Lubricating oil composition for diesel engines

A technology of lubricating oil composition and diesel engine, applied in the directions of lubricating composition, petroleum industry, additives, etc., can solve problems such as piston cleanliness without special concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

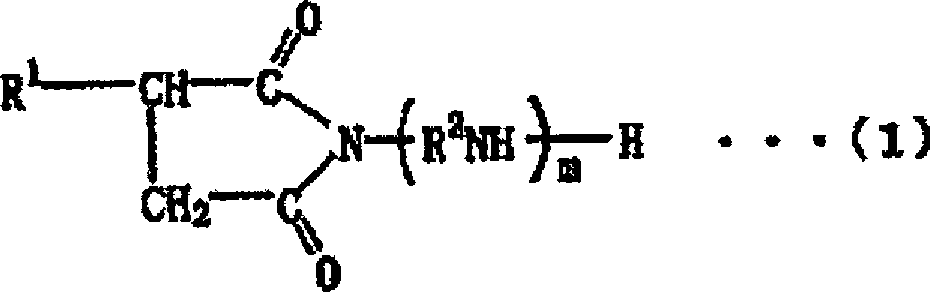

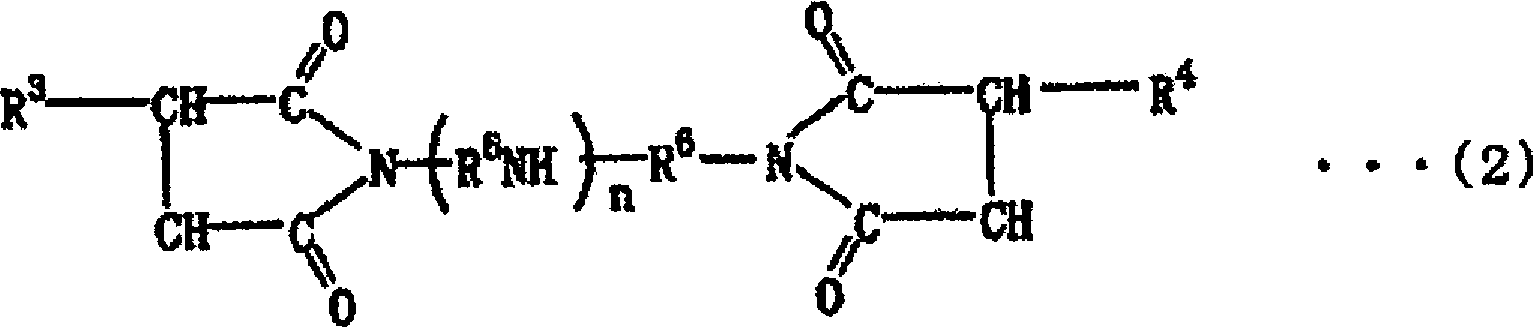

Method used

Image

Examples

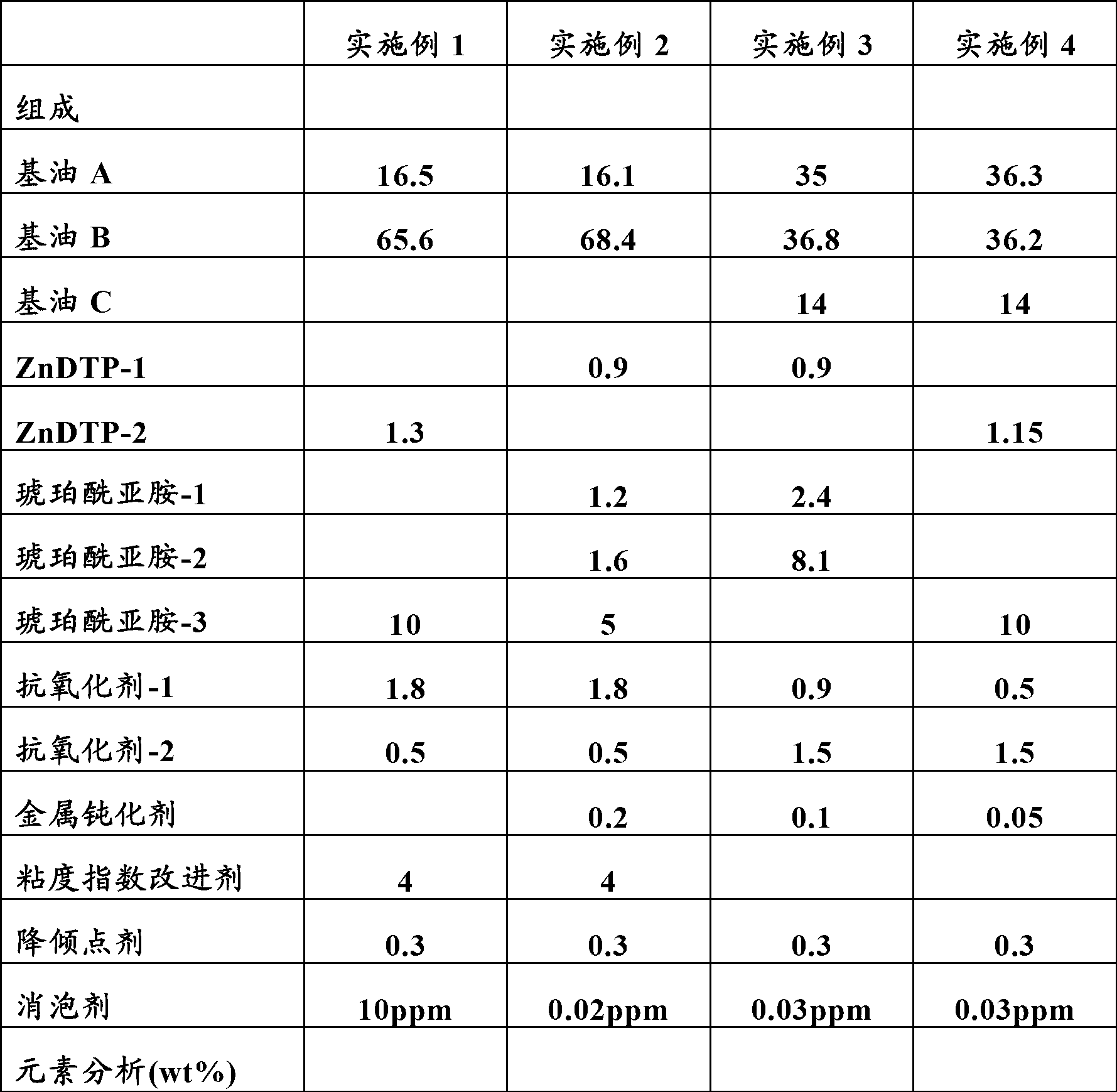

Embodiment 1

[0121] Example 1 did not contain any metal detergent. Succinimide-3 ashless dispersant gives 0.15wt% nitrogen, amine-based antioxidant gives 0.08wt% nitrogen, and succinimide-based dispersant gives 0.047wt% boron, while ZnDTP A Zn amount of 0.10 wt% is given, so that the parameter Zn amount x (nitrogen amount of succinimide+nitrogen amount of amine-based antioxidant) has a value of 0.023, and a TGF of 12% and cam tip wear of 7 μm. In addition, the sulfate ash content is 0.23 wt%, which satisfies the standard, so that satisfactory performance has been obtained.

Embodiment 2

[0122] Example 2 does not use metal detergent. The point is that the total nitrogen content of the mixture of succinimide-1, succinimide-2 and succinimide-3 gives a total nitrogen content of 0.12 wt%, and thus the parameter value is 0.020. The TGF is 12%, and the cam tip wear is 18 μm, which means that satisfactory performance has been achieved.

Embodiment 3

[0123] For Example 3, the nitrogen content of succinimide was 0.15 wt%, and it was a mixture of succinimide-1 and succinimide-2. The Zn amount is 0.1 wt%, and the amine-based antioxidant gives a nitrogen amount of 0.0396 wt%, which means that the parameter value is 0.019. The TGF value was 9% and the cam tip wear was 24.7 μm.

[0124] As in Example 4, when the nitrogen content of the amine-based antioxidant is 0.022wt%, the parameter value is 0.015, TGF is 7% and cam tip wear is 84.9 μm, but this is within the range of satisfactory performance.

[0125] On the other hand, for Comparative Example 1, the succinimide-based dispersant gave a nitrogen amount of 0.075 wt%. In addition, the amount of Zn was 0.077wt%, and no amine-based antioxidant was added, so that the parameter value was significantly reduced to 0.006, the TGF was 47%, and the cam tip wear was significantly increased. In Comparative Example 2, the amount of nitrogen from the succinimide-based dispersant was 0.12 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com