Lubricant Composition

a technology of lubricant composition and lubricant, applied in the field of lubricant composition, can solve the problems of easy cause of corrosive wear, exponential deterioration of the inhibiting effect of corrosive wear, and easy cause of corrosion, and achieve the effects of excellent long-drain performance, and inhibiting lead corrosion or corrosive wear

Inactive Publication Date: 2008-01-24

NIPPON OIL CORP

View PDF25 Cites 48 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

[0030] The lubricant composition of the present invention, particularly in the case of reduction or nonuse of zinc dithiophosphate which is significantly effective for inhibiting lead corrosion or corrosive wear, can inhibit lead corrosion or corrosive wear and suitably used under a contact with metallic materials containing lead. This lubricant composition is low-sulfur, further, low-phosphorus and low-ash, and is excellent in long drain performance.

[0031] Further, the lubricant composition of the invention that limits the organomolybdenum compounds to a particular compound is excellent in anticorrosive property for both lead and copper. Accordingly, the lubricant composition obtained by adding the above particular compound can effectively inhibit corrosion or corrosive wear of metallic materials containing copper-lead or both of the metallic materials containing copper and metallic materials containing lead, at the same time.

[0032] Thus, the lubricant composition of the invention can be suitably used as a lubricant for internal combustion engine contacting metallic materials containing lead (in the aspect thereof limiting the organomolybdenum compound to a particular one, the lubricant for internal combustion engine contacting metallic materials containing lead, metallic materials containing copper, metallic materials containing lead-copper: hereinafter, these can be described as “metallic materials containing lead and the like”.), especially diesel engine oil and gas engine oil having lead-series slide materials. But also, the lubricant composition of the invention can be suitably used as a lubricant for apparatus having a lubrication system where the lubricant contacts the metallic materials containing lead and the like. The examples include: a lubricant for drive-train such as automatic transmission, manual transmission, continuously variable transmission, and gears; lubricant such as wet-type brake oil, hydraulic oil, turbine oil, compressor oil, bearing oil, and refrigerant oil.

Problems solved by technology

Such metallic materials containing lead have an excellent feature that it has little fatigue phenomena, whereas the material has a fault that the corrosive wear thereof is easily caused.

The reality of cause of corrosion is more complex, as it is controlled by many factors.

Nevertheless, it is known that when the content of zinc dithiophosphate is reduced, the corrosive-wear inhibiting effect of lead is exponentially deteriorated (e.g., Non-Patent Document 6).

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

examples

[0185] Hereinafter, the invention will be more specifically described by way of the following examples and comparative examples. However, it is not limited by such examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Login to View More

Abstract

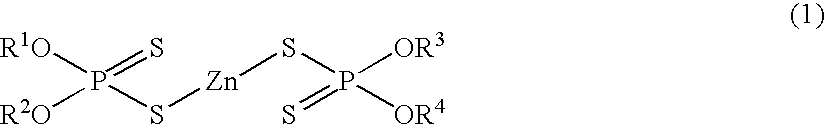

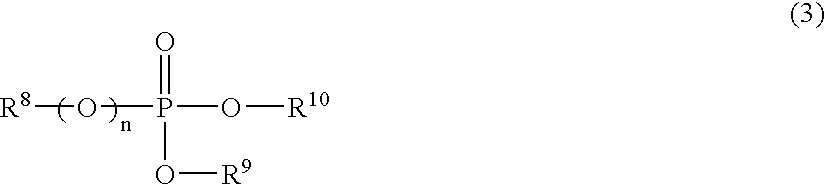

The present invention provide a lubricant composition comprising a lubricant base oil, wherein said lubricant composition contains 0.08% by mass or less of zinc dithiophosphate or no zinc dithiophosphate as phosphorus amount for total amount of said lubricant composition, contacts metallic materials containing lead, and contains at least a kind of additive selected from a group consisting of following (A)˜(D): (A) organomolybdenum compounds (except molybdenum dithiophosphate); (B) borate ester and / or derivatives thereof; (C) organomolybdenum compounds, and borate ester and / or derivatives thereof; and (D) organomolybdenum compounds, and borated alkyl or alkenyl succinimide.

Description

TECHNICAL FIELD [0001] The present invention relates to a lubricant composition that enables to inhibit corrosion or corrosive wear of metallic materials containing lead, metallic materials containing copper-lead, or both of the metallic materials containing lead and metallic materials containing copper. In particular, the present invention relates to a lubricant composition that enables to inhibit corrosion or corrosive wear of the above materials even if the content of zinc dithiophosphate is small. BACKGROUND ART [0002] Slide materials for engine and so on mainly consist of ferrous-series and aluminum-series metallic materials. Among the slide materials, however, for making slide members of main bearing and connecting rod bearing such as bearing metal, not only metallic materials like aluminum, copper, and tin, but also metallic material containing lead and metallic material containing copper-lead are sometimes used. Such metallic materials containing lead have an excellent featu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M129/68C10M133/16C23F11/10

CPCC10M139/00C10M141/12C10N2260/14C10N2240/10C10N2230/42C10M159/18C10M163/00C10M2203/1006C10M2207/02C10M2207/026C10M2207/10C10M2207/126C10M2207/262C10M2207/289C10M2215/02C10M2215/04C10M2215/064C10M2215/08C10M2215/28C10M2219/068C10M2223/04C10M2223/042C10M2223/045C10M2223/049C10M2227/061C10M2227/066C10M2227/09C10N2210/06C10N2230/06C10N2230/10C10N2230/12C10N2010/12C10N2030/06C10N2030/10C10N2030/12C10N2040/25C10N2060/14C10N2030/42

Inventor YAGISHITA, KAZUHIRO

Owner NIPPON OIL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com