Tread rubber composition and pneumatic tire

A rubber composition and tread technology, which is applied in the field of pneumatic tires and rubber compositions for treads, can solve the problems of tread damage, reduction of rubber rigidity, defects, etc., achieve high grip performance and reduce the occurrence of tire blowouts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

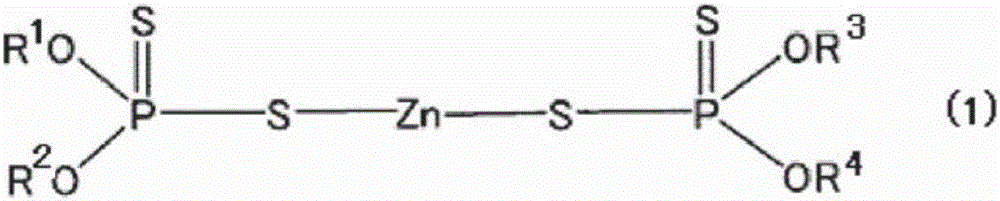

Method used

Image

Examples

preparation example Construction

[0141] In the usual production methods, vulcanizing agents are introduced into the final kneading. However, it is preferable to introduce zinc dithiophosphate into the base kneading in order to improve its dispersibility in the rubber component to produce more uniform crosslinking.

[0142] After the basic kneading step, for example, a final kneading step (in which the prepared kneaded mixture 1 is mixed with a vulcanizing agent such as sulfur ), a vulcanization accelerator, etc.), followed by a vulcanization step (in the vulcanization step, the prepared kneaded mixture 2 (unvulcanized rubber composition) is heated and pressurized at 150° C. to 170° C. for 10 to 30 minutes), by This makes it possible to prepare the rubber composition of the present invention.

[0143] The rubber composition of the present invention is used for a tread of a pneumatic tire. In particular, the rubber composition may be suitable for use in cap treads (which form the outer surface layer of a mult...

Embodiment

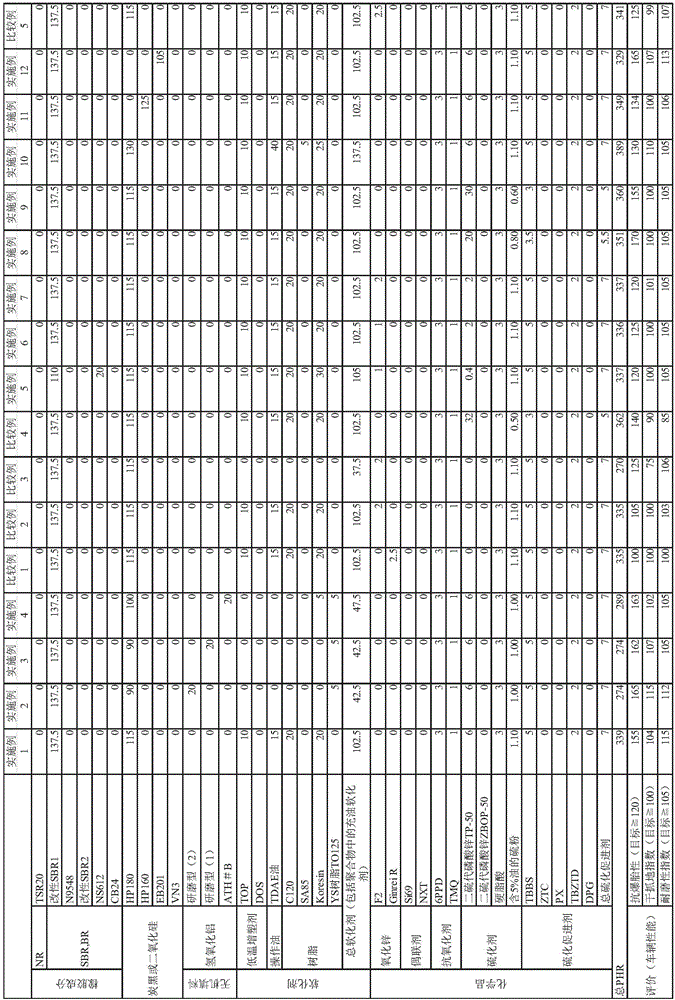

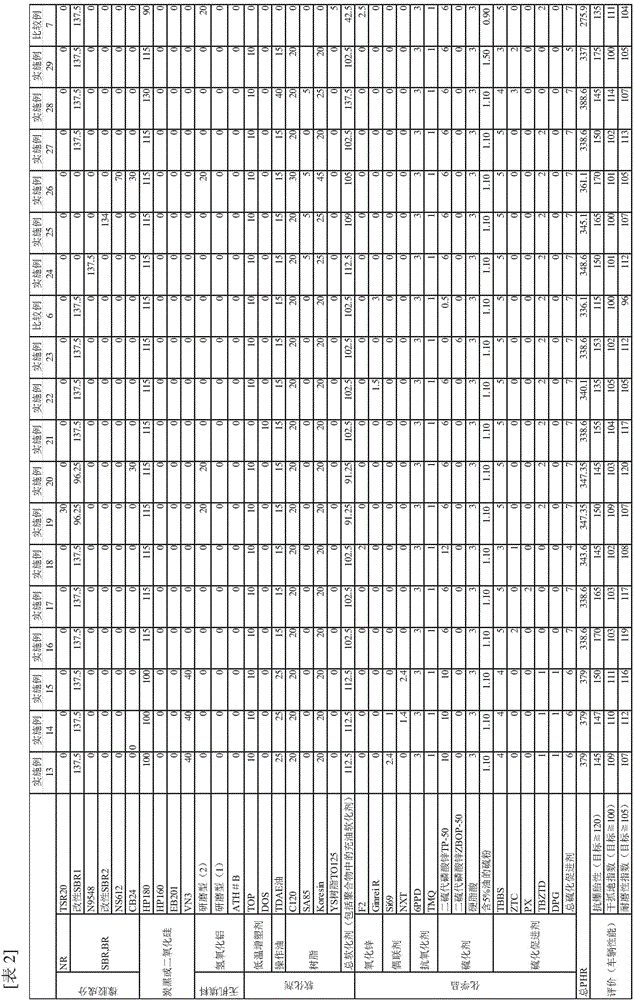

[0148] The invention will be described in more detail with reference to non-limiting examples.

[0149] Chemicals used in Examples and Comparative Examples are listed below.

[0150]

[0151] TSR20

[0152]

[0153] Modified SBR1: a product prepared as follows (oil extender: 37.5 parts, styrene content: 41%, vinyl content: 40%, Tg: -29°C, weight average molecular weight: 1,190,000)

[0154] N9548: Product purchased from Japan Zeon Co., Ltd. (oil extender: 37.5 parts, styrene content: 35%, vinyl content: 18%, Tg: -40°C, weight average molecular weight: 1,090,000)

[0155] Modified SBR2: 0122 available from JSR Corporation (oil extender: 34 parts, styrene content: 36%, vinyl content: 18%, Tg: -44°C, weight average molecular weight: 945,000)

[0156] NS612: Product purchased from Japan Zeon Co., Ltd. (non-oil-extended, styrene content: 15%, vinyl content: 30%, Tg: -65°C, weight average molecular weight: 780,000)

[0157]

[0158] (1) Preparation of chain end modifiers

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com