Cable clamp bolt for suspension bridge and surface treatment method of cable clamp bolt for suspension bridge

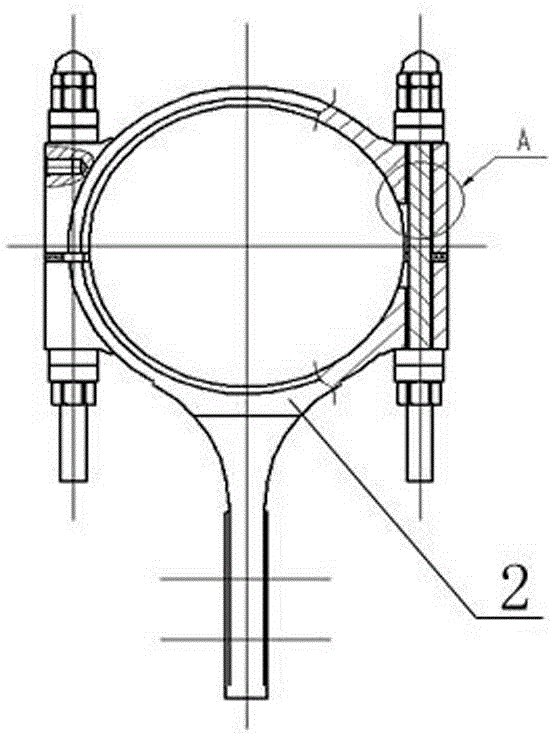

A technology for suspension bridges and bolts, which is applied to special surfaces, pretreatment surfaces, and devices for coating liquids on surfaces, etc., can solve the problem that the galvanized layer of the screw is easily corroded by salt spray, cannot achieve maintenance and anti-corrosion, and the construction period of the cable bridge is long. and other problems, to achieve the effect of reducing bridge maintenance costs, simplifying bridge construction steps, and reducing bridge construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

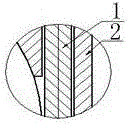

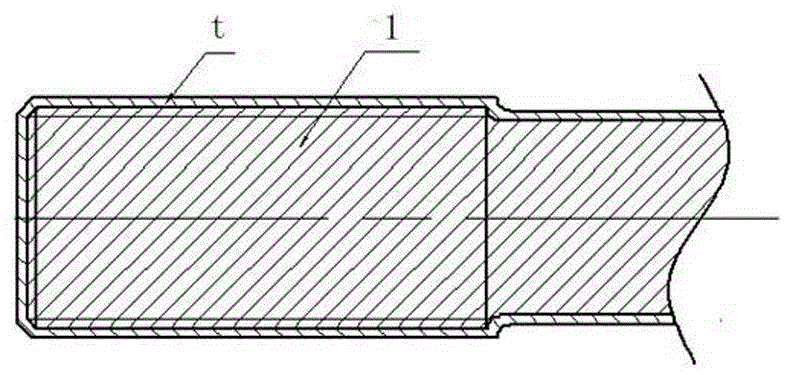

[0035] In the suspension bridge cable clip bolt in this specific embodiment, the surface of the bolt 1 has a Teflon penetration layer t with a depth of 10 μm. The surface treatment method for the cable clamp bolt 1 of the suspension bridge comprises steps:

[0036] (1) The cable clamp bolt 1 is manufactured, and the size and performance are qualified;

[0037] (2) Clean the surface of cable clamp bolt 1;

[0038] (3) Spray the coating of the corrosion-resistant layer on the surface of the cable clamp bolt 1, wherein: the angle between the spray beam of the paint sprayed by the spray gun and the surface of the cable clamp bolt 1 is 70°, the distance between the spray gun and the workpiece is 150mm, and the spraying speed is 100mm / s, there is more than 20% overlap of adjacent spraying tracks;

[0039] (4) Curing and sintering the coating to form a Teflon permeable layer t, wherein: the sintering temperature is 330° C., and the sintering time is 5 days.

[0040] (5) After coo...

Embodiment 2

[0042] In the suspension bridge cable clip bolt in this specific embodiment, the surface of the bolt 1 has a Teflon penetration layer t with a depth of 20 μm. The surface treatment method for the cable clamp bolt 1 of the suspension bridge comprises steps:

[0043] (1) The cable clamp bolt 1 is manufactured, and the size and performance are qualified;

[0044] (2) Clean the surface of cable clamp bolt 1;

[0045] (3) Spray the coating of the corrosion-resistant layer on the surface of the cable clamp bolt 1, wherein: the angle between the spray beam of the paint sprayed by the spray gun and the surface of the cable clamp bolt 1 is 90°, the distance between the spray gun and the workpiece is 200mm, and the spraying speed is 150mm / s, there is more than 20% overlap of adjacent spraying tracks;

[0046] (4) curing and sintering the coating to form a Teflon permeable layer t, wherein: the sintering temperature is 380° C., and the sintering time is 3 days.

[0047] (5) After coo...

Embodiment 3

[0049] In the suspension bridge cable clip bolt in this specific embodiment, the surface of the bolt 1 has a Teflon penetration layer t with a depth of 10 (10-20, please give a preferred value) μm. The surface treatment method for the cable clamp bolt 1 of the suspension bridge comprises steps:

[0050] (1) The cable clamp bolt 1 is manufactured, and the size and performance are qualified;

[0051] (2) Clean the surface of cable clamp bolt 1;

[0052] (3) Spray the coating of the corrosion-resistant layer on the surface of the cable clamp bolt 1, wherein: the angle between the spray beam of the paint sprayed by the spray gun and the surface of the cable clamp bolt 1 is 70°, the distance between the spray gun and the workpiece is 200mm, and the spraying speed is 150mm / s, there is more than 20% overlap of adjacent spraying tracks;

[0053] (4) Curing and sintering the coating to form a Teflon permeable layer t, wherein: the sintering temperature is 350° C., and the sintering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com