Hydrophilic type super-lubricity urinary catheter and preparation method thereof

A hydrophilic, super-slip technology, applied in catheters and other directions, can solve the problems of increased production costs, difficult quality control, high manufacturing costs, etc., and achieve the effects of convenient processing, simple processing technology, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

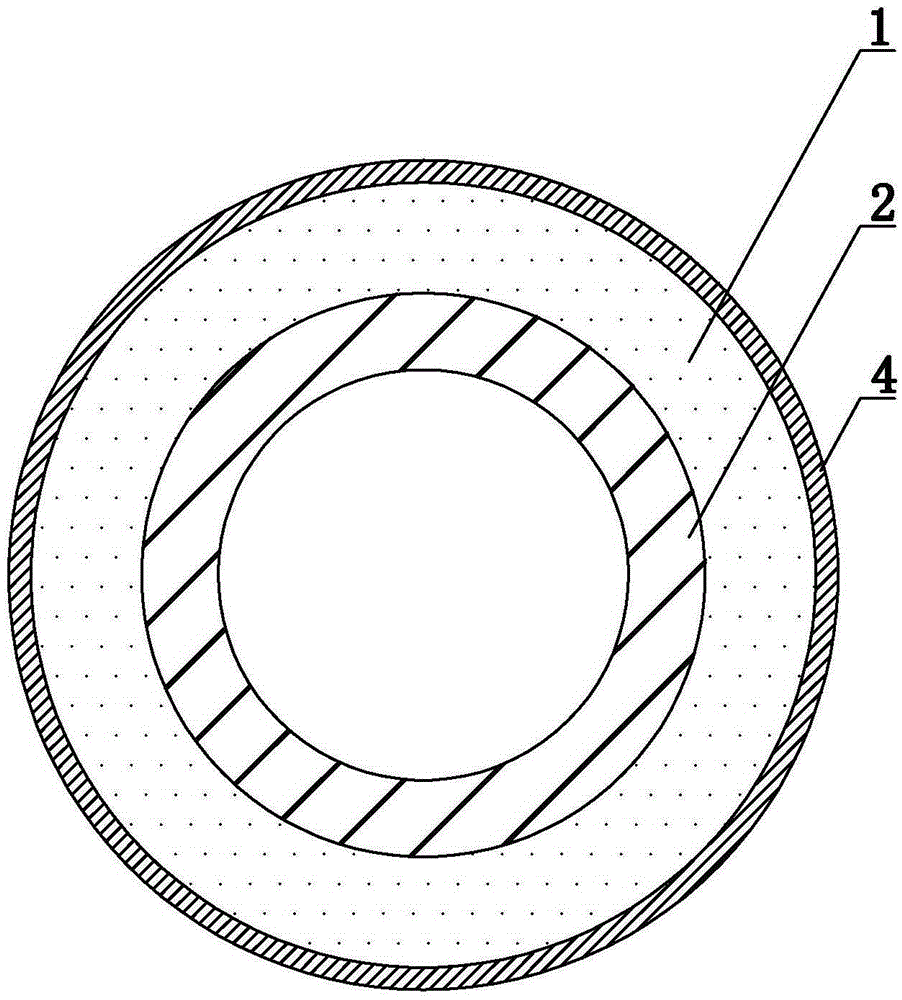

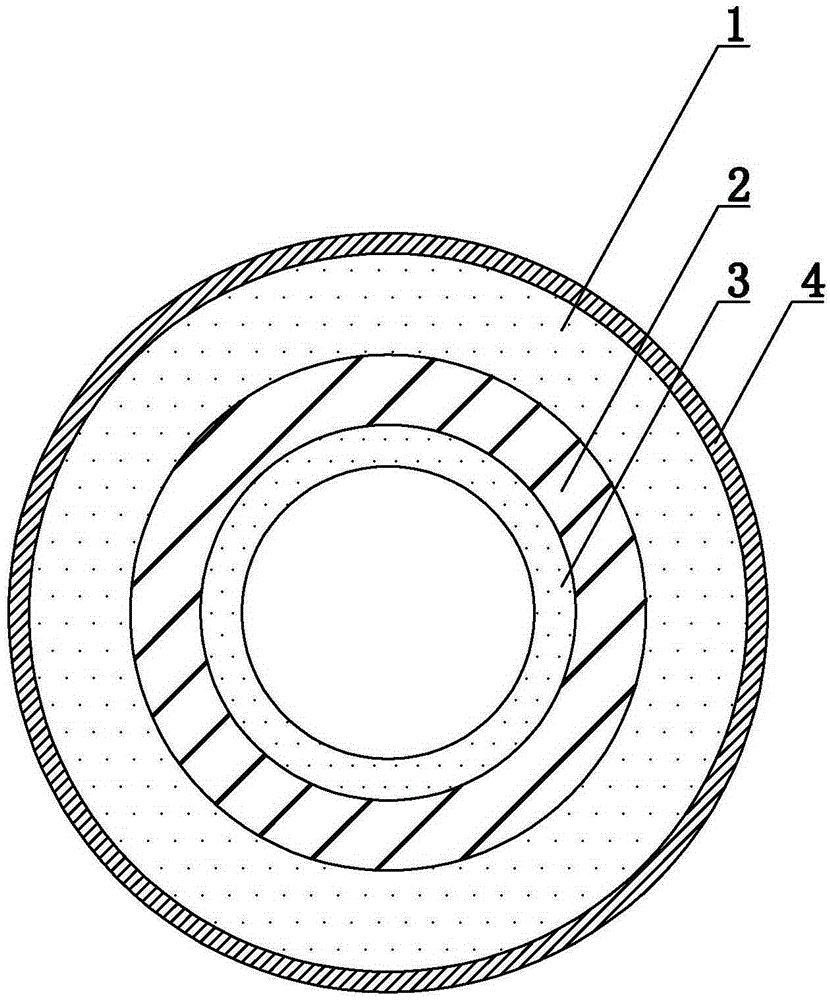

[0030] The present embodiment hydrophilic type ultra-slippery catheter combines figure 1 , consisting of a polyurethane polymer outer layer 1, a tube main body layer 2 and a hydrophilic super-slip coating 4, the outer side of the polyurethane polymer outer layer 1 is a hydrophilic super-slip coating 4, and the inner side is provided with a tube main body layer 2, and The polyurethane polymer outer layer 1 is arranged concentrically with the pipe main body layer 2, wherein, in this embodiment, the polyurethane polymer outer layer 1 has a thickness of 0.05-0.5 mm, and the pipe main body layer 2 has a thickness of 0.1-1 mm; the polyurethane polymer outer layer 1 It is made of polyester polyurethane, the pipe main body layer 2 is made of PVC, and the hydrophilic super slippery coating 4 is formed of hydrophilic high molecular polymer, adhesive polymer, film forming agent and solvent The solution is dried, wherein the hydrophilic polymer is polyvinylpyrrolidone, the adhesive polyme...

Embodiment 2

[0036] The setting and working principle of this embodiment are the same as those of Embodiment 1, the difference is that in this embodiment, the basic pipe body is formed integrally by dipping: the pipe main body layer 2 is dipped in polyurethane polymer, so that on the pipe main body layer 2 Covered with an outer layer of polyurethane polymer 1 .

[0037] The hydrophilic super-slip coating 4 is set on the base pipe body by dipping: insert the base pipe body into the hydrophilic super-slip coating solution, dip for 5-60 seconds, and then dry it.

Embodiment 3

[0039] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that in this embodiment, the basic pipe body is integrally formed by spraying: the polyurethane polymer is sprayed on the pipe main body layer 2, so that it is formed on the pipe main body layer 2 is covered to form a layer of polyurethane polymer outer layer 1.

[0040] The hydrophilic super-slip coating 4 is set on the base pipe body by dipping: insert the base pipe body into the hydrophilic super-slip coating solution, dip for 5-60 seconds, and then dry it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com