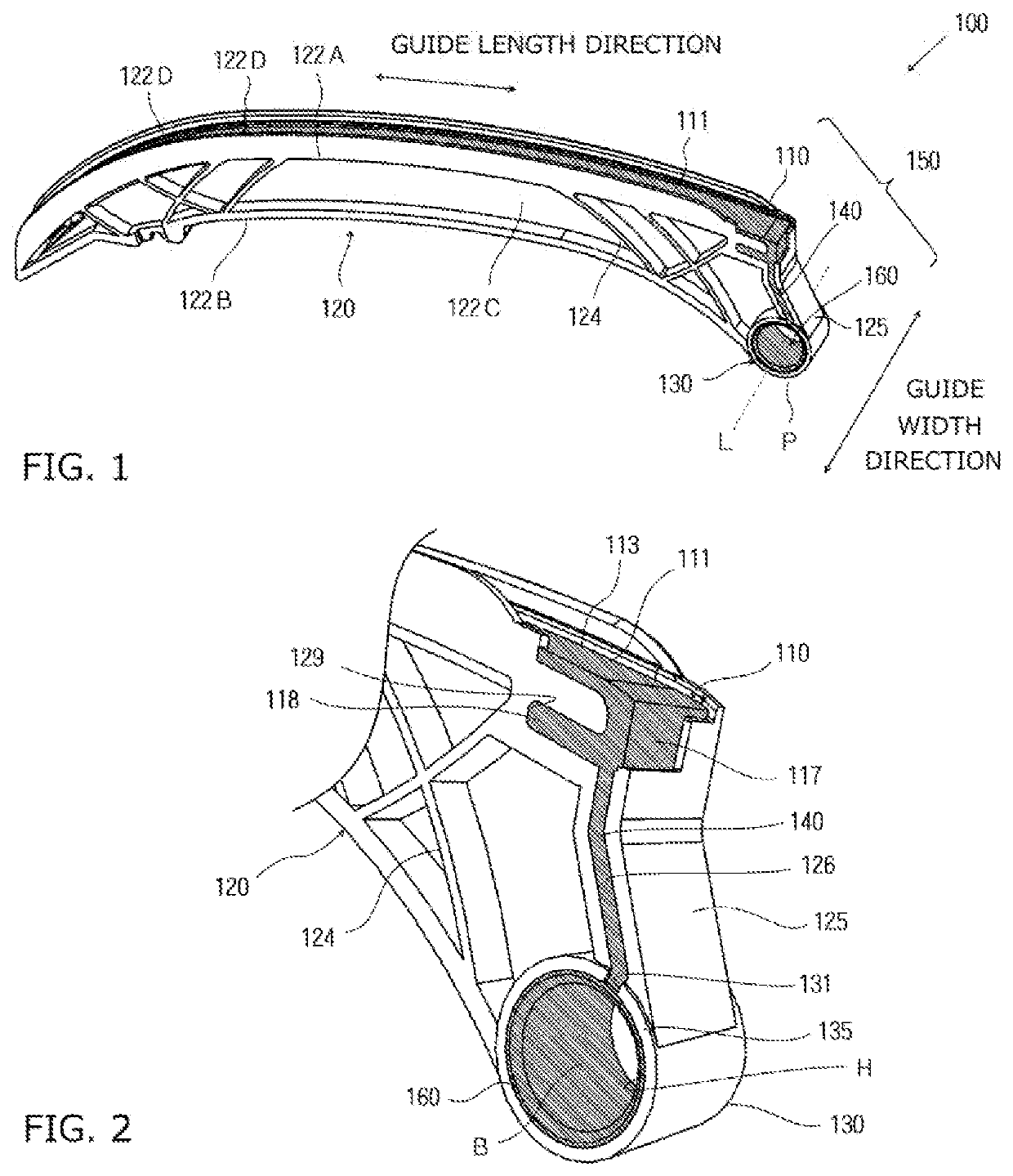

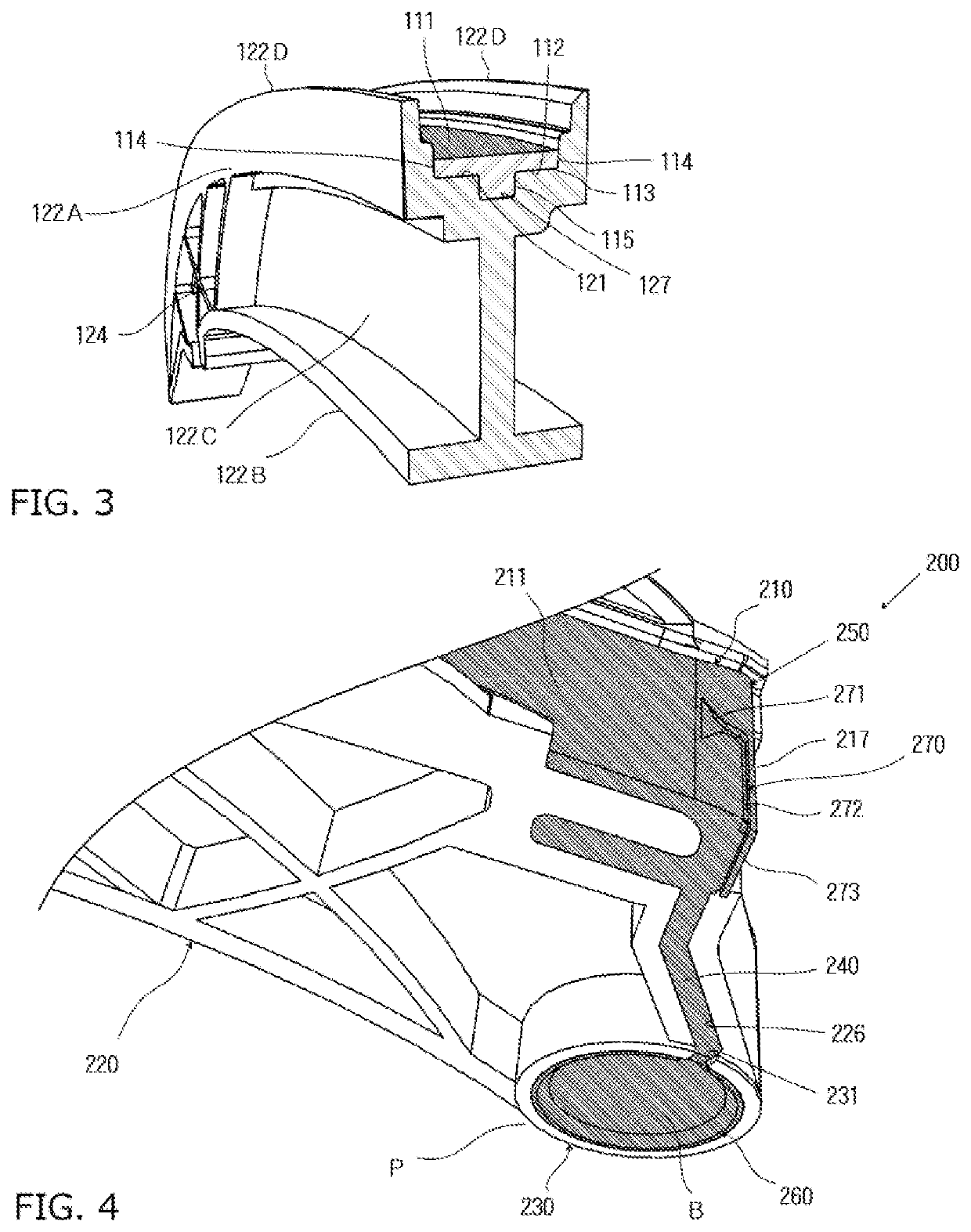

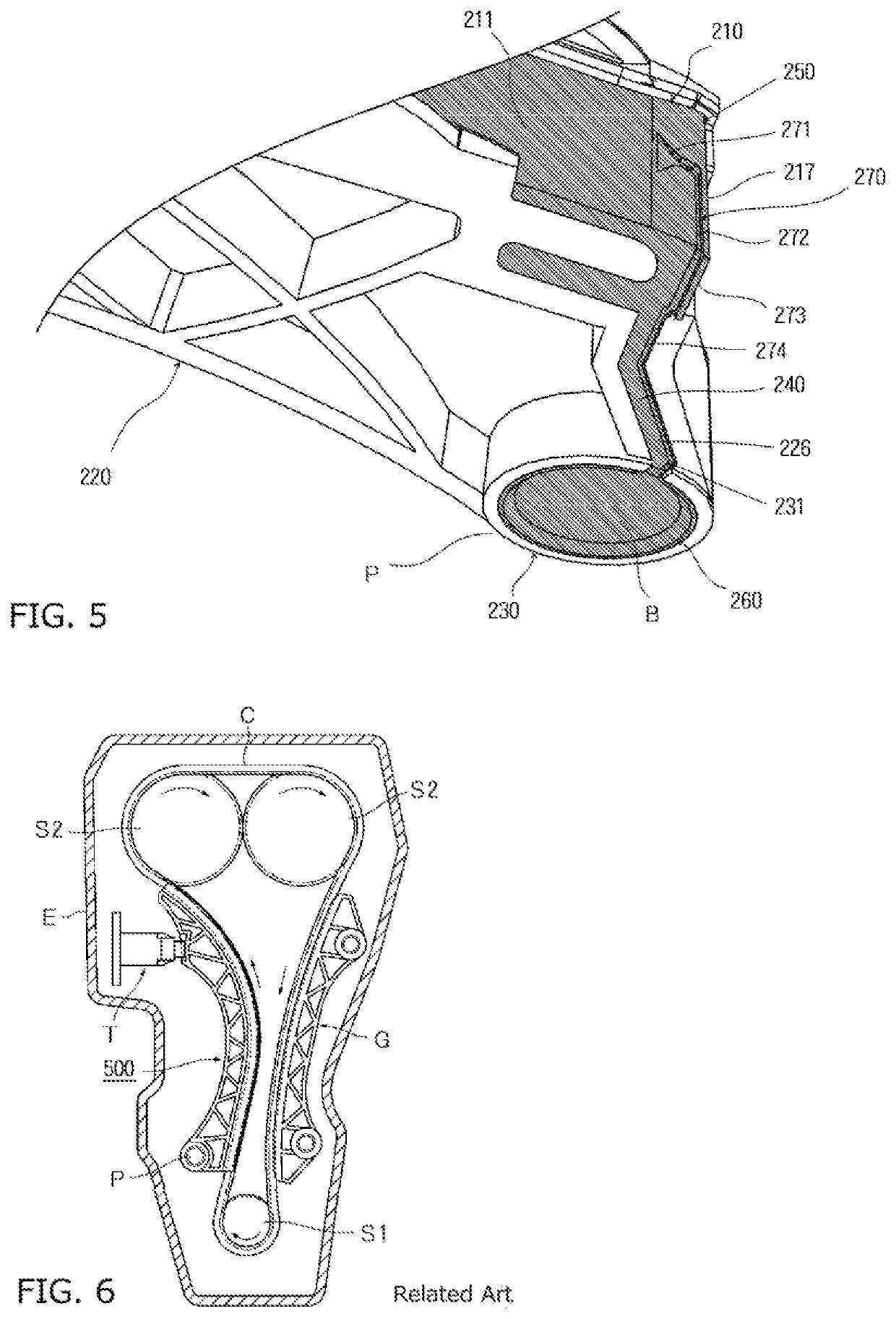

Tensioner lever

ActiveUS11248682B2Easy to produceIncreased durabilityGearingGearing detailsSlider bearingEngineering

The problem to be solved is to provide a tensioner lever that inhibits friction-induced wear or seizure on a surface of a pivoting support boss contacting a shoulder bolt so that high durability is achieved, and that is easily producible and enables cost reduction. As a solution to the problem noted above, the tensioner lever includes a shoe having a traveling surface, a lever body, and a pivotal support boss provided at a proximal end of the lever body to allow a distal end thereof to swing. The shoe and the lever body are integrally formed and assembled together by double injection molding. The lever body includes a slide bearing member, and a connecting part that connects the slide bearing member and the shoe. The slide bearing member, the connecting part, and the shoe are made of the same synthetic resin, and configured as a continuous one-piece component.

Owner:TSUBAKIMOTO CHAIN CO

Tensioner lever

ActiveUS20200362944A1Reduce friction lossIncreased durabilityGearingGearing detailsSlider bearingEngineering

The problem to be solved is to provide a tensioner lever that inhibits friction-induced wear or seizure on a surface of a pivoting support boss contacting a shoulder bolt so that high durability is achieved, and that is easily producible and enables cost reduction. As a solution to the problem noted above, the tensioner lever includes a shoe having a traveling surface, a lever body, and a pivotal support boss provided at a proximal end of the lever body to allow a distal end thereof to swing. The shoe and the lever body are integrally formed and assembled together by double injection molding. The lever body includes a slide bearing member, and a connecting part that connects the slide bearing member and the shoe. The slide bearing member, the connecting part, and the shoe are made of the same synthetic resin, and configured as a continuous one-piece component.

Owner:TSUBAKIMOTO CHAIN CO

Fluorine rubber molded article

InactiveUS20130280490A1Increase resistanceImprove transmittanceLayered productsThin material handlingPolymer scienceHexafluoropropylene

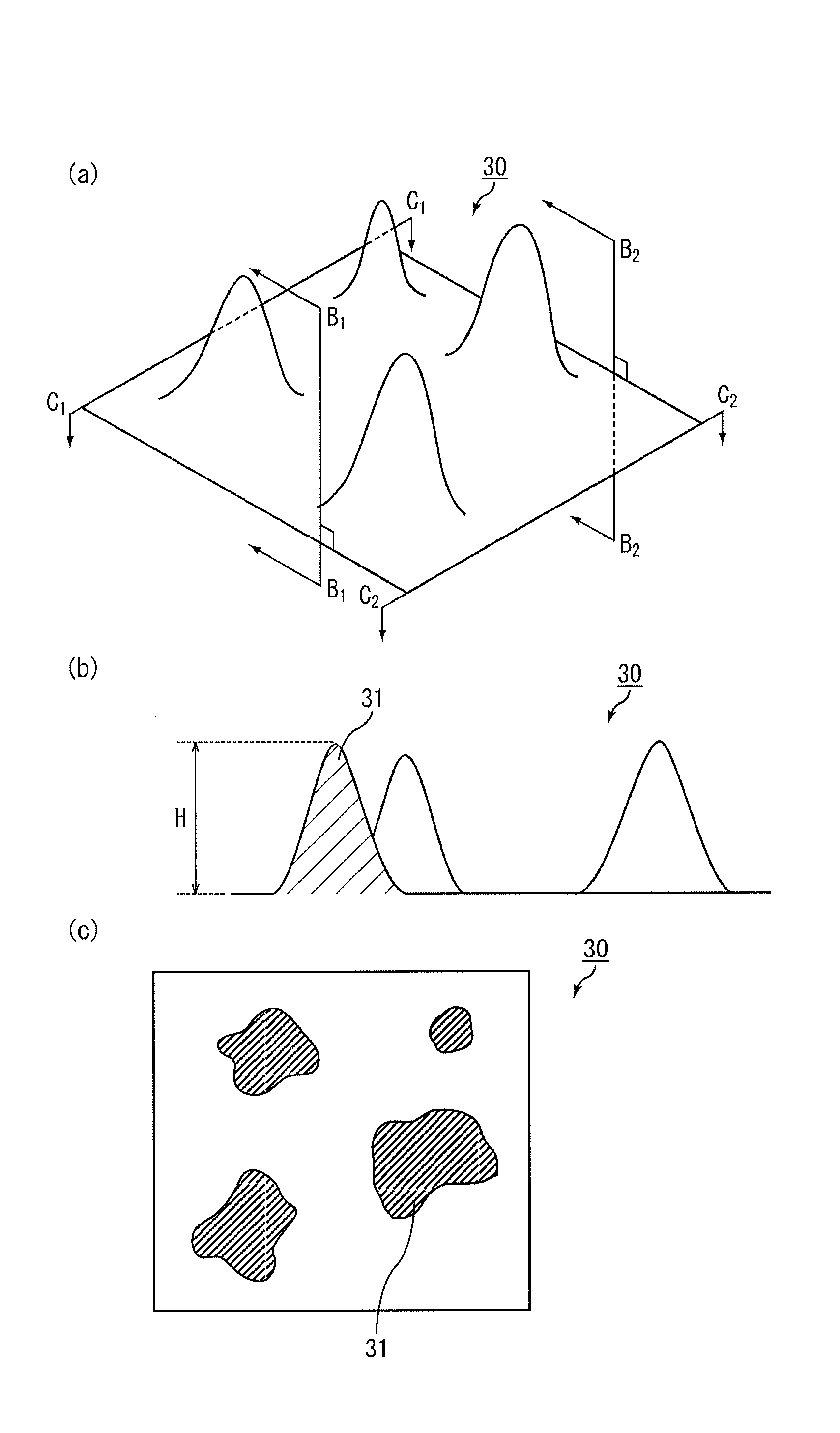

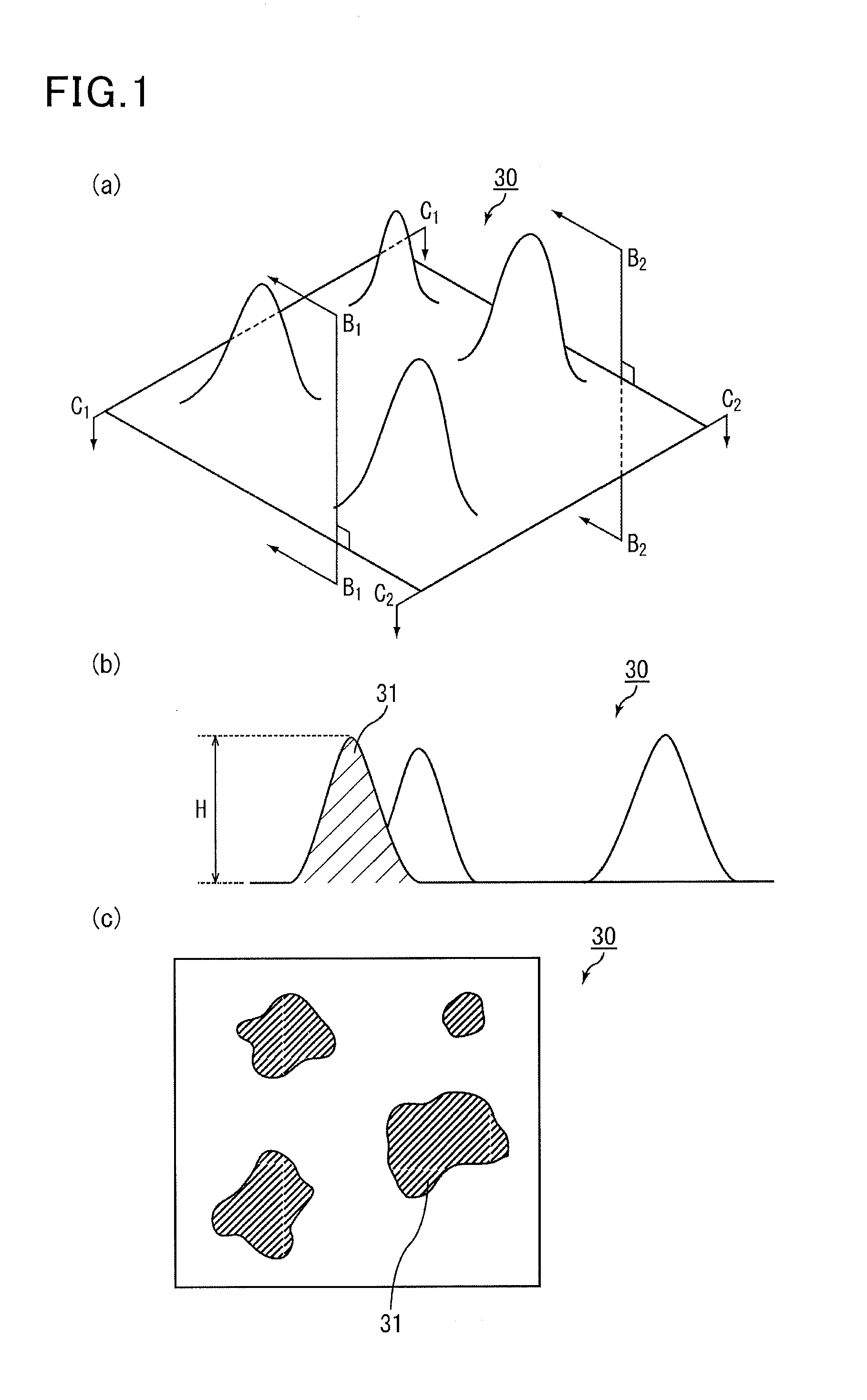

A fluororubber molded article produced by crosslinking a crosslinkable composition containing a fluororubber (A) and a fluororesin (B), wherein the fluororubber molded article has a surface with projecting portions, an area ratio of areas having the projecting portions to the entire surface of the fluororubber molded article is not less than 0.06, a volume ratio of the fluororesin (B) to the fluororubber molded article is 0.05 to 0.45, the area ratio of the areas having the projecting portions is 1.2 times or more larger than the volume ratio of the fluororesin (B), and the fluororesin (B) is a tetrafluoroethylene / hexafluoropropylene copolymer.

Owner:DAIKIN IND LTD

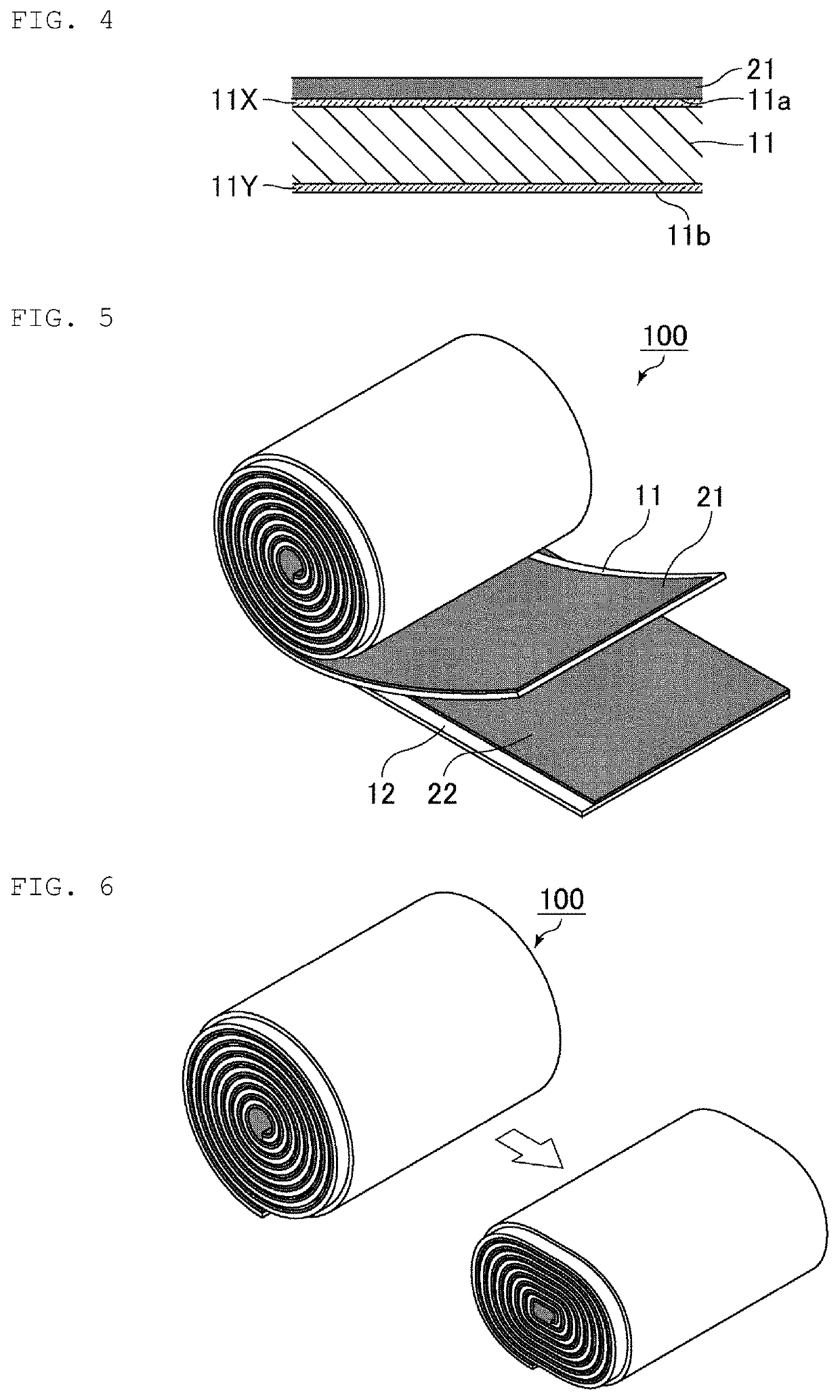

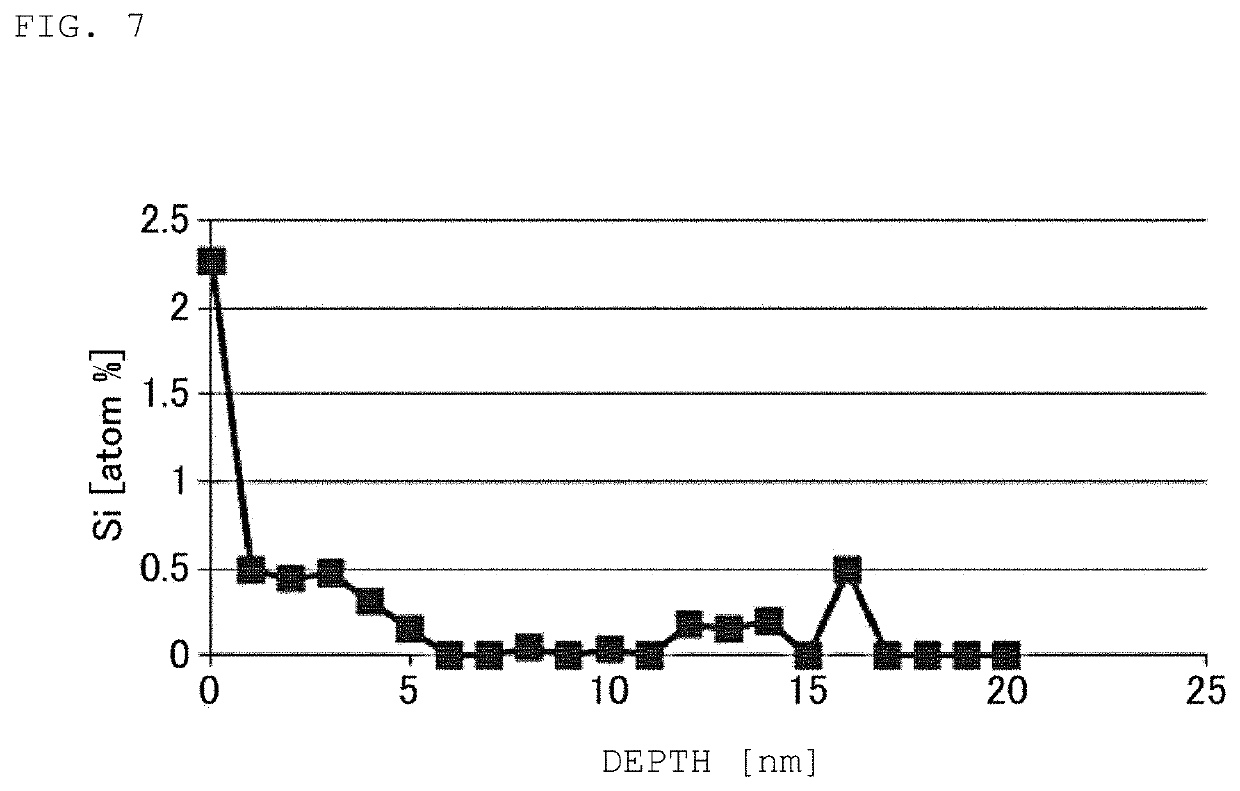

Film capacitor, method of producing film capacitor, dielectric resin film, and method of producing dielectric resin film

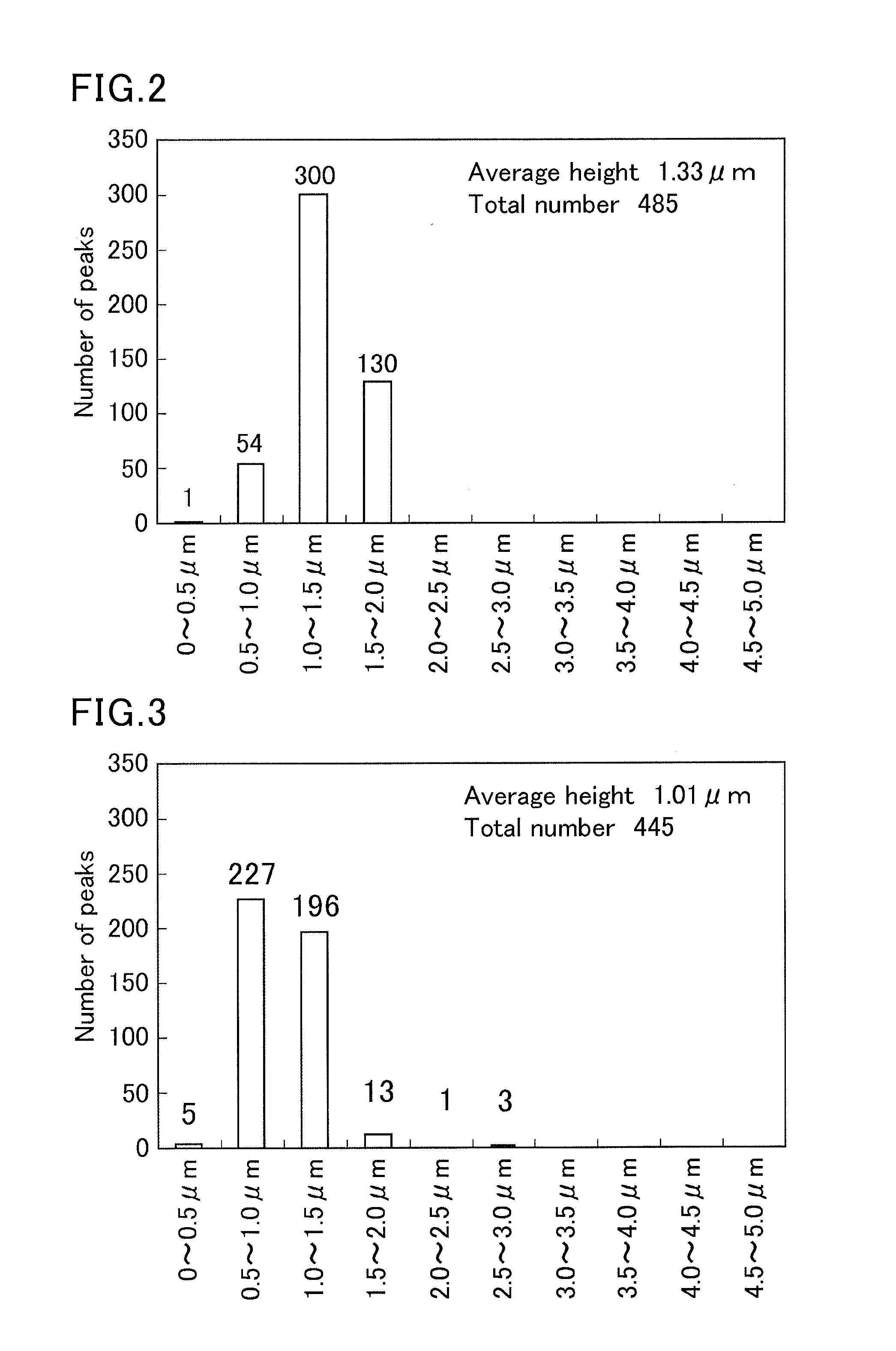

ActiveUS20190348220A1Lower performance requirementsImprove performanceFixed capacitor electrodesThin/thick film capacitorFilm capacitorMetal

A film capacitor that includes a dielectric resin film having a first surface and a second surface opposite to the first surface, the second surface having a silicone resin-containing layer; a first metal layer opposite to the first surface of the dielectric resin film; and a second metal layer opposed to the second surface of the dielectric resin film.

Owner:MURATA MFG CO LTD

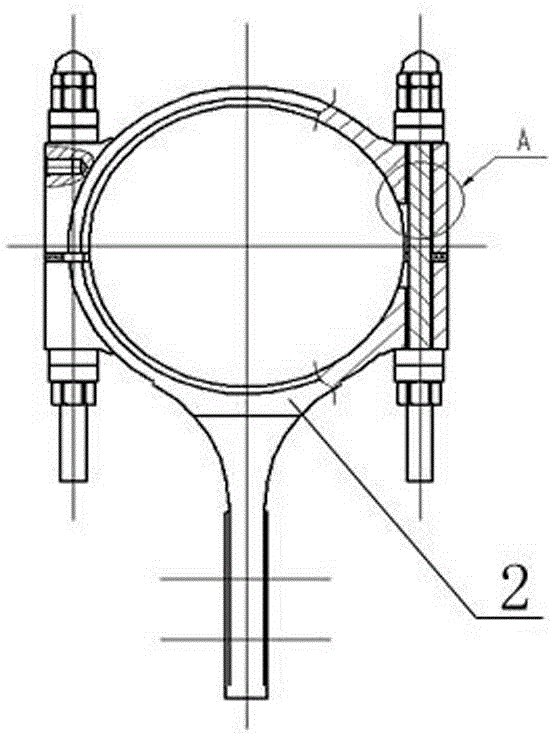

Cable clamp bolt for suspension bridge and surface treatment method of cable clamp bolt for suspension bridge

InactiveCN104562933AStrong connectionPersistent connectionPretreated surfacesBridge structural detailsEngineeringWear resistance

The invention provides a cable clamp bolt for a suspension bridge and a surface treatment method of the cable clamp bolt for the suspension bridge, wherein a corrosion resistant layer is arranged on the surface of the bolt; the corrosion resistant layer is a Teflon permeation layer with a depth of 10-20 microns. The surface treatment method of the cable clamp bolt for the suspension bridge sequentially comprises the following steps of manufacturing the cable clamp bolt, checking the size and performance of the bolt successfully, cleaning the surface of the bolt, spraying paint on the surface of the bolt, curing and sintering a coating, and cooling and post-processing the bolt. According to the cable clamp bolt for the suspension bridge and the surface treatment method of the cable clamp bolt for the suspension bridge, a layer of thinner Teflon coating is arranged on the surface of the cable clamp bolt for the suspension bridge, so that the precision of a thread pair cannot be influenced; the bolt painted with the Teflon coating has the advantages of excellent corrosion resistance, wear resistance and a lower stable coefficient of friction resistance, and cannot be corroded for 1000 hours in a salt fog resistance test. The cable clamp bolt for the suspension bridge and the surface treatment method of the cable clamp bolt for the suspension bridge have the advantages of simple structure, convenience in manufacture, stability, reliability and strong structural safety, and the climate adaptability of the cable clamp bolt is improved.

Owner:DEYANG TIANYUAN HEAVY IND

Grease composition, grease-packed bearing, universal joint and linear motion device

InactiveUS9139793B2Improve the lubrication effectImprove wear resistanceToothed gearingsBearing componentsLinear motionContact pressure

Owner:NTN CORP

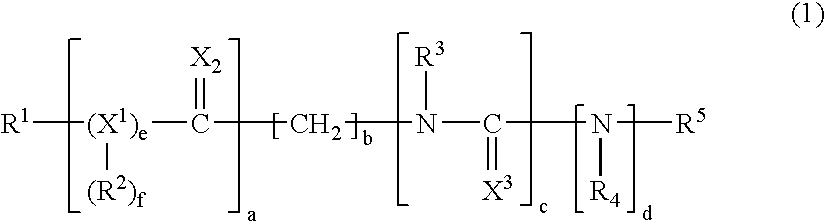

Coating composition and method for producing the same, coating film and underwater structures

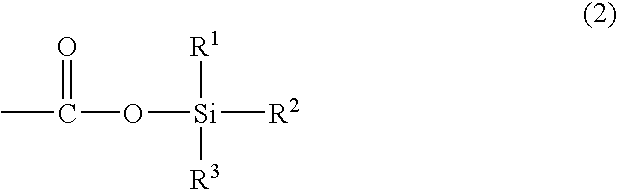

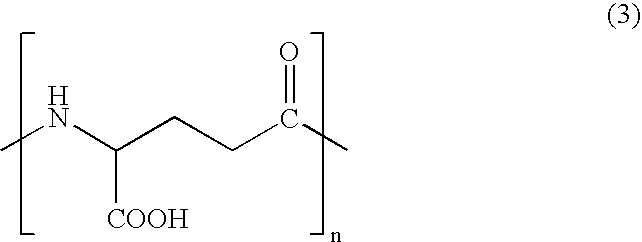

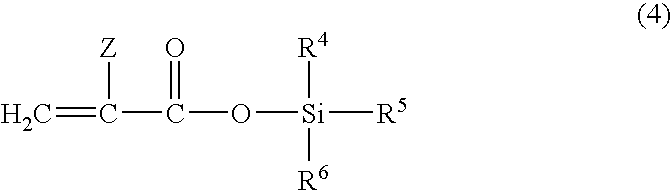

ActiveUS20110178204A1Excellent low frictional performanceReduce fuel consumptionAntifouling/underwater paintsPaints with biocidesOrganic acidSide chain

Provided are coating composition containing an organic polymer particle (A) composed of an organic polymer having a hydroxyl group and a cationic group in a molecule, the weight average particle size of which being 10 to 35 μm, and a base resin (B), wherein the content of the organic polymer particle (A) is 0.5 to 5.0% by weight in the solid content of the coating composition, and a method of producing the same, and a coating film and underwater structure using the coating composition. The base resin (B) has a group represented by the following general formula (1):—COO-M-OCO-A (1)(wherein, M represents a divalent or higher valent metal, and A represents an organic acid residue of monobasic acid) or a group represented by the following general formula (2):—COO—Si(R1R2R3) (2)(wherein, R1, R2 and R3, which may be the same or different, represent an isopropyl group or an n-butyl group) in a side chain, or has a cross-linking structure represented by the following general formula (3):—COO-M-OCO— (3)(wherein, M represents the same meaning as described above).

Owner:NIPPON PAINT MARINE COATINGS +1

Slide part

Owner:HITACHI METALS LTD

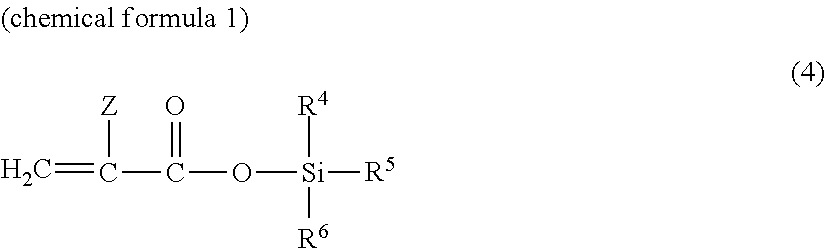

Coating composition and coating film formed from the same

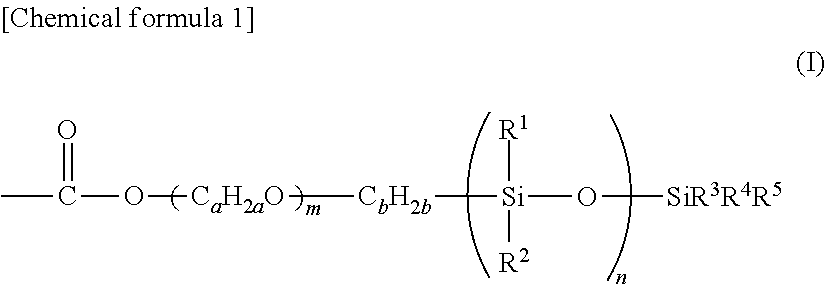

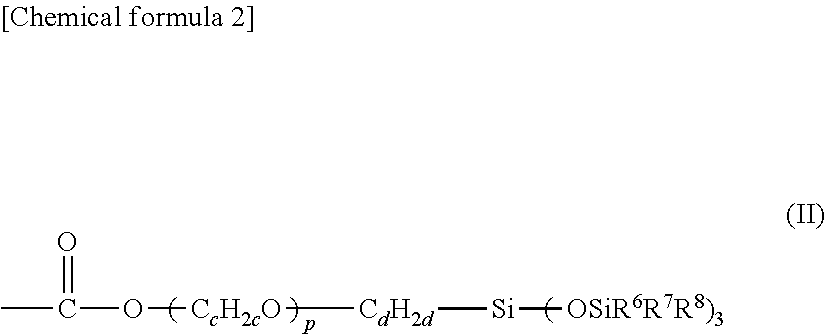

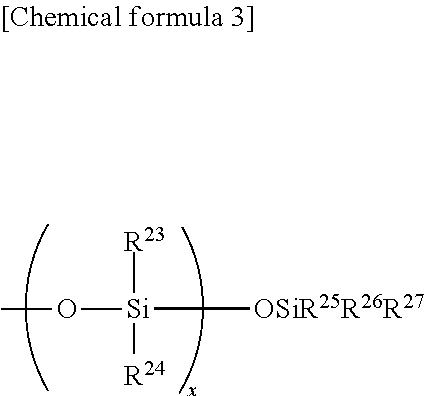

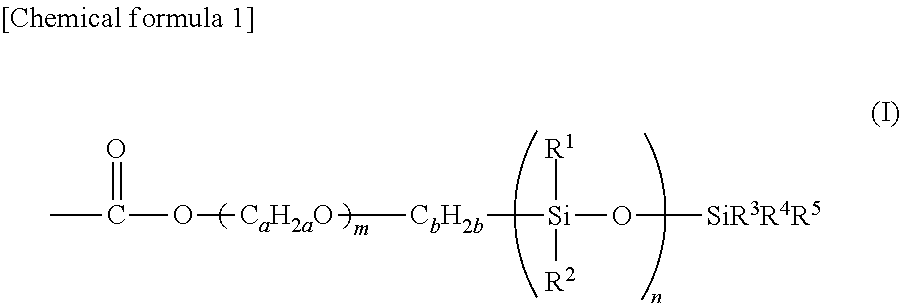

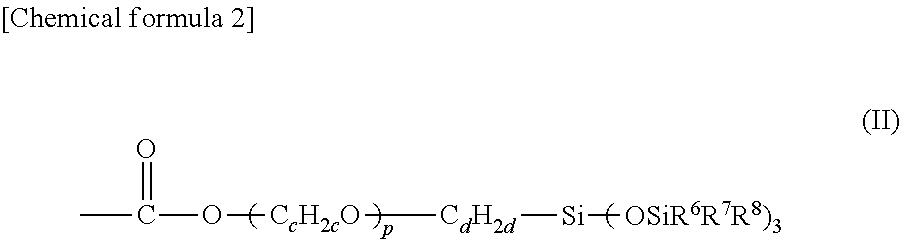

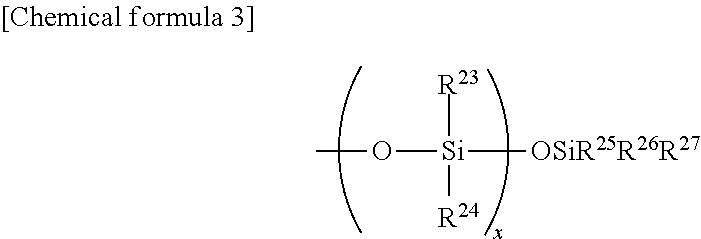

ActiveUS20190300725A1Good storage stabilityAnti-sagging propertyVessel cleaningAntifouling/underwater paintsSiliconPolymer chemistry

Provided are a coating composition containing a silicon atom-containing resin and an anti-sagging agent, a coating film formed from the same, an in-water structure and a ship including the coating film. In the coating composition, the silicon atom-containing resin includes a constituent unit (A) derived from a monomer (a) having at least one kind of silicon atom-containing group selected from the group consisting of groups represented by the formula (I), the formula (II), the formula (III), and the formula (IV), the monomer (a) has a molecular weight of greater than or equal to 400 and less than or equal to 2500, and the content of the anti-sagging agent is greater than or equal to 0.7 parts by mass and less than or equal to 3.6 parts by mass with respect to 100 parts by mass of the silicon atom-containing resin.

Owner:NIPPON PAINT MARINE COATINGS

Grease compositions

The invention relates to a grease composition including a base oil and a thickener that provides hydrophilic metal oxide particles and one or more amides which contain one or more unsaturated C—C bonds and / or at least one OH group. The hydrophilic metal oxide particles have a BET specific surface area of at least 10 m2 / g and at least 80% of the hydrophilic metal oxide particles have a particle size in the range of from 5 nm to 900 μm. The amount of the thickener is in the range of from 0.1-40% by weight, based on the total weight of the grease composition. The invention further relates to methods for manufacturing the grease composition, and the use of the grease composition for lubricating bearings, gears and couplings.

Owner:AB SKF

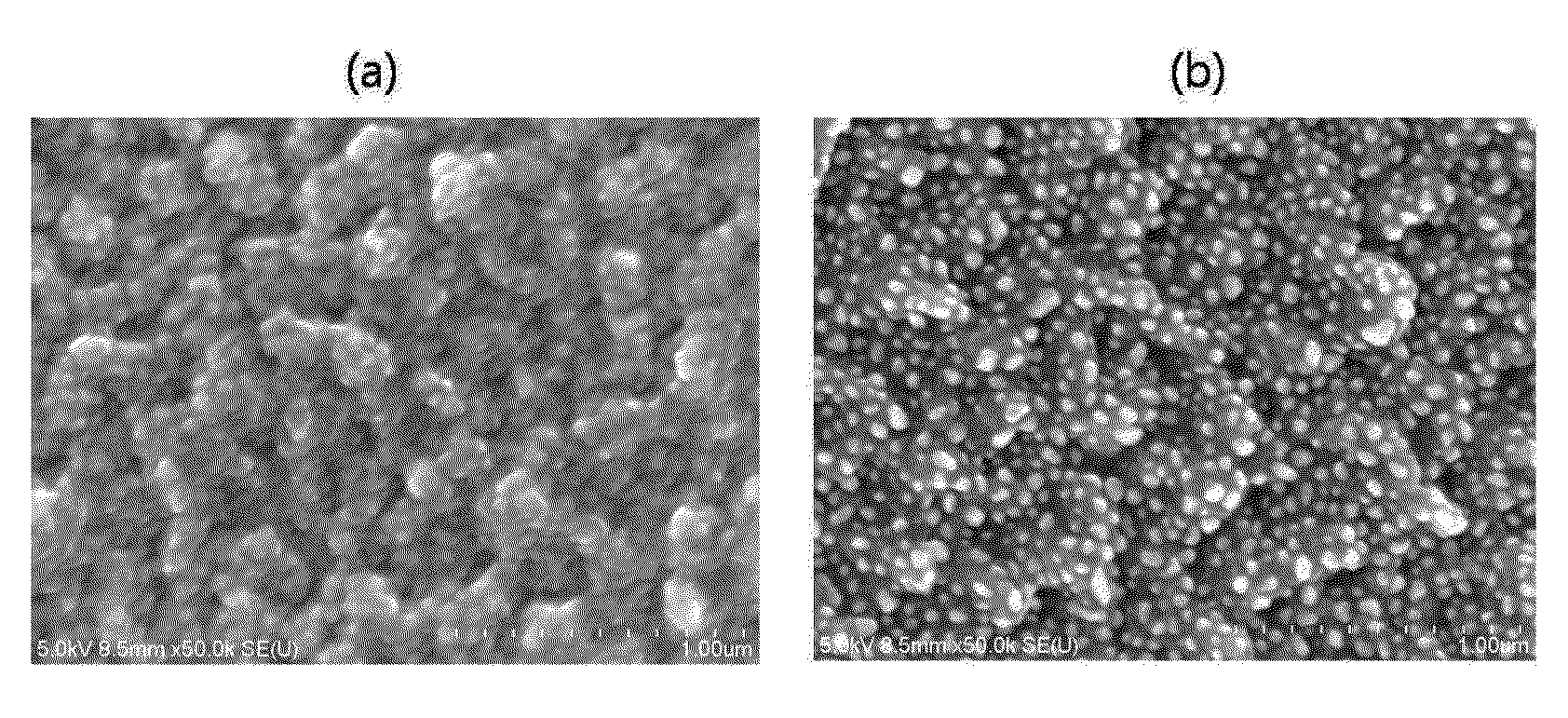

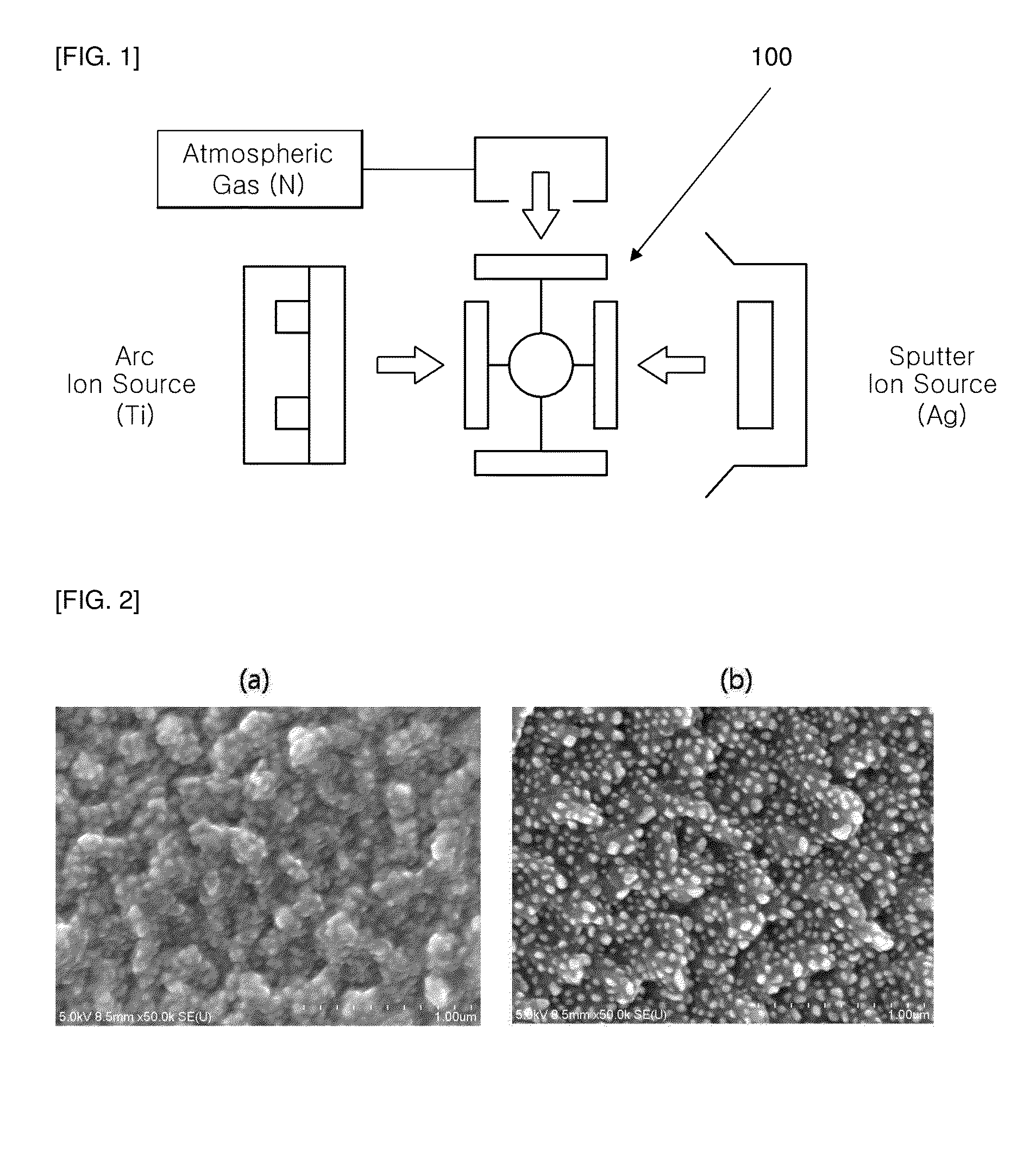

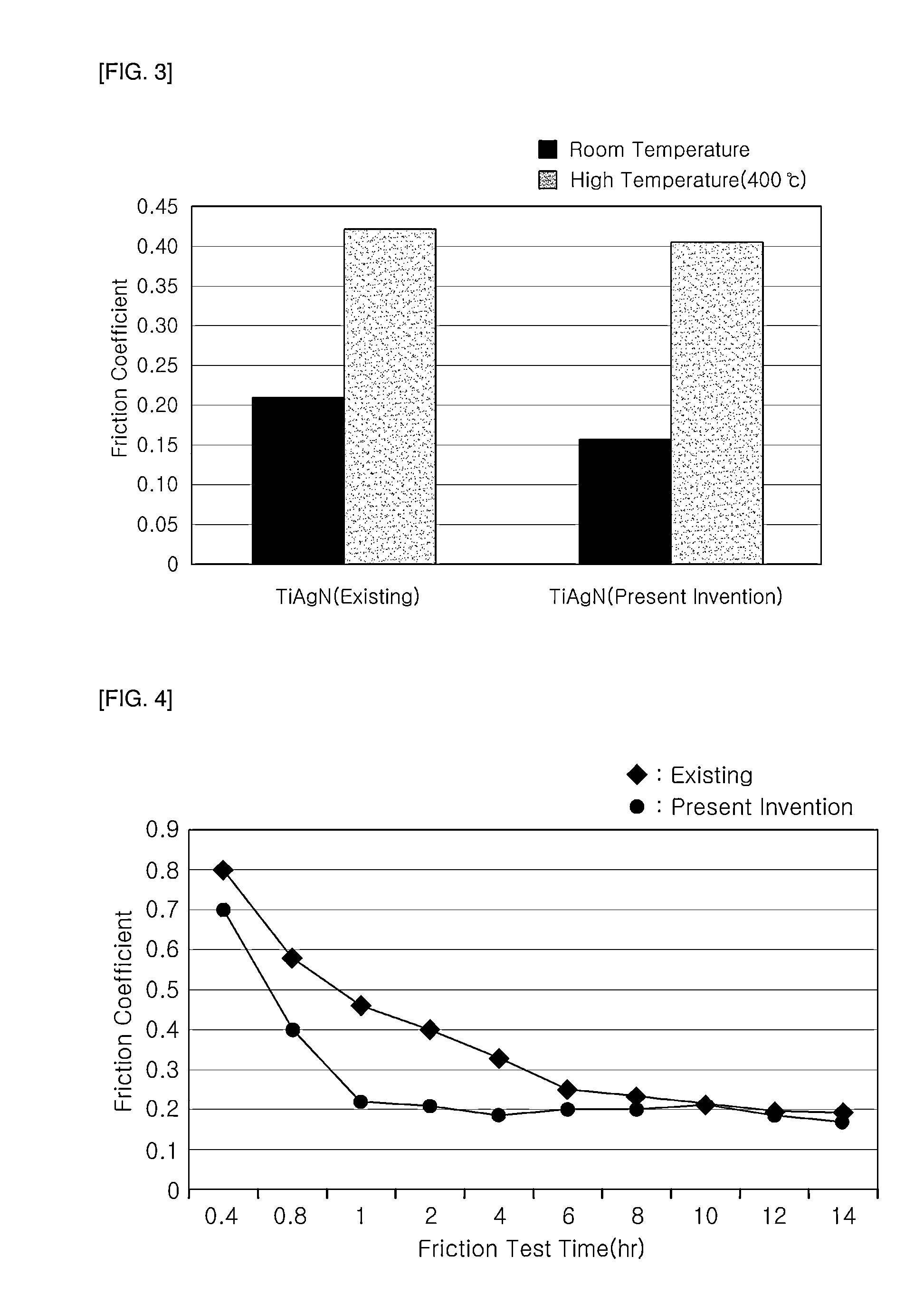

Method for producing coating layer with low-friction

InactiveUS20130136896A1Excellent low frictionElectric discharge tubesLayered productsSputteringMetallurgy

In a method for producing a coating layer using plasma which includes heating, buffer layer coating, coating and cooling, a method for producing a coating layer with low-friction comprises: a coating step of forming TiAgN coating layer on the surface of a base material using Ti arc source and Ag sputtering source at a certain coating temperature; a fraction increase step of increasing the Ag fraction on the surface by increasing bias voltage and sputtering power for a certain time period; and a nano-forming step of forming Ag nanoparticles on the surface by maintaining the temperature at 50˜100° C. higher than the certain coating temperature for a certain time period.

Owner:HYUNDAI MOTOR CO LTD

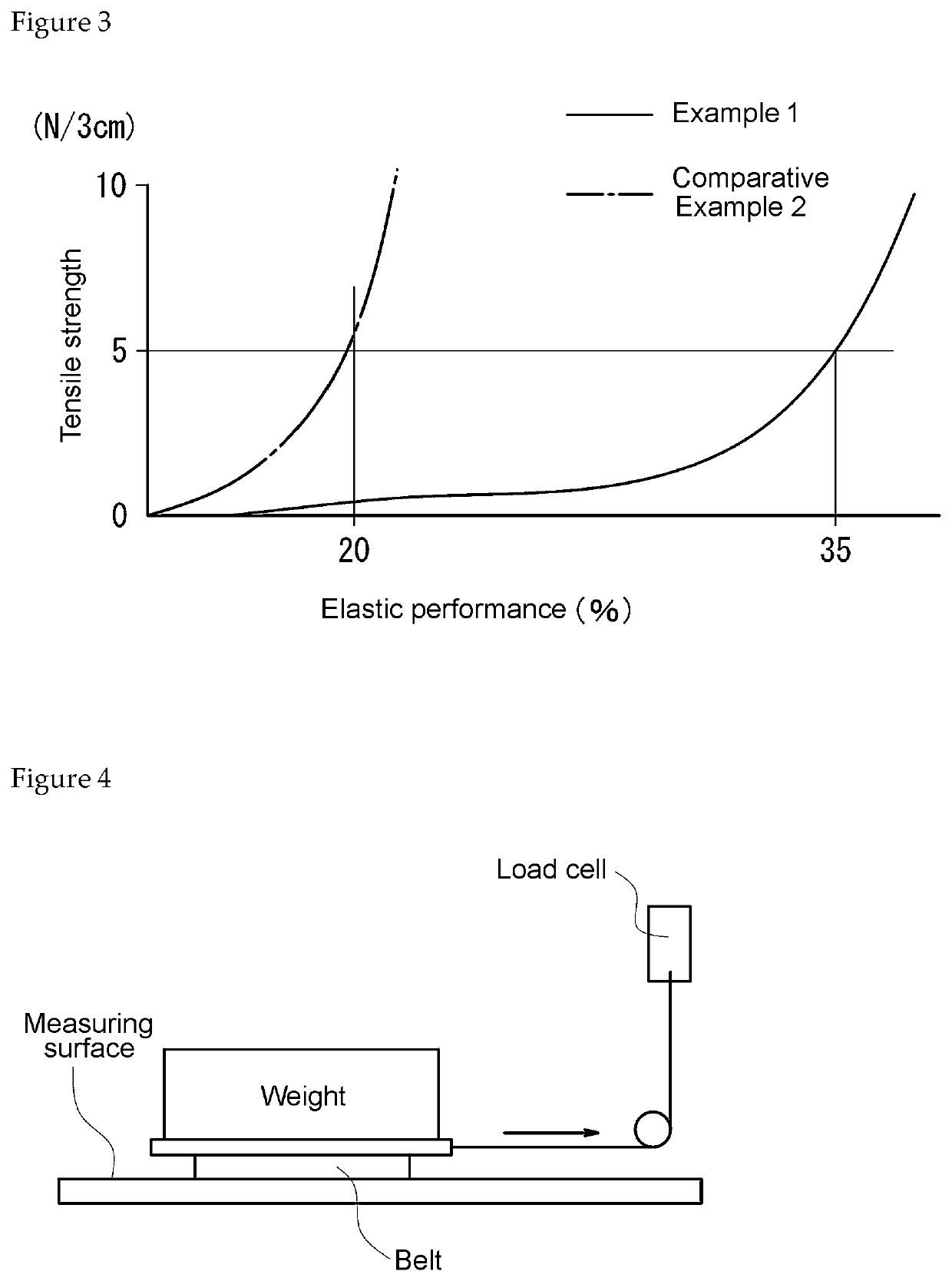

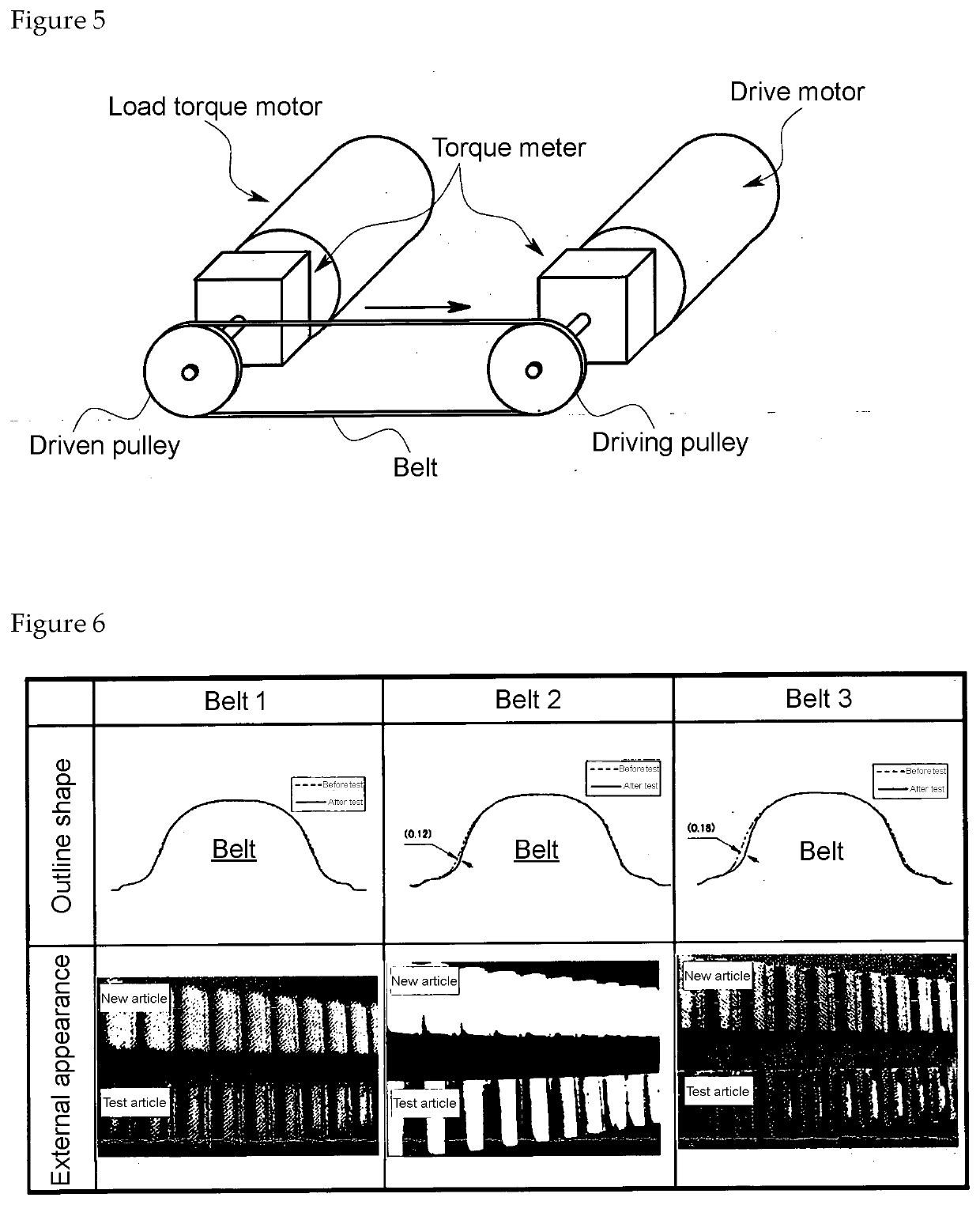

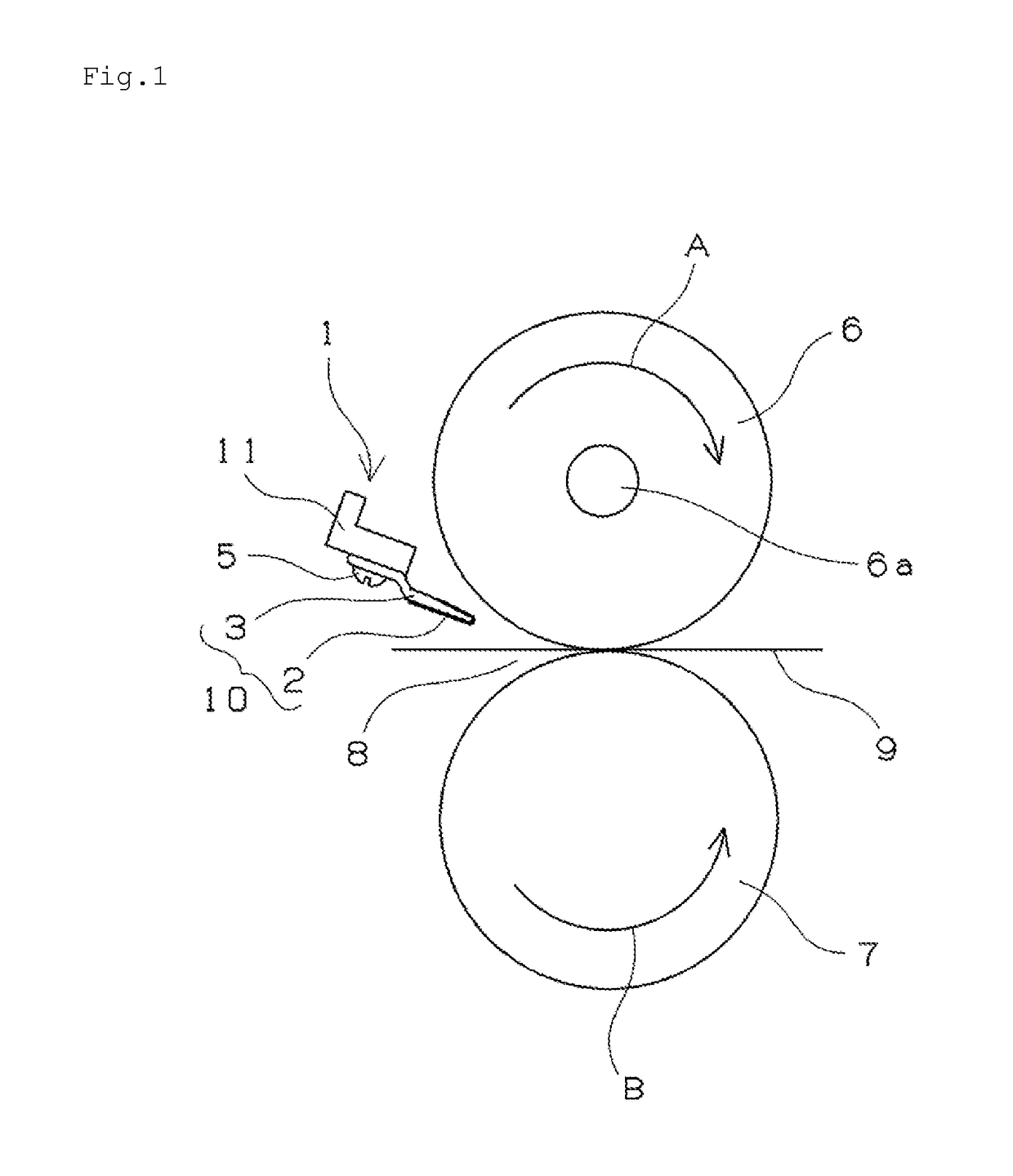

Resin belt

InactiveUS20200080618A1Improve wear resistanceExcellent low frictionDriving beltsWoven fabricsFiberPolymer science

A resin belt includes: a plurality of teeth disposed at predetermined intervals along a longitudinal direction of the belt on a running surface of a belt body made of a thermoplastic resin; and a cloth covering the teeth, characterized in that: the cloth is a woven cloth obtained by weaving a thermoplastic synthetic resin fiber used as a warp yarn in the longitudinal direction of the belt and a fluorine resin fiber used as a weft yarn in a width direction of the belt; and a percentage of the fluorine resin fiber exposed on a side of a cloth surface of the teeth is 50% or more per unit area, and a percentage of the fluorine resin fiber exposed on a side of a bonded surface with the belt body is 50% or less per unit area.

Owner:NOK CORP +1

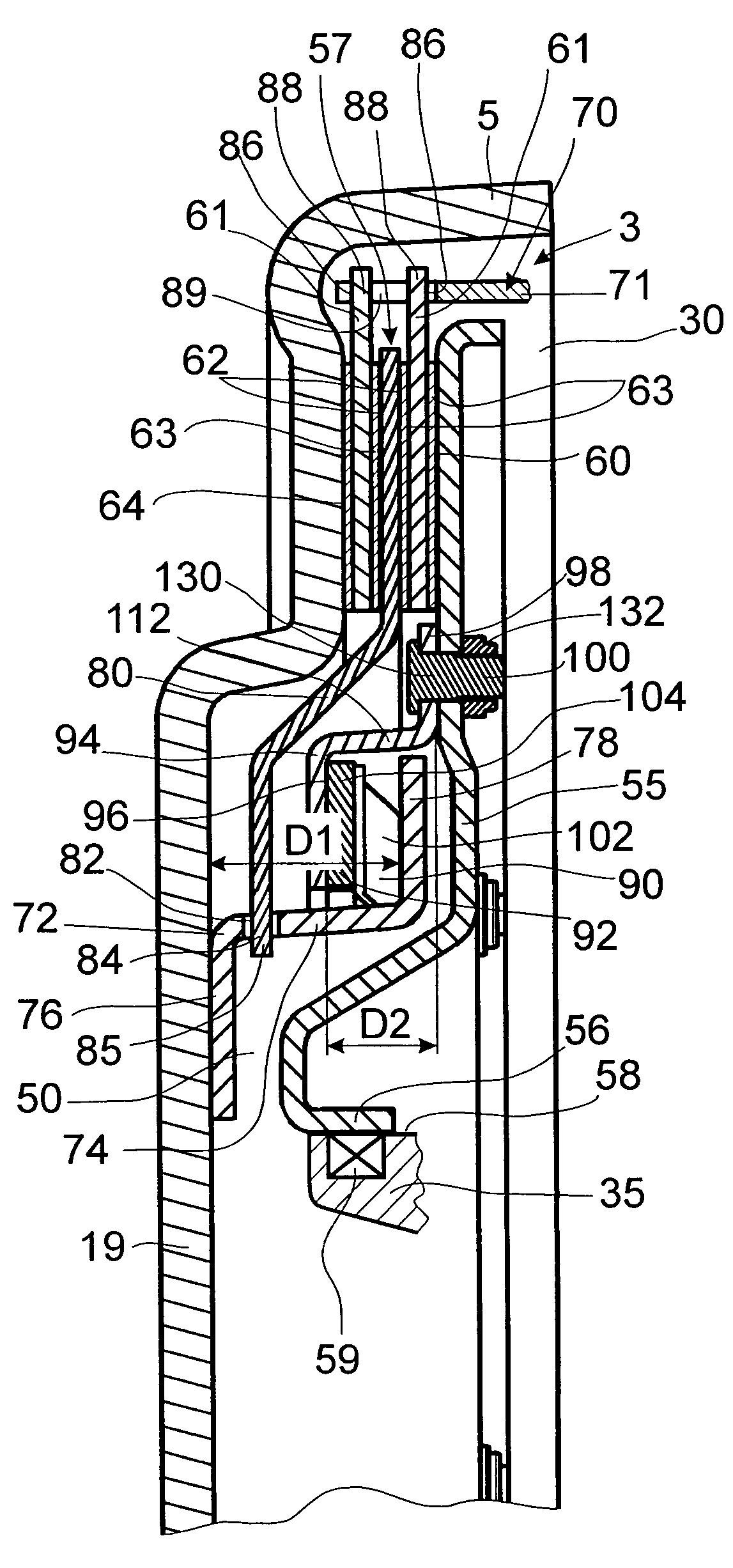

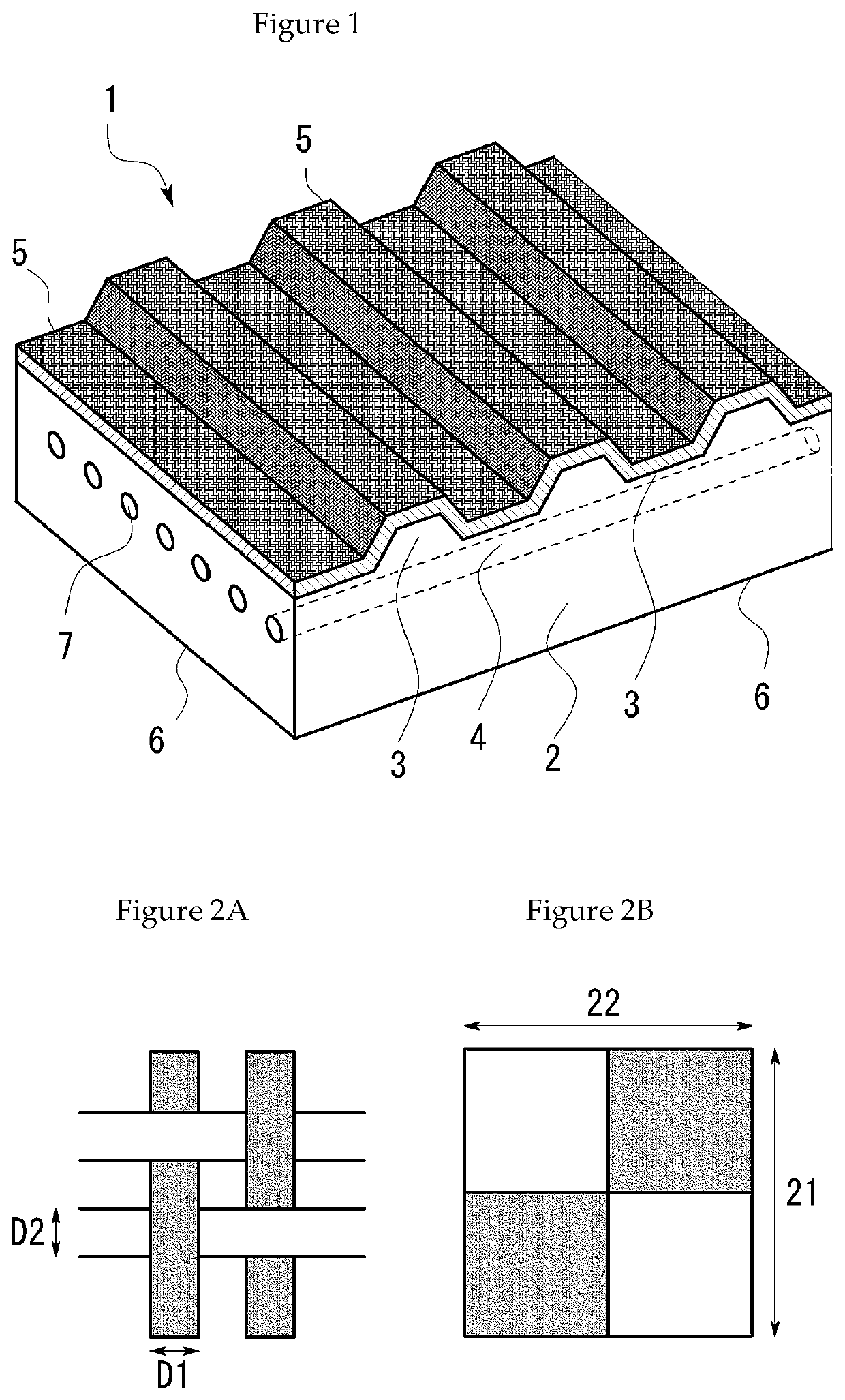

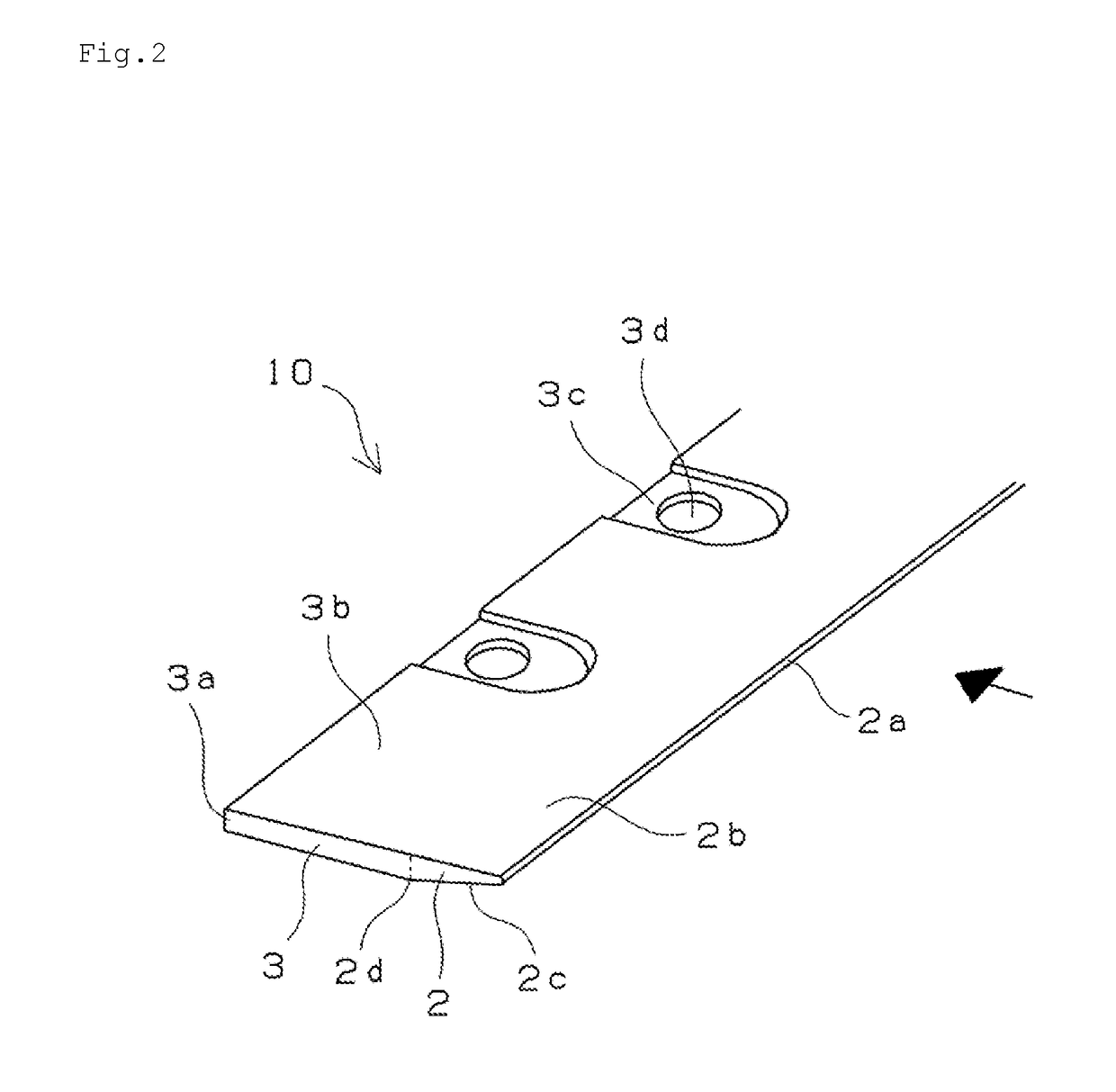

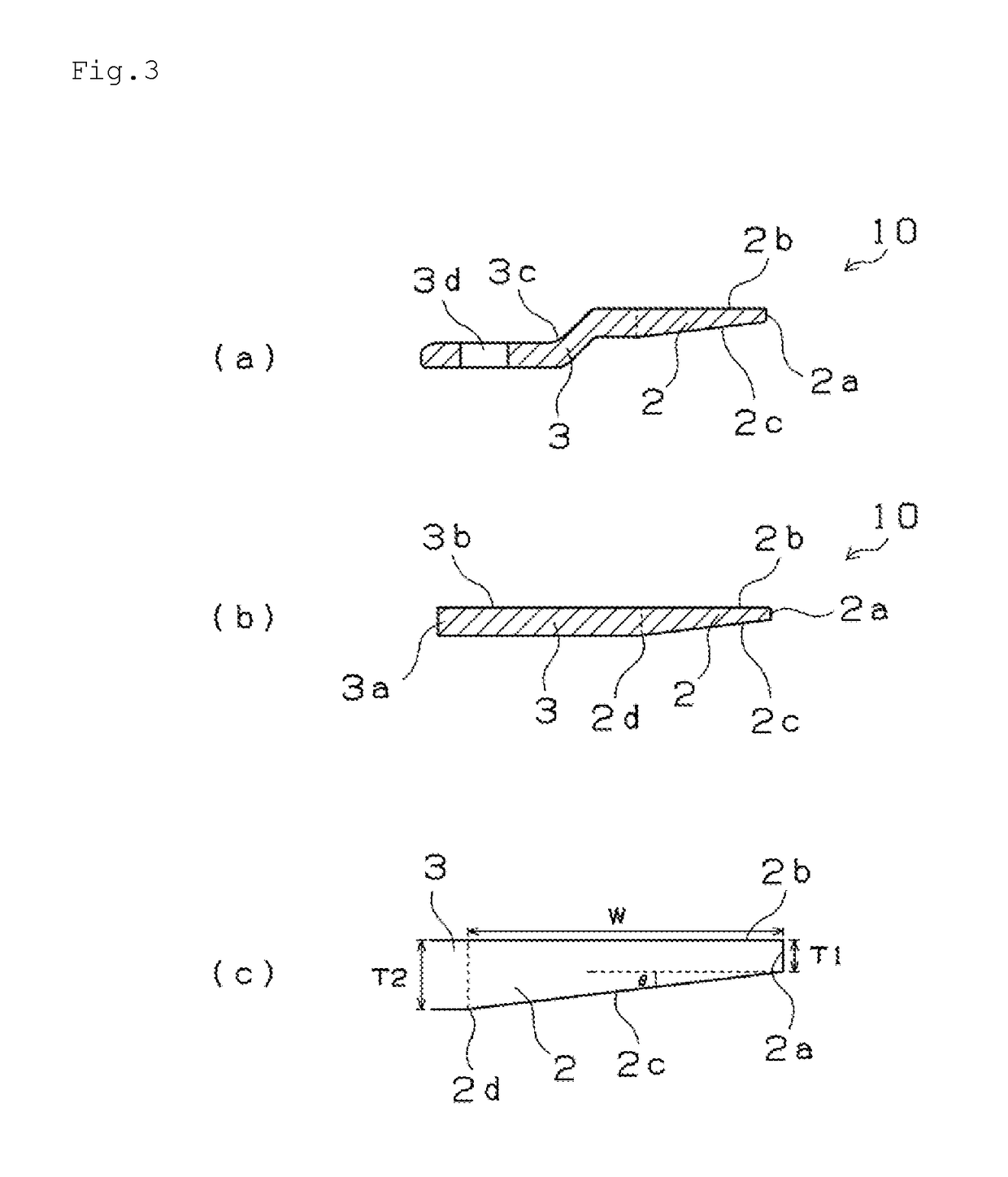

Peeling member and peeling device

InactiveUS20180373192A1Excellent peelabilityEasy to insertElectrographic process apparatusCorona dischargePulp and paper industryWave phenomenon

To provide a peeling member capable of suppressing a waving phenomenon of a peeling sheet, contacting linearly with a roller sufficiently, preventing deformation due to jamming of a paper and showing excellent paper peeling performance, and to provide a peeling device provided with the peeling member . The peeling member includes a peeling sheet 10 that peels a paper from a fixing roller 6 of an electronic photographic device. The peeling sheet 10 is formed of one metal plate, the peeling sheet 10 including a peeling portion 2 that forms the distal end portion, and a support potion 3 that is thicker than the peeling portion 2. The peeling portion 2 is arranged at one long side of the metal plate such that a paper passing surface 2b of the peeling portion 2 is formed as a flat surface continued to a surface of the support portion 3 and an opposite paper passing surface of the peeling portion 2 is formed as an inclined surface 2c inclined against the paper passing surface 2b such that a thickness of the peeling portion 2 is increased from a most distal end portion 2a of the peeling portion 2 toward a boundary portion 2d the peeling portion 2 and the support portion 3. The inclined surface 2c is arranged at a side of the fixing roller 6. A distance D1 between the most distal end portion 2a and the roller and a distance D2 between the boundary portion 2d and the roller fulfil a relation of D1≤D2≤5×D1.

Owner:NTN CORP

Coating composition and coating film formed from the same

ActiveUS10487216B2Excellent low frictionGood storage stabilityVessel cleaningAntifouling/underwater paintsPolymer scienceOrganic chemistry

Provided are a coating composition containing a silicon atom-containing resin and an anti-sagging agent, a coating film formed from the same, an in-water structure and a ship including the coating film. In the coating composition, the silicon atom-containing resin includes a constituent unit (A) derived from a monomer (a) having at least one kind of silicon atom-containing group selected from the group consisting of groups represented by the formula (I), the formula (II), the formula (III), and the formula (IV), the monomer (a) has a molecular weight of greater than or equal to 400 and less than or equal to 2500, and the content of the anti-sagging agent is greater than or equal to 0.7 parts by mass and less than or equal to 3.6 parts by mass with respect to 100 parts by mass of the silicon atom-containing resin.

Owner:NIPPON PAINT MARINE COATINGS

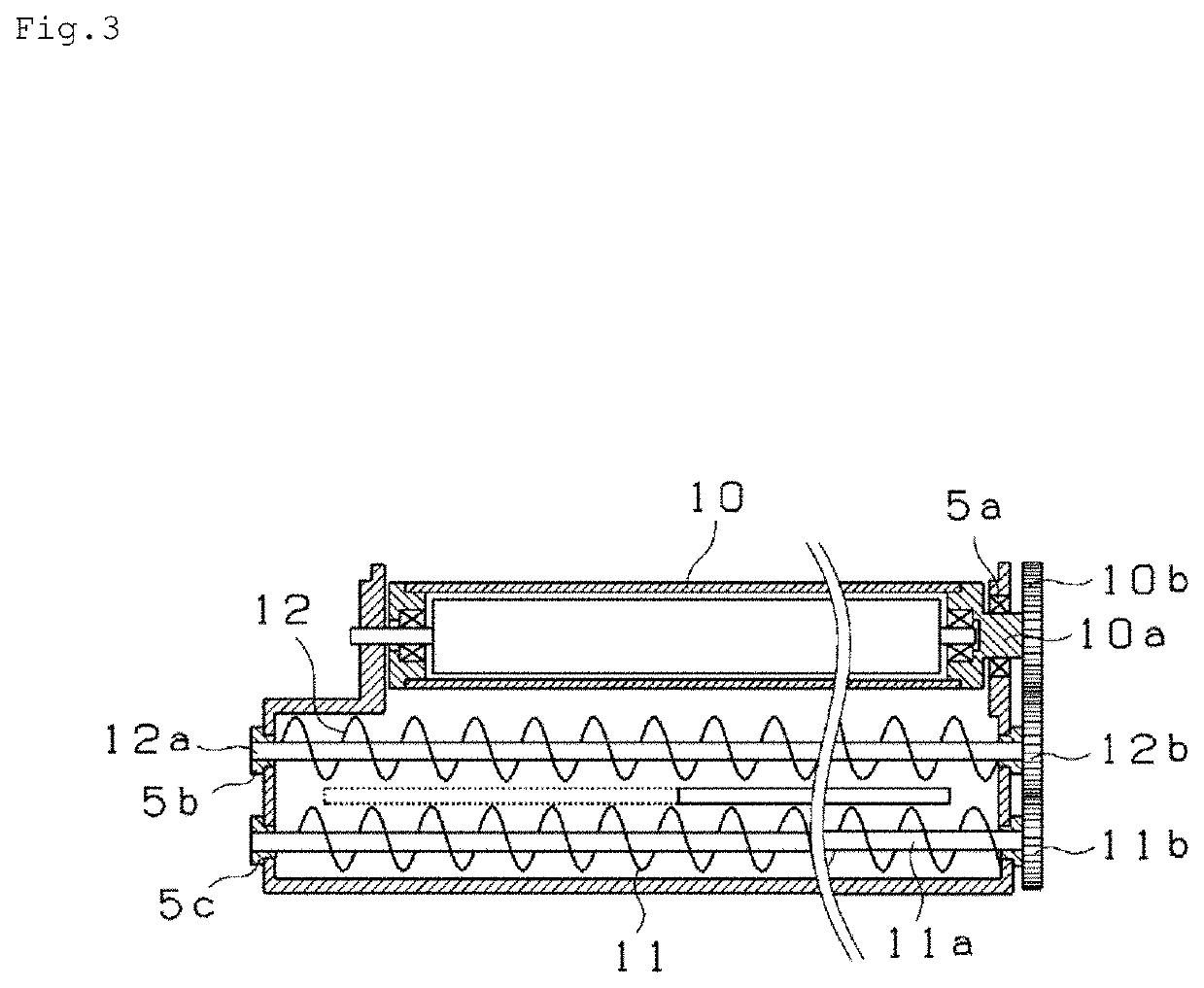

Sliding bearing, bearing apparatus, and image forming apparatus

ActiveUS11346398B2Excellent low frictionReduce frictionShaftsElectrographic process apparatusPolymer scienceContinuous use

To provide a non-oil-impregnated sliding bearing having superior low friction capable of suppressing an increase of a shaft temperature in a continuous use, and a bearing apparatus and an image forming apparatus provided with the sliding bearing. Sliding bearings 5a to 5c support rotation shafts on cylinder inner surface in a rotatable manner. Each of the sliding bearings 5a to 5c is formed of a molded member of a non-oil-impregnated resin composition that does not contain oil. The resin composition contains an injection-moldable ultrahigh molecular weight polyethylene resin as a base resin, a polytetrafluoroethylene resin as an additive, and an acicular inorganic filler having Mohs hardness of 3 or less. The resin composition contains 65 vol % or more of the ultrahigh molecular weight polyethylene resin, 5-25 vol % of the polytetrafluoroethylene resin, and 1-20 vol % of the acicular inorganic filler, based on the whole of the resin composition.

Owner:NTN CORP

Lubricating oil additive and lubricating oil composition

InactiveUS8481467B2Excellent low frictionImprove suppression propertiesOrganic chemistryLiquid carbonaceous fuelsCombustionChemical composition

Lubricating oil compositions have low friction properties and anti-wear properties and are excellent in long drain capability. The lubricating oil compositions are particularly suitable for use as a fuel efficient type lubricating oil for internal combustion engines. The lubricating oil compositions contain a lubricating oil additive comprising one or more compounds selected from a specific nitrogen-containing compound, an acid-modified derivative thereof, and an oil soluble metal complex obtained by mixing the nitrogen-containing compound and / or acid-modified derivative thereof with an organic metal salt and / or organic metal complex.

Owner:NIPPON OIL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com