Patents

Literature

36results about How to "Maintain friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

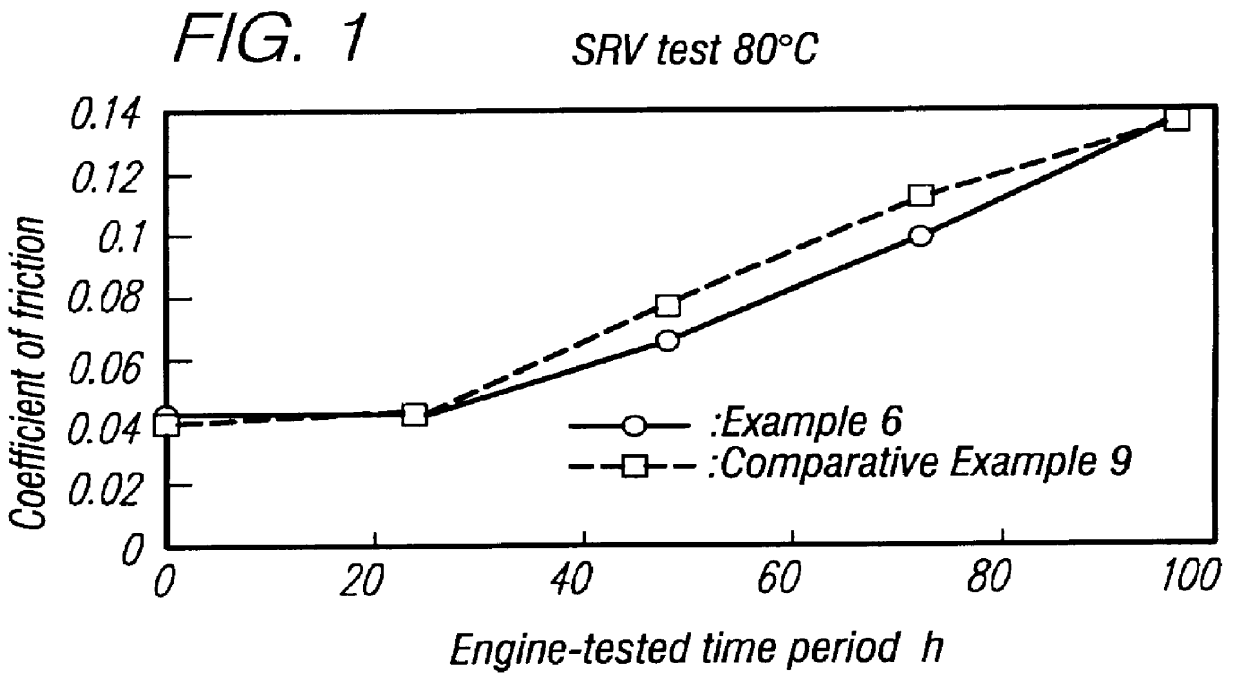

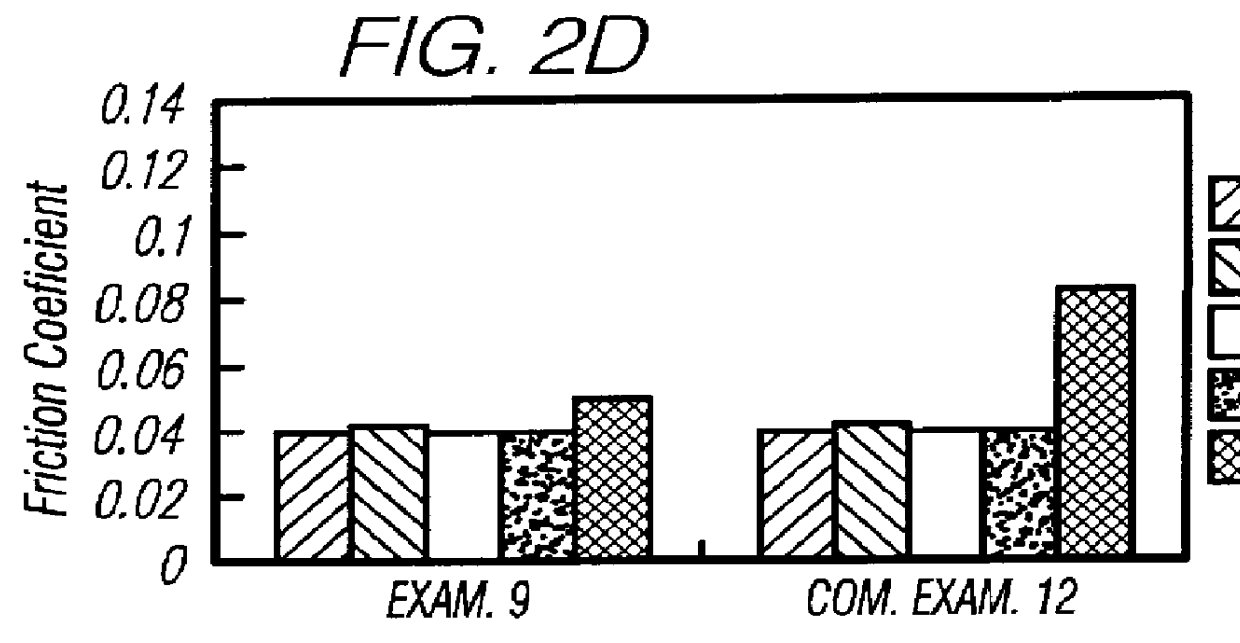

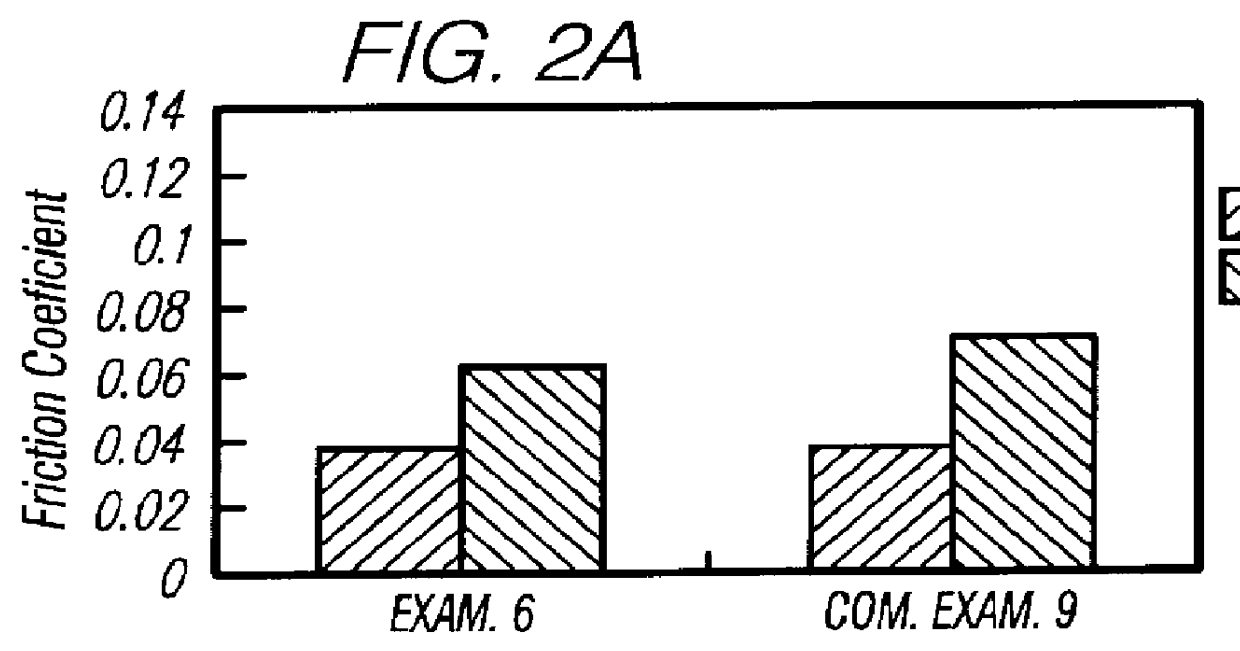

Engine oil composition

An engine oil composition is composed of: (1) at least one oil selected from the group consisting of a mineral oil and a synthetic lubricant as a base oil; (2) a molybdenum dithiocarbamate in an amount of 50 to 2000 ppm by weight when calculated as molybdenum (Mo), relative to the total weight of the engine oil composition; (3) zinc dithiophosphate in an amount of 0.01 to 0.2 wt % when calculated as phosphorus (P), relative to the total amount of the engine oil composition; and (4) an ashless organic polysulfide compound in an amount of 0.01 to 0.4 wt % when calculated as sulfur (S), relative to the total amount of the engine oil composition.

Owner:JAPAN ENERGY CORP +1

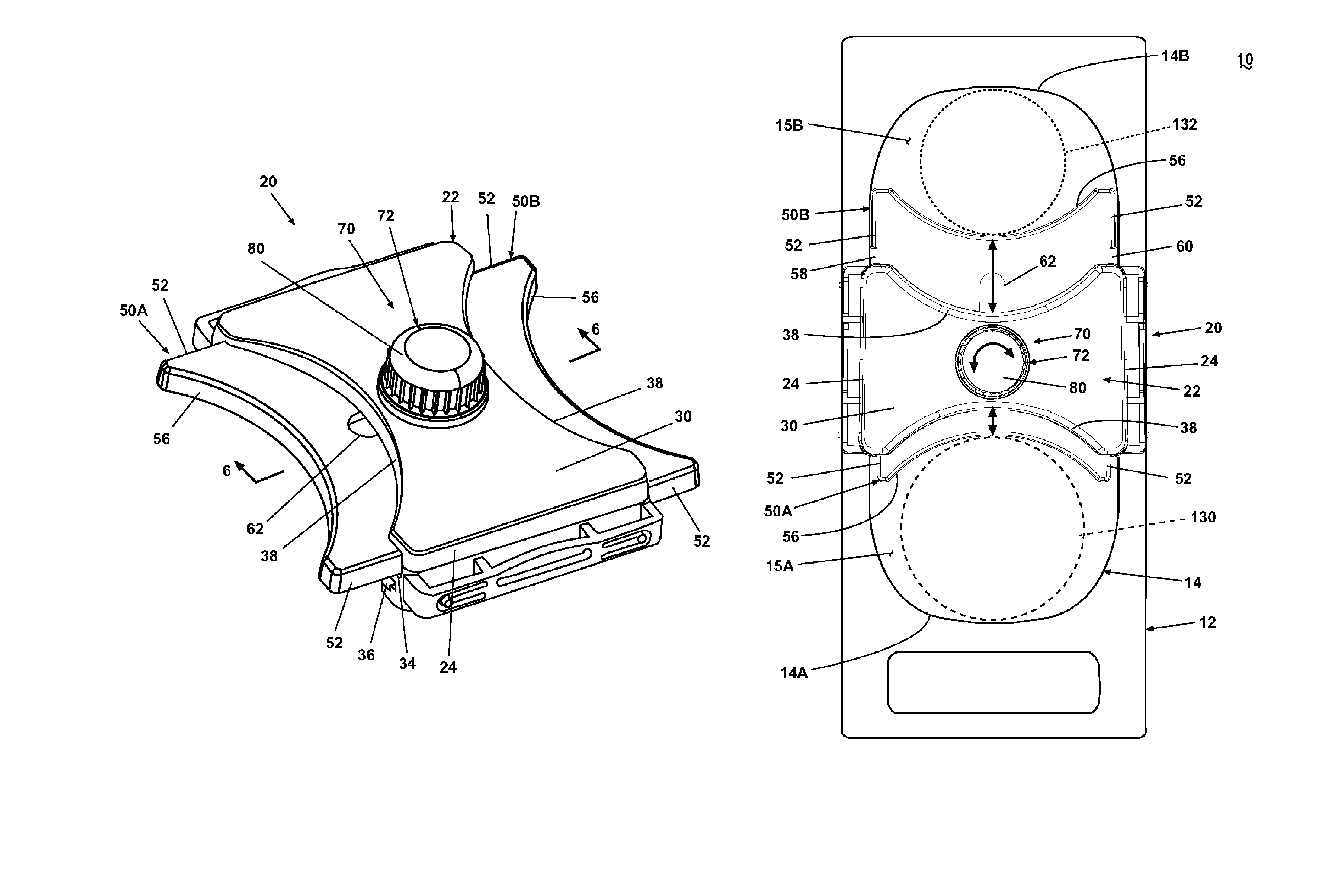

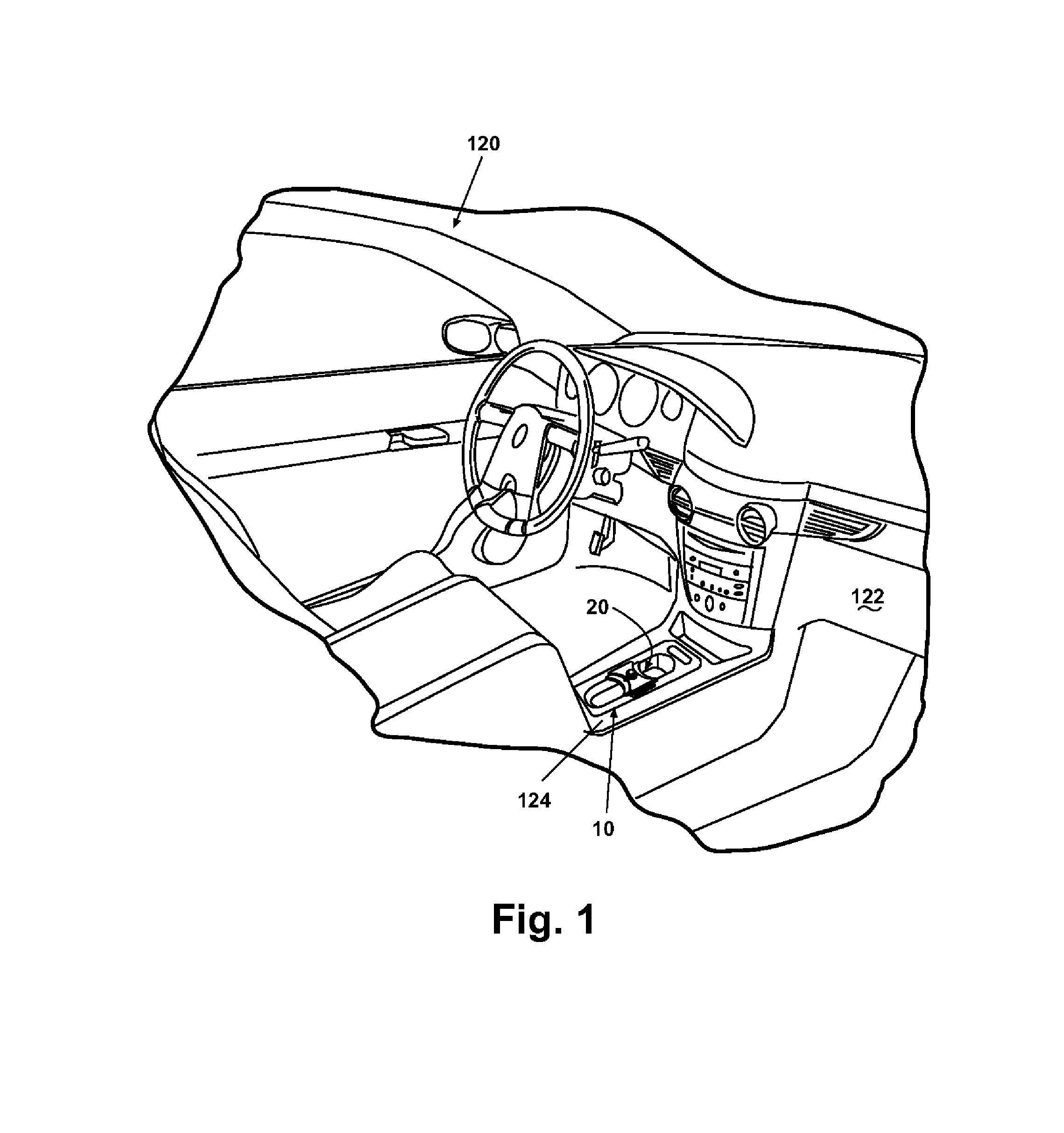

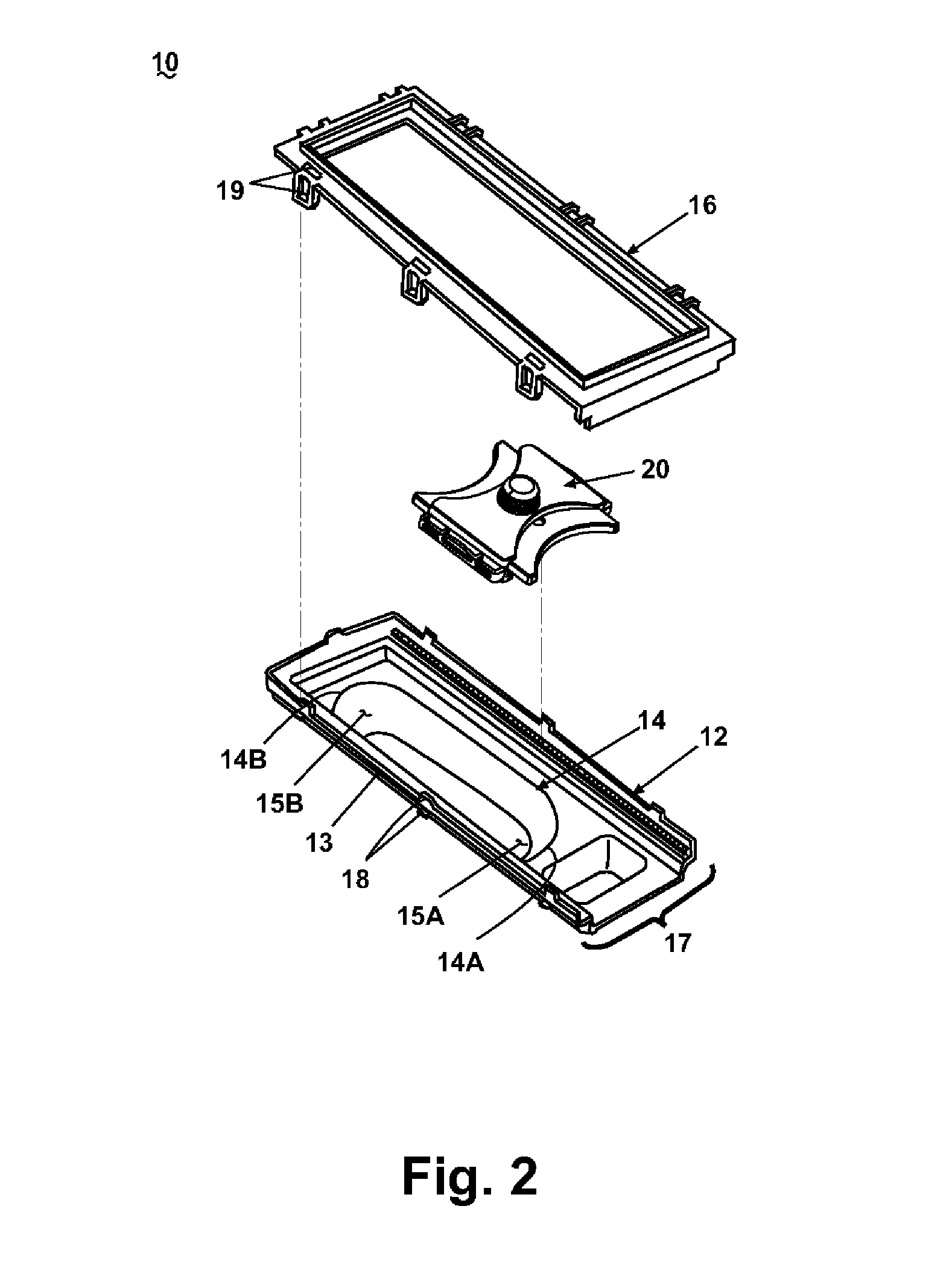

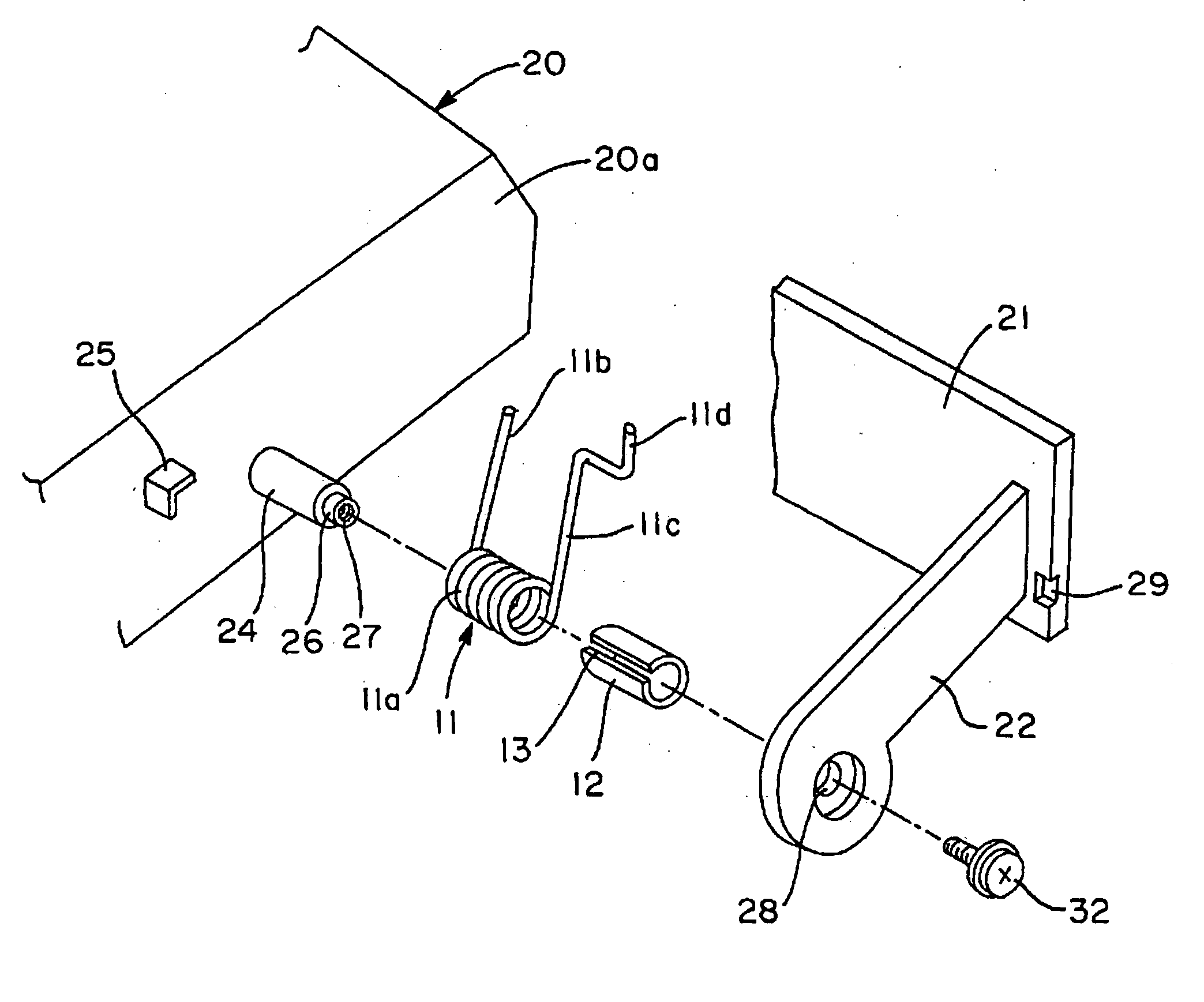

Multi-chamber vehicular beverage container holder with common actuator

InactiveUS7510158B1Easy to installProvide aesthetic appearanceTravelling carriersVehicle arrangementsEngineeringActuator

A vehicular beverage container holder comprises a receptacle with an elongated compartment and an adjuster assembly mounted to the receptacle to define separate beverage container compartments within the compartment for receiving individual beverage containers. The adjuster assembly comprises a body and a pair of adjusters slidably mounted to and extending from opposite sides of the body. Rotation of a knob and gear assembly of the adjuster assembly effects movement of the adjusters relative to the body to adjust the sizes of openings for the beverage container compartments for accommodating a range of beverage container sizes. Additionally, the knob and gear assembly includes a slip clutch mechanism that enables movement of one of the adjusters while movement of the other of the adjusters is retarded by a beverage container.

Owner:SUMMIT POLYMERS +1

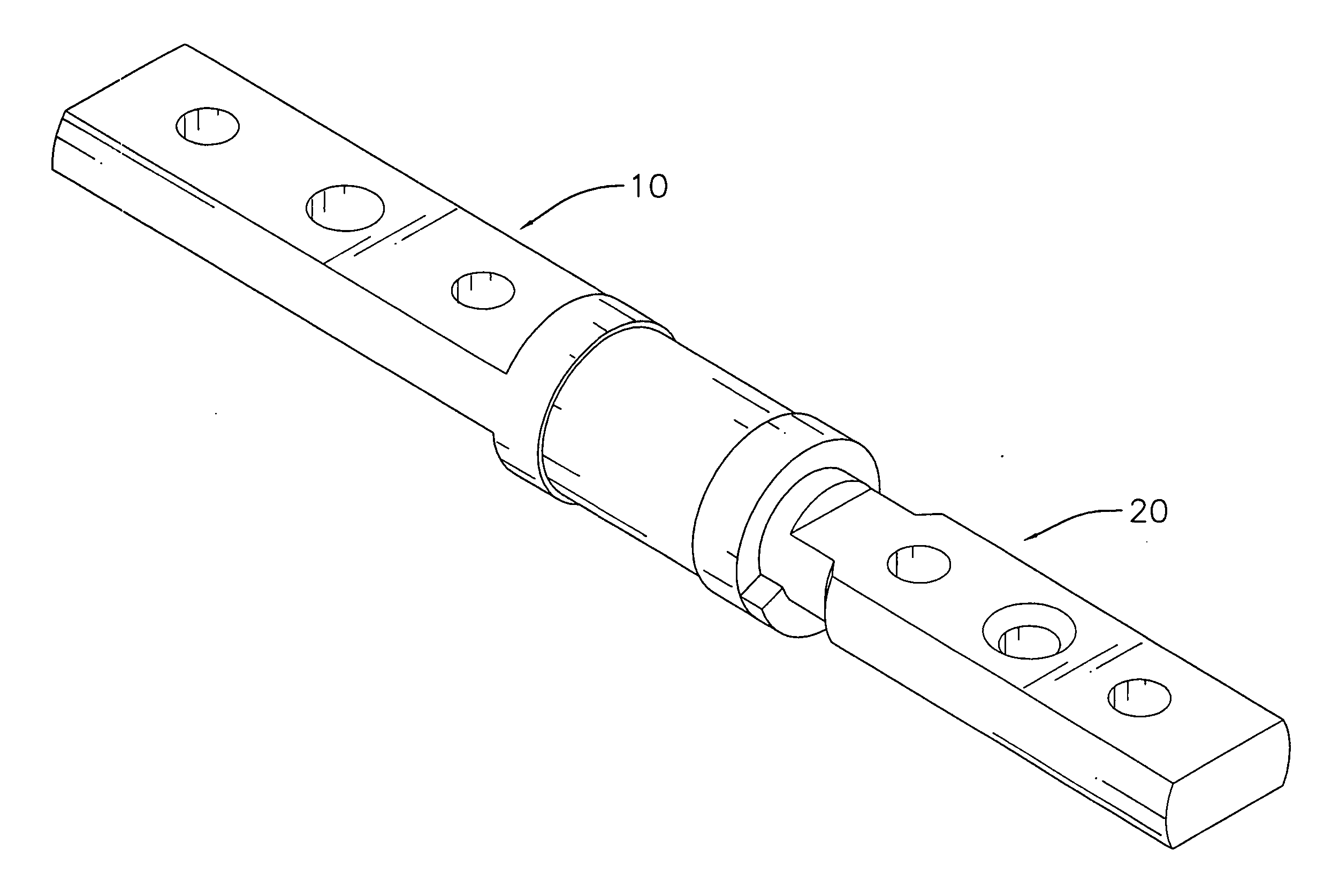

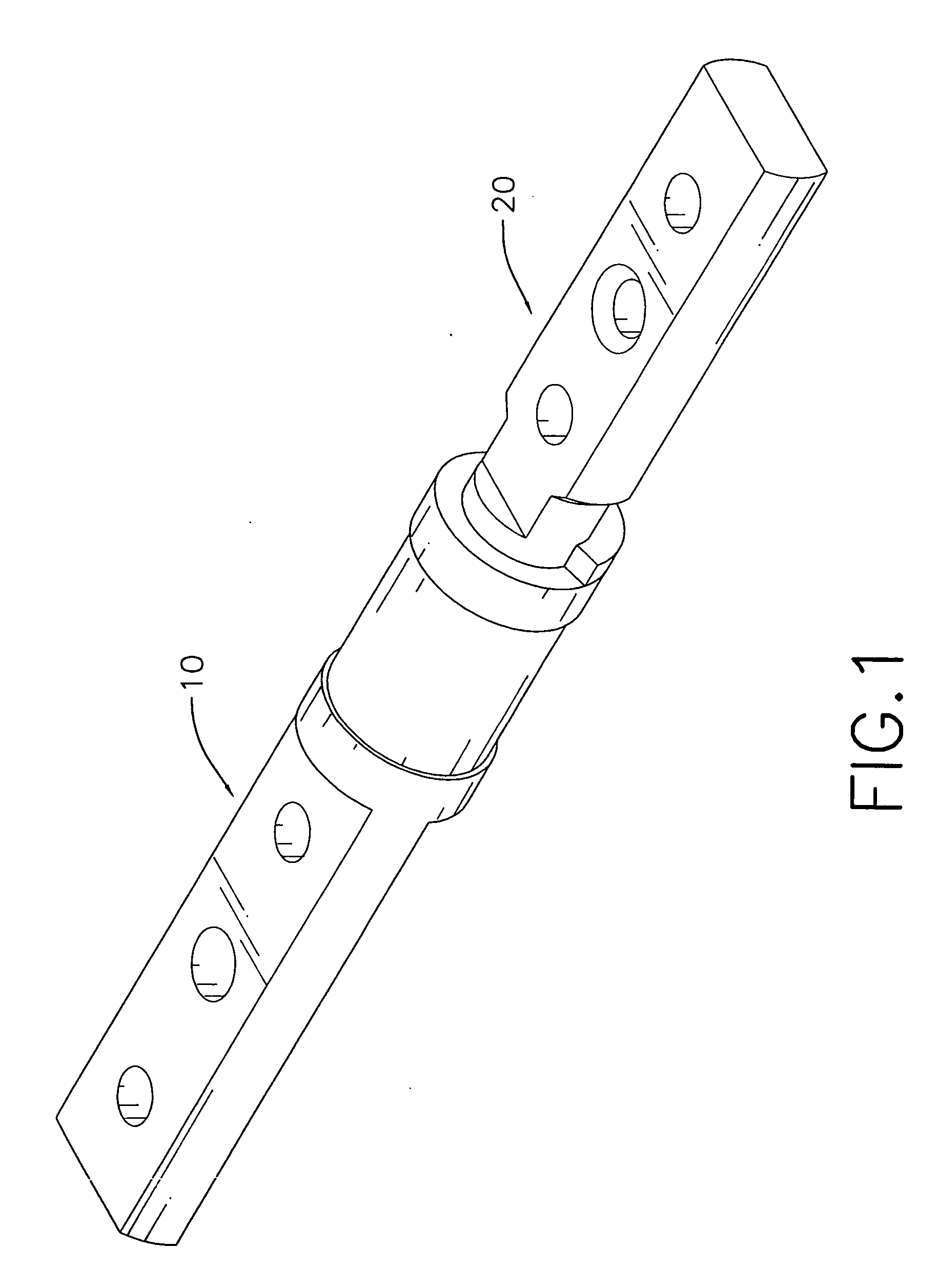

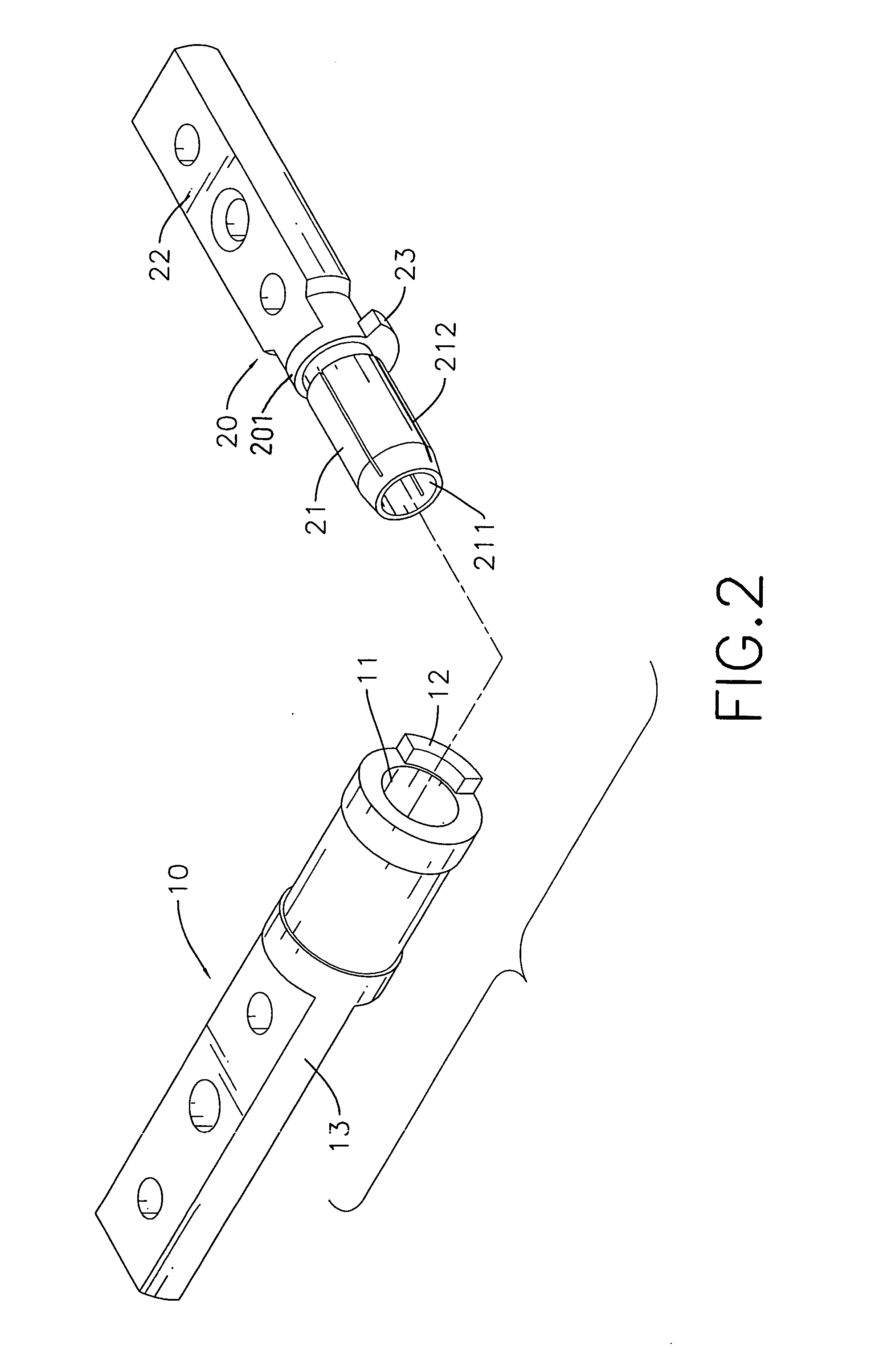

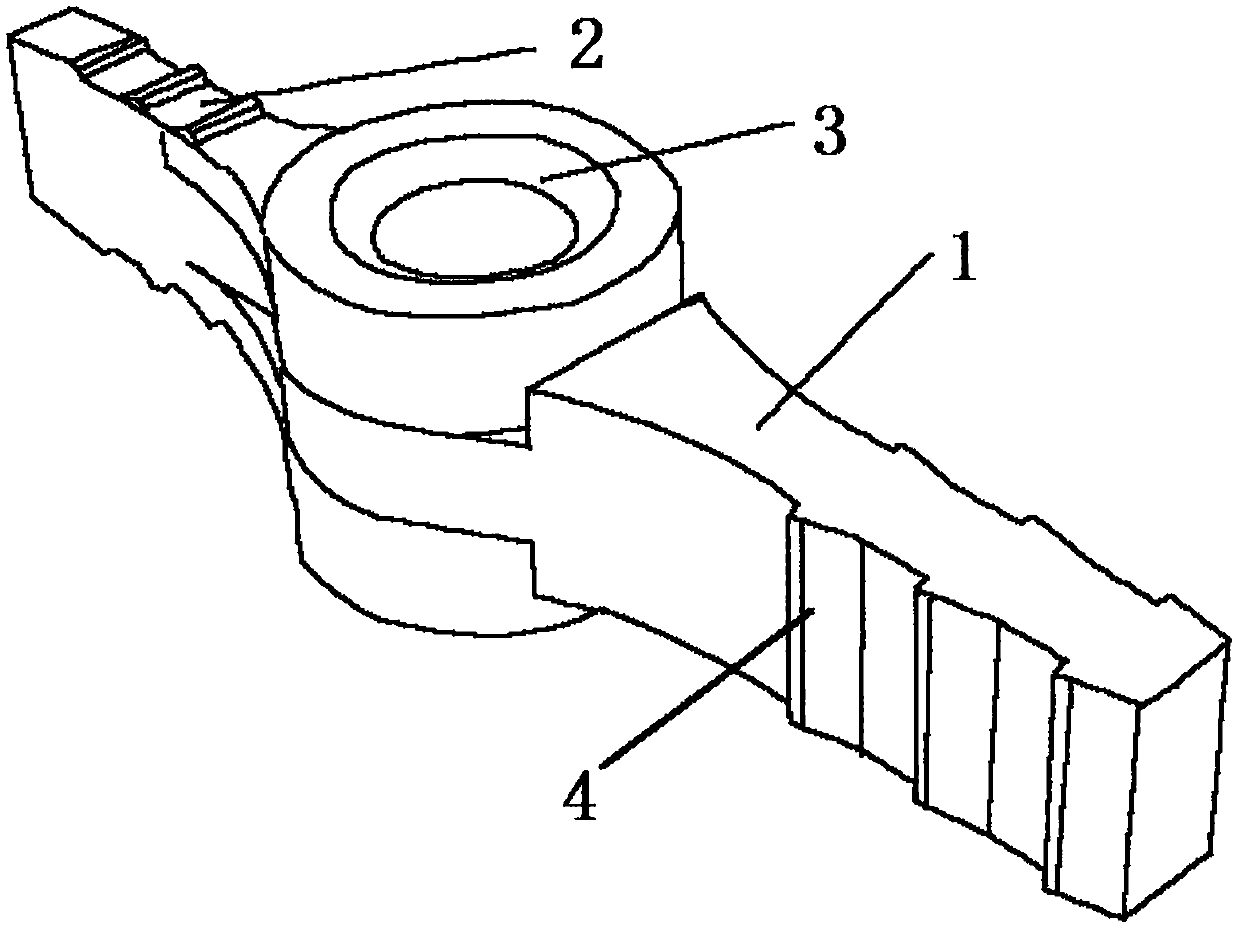

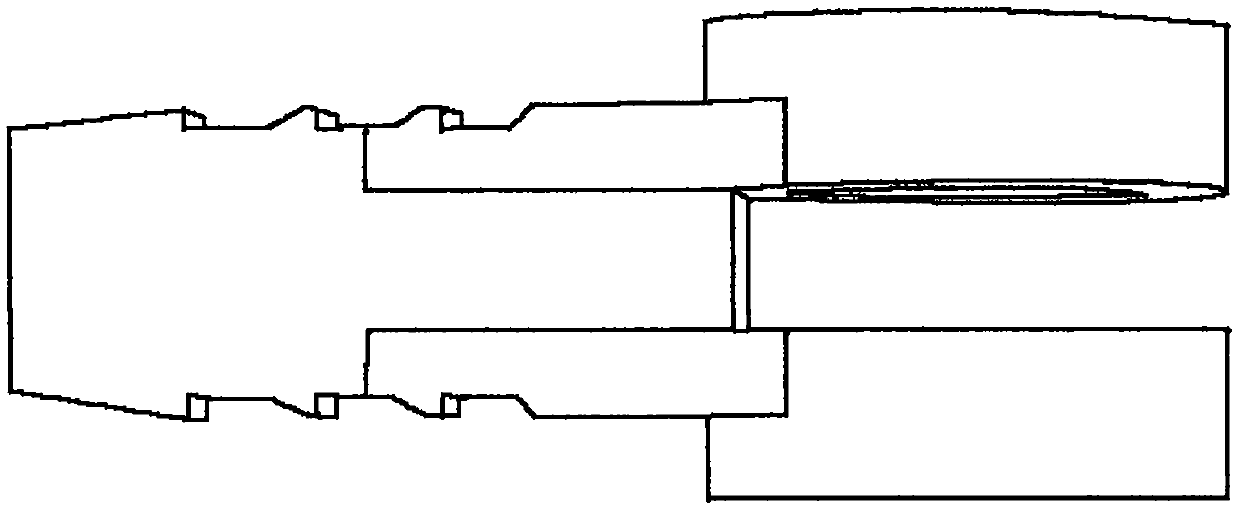

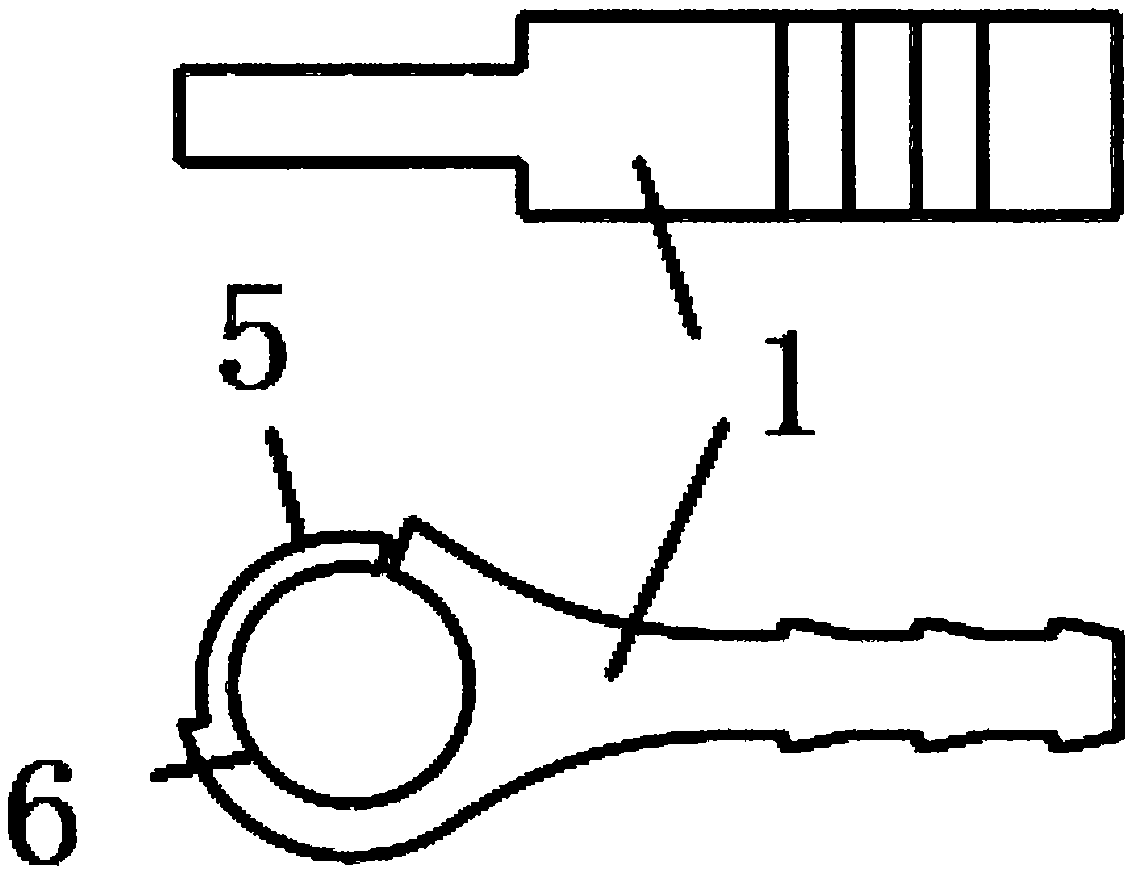

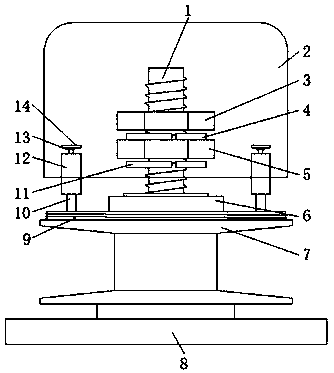

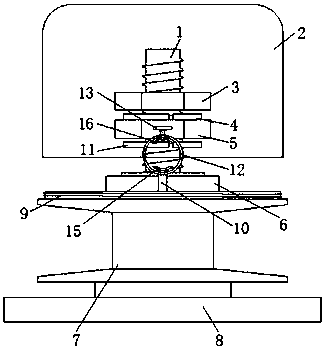

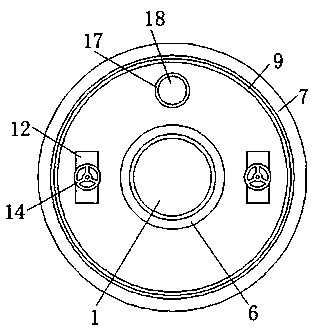

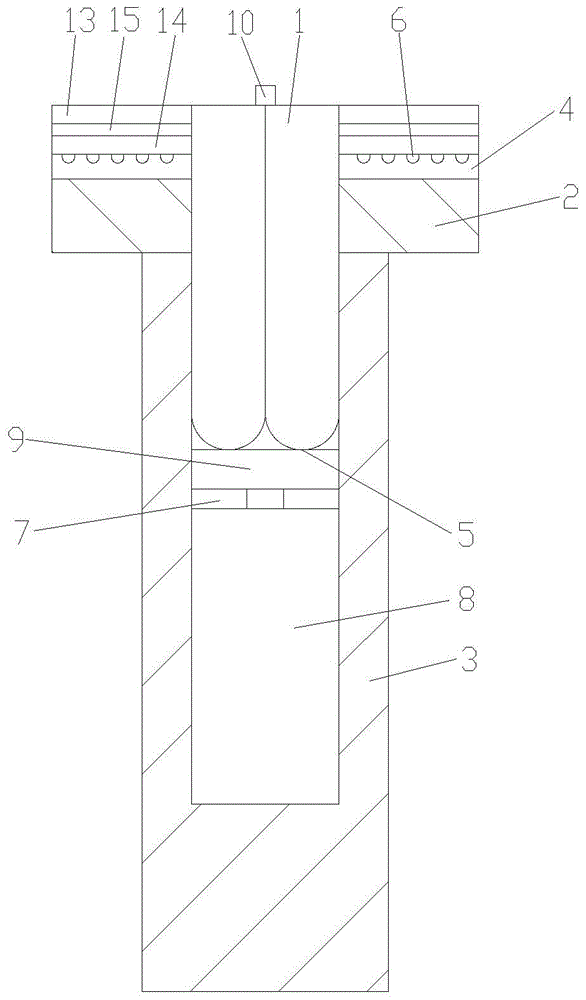

Hinge

InactiveUS20060236504A1Uniform frictionMaintain frictionWing fastenersDetails for portable computersHinge angleBiomedical engineering

A hinge has a sleeve and a shaft and is mounted between a cover and a base of an electrical device. The sleeve is hollow, is attached to the base and has an internal diameter. The shaft is attached to the cover, is mounted pivotally in the sleeve and has a hollow torsion rod. The torsion rod has an external diameter, an opening end and multiple slots. The external diameter of the torsion rod is bigger than the internal diameter of the sleeve to provide friction. The slots are formed in the torsion rod without communicating with the opening end to provide uniform friction. Because the torsion rod is hollow to provide spaces for the torsion rod to be deformed, the torsion rod maintains its shape. Therefore the torsion rod provides uniform friction with the sleeve.

Owner:SHIN ZU SHING

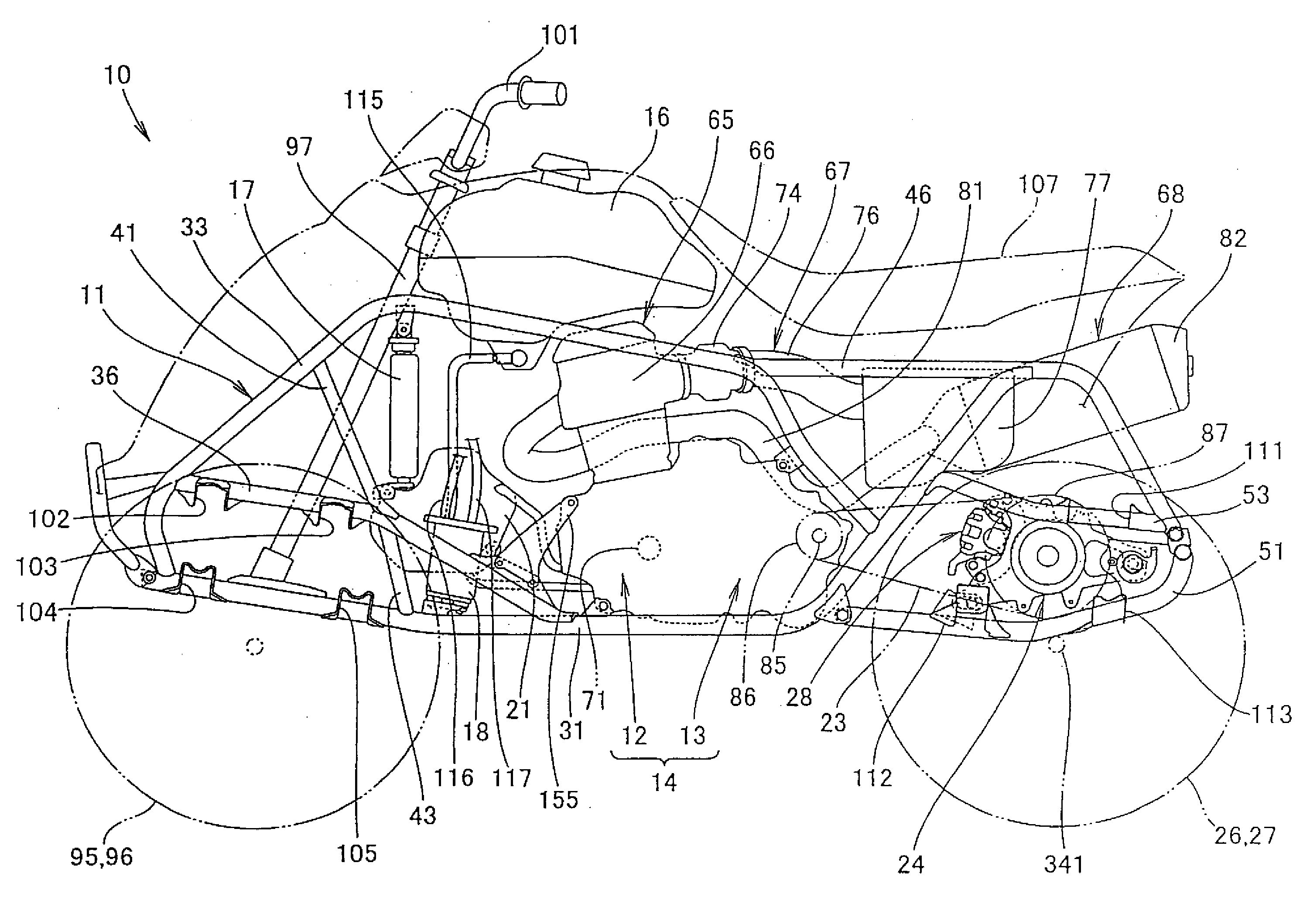

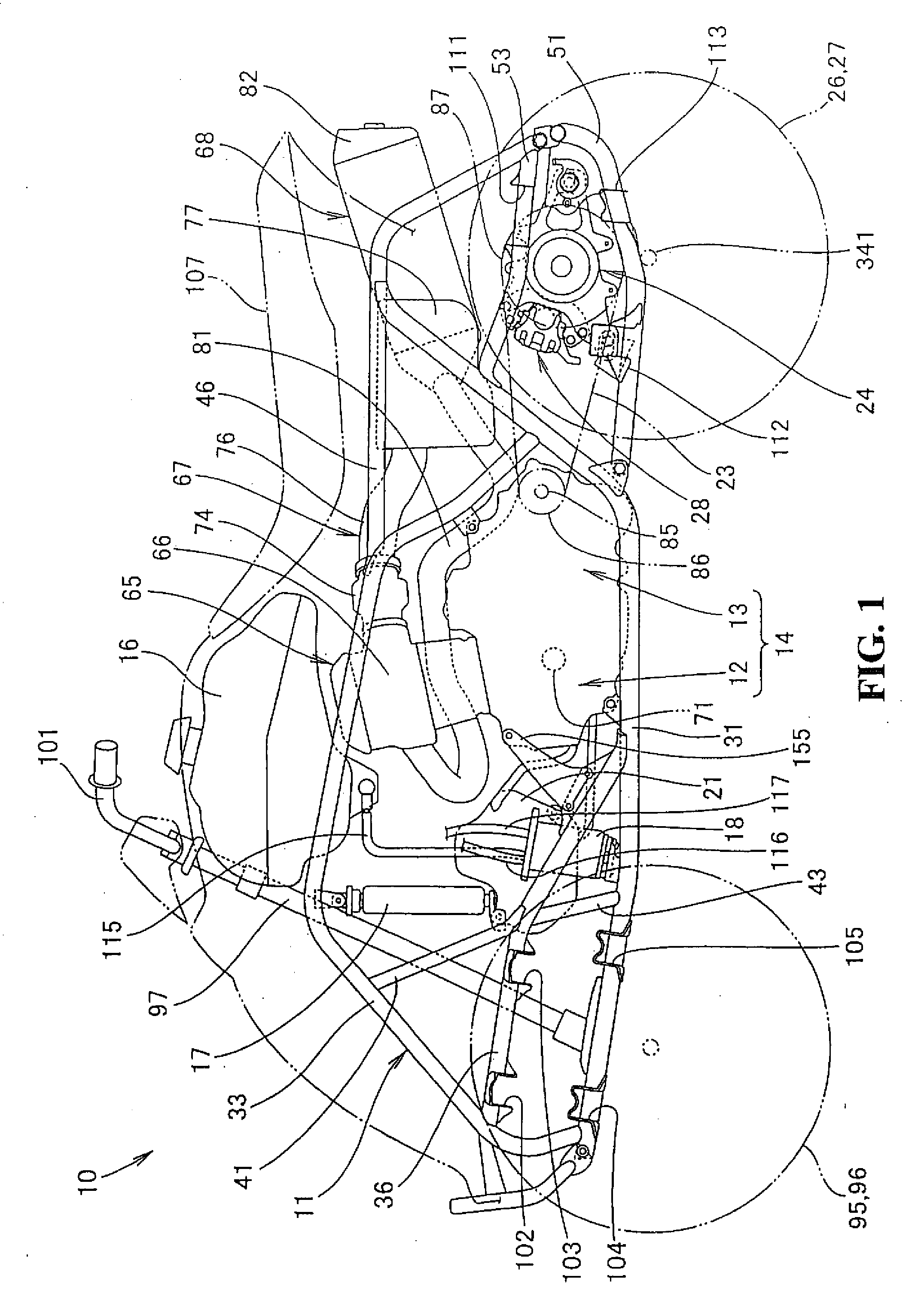

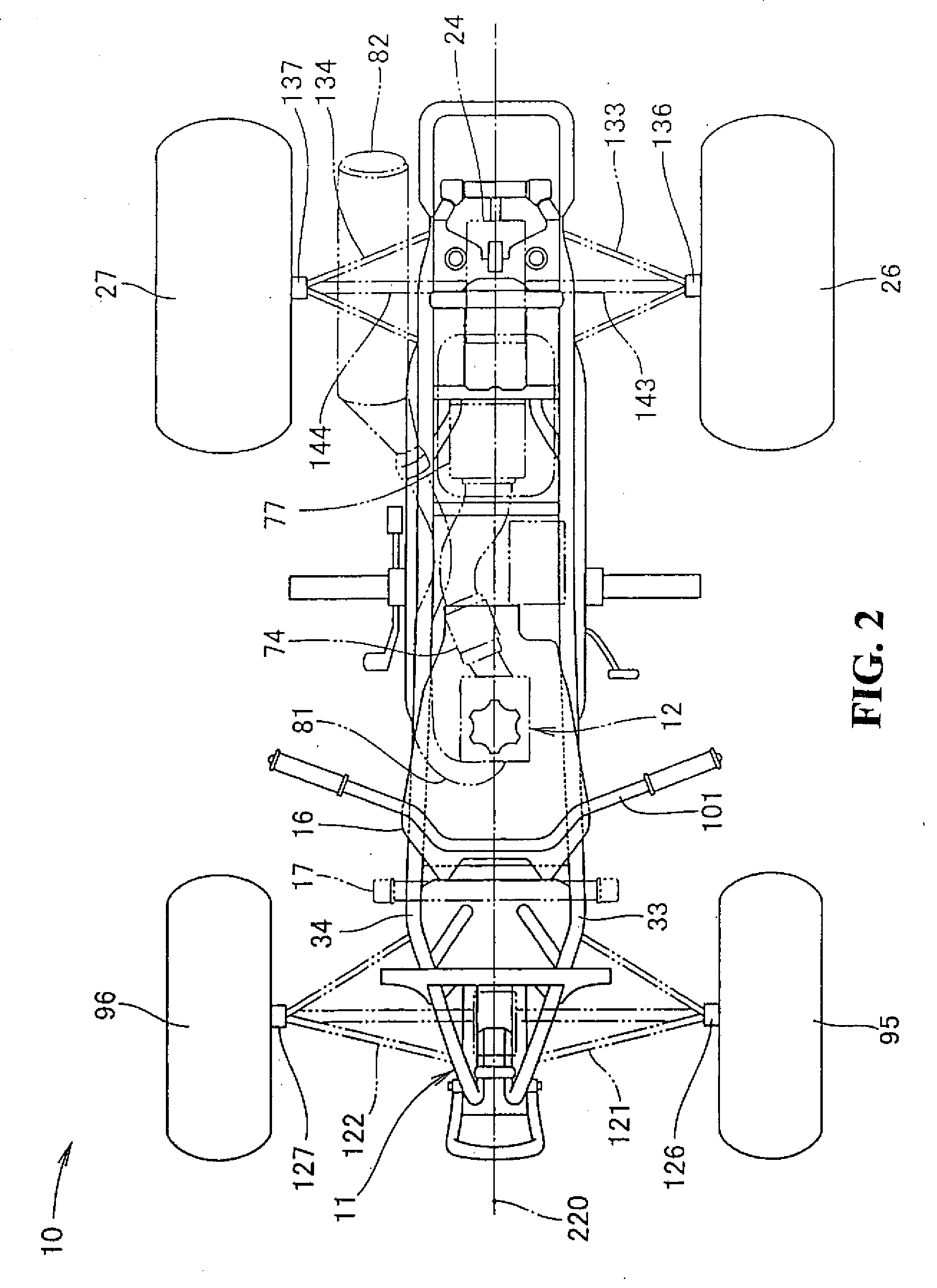

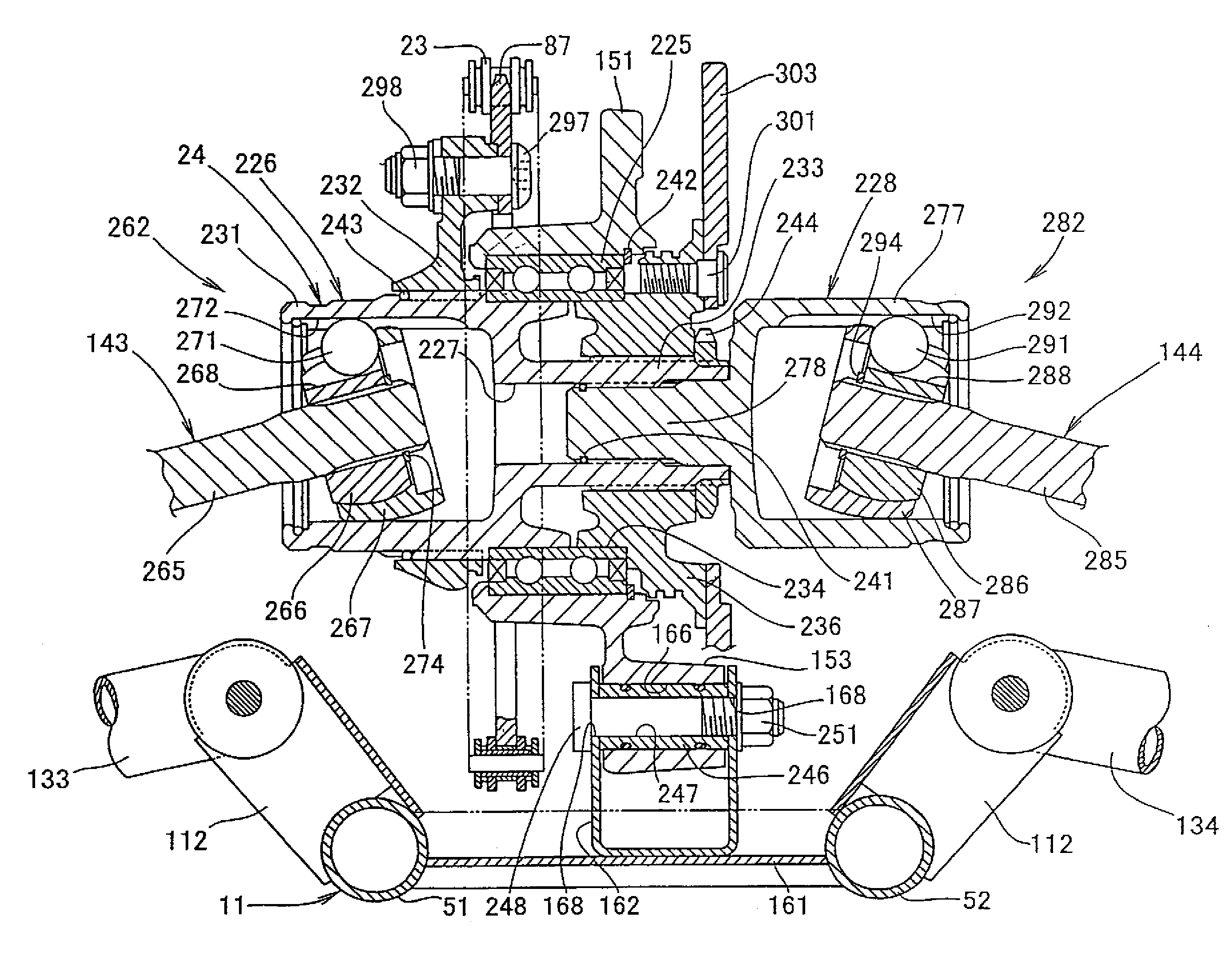

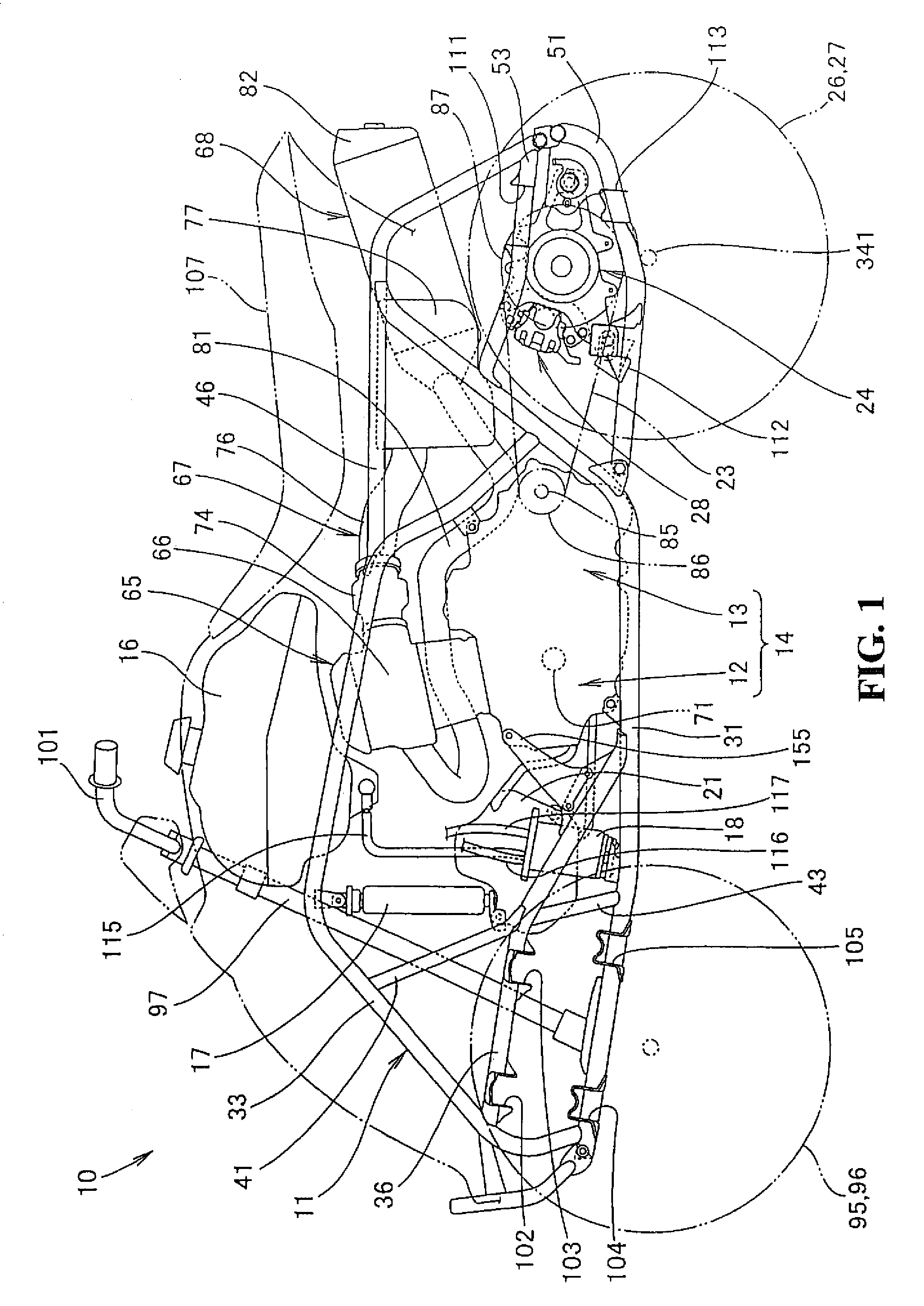

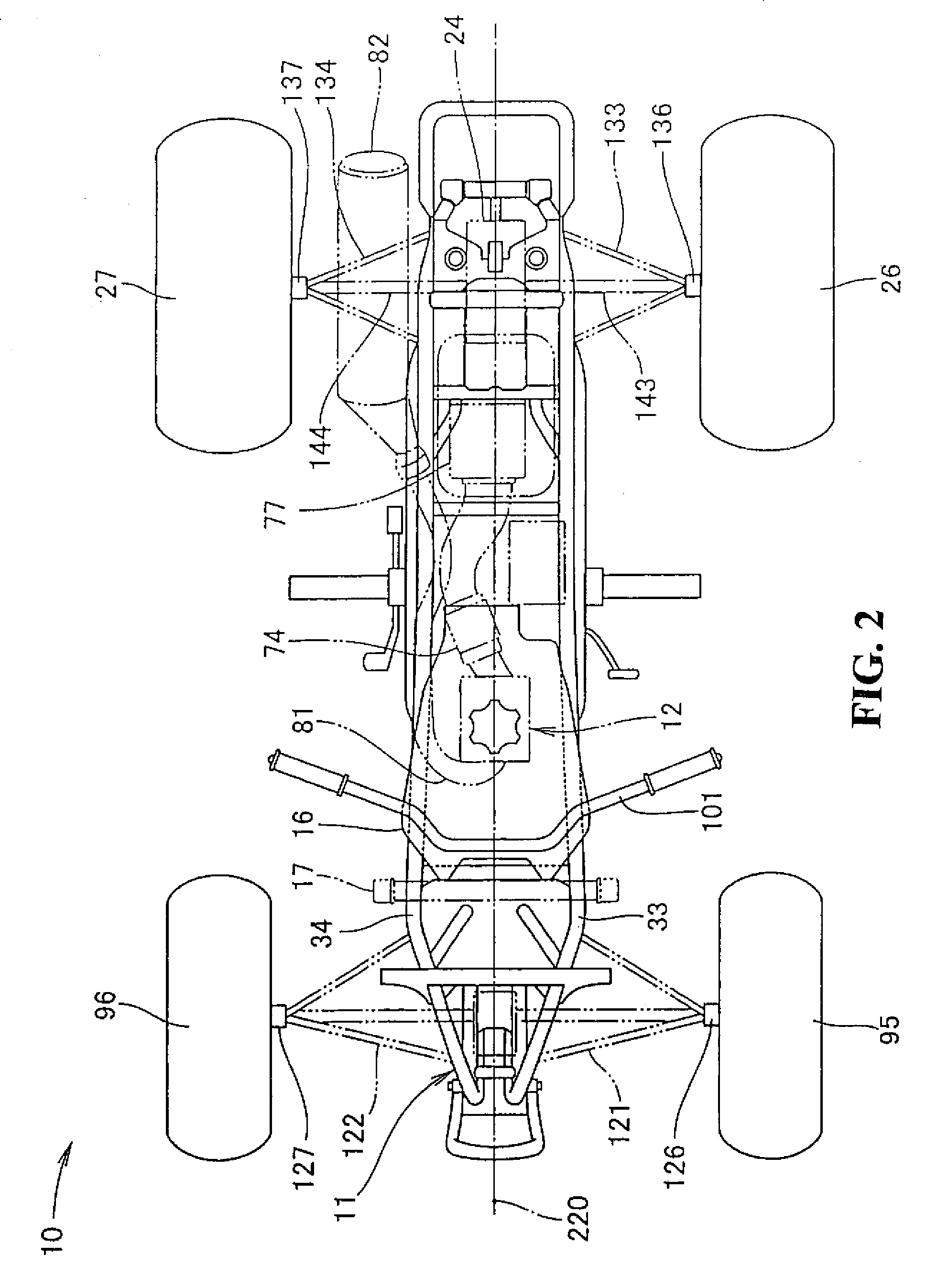

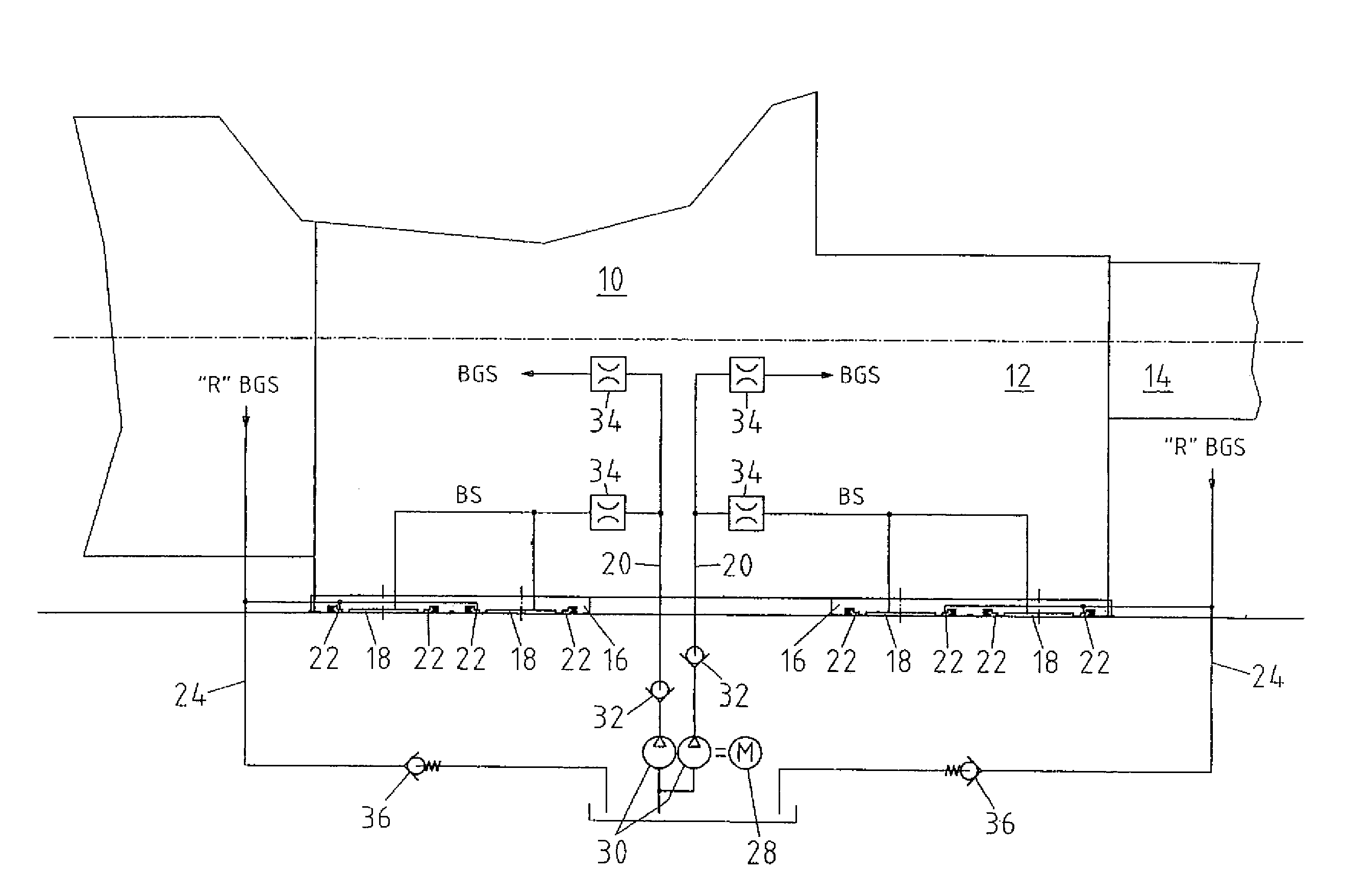

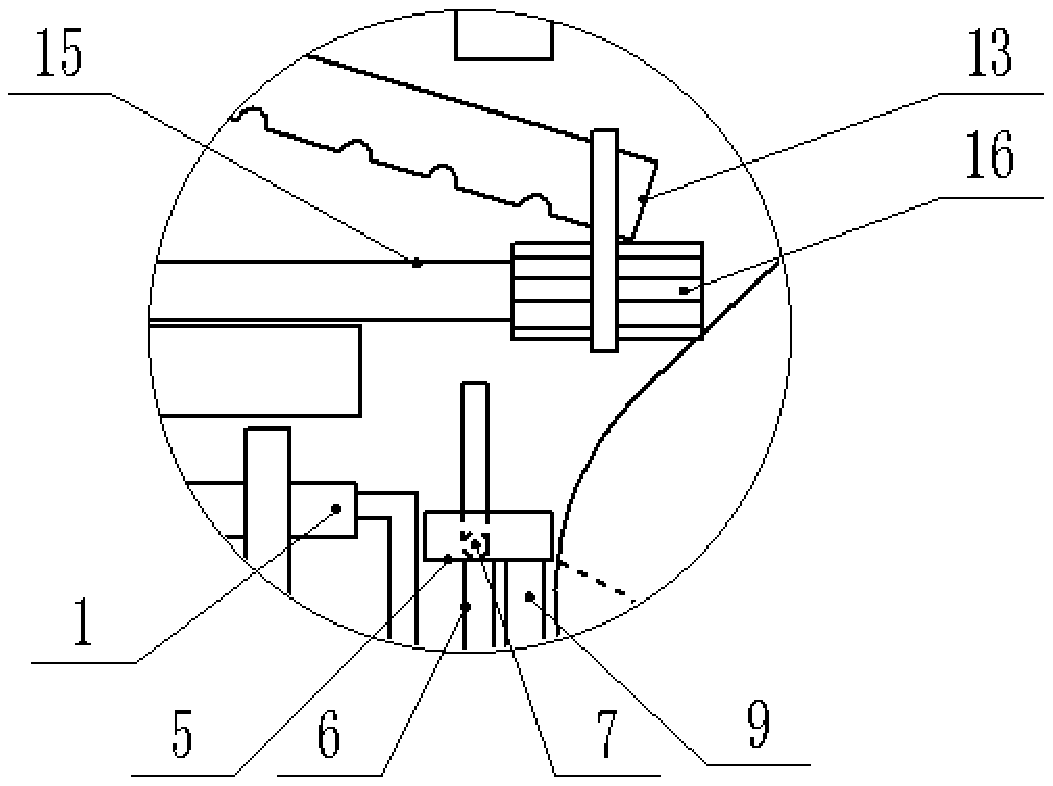

Speed reduction device of vehicle

InactiveUS20070199761A1Small sizeSolution value is not highCyclesBraking element arrangementsDrive wheelVehicle frame

A speed reduction device of a vehicle for reducing the rotation of drive wheels includes a casing mounted on a vehicle frame, first and second drive axles rotatably mounted on the casing and connected to first and second drive shafts, respectively, and a driven sprocket wheel and a brake disc for braking the first and second drive axles are mounted on the first drive axle. The second drive axle is detachably joined to the first drive axle.

Owner:HONDA MOTOR CO LTD

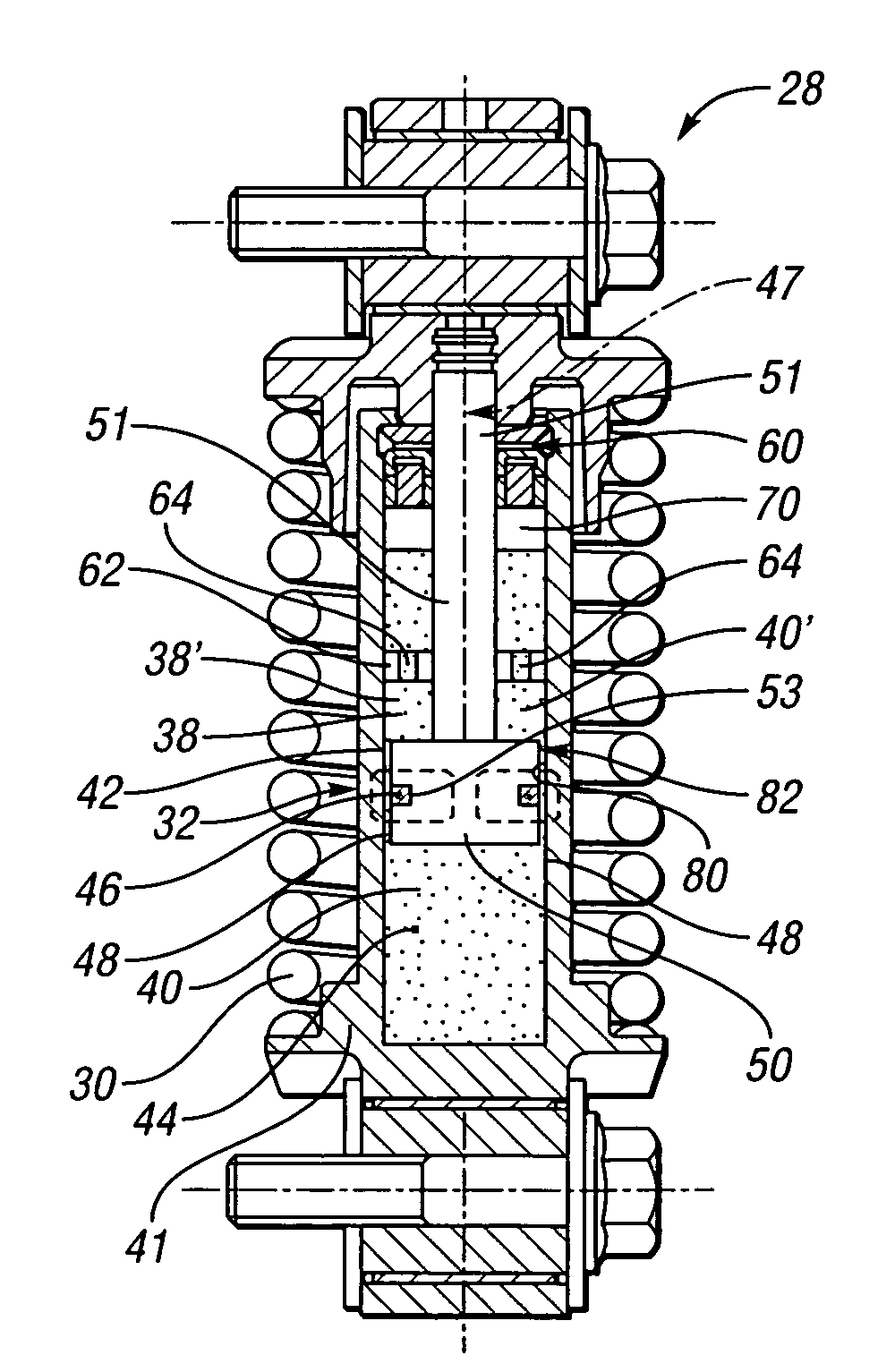

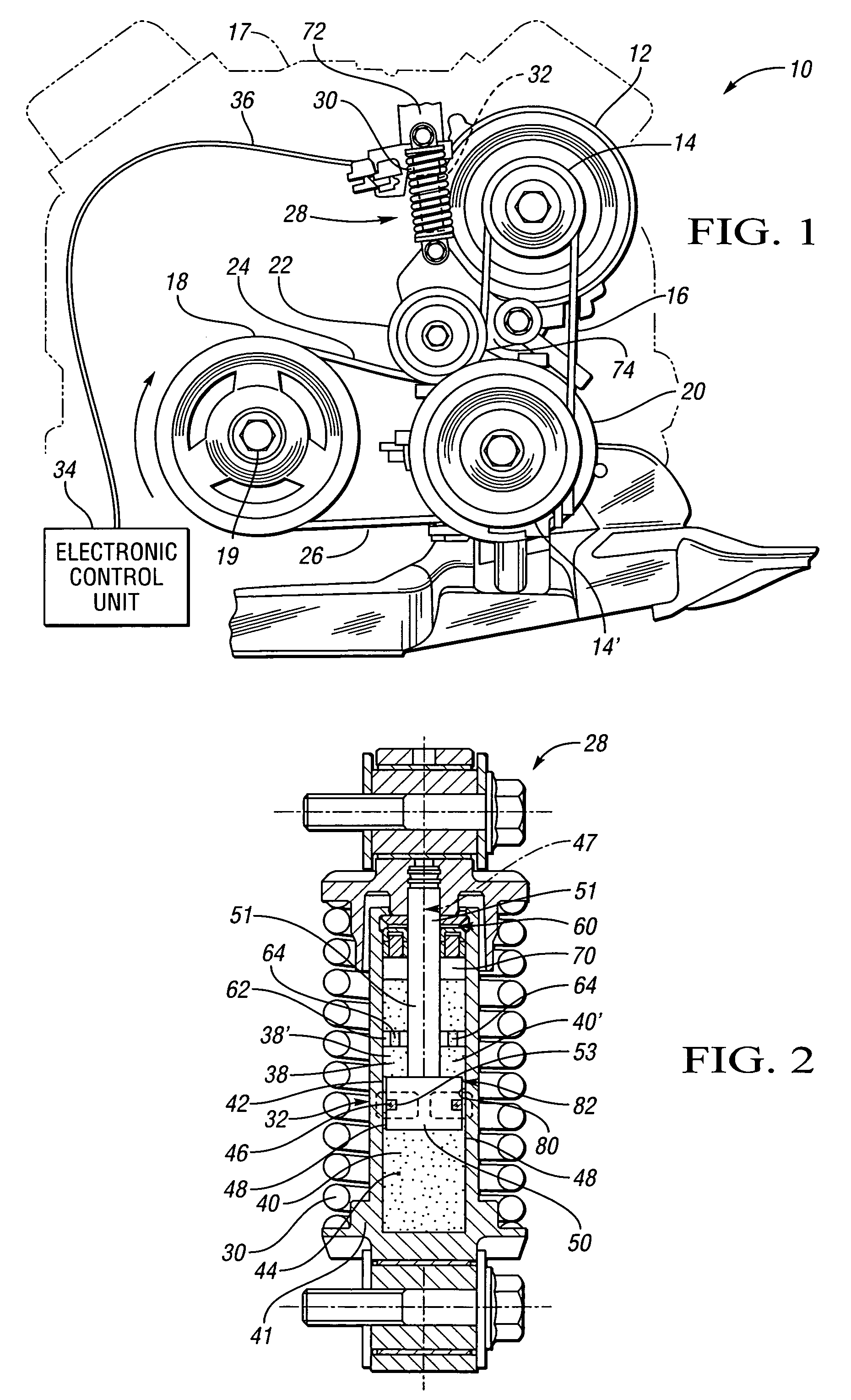

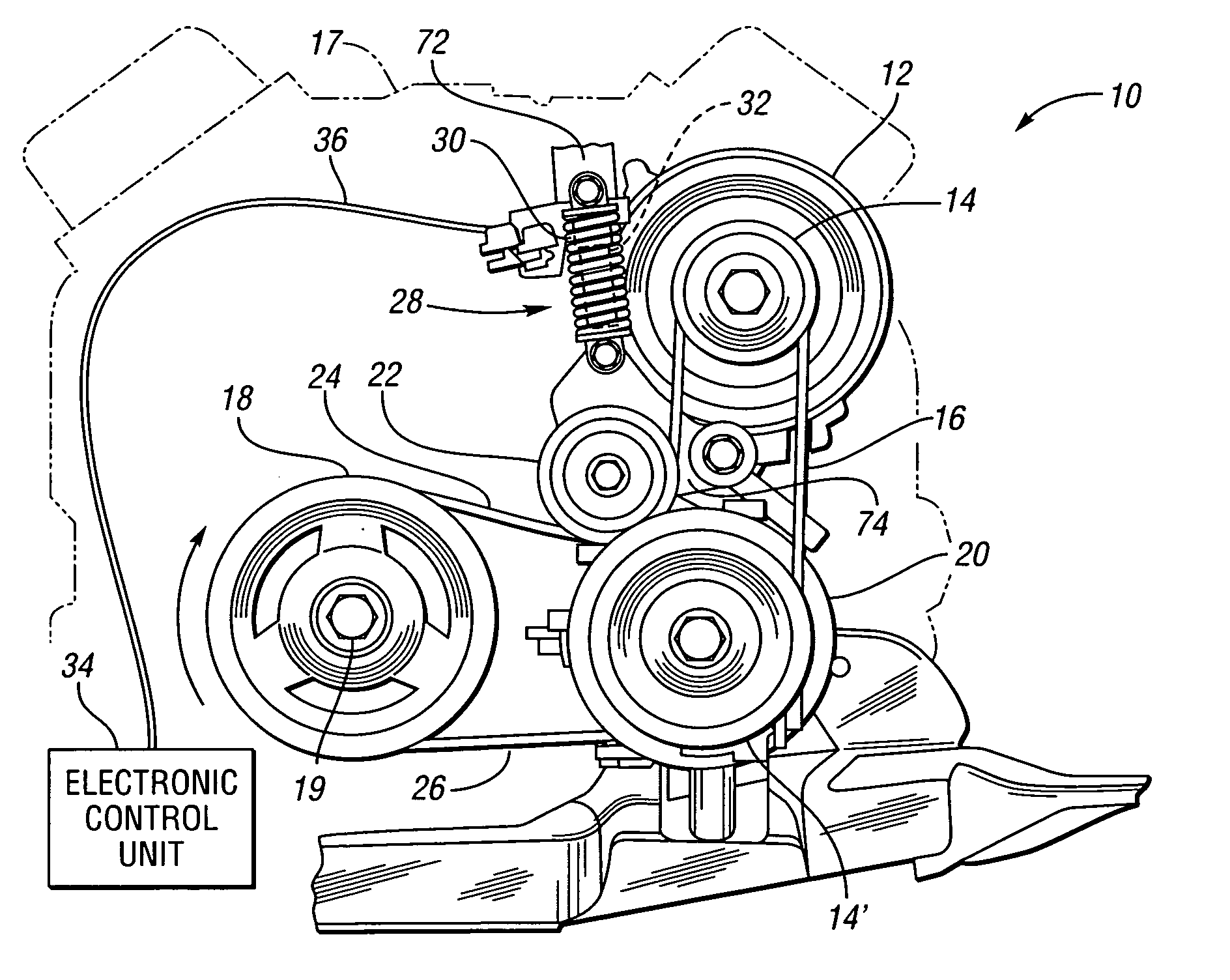

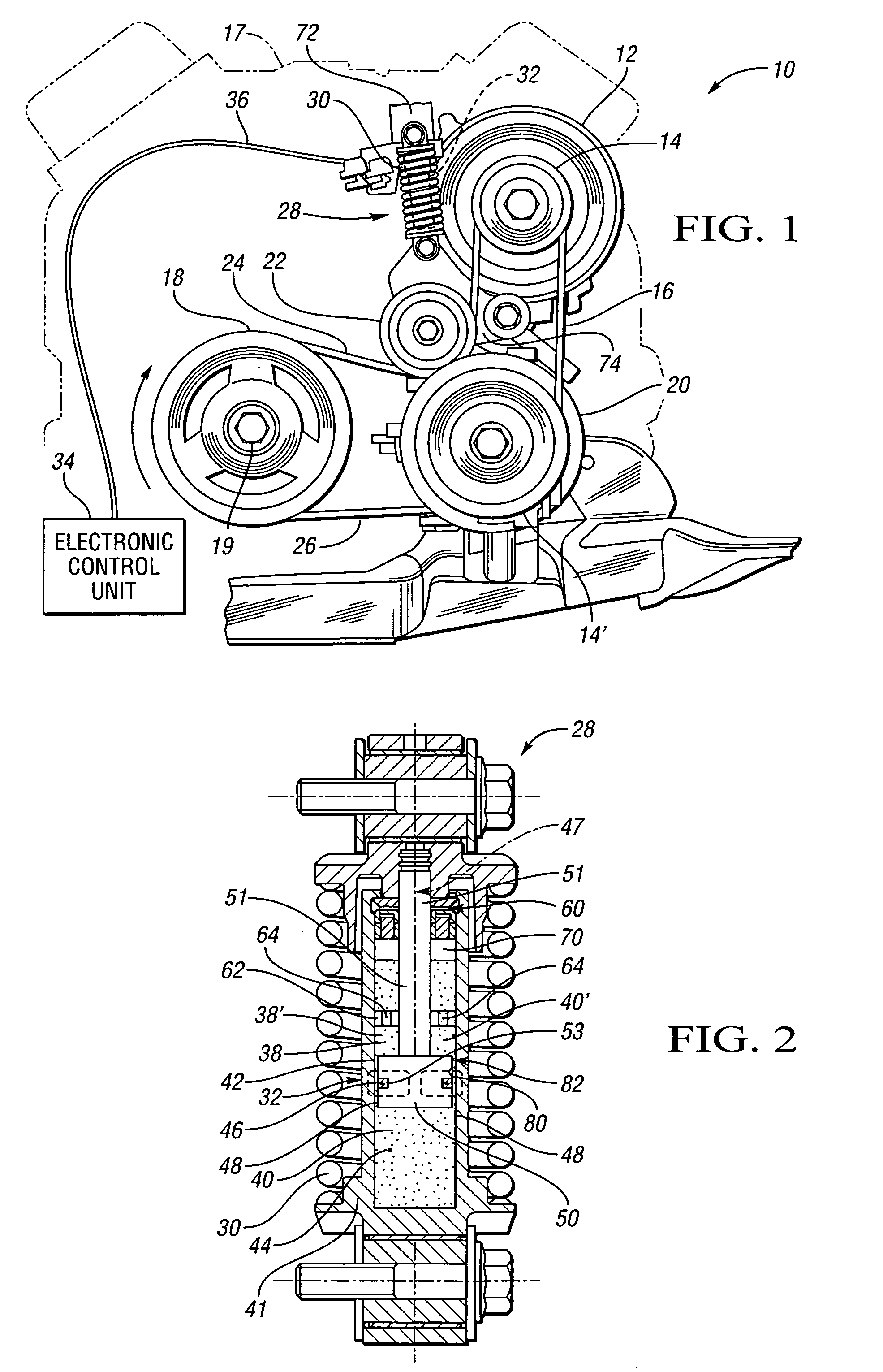

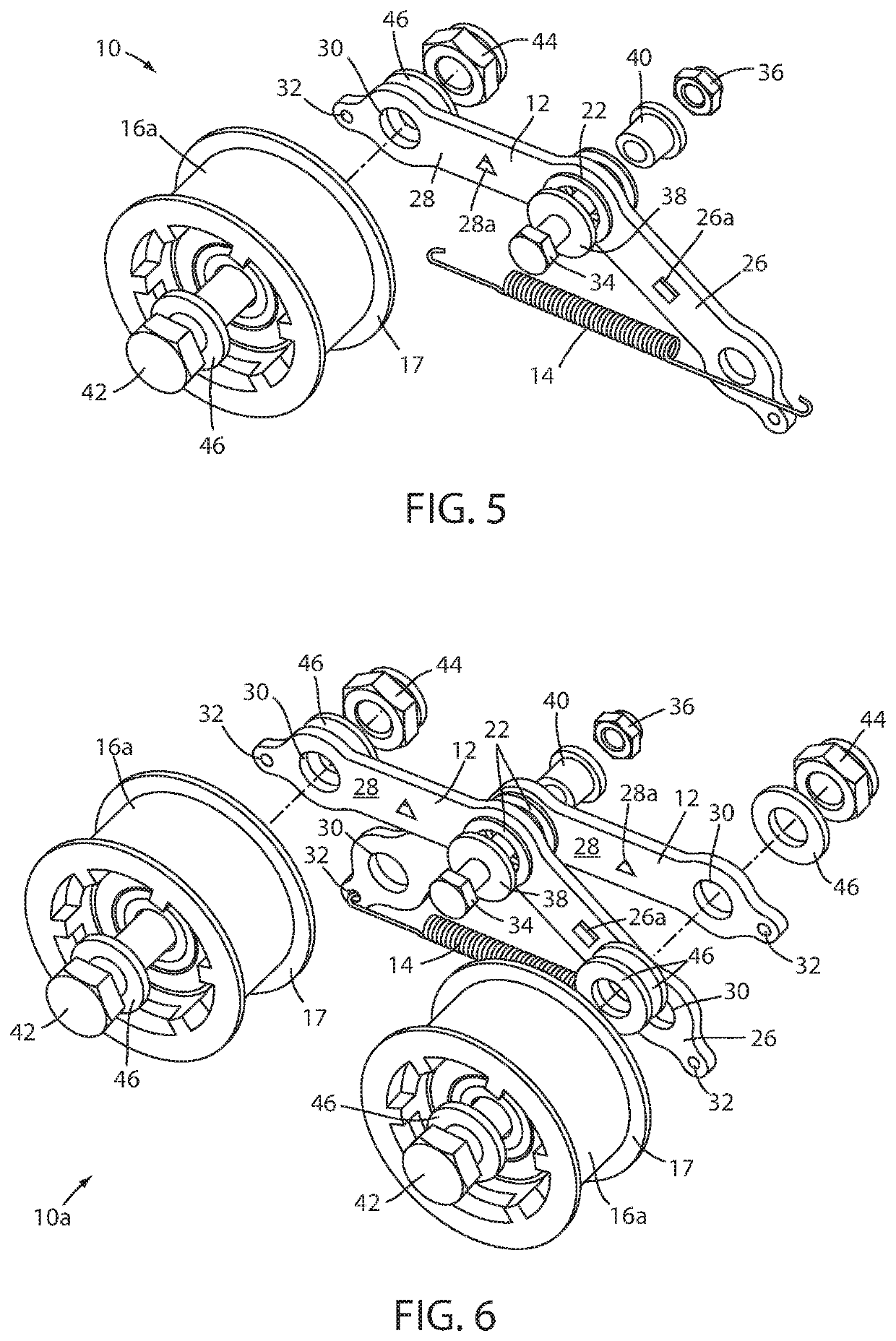

Automotive accessory drive system

The apparatus of the present invention provides an improved automotive accessory drive system. The automotive accessory drive system including a drive pulley operatively connected to an engine, and a plurality of driven pulleys operatively connected to one of a plurality of driven devices. A flexible drive belt connectively couples the drive pulley and the plurality of driven pulleys, and is operable to transfer drive forces therebetween. The automotive accessory drive system also includes a flexible drive belt tensioner operable to maintain frictional engagement between the flexible drive belt and the drive pulley and at least one of the driven pulleys. The flexible drive belt tensioner has a damper element that preferably includes a damper housing, and a variable viscosity fluid disposed within the damper housing. The variable viscosity fluid is configured to provide a variable dampening rate and is selectively operable to lock the flexible drive belt tensioner.

Owner:GM GLOBAL TECH OPERATIONS LLC

Automotive accessory drive system

ActiveUS20070142145A1Maintain frictional engagementMaintain frictionGearingAccessory driveConveyor belt

The apparatus of the present invention provides an improved automotive accessory drive system. The automotive accessory drive system including a drive pulley operatively connected to an engine, and a plurality of driven pulleys operatively connected to one of a plurality of driven devices. A flexible drive belt connectively couples the drive pulley and the plurality of driven pulleys, and is operable to transfer drive forces therebetween. The automotive accessory drive system also includes a flexible drive belt tensioner operable to maintain frictional engagement between the flexible drive belt and the drive pulley and at least one of the driven pulleys. The flexible drive belt tensioner has a damper element that preferably includes a damper housing, and a variable viscosity fluid disposed within the damper housing. The variable viscosity fluid is configured to provide a variable dampening rate and is selectively operable to lock the flexible drive belt tensioner.

Owner:GM GLOBAL TECH OPERATIONS LLC

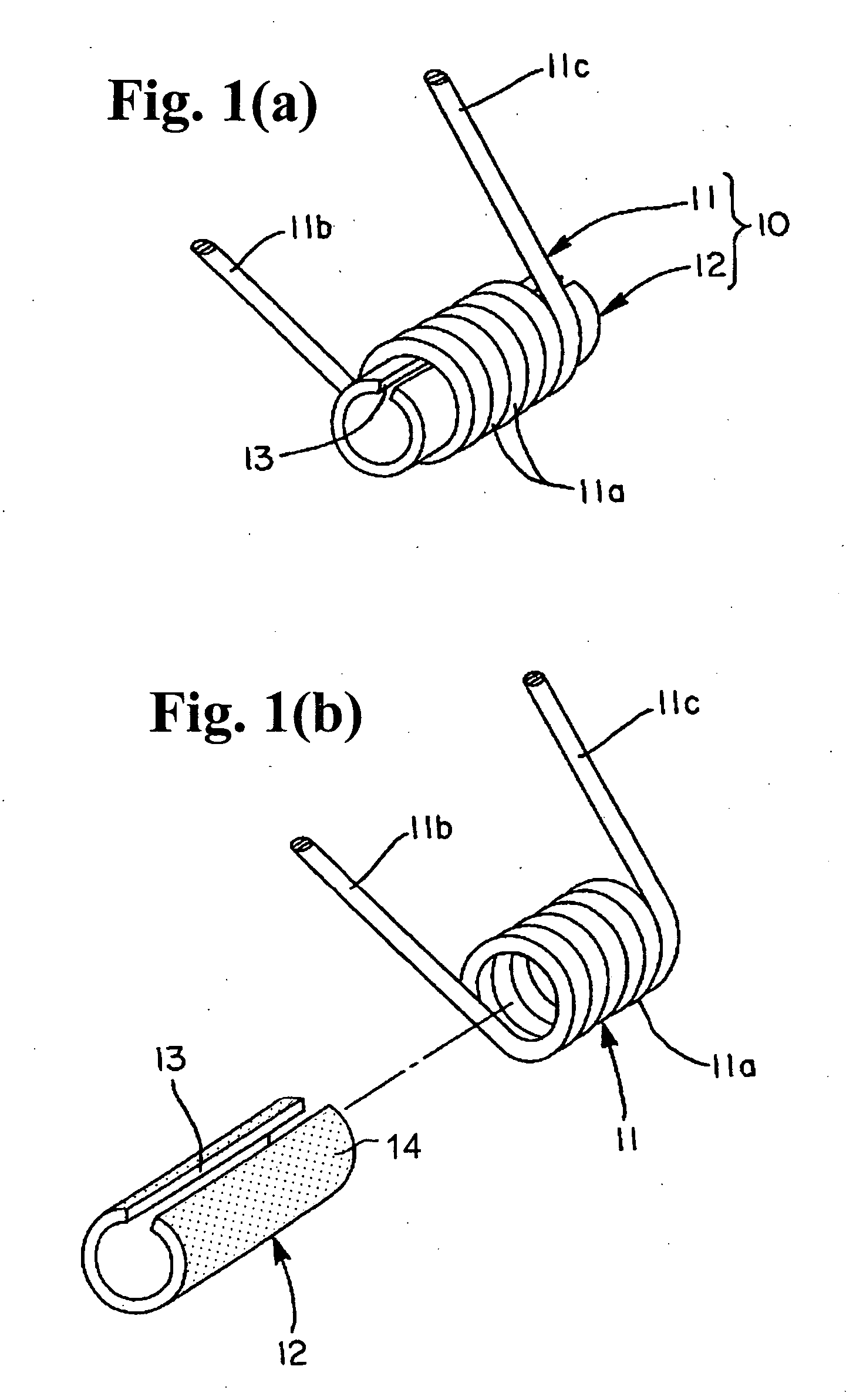

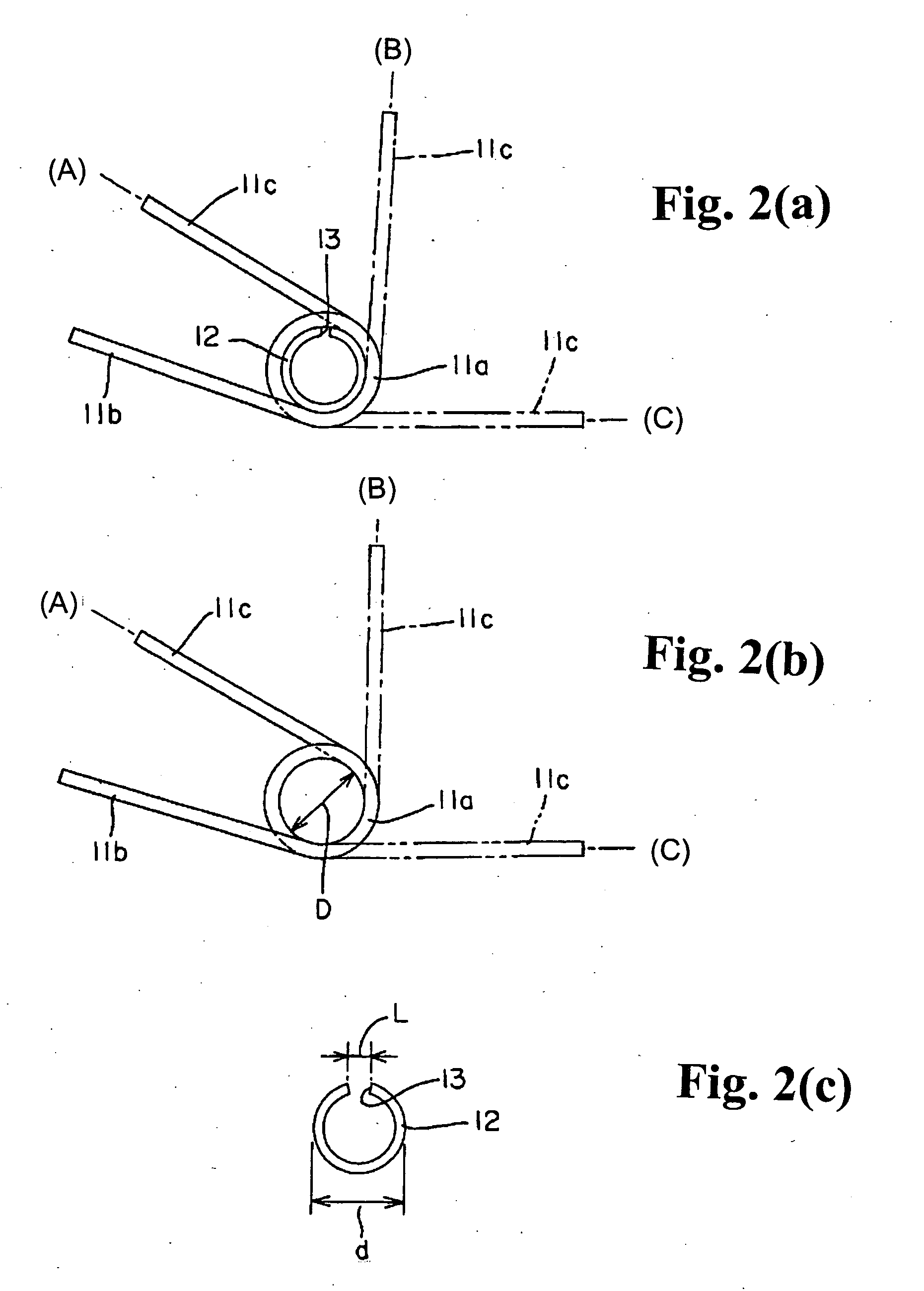

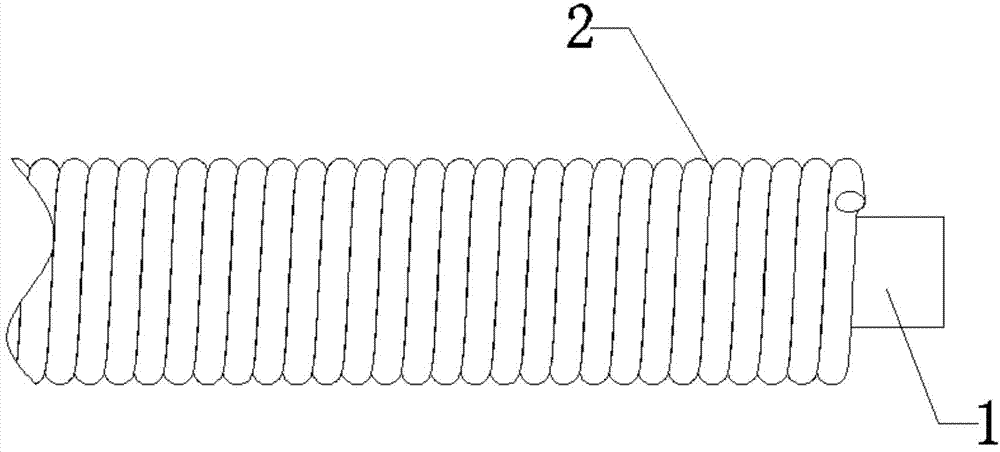

Spring unit with damper and opening-closing device

InactiveUS20050242594A1Maintaining the damping force constant without a variance in the damping forceReduce frictionBuilding braking devicesBuilding locksCoil springEngineering

A spring unit with a damper includes a torsion coil spring having two ends portions and a wound portion between the two end portions, and a cylindrical spring member having a slit extending in a longitudinal direction and an outer diameter larger than an inner diameter of the wound portion. When the two end portions of the torsion coil spring rotates, the inner diameter is changed to generate a friction force between the torsion coil spring and the cylindrical spring member, thereby utilizing the friction force as a damping force.

Owner:NIFCO INC

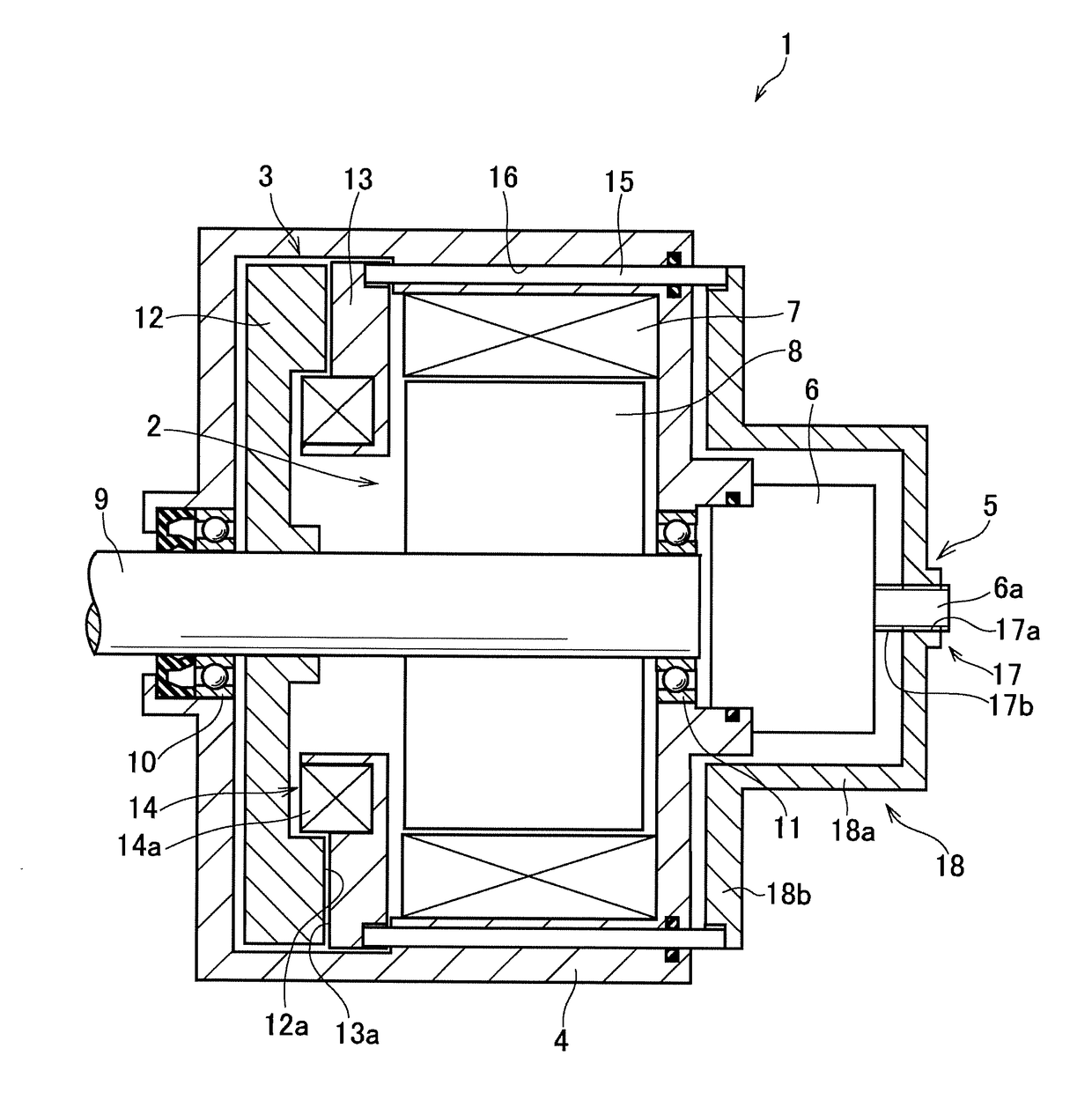

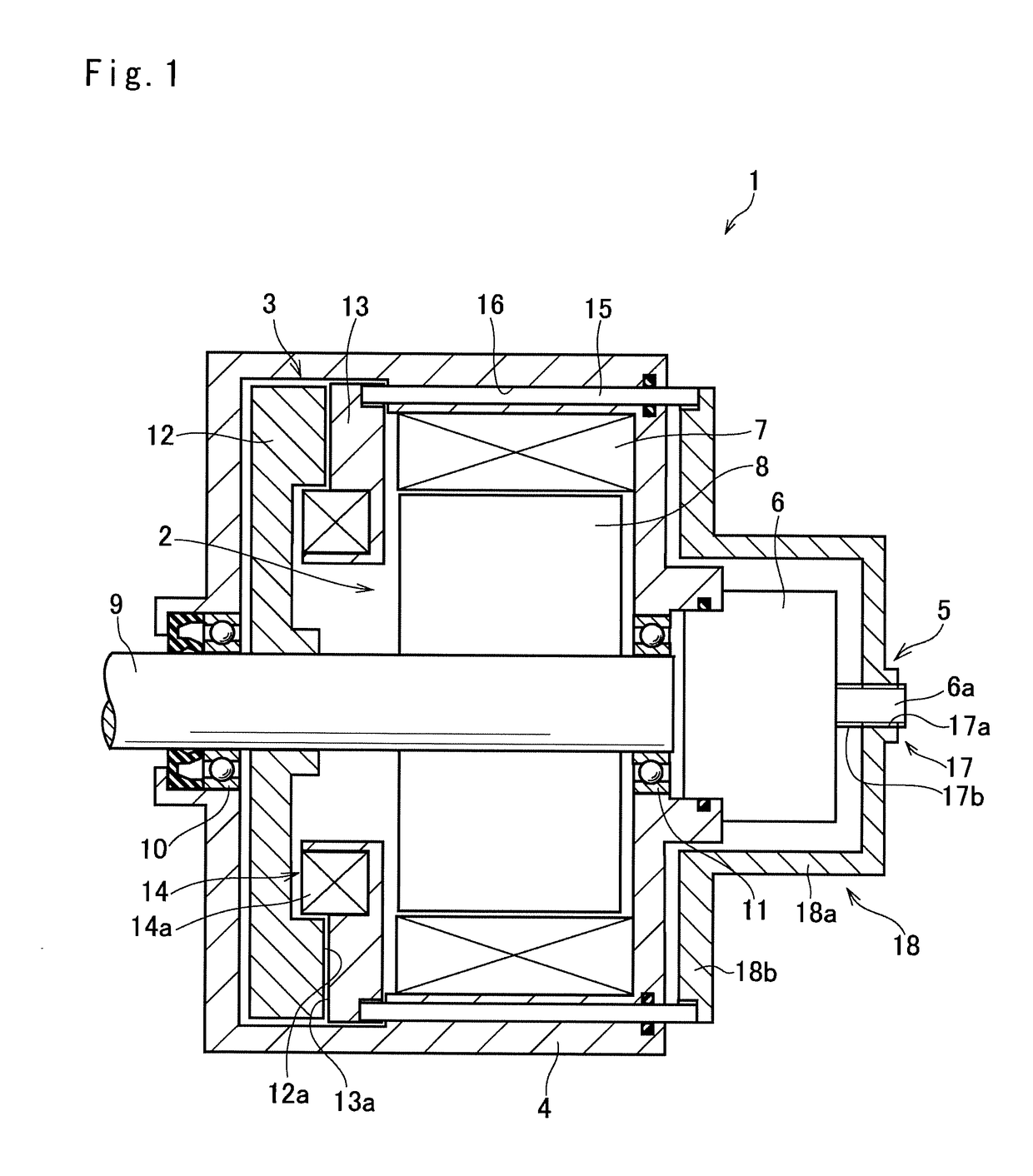

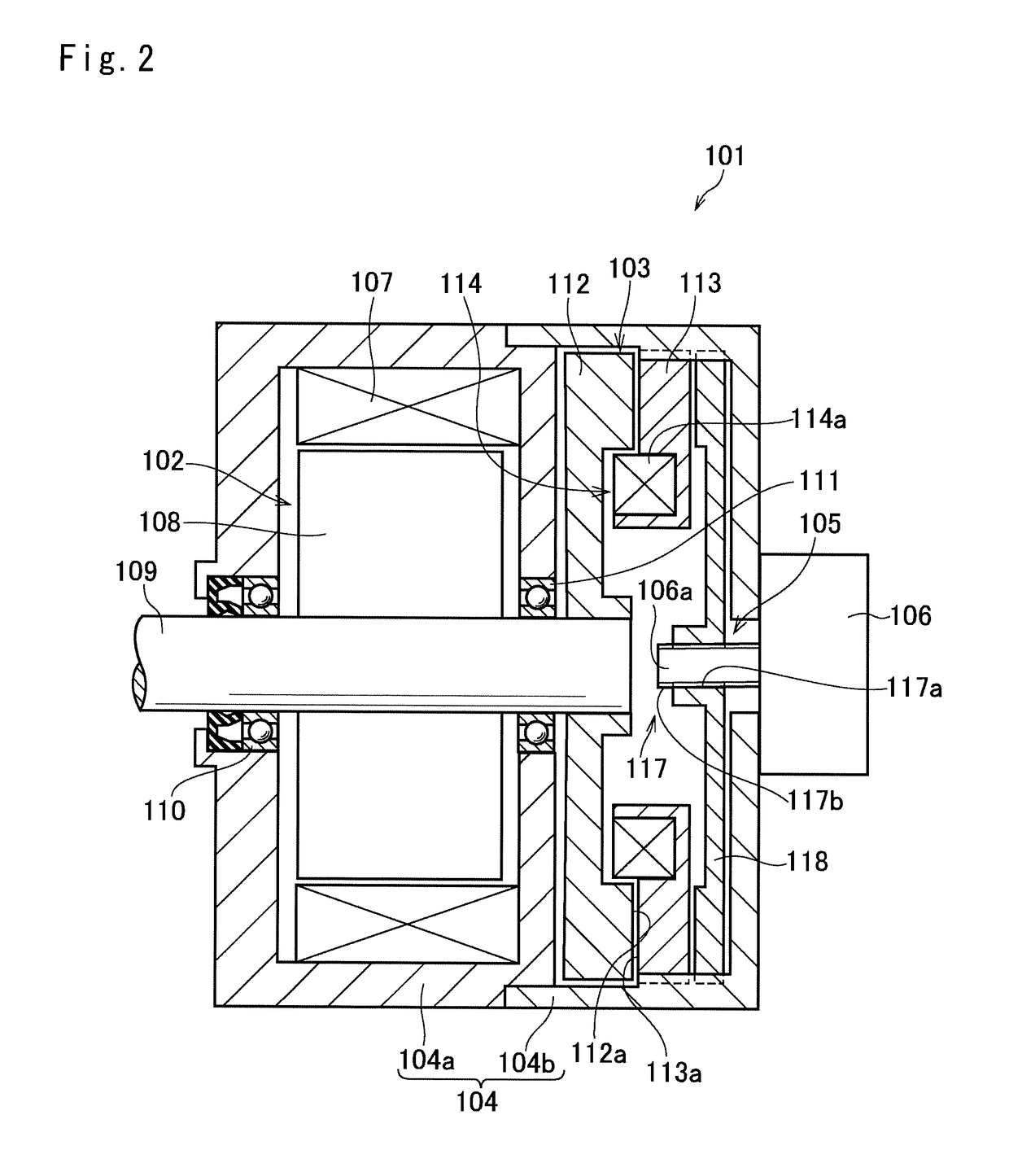

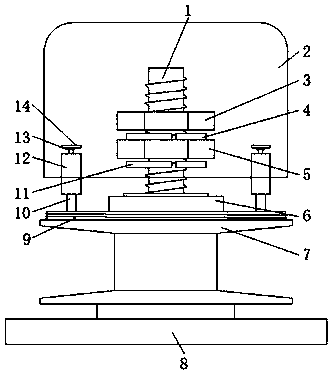

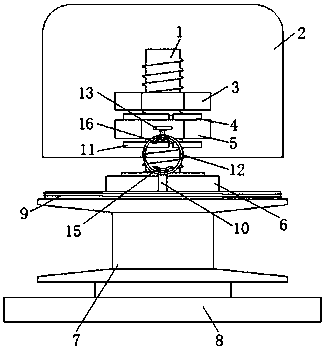

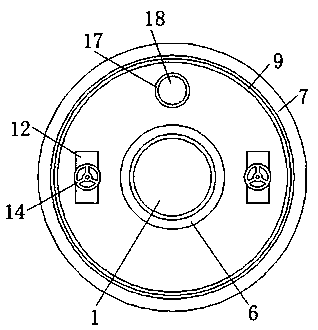

Motor assembly

InactiveUS20170166061A1Maintain the braking torqueMaintain frictionElectric devicesAxially engaging brakesLinear motionBrake torque

A motor having an electromagnetic brake is provided to ensure a braking torque even when power is off. The motor assembly comprises a drive motor and an electromagnetic brake. A thrust generating mechanism translates rotational motion of a brake motor to linear motion to generate thrust force for moving any one of brake stator and brake rotor of the electromagnetic brake thereby maintaining frictional contact therebetween to stop rotation of a motor shaft.

Owner:TOYOTA JIDOSHA KK +1

Cleaning device and manufacturing method thereof

InactiveCN103932650APrevent scratching itemsAvoid scratchesKitchenware cleanersYarnPolyesterBiomedical engineering

The invention relates to the field of daily necessities, in particular to a cleaning device and a manufacturing method of the cleaning device. The cleaning device comprises at least one monofilament, the monofilament comprises a filamentous low-melting-point polyester fiber filament, and the polyester fiber filament is wrapped by a fiber wrapping layer. According to the cleaning device and the manufacturing method of the cleaning device, materials are formed by combining low-melting-point polyester fibers and polyester fibers or polypropylene fibers, the materials are wound and are in the shape of the cleaning device, the hardness and friction force of the cleaning device can be kept through the characteristics of the low-melting-point polyester fiber materials, and the cleaning capacity of the cleaning device is guaranteed finally. It is guaranteed that friction force and hardness of the cleaning device cannot be too large through chinlon materials with the outer layers covered with threads, the low-melting-point polyester fibers are prevented from scratching objects, and the cleaning device and the manufacturing method can be widely applied to cleaning balls and net-shaped or block-shaped cleaning products.

Owner:陈玲君

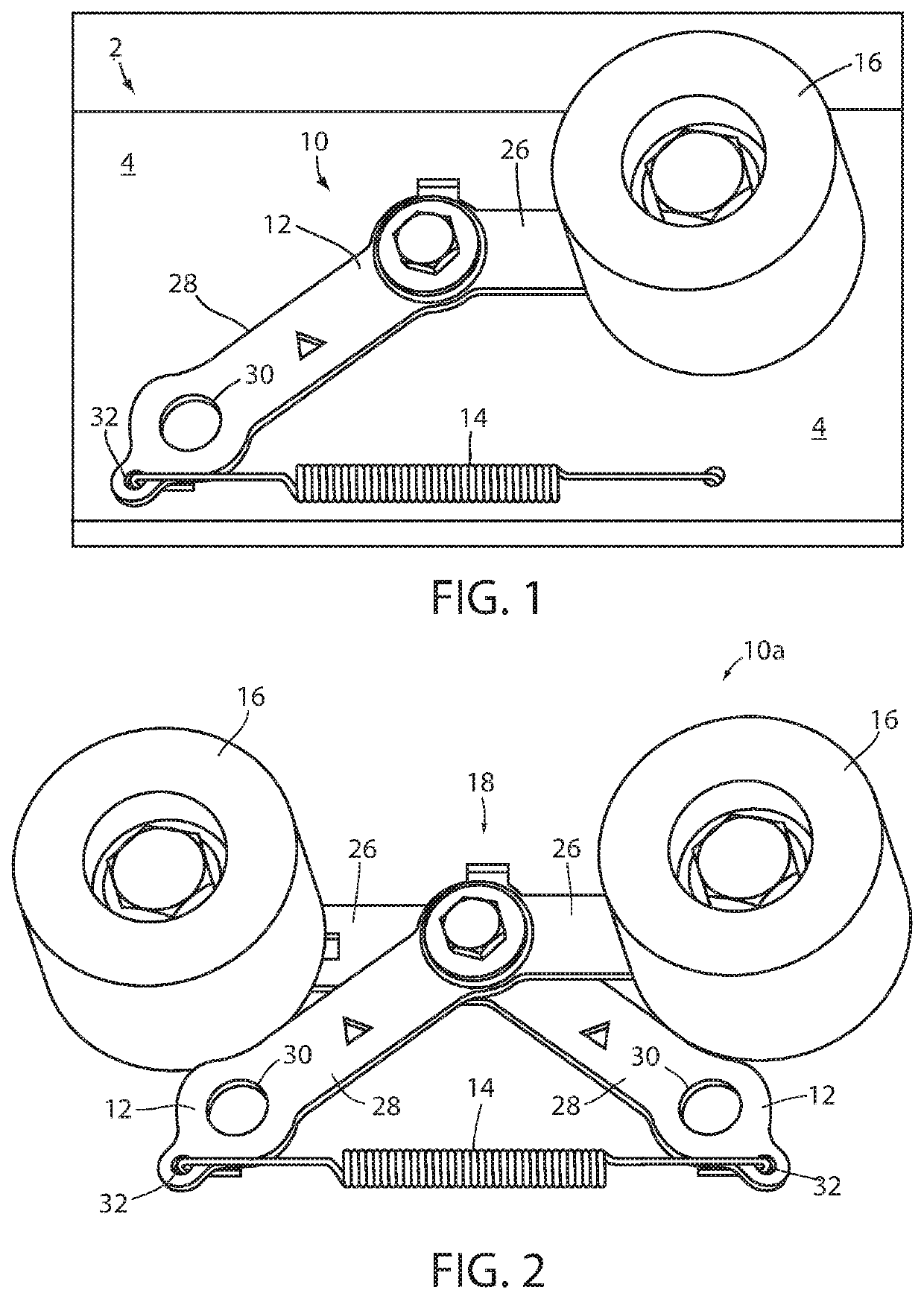

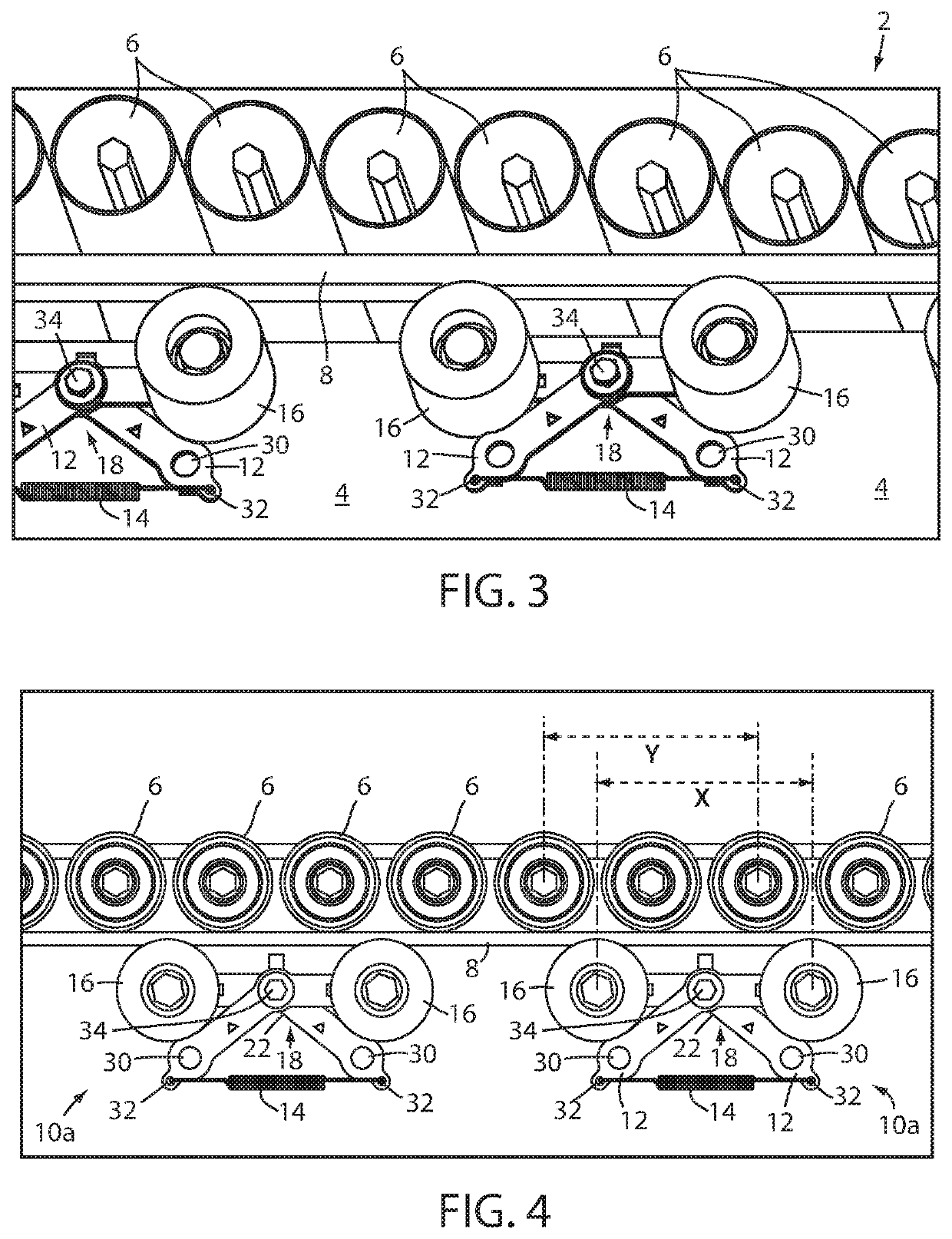

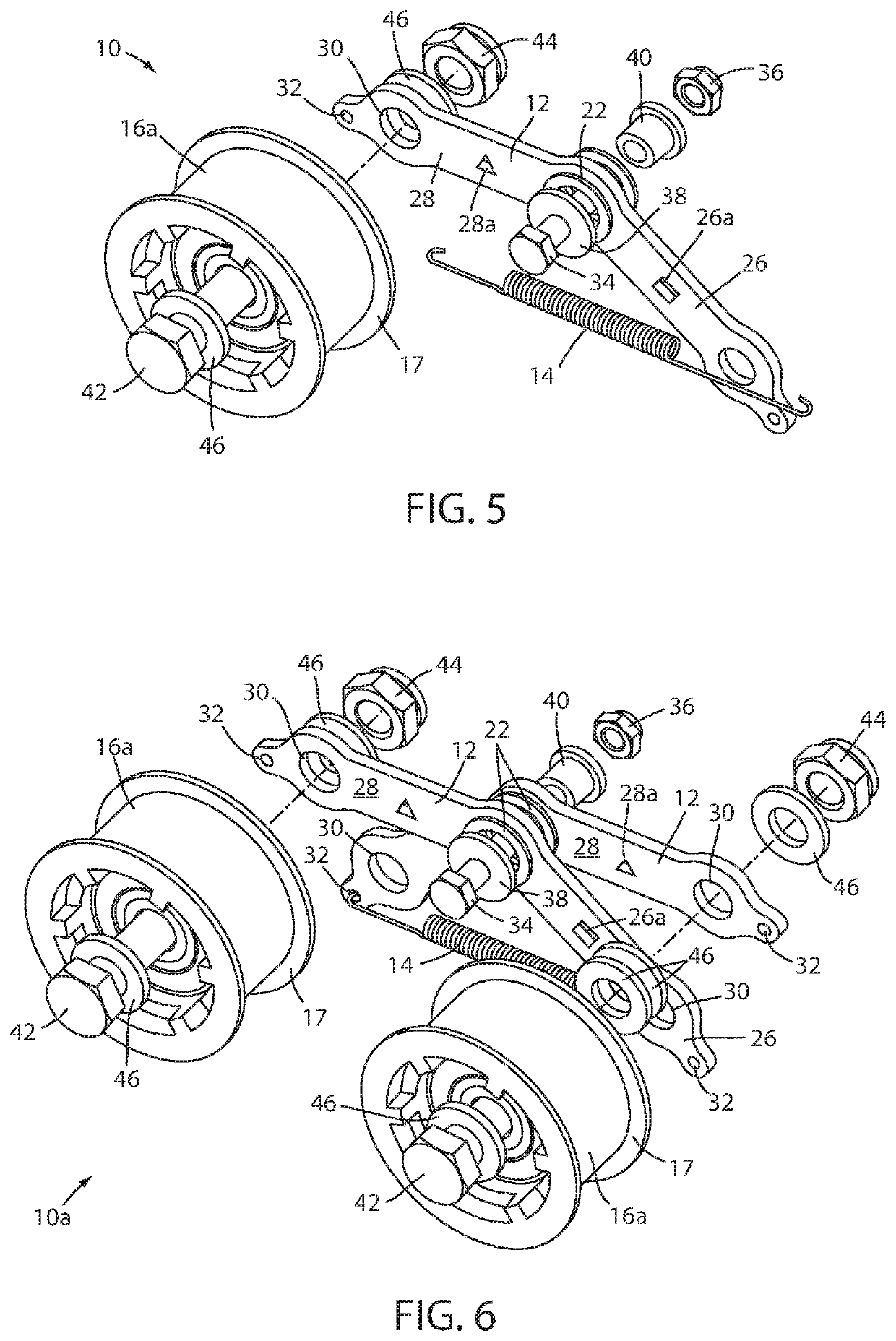

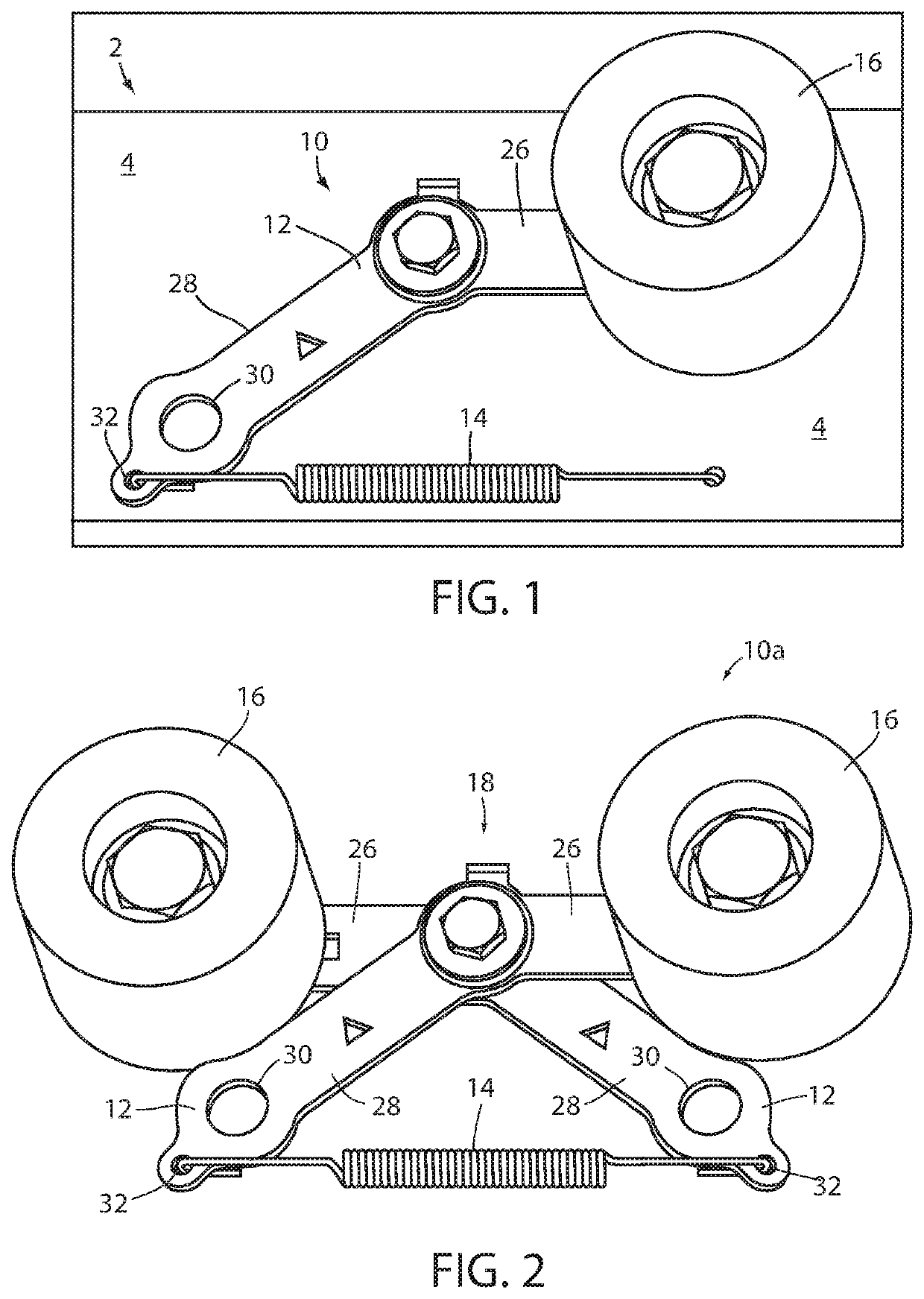

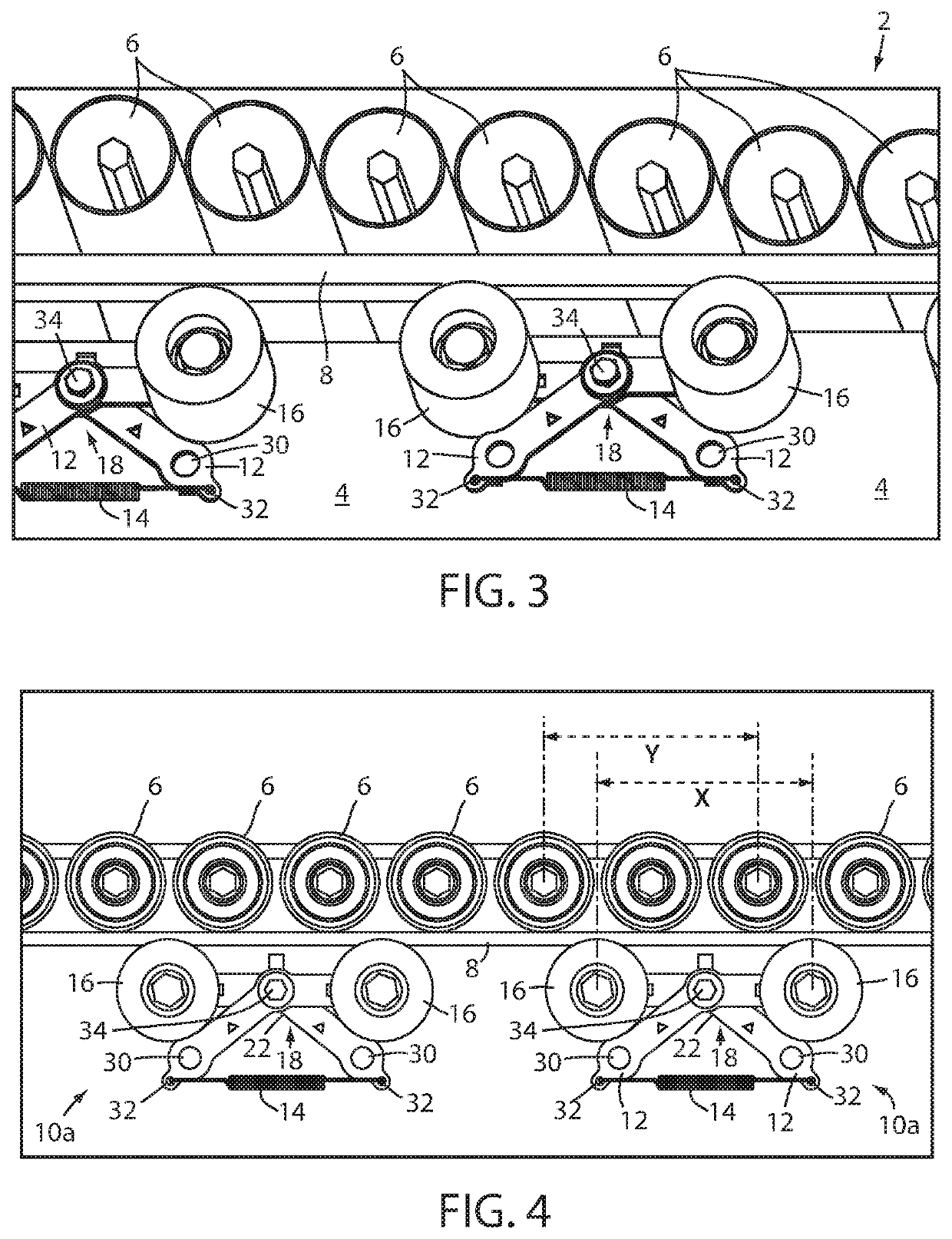

Automatic drive belt biasing device

ActiveUS20200354153A1Reduce fatigueReduce wearConveyorsControl devices for conveyorsControl theoryConveyor belt

An automatic belt biasing device is provided for biasing a drive belt into frictional contact with rollers of a conveyor. The belt biasing device maintains a drive belt in contact with rollers of a live roller conveyor to provide drive for the rollers to propel items or packages along the conveyor. A spring attached to a pivot arm or pair of scissoring pivot arms adjusts a biasing force applied by guide wheels of the belt biasing device to the drive belt due to changes in drive belt tension. The belt biasing device may be selectively adjustable based on required roller pitch distances. The belt biasing device is pivotably coupled to the roller conveyor allowing the guide wheels to apply equal pressure to the drive belt while allowing the pivot arms to actuate and increase or decrease the biasing force provided by the belt biasing device.

Owner:DEMATIC

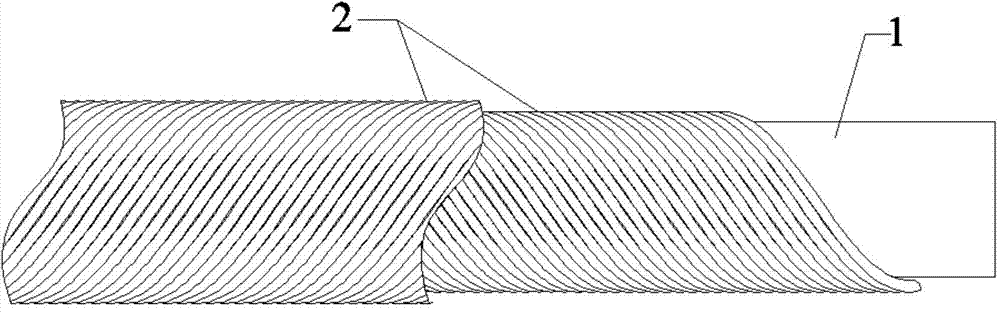

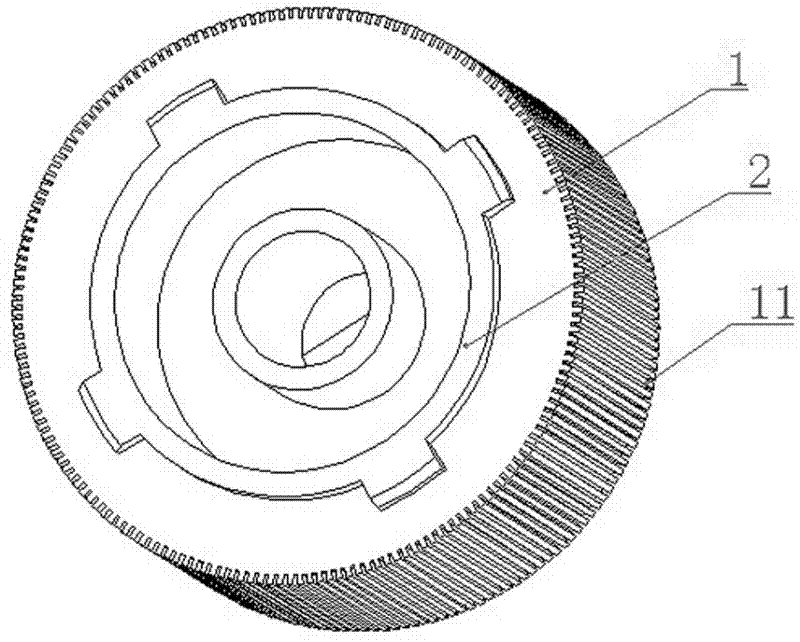

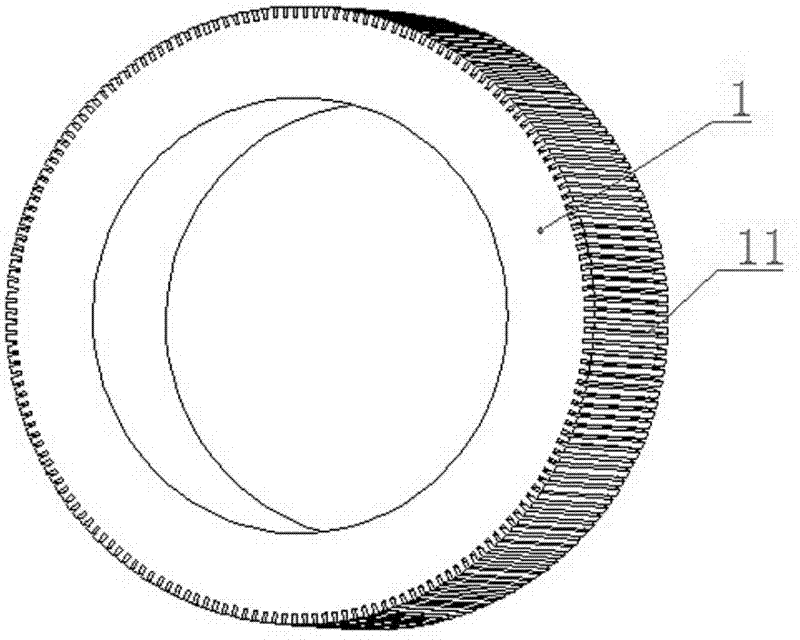

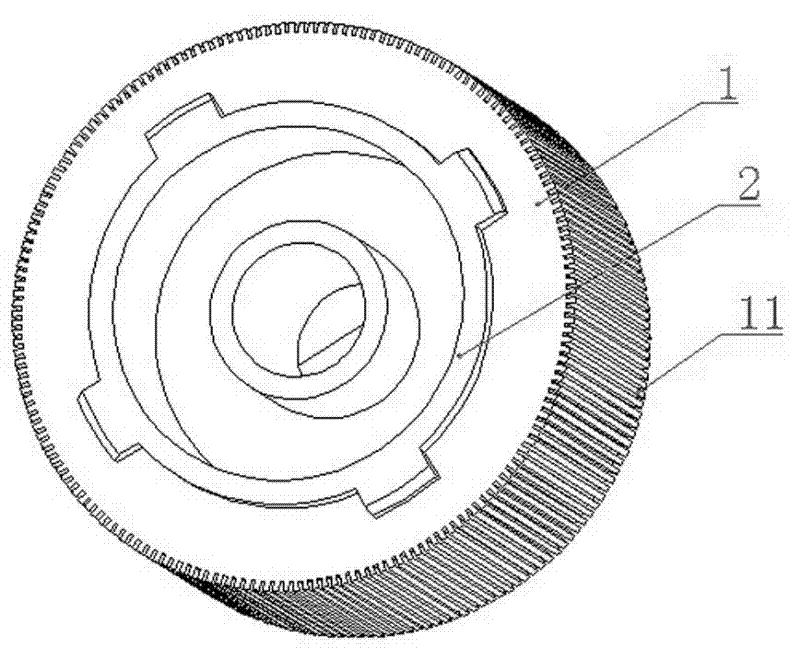

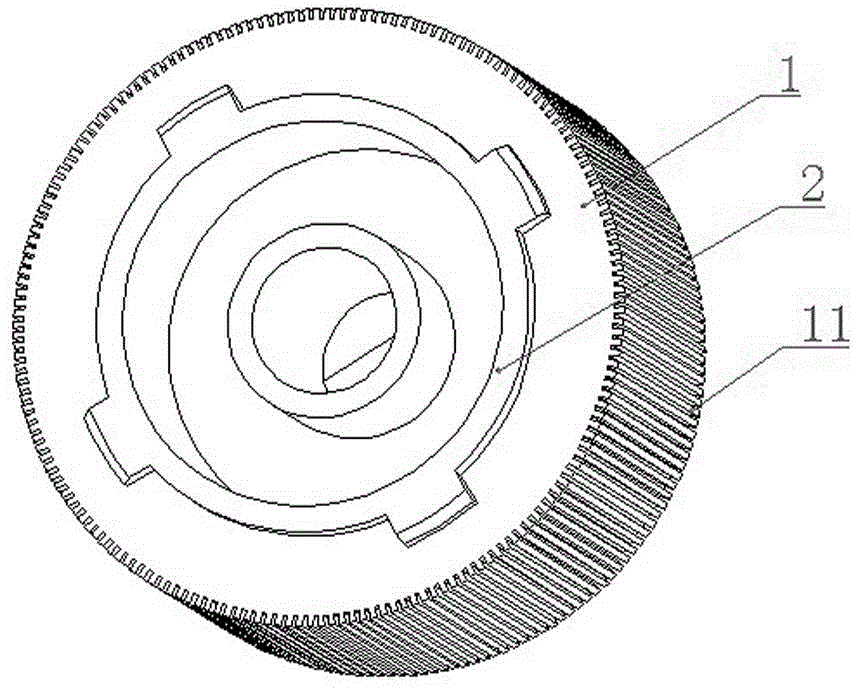

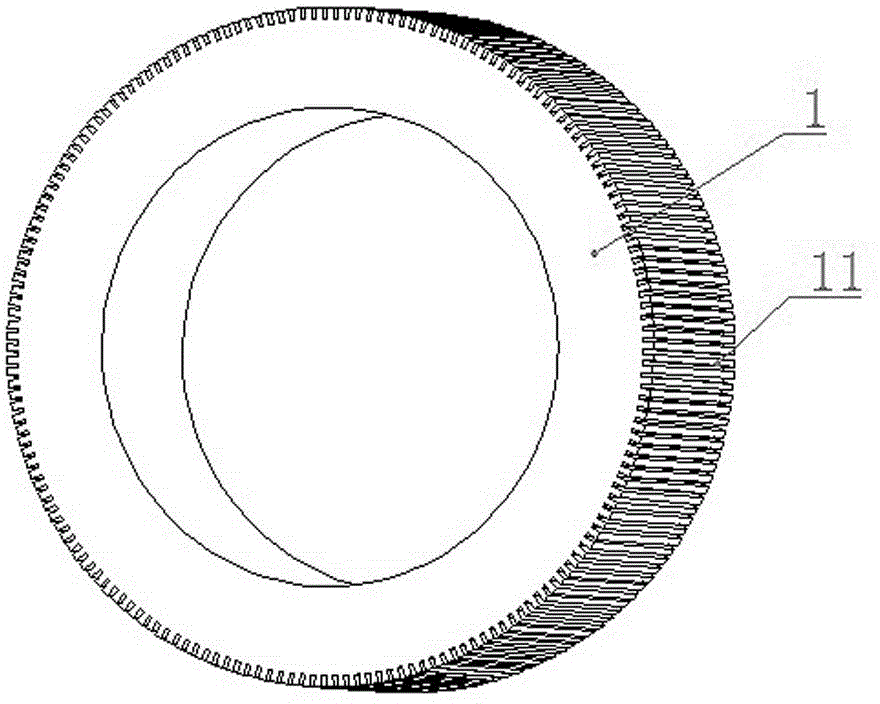

Paper feeding wheel and manufacturing method thereof

ActiveCN102358527AEasy to demouldImprove work efficiencyArticle feedersMetal layered productsAntioxidantHardness

The invention discloses a paper feeding wheel and a manufacturing method thereof. The paper feeding wheel consists of a plastic framework and a rubber wheel sleeved on the plastic framework, wherein the rubber wheel is made of a rubber composition; and the rubber composition comprises rubber with high wear resistance and strength, an effective rubber vulcanizing system, more than one antioxidants, and a proper amount of reinforcing filler and softening agent, wherein the effective rubber vulcanizing system is suitable for a composition of butadiene rubber and natural rubber; one of the more than one antioxidant has a function of assisting in demoulding after rubber is vulcanized; and the proper amount of reinforcing filler and softening agent can improve the strength of the rubber wheel and cannot obviously improve hardness. The invention has the advantages that: the manufacturing process is simple, and the rubber wheel is formed by a mold through one-time compression moulding, and is not required to be processed; the surface of the paper feeding wheel is hardly subjected to frost spray; and the frictional property of the surface of the paper feeding wheel can be kept for a long time.

Owner:BEIJING LASER HI TECH CO LTD

Speed reduction device of vehicle

InactiveUS7950493B2Small sizeSolution value is not highCyclesBraking element arrangementsVehicle frameDrive wheel

A speed reduction device of a vehicle for reducing the rotation of drive wheels includes a casing mounted on a vehicle frame, first and second drive axles rotatably mounted on the casing and connected to first and second drive shafts, respectively, and a driven sprocket wheel and a brake disc for braking the first and second drive axles are mounted on the first drive axle. The second drive axle is detachably joined to the first drive axle.

Owner:HONDA MOTOR CO LTD

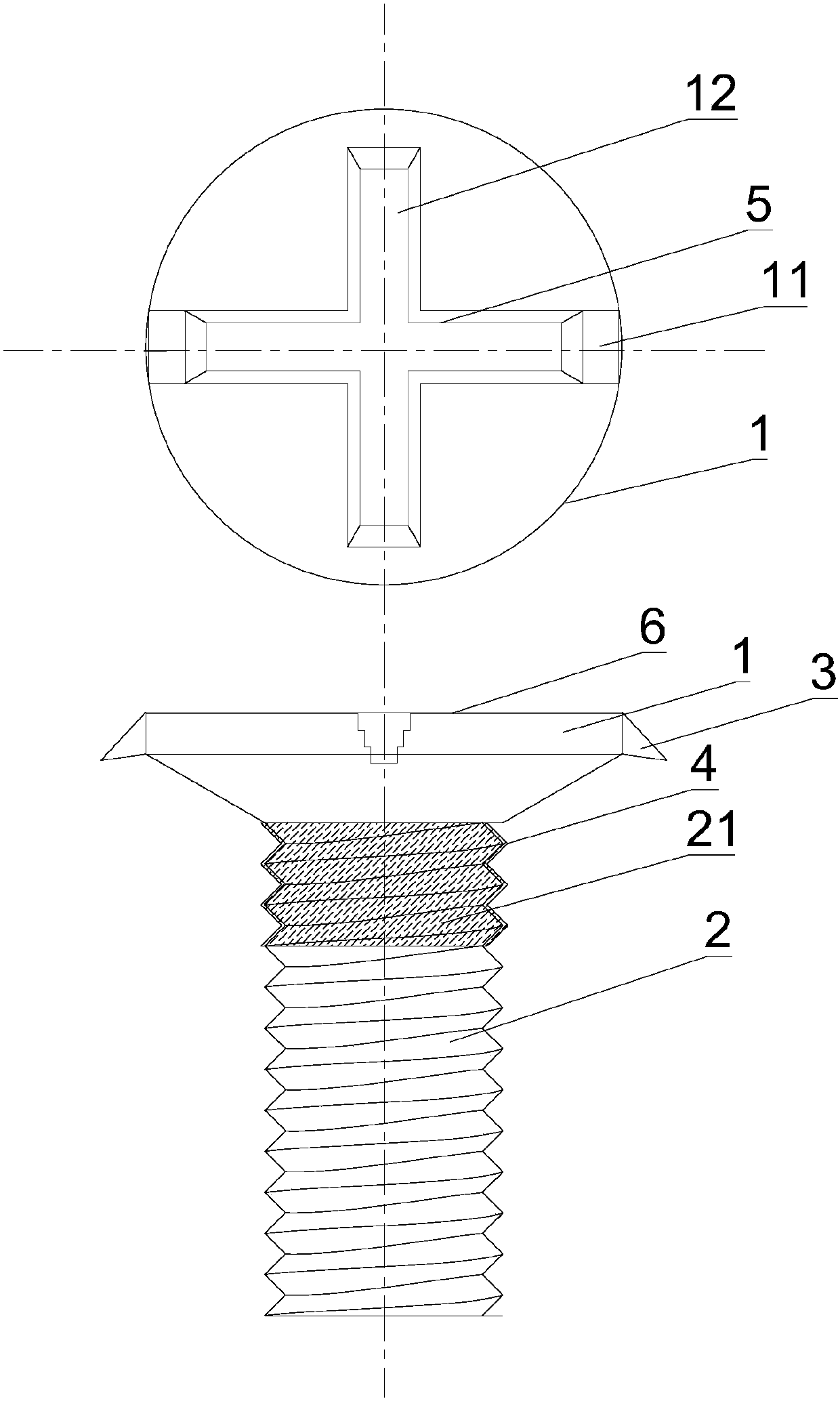

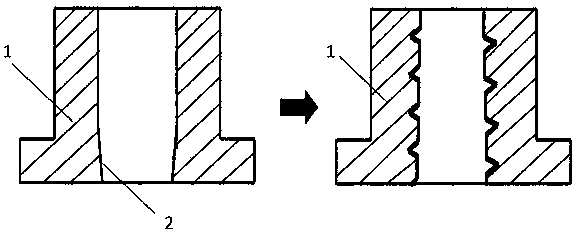

Anti-falling screw

The invention discloses an anti-falling screw, which belongs to the field of fasteners. The structure includes a screw head and a screw rod. The screw head is a circular cylinder with a layer of wear-resistant coating sprayed on the surface. The structure overlaps a word groove and a cross groove, and the groove is provided with a magnet adsorption film and a wear-resistant layer, and a wing-shaped protective edge is provided around the screw head cylinder; the surface of the screw rod forms an external thread The outer surface of the upper part of the screw rod near the screw head is provided with an elastic ring. The invention solves the problems of inconvenient use of ordinary screws, wear of the groove after repeated use, and easy falling off, which causes the screw to rust and harm the human body.

Owner:CHENGDU XINXIN HIGH STRENGTH FASTENER MFRCO

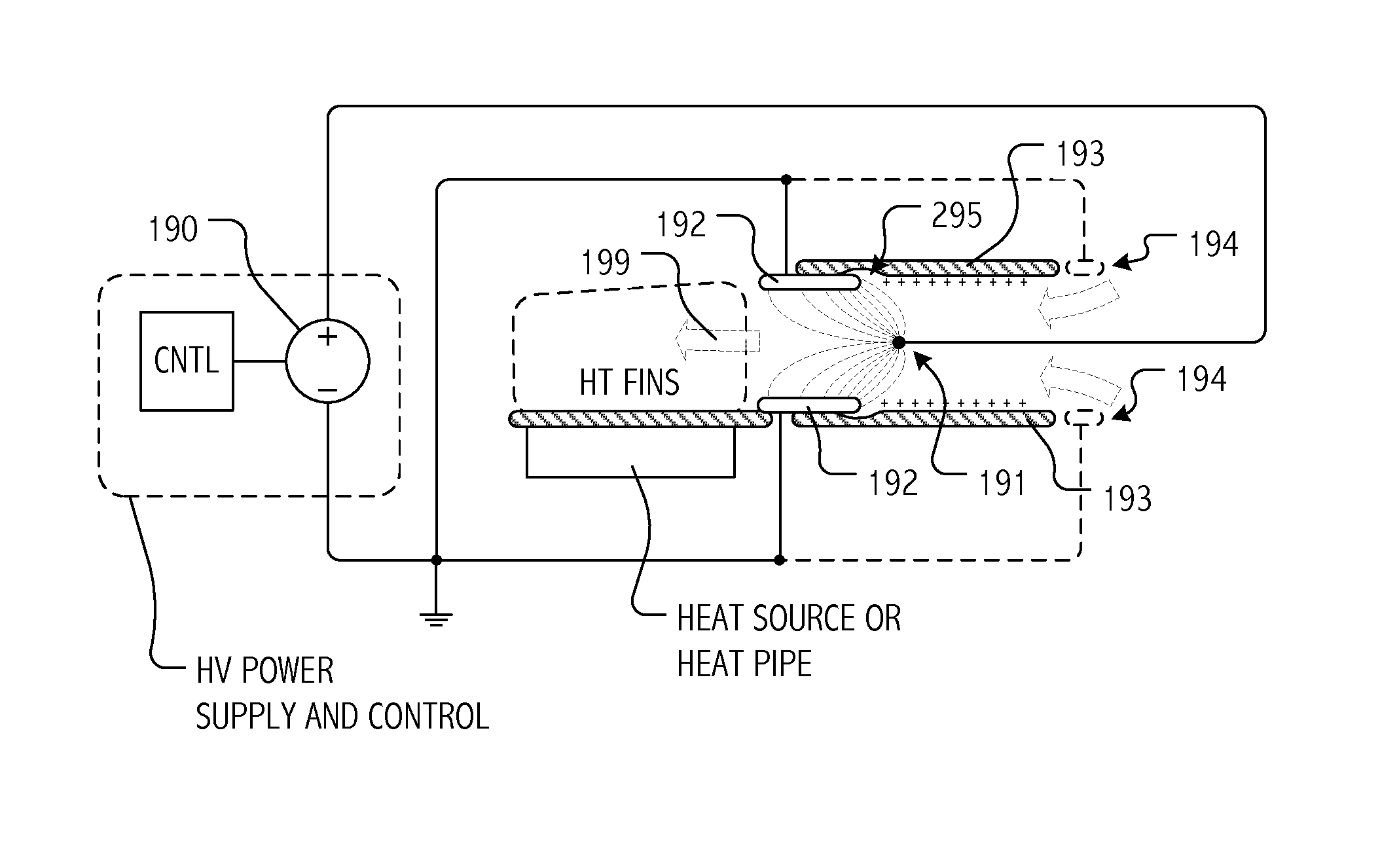

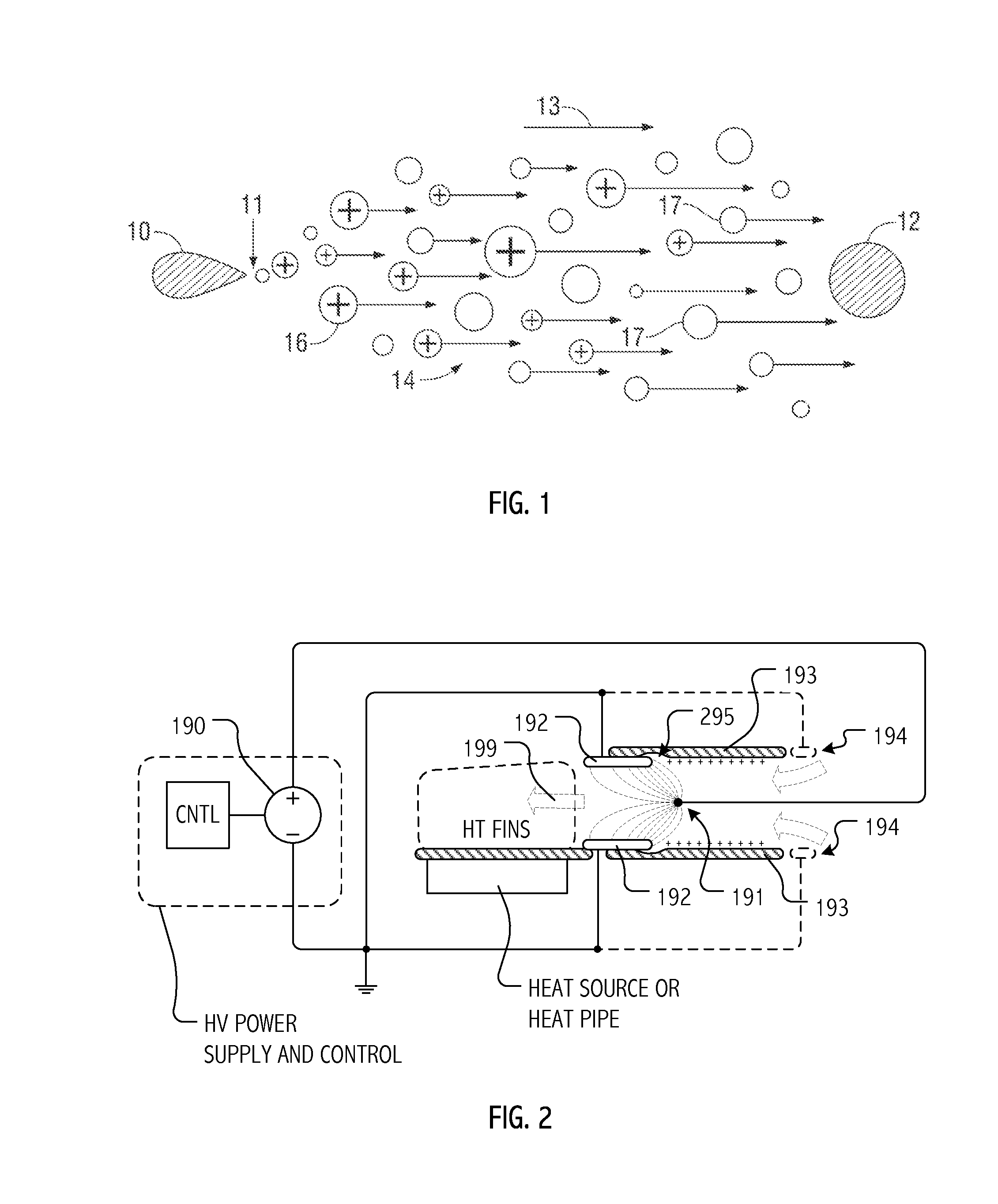

Electrohydrodynamic (EHD) fluid mover with collector electrode leading surface shaping for spatially selective field reduction

InactiveUS20140097722A1Efficiently definedFluid to flowDigital data processing detailsElectrical apparatus contructional detailsChemical physicsElectrical field strength

In various electrohydrodynamic (EHD) fluid mover designs disclosed herein, electric field strength may be locally reduced in peripheral regions of an emitter-to-collector electrode gap. As a result, detrimental accumulations of silica, dust and other airborne contaminants can be reduced on surfaces in such peripheral regions, which may otherwise be susceptible to accumulations and / or difficult to clean or condition. In some cases, localized reduction in electric field near sidewall surfaces can provide desirable localized reductions in susceptibility to contaminant related spark or shunting current paths. In some cases, such as when a field blunting structure is employed and (as a result) a generally more uniform electric field pattern is provided locally, an engineered or purposeful local reduction both electric field strength and ion generation in peripheral regions of an emitter-to-collector electrode gap may be quite desirable.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

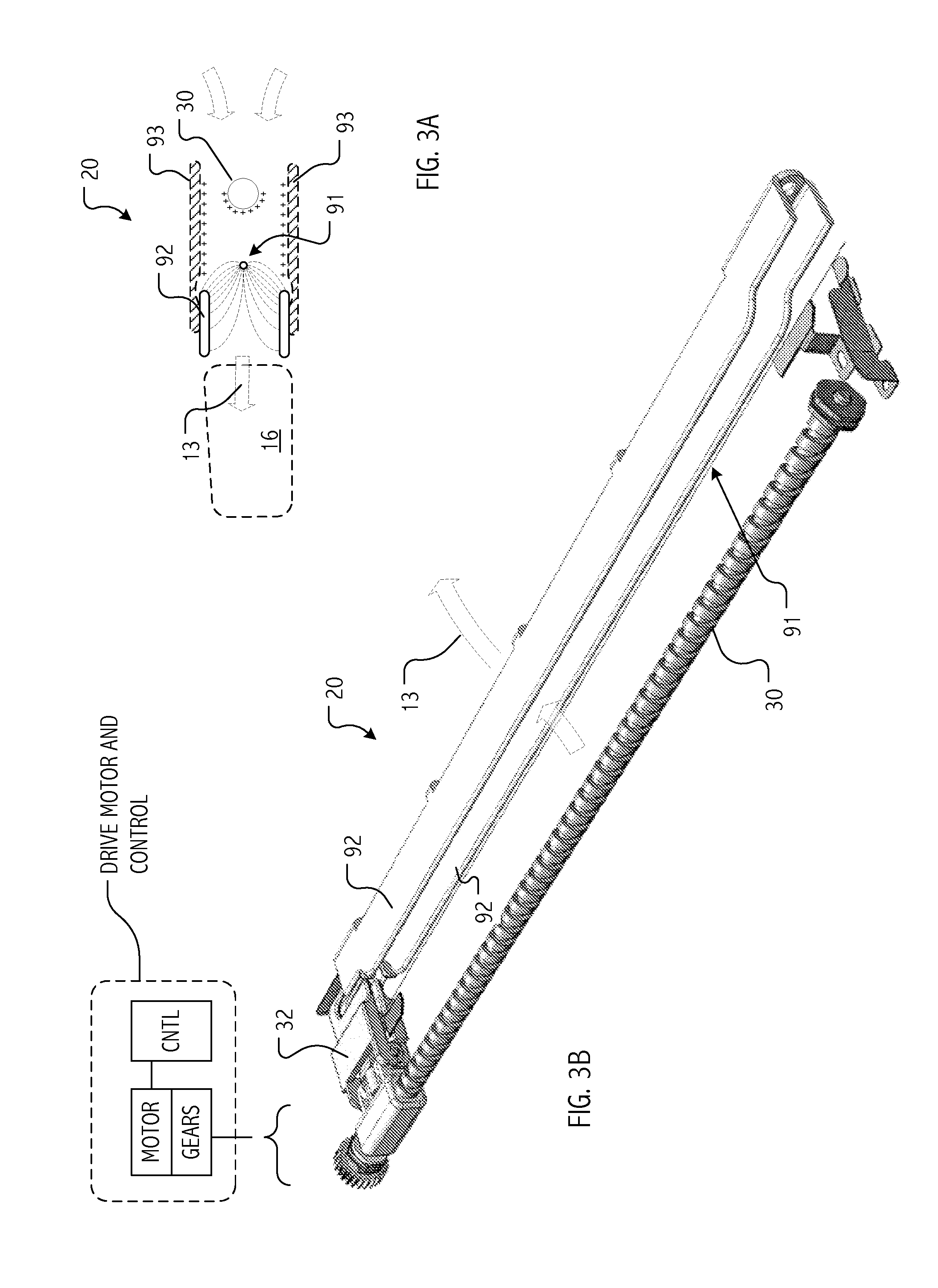

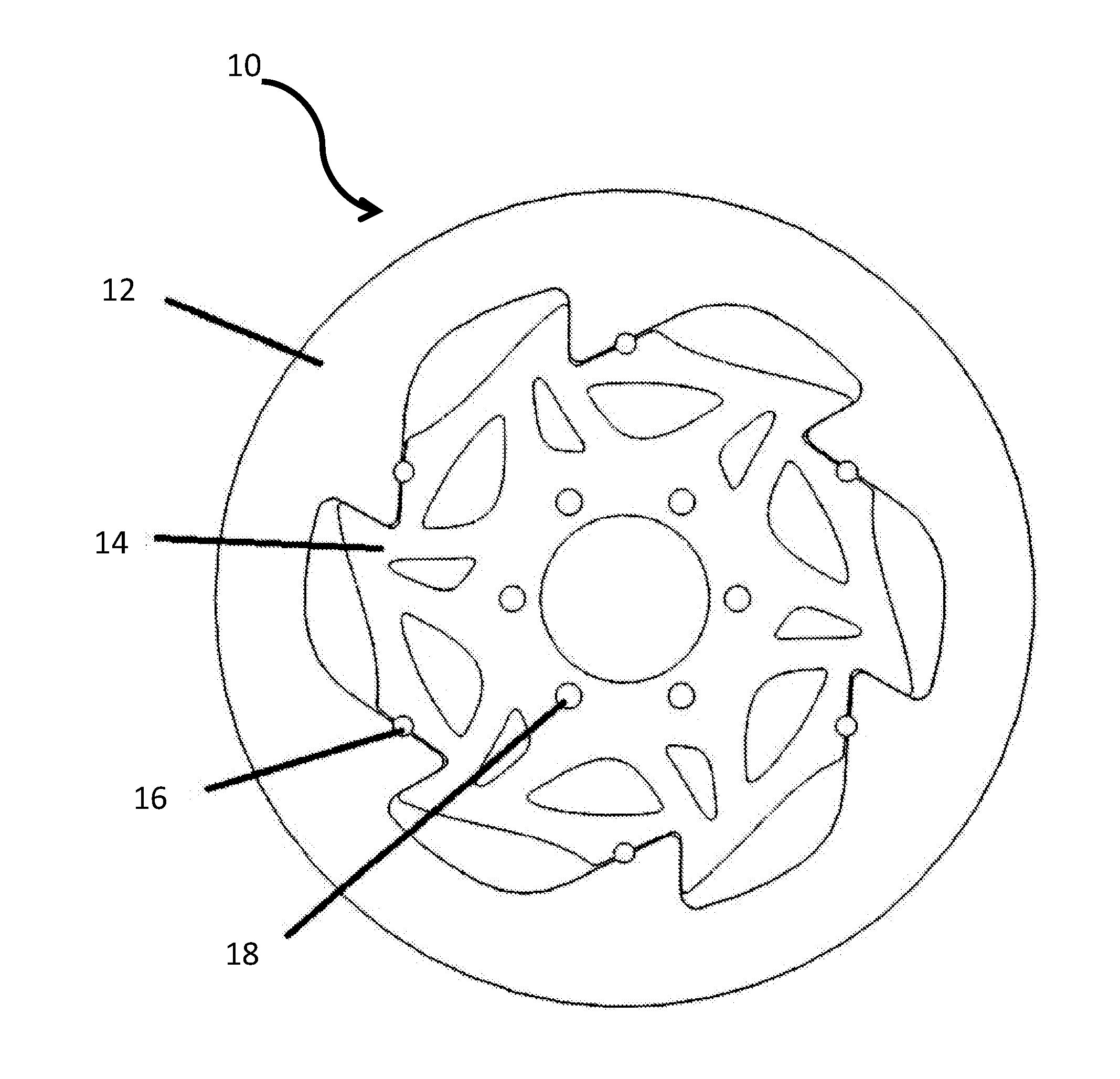

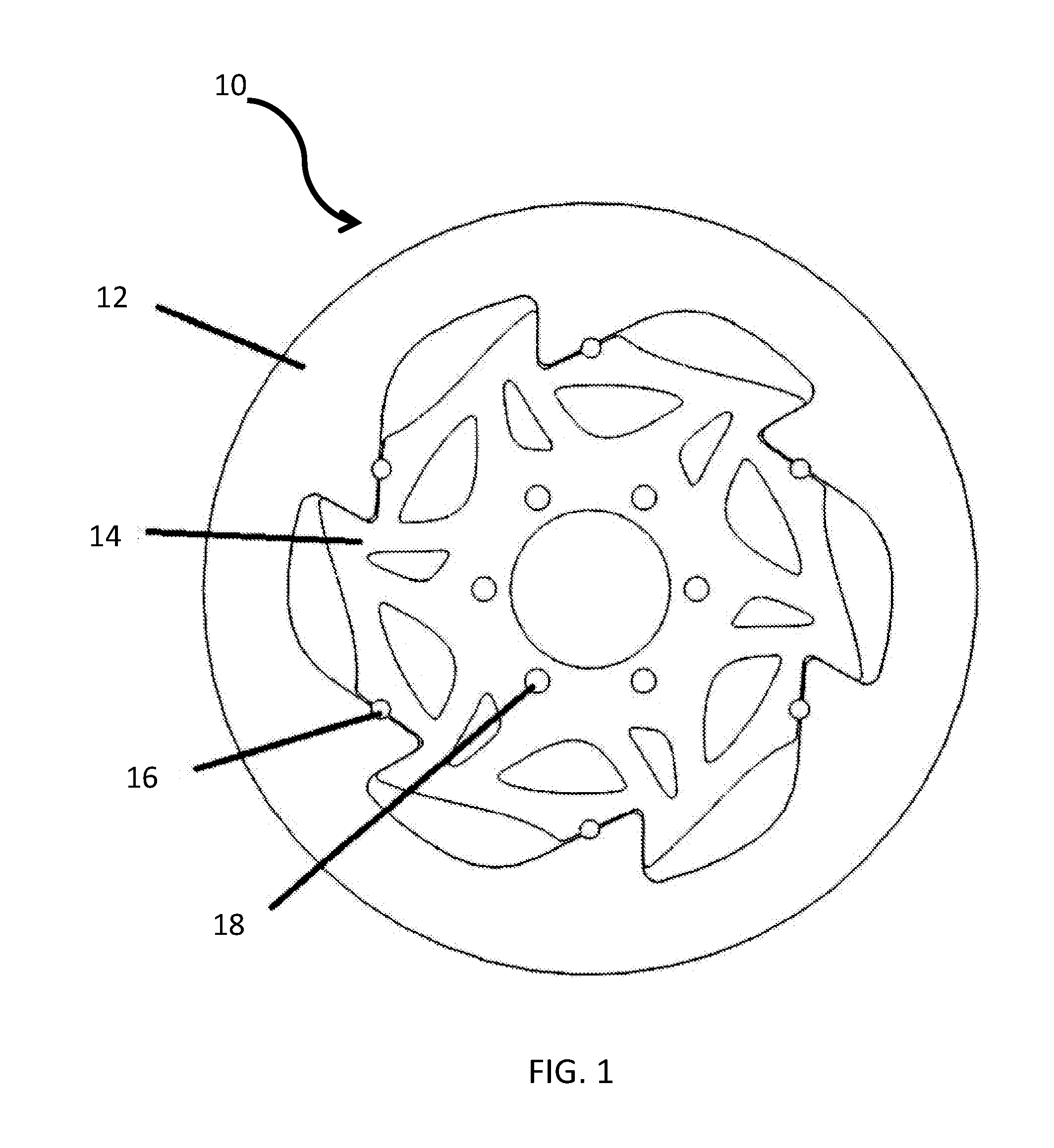

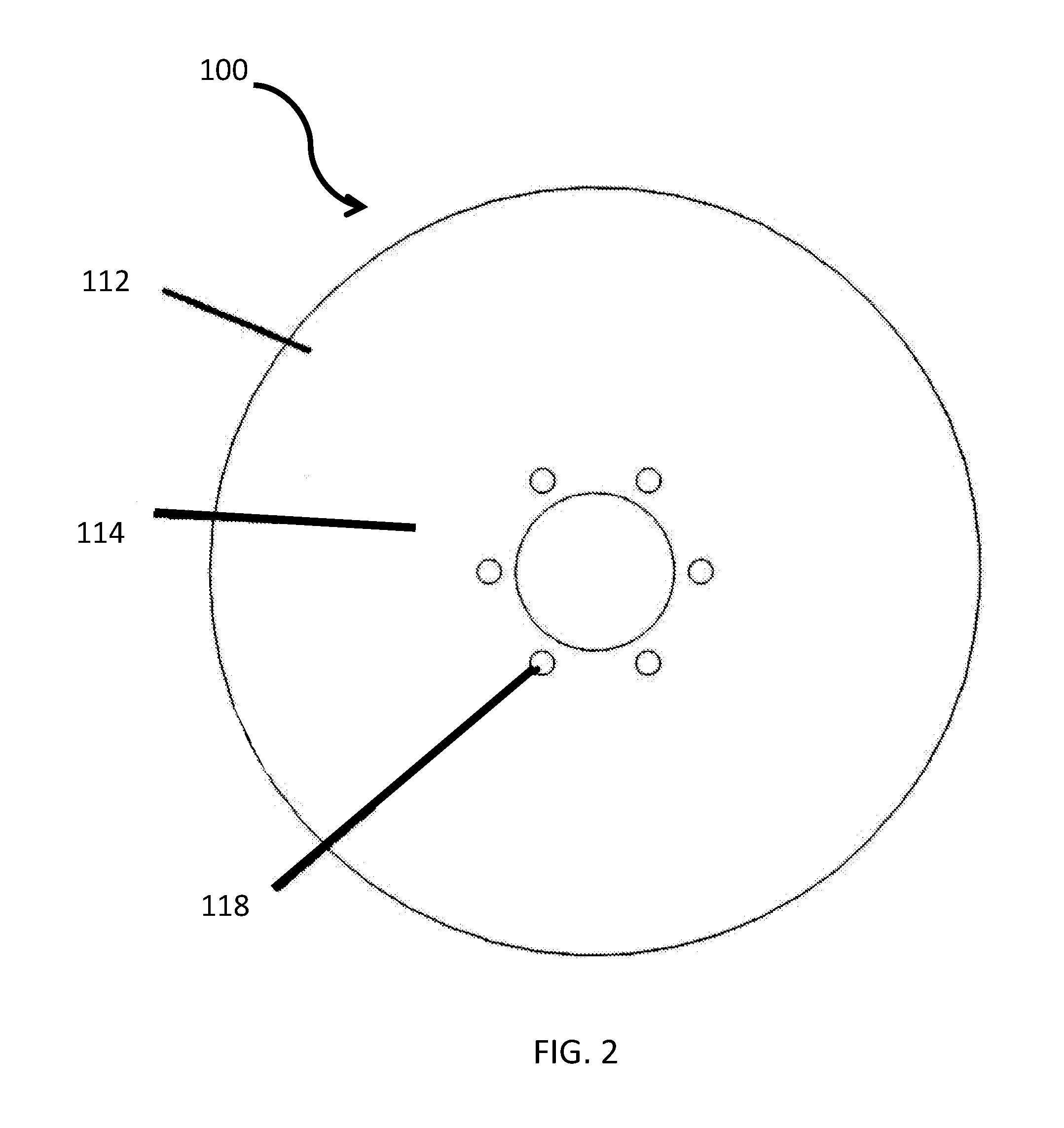

Bicycle Disc Brake Rotors and Methods of Making and Using the Same

InactiveUS20140131151A1Increase coefficient of frictionHeat dissipation fastBraking element arrangementsSynthetic resin layered productsFiberCarbon fibers

Bicycle disc brake rotors of the present invention are lightweight, have relatively high coefficients of friction to maintain braking friction under heavy braking, and quickly shed heat. The parts may preferably be made from a compound having carbon fiber and / or a refractory material, such as ceramic filler, within a polycarbosilane polymer resin, the polymer resin having a silicon-oxygen polymer backbone, producing silicon oxycarbides upon pyrolysis. Methods of making and using the same are further provided.

Owner:GORE JOSHUA R +1

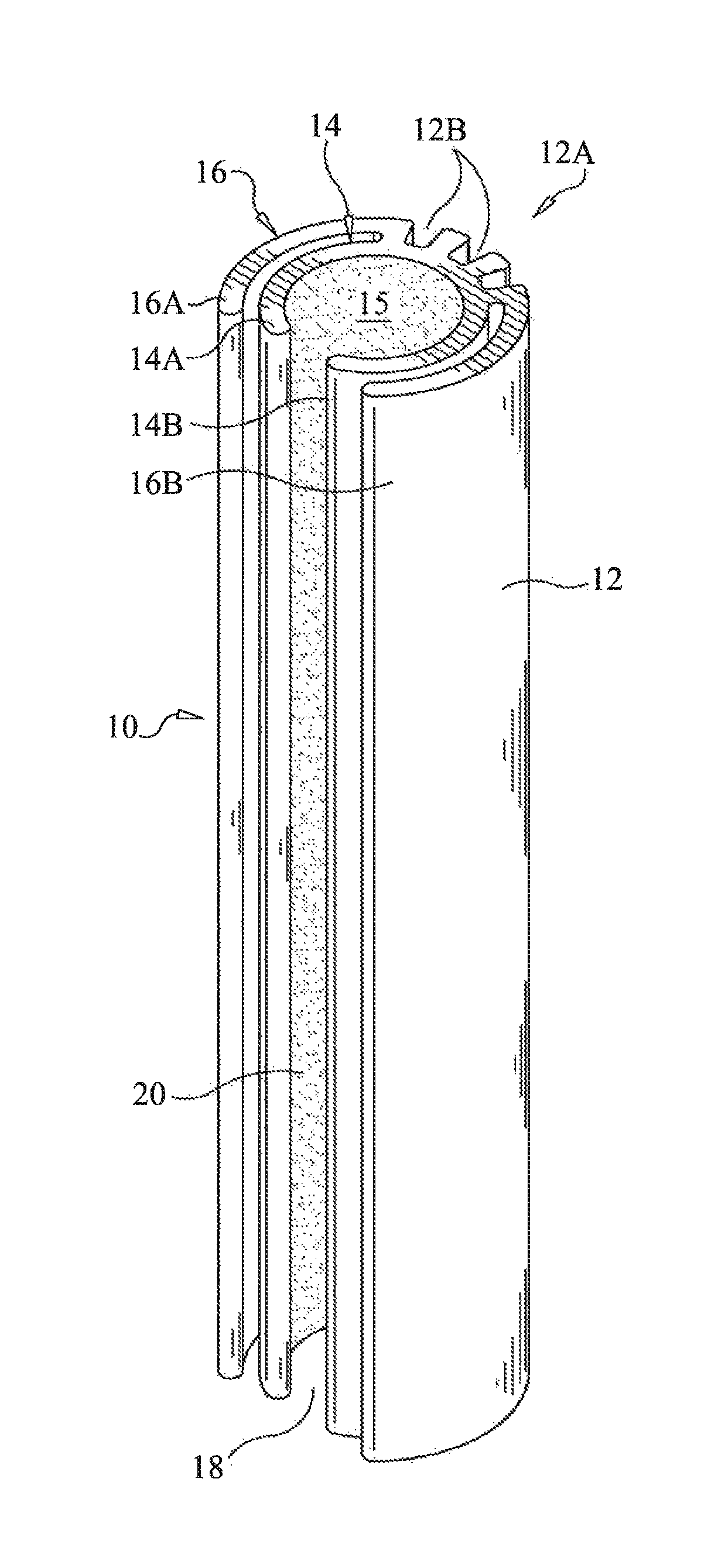

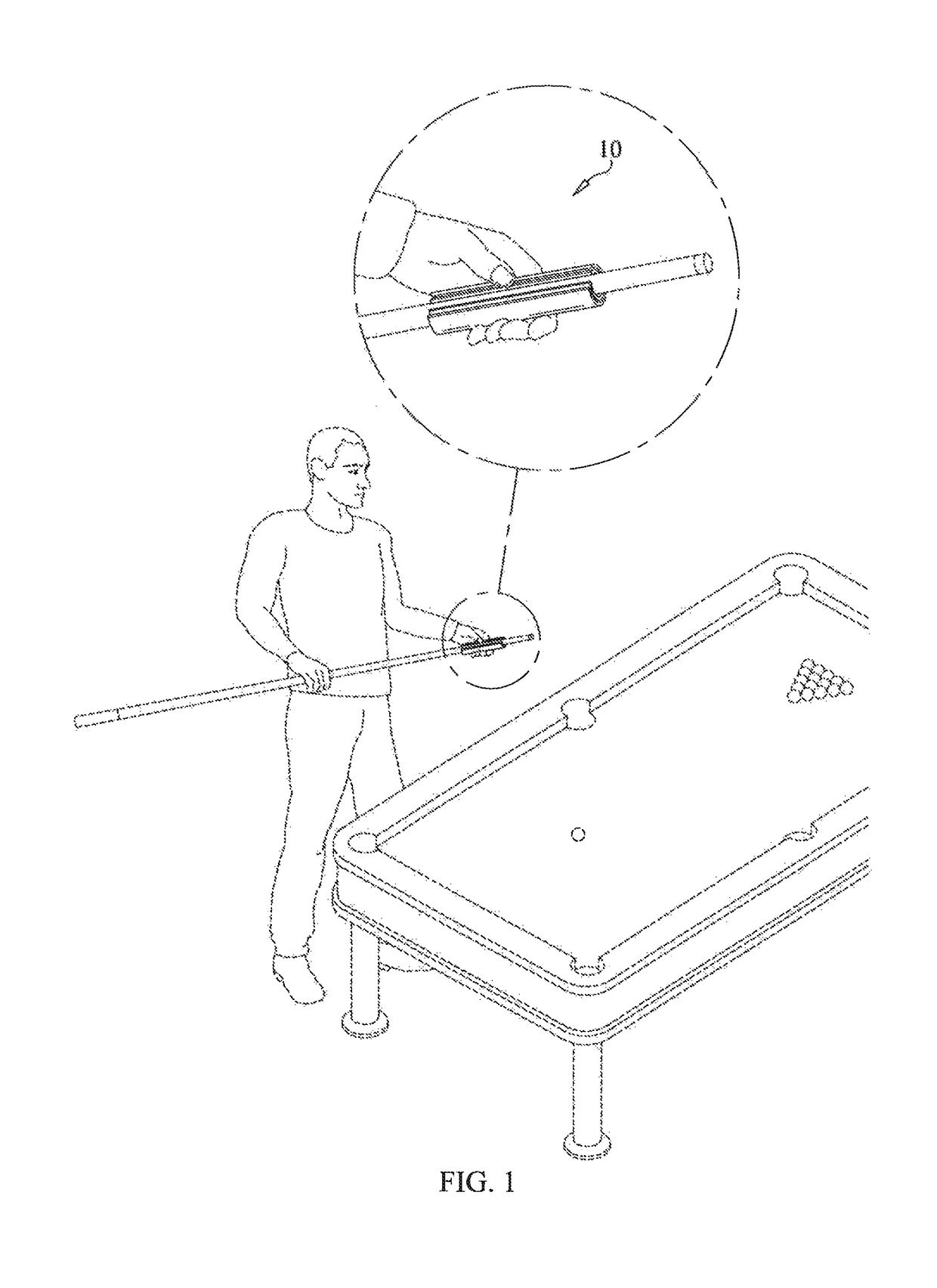

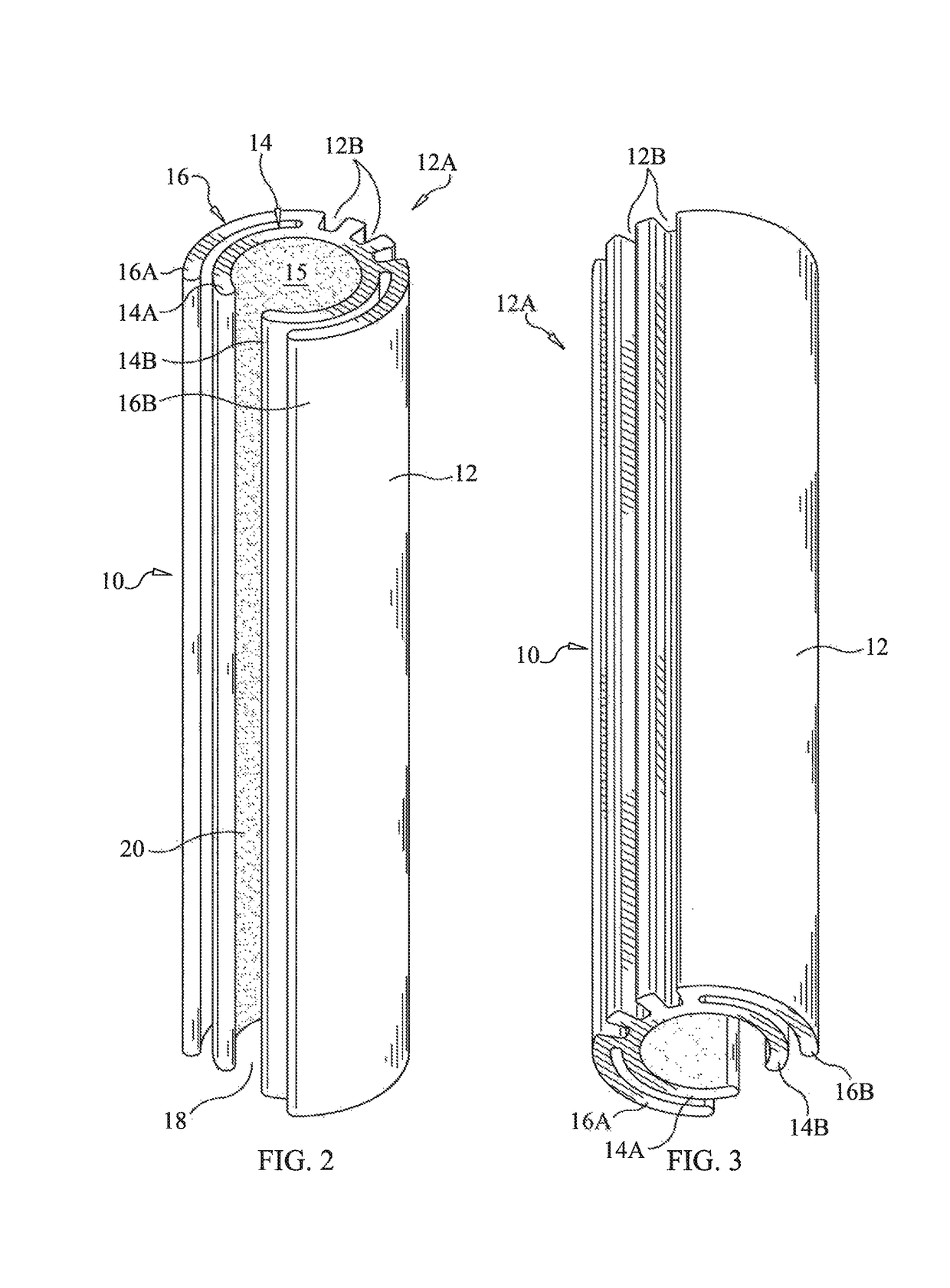

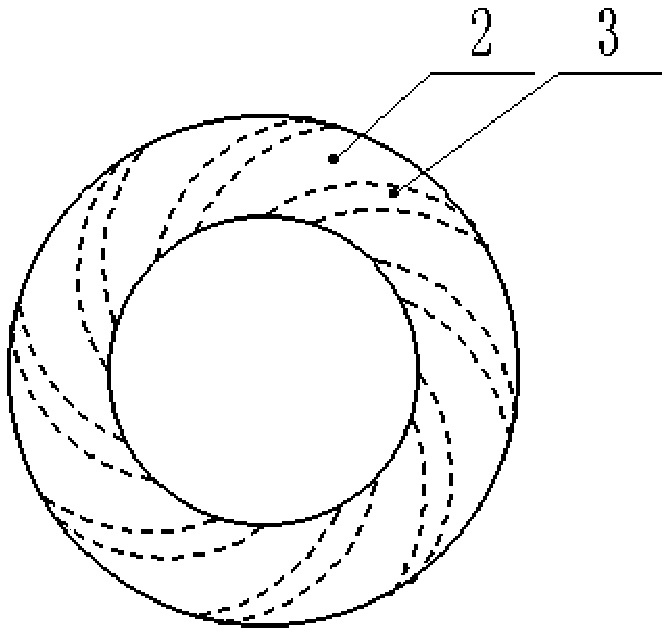

Sanding apparatus for billiard cue sticks

ActiveUS10046440B1Low staticLow dynamic coefficientBilliardsGrinding/polishing hand toolsEngineeringMechanical engineering

A sanding and smoothing apparatus for pool cue shafts comprises an elongate resilient main body having generally concentrically disposed resilient radially-inner and radially-outer C-shaped members. The apparatus is sized for mating engagement with the tapered shaft of a pool cue received in close fitting conforming relation with the inner surface of the radially-inner C-shaped member. The inner surface of the radially-inner C-shaped member is provided with a suitable abrasive sanding material, which may comprise a sanding sheet or an abrasive coating.

Owner:COLOMBO KEITH A +1

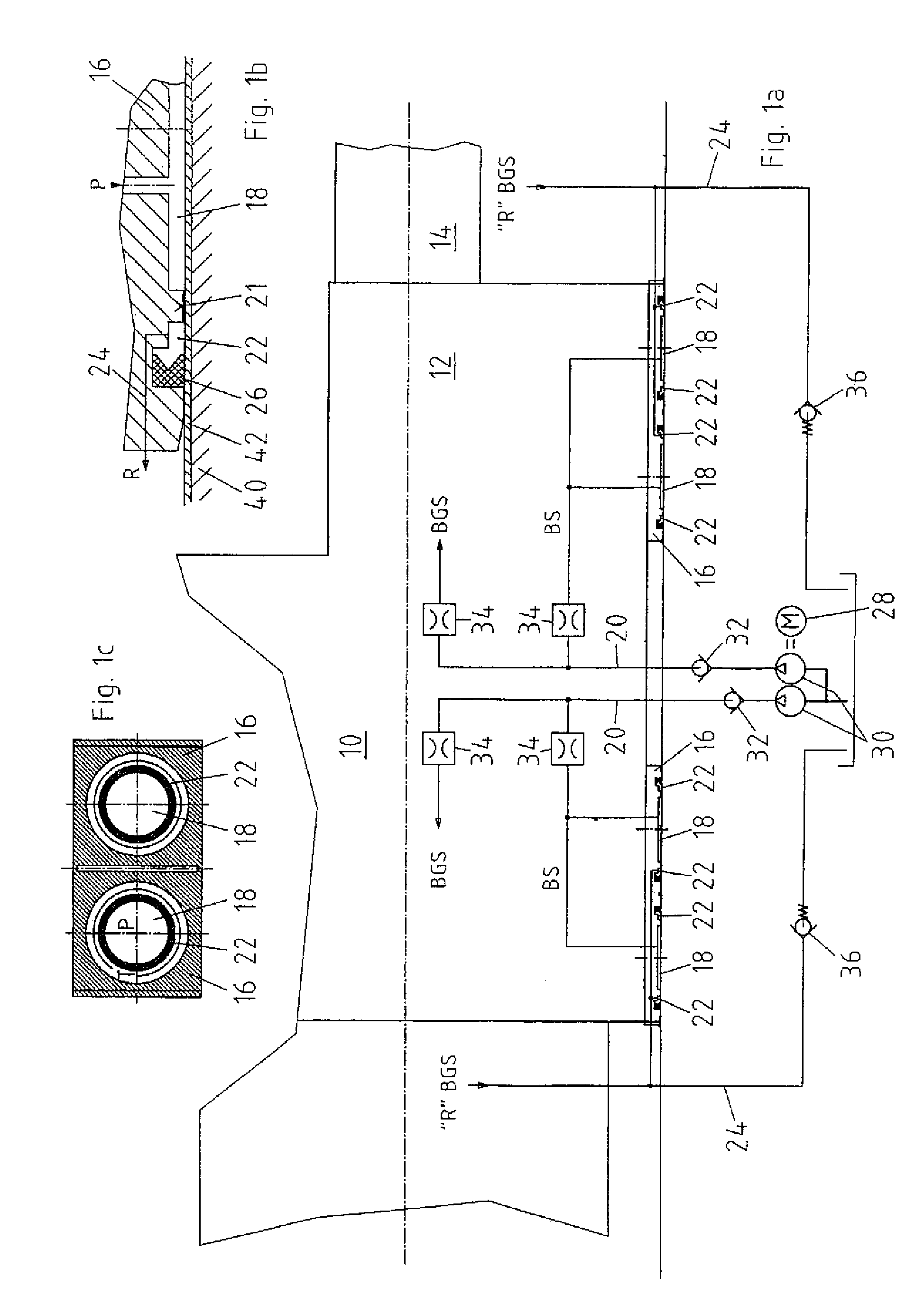

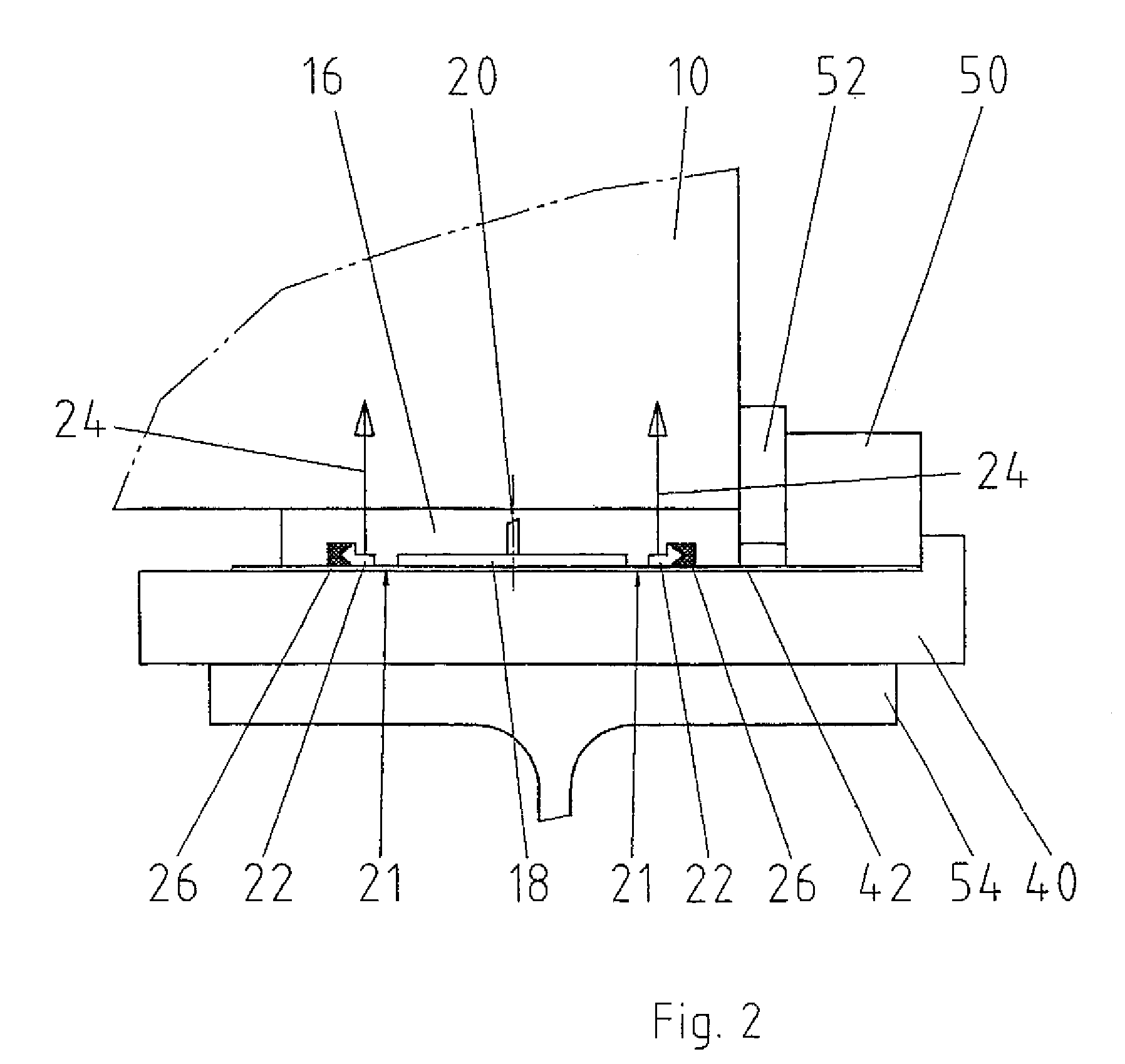

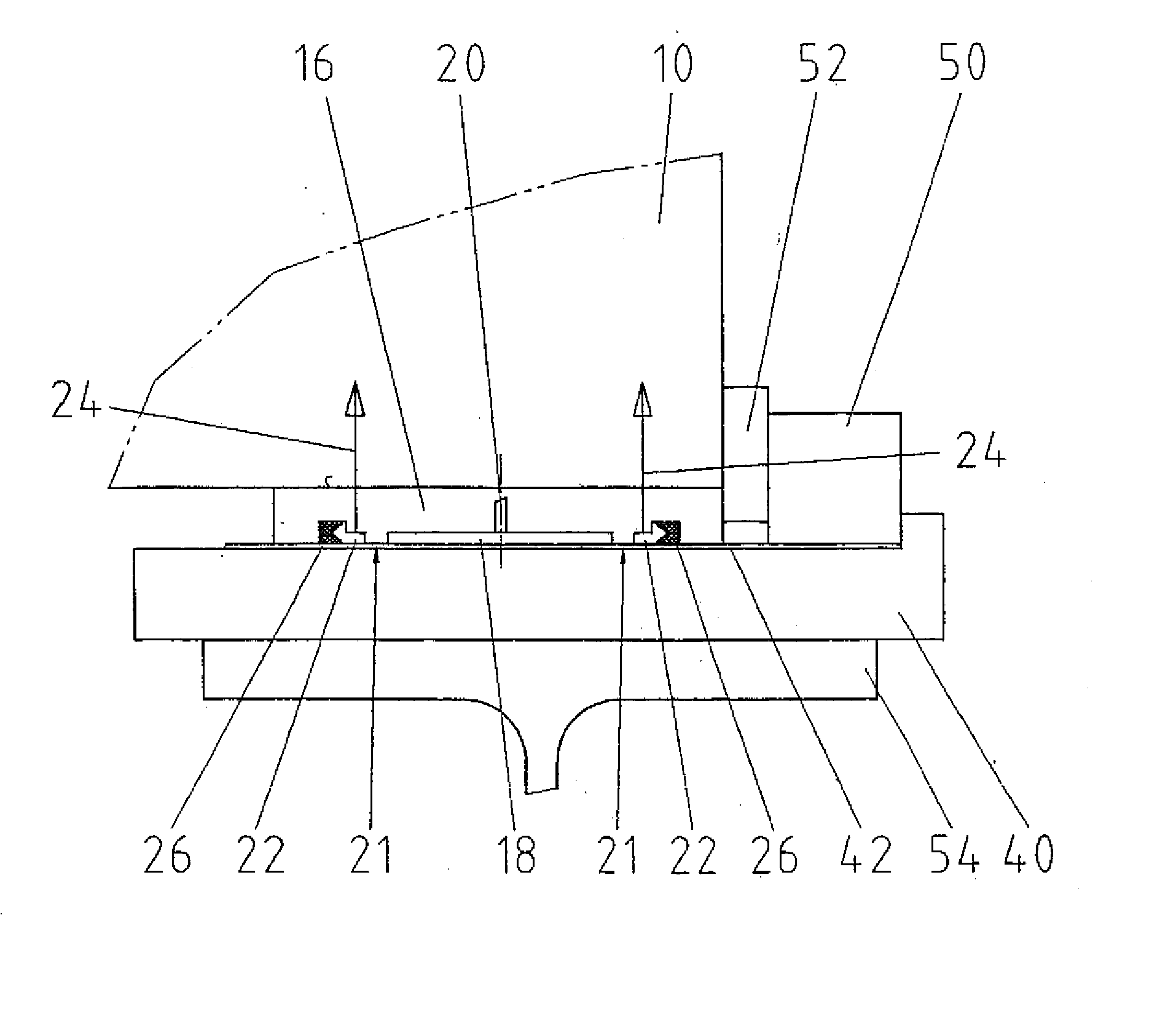

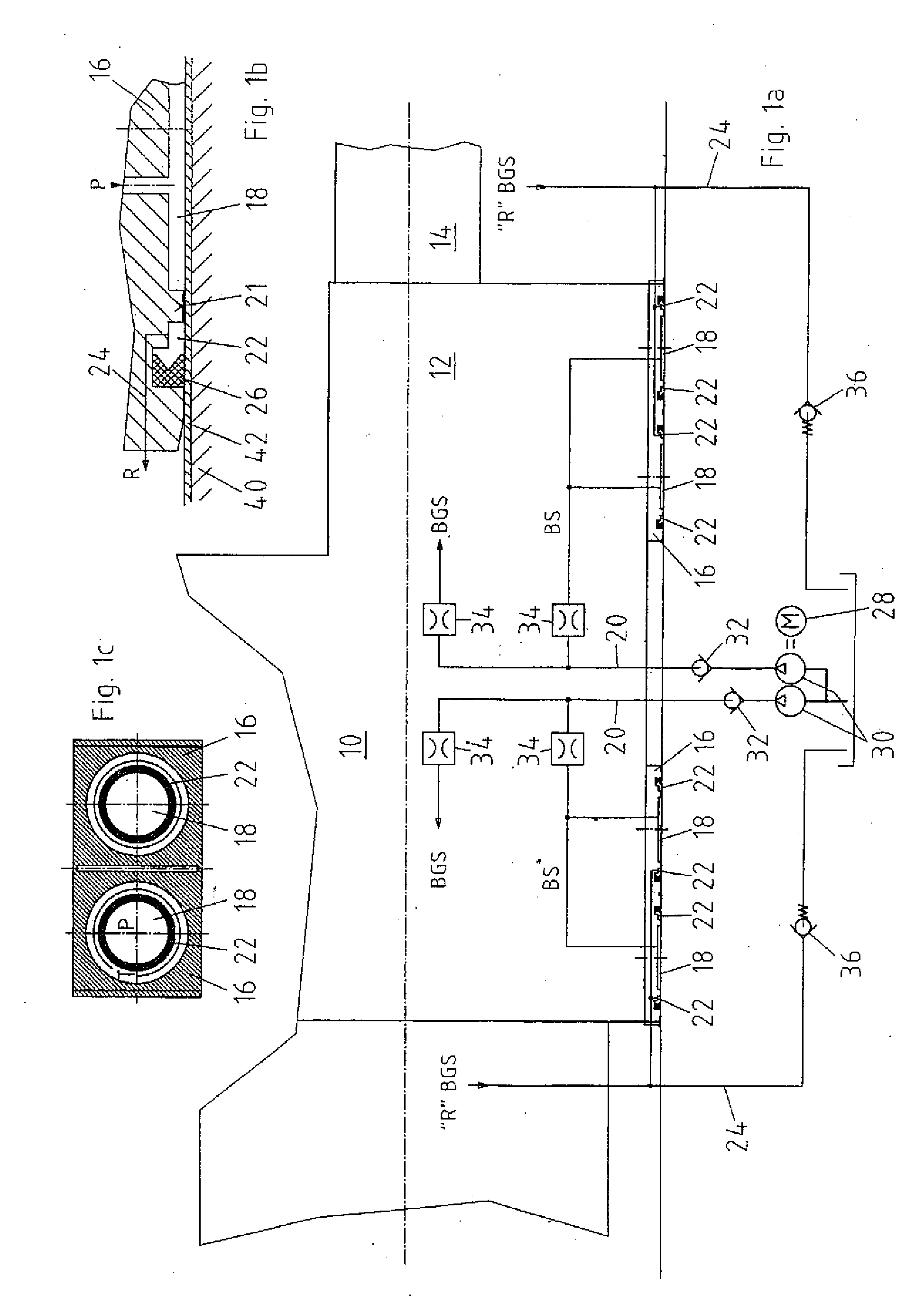

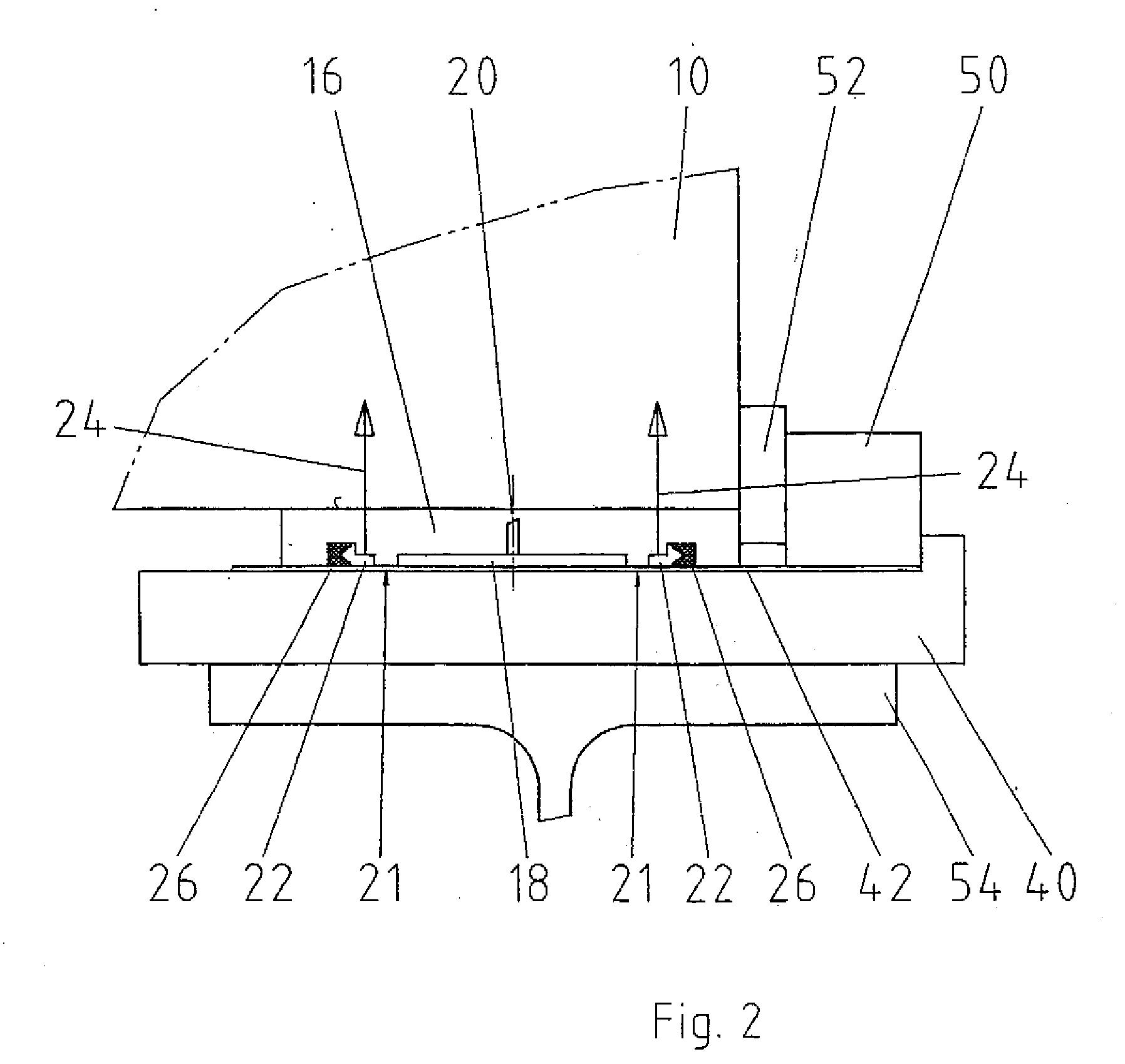

Clamping unit with a platen hydrostatically supported on a frame element

InactiveUS7399441B2Stimulate displacementMaintain frictionLinear bearingsCeramic shaping apparatusEngineeringInjection molding machine

A clamping unit, particularly for an injection molding machine, includes at least one moving platen which is moveably arranged on a frame element. At least one hydrostatic support is provided in an area between the platen and the frame element for facilitating back and forth displacement of the moving platen to thereby avoid speed-dependent friction values. Operation of the clamping unit is realized by building up pressure in a hydrostatic support before the moving platen is initiated for displacement so that the moving plate is slightly raises platen in relation to the frame element. After displacement of the moving platen, the pressure in the hydrostatic support is decreased again.

Owner:KRAUSS MAFFEI KUMSTSTOFFTECHNIK GMBH

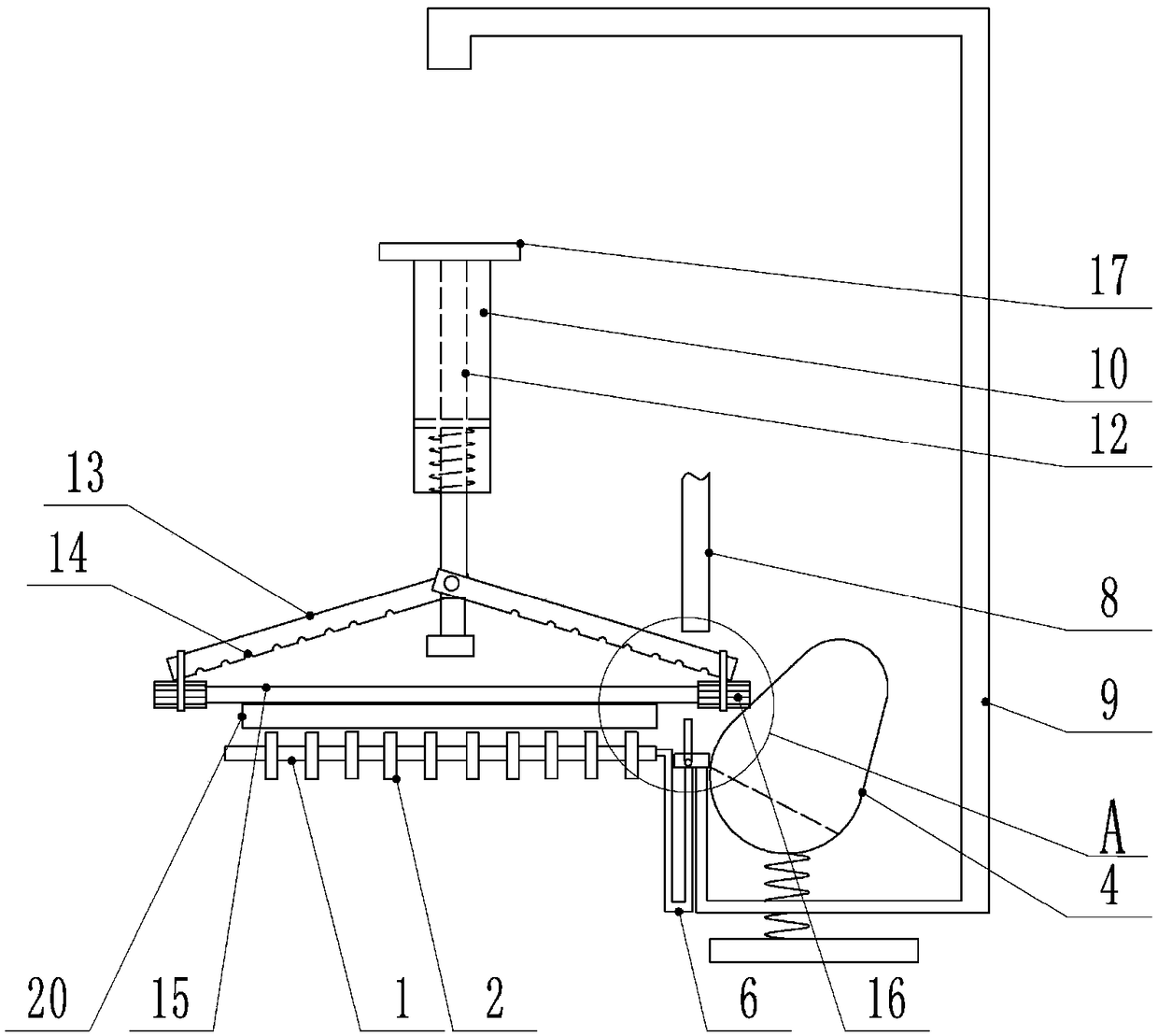

Conveying mechanism for building glass processing

ActiveCN109292454AConvenience to workEasy to operateCharge manipulationConveyor partsEngineeringPendulum

The invention relates to the field of conveying structures for glass processing, and discloses a conveying mechanism for building glass processing. The conveying mechanism for building glass processing comprises multiple conveying rollers, a reset mechanism, an airflow power mechanism and a pushing mechanism, wherein the reset mechanism comprises slide reset pieces arranged on the outer sides of the end parts of the conveying rollers in a swinging way; the airflow power mechanism comprises an air inlet pipe and an air guiding pipe located between the conveying rollers and the slide reset pieces; a pipe port at one end of the air guiding pipe directly faces a pipe port at one end of the air inlet pipe; the pushing mechanism comprises a sliding barrel fixedly arranged above the conveying rollers; a sliding shaft is arranged in the sliding barrel in a penetrating way and is connected with a reset spring; a pipe port at one end, far away from the air inlet pipe, of the air guiding pipe directly faces the upper end of the sliding shaft and is located on the axial direction of the sliding shaft; pendulum shafts are hinged to the lower end of the sliding shaft; a torsional spring is connected between the pendulum shafts and the sliding shaft; and one ends, far away from the sliding shaft, of the pendulum shafts penetrate through the gap between the air inlet pipe and the air guiding pipe and are abutted against the slide reset pieces so as to enable the slide reset pieces to deviate. The conveying mechanism for building glass processing provided by the invention can solve the problem that glass is easy to deviate and slide during the conveying process.

Owner:重庆市渝大节能玻璃有限公司

Screwless hinge

PendingCN110671420AMake sure you don't shake your feetEasy to openPivotal connectionsInterference fitEngineering

The invention relates to a screwless hinge which comprises a single-tooth connecting piece, a double-tooth connecting piece and a sleeve pipe. The double-tooth connecting piece and the a single-toothconnecting piece are connected through the sleeve pipe; the sleeve pipe and a single tooth are in interference fit; and an opening is formed in the double-tooth connecting piece. According to the screwless hinge provided by the invention, a rotation effect of an existing hinge is improved, a certain friction force can be always kept after wear in the hinge rotation process, and the hinge is prevented from sliding.

Owner:温州创誉光学有限公司

Clamping unit with a platen hydrostatically supported on a frame element

InactiveUS20070126154A1Stimulate displacementMaintain frictionLinear bearingsCeramic shaping apparatusMechanical engineeringInjection molding machine

A clamping unit, particularly for an injection molding machine, includes at least one moving platen which is moveably arranged on a frame element. At least one hydrostatic support is provided in an area between the platen and the frame element for facilitating back and forth displacement of the moving platen to thereby avoid speed-dependent friction values. Operation of the clamping unit is realized by building up pressure in a hydrostatic support before the moving platen is initiated for displacement so that the moving plate is slightly raises platen in relation to the frame element. After displacement of the moving platen, the pressure in the hydrostatic support is decreased again.

Owner:KRAUSS MAFFEI KUMSTSTOFFTECHNIK GMBH

A paper feed wheel and its manufacturing method

ActiveCN102358527BNot easy to bloomMaintain frictionArticle feedersRubber layered productsAntioxidantEngineering

The invention discloses a paper feeding wheel and a manufacturing method thereof. The paper feeding wheel consists of a plastic framework and a rubber wheel sleeved on the plastic framework, wherein the rubber wheel is made of a rubber composition; and the rubber composition comprises rubber with high wear resistance and strength, an effective rubber vulcanizing system, more than one antioxidants, and a proper amount of reinforcing filler and softening agent, wherein the effective rubber vulcanizing system is suitable for a composition of butadiene rubber and natural rubber; one of the more than one antioxidant has a function of assisting in demoulding after rubber is vulcanized; and the proper amount of reinforcing filler and softening agent can improve the strength of the rubber wheel and cannot obviously improve hardness. The invention has the advantages that: the manufacturing process is simple, and the rubber wheel is formed by a mold through one-time compression moulding, and is not required to be processed; the surface of the paper feeding wheel is hardly subjected to frost spray; and the frictional property of the surface of the paper feeding wheel can be kept for a long time.

Owner:BEIJING LASER HI TECH CO LTD

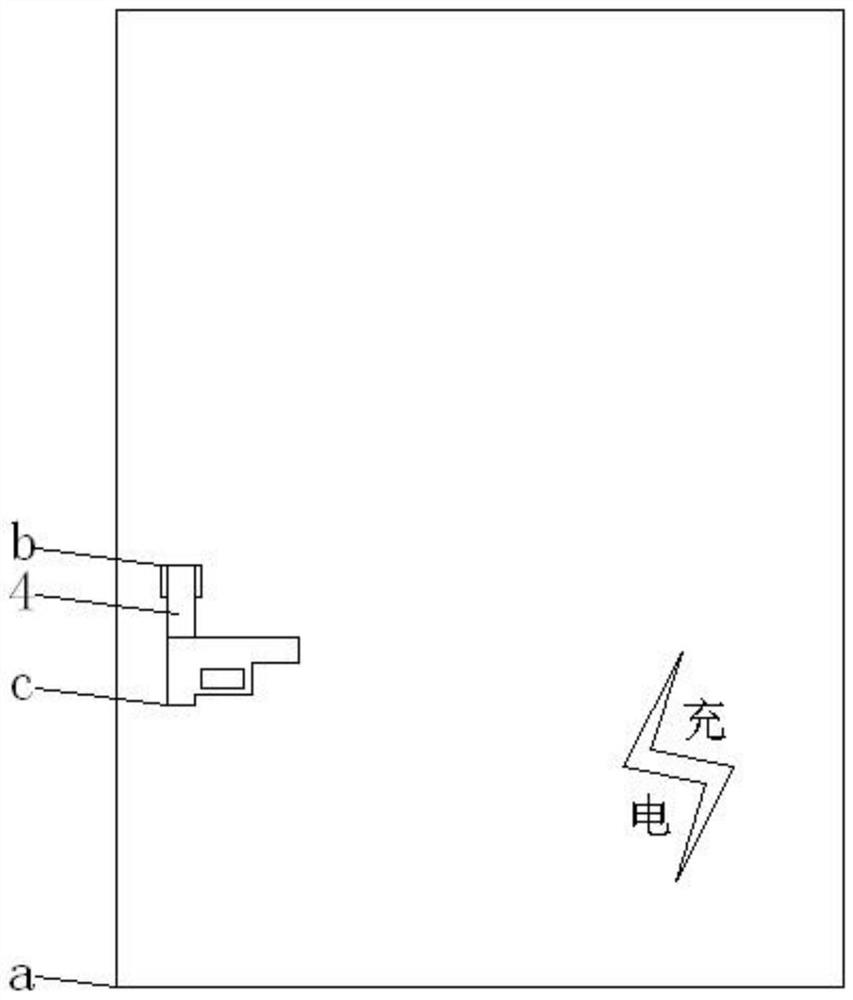

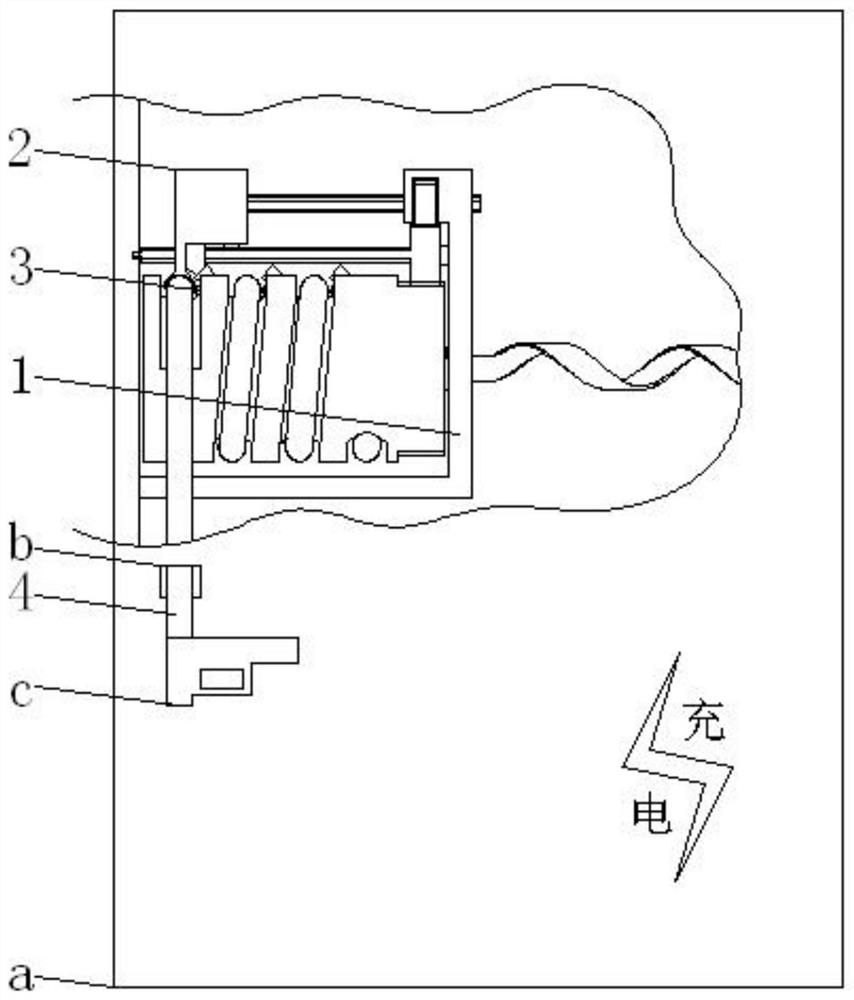

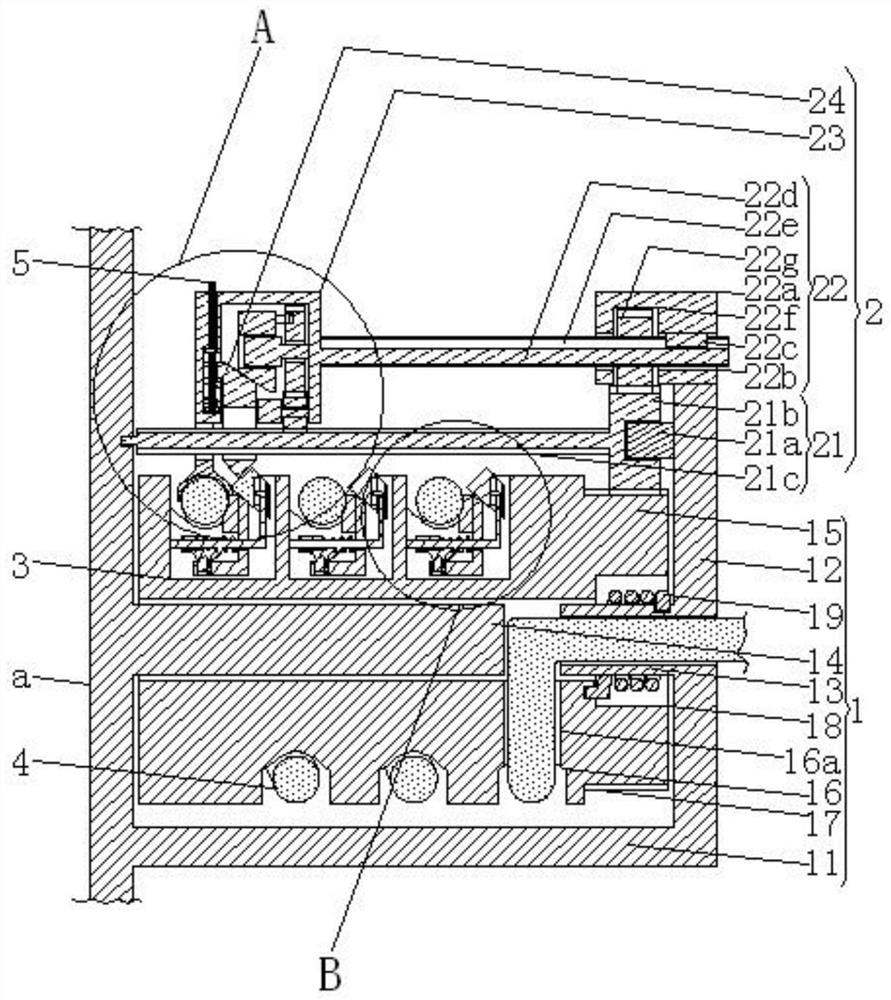

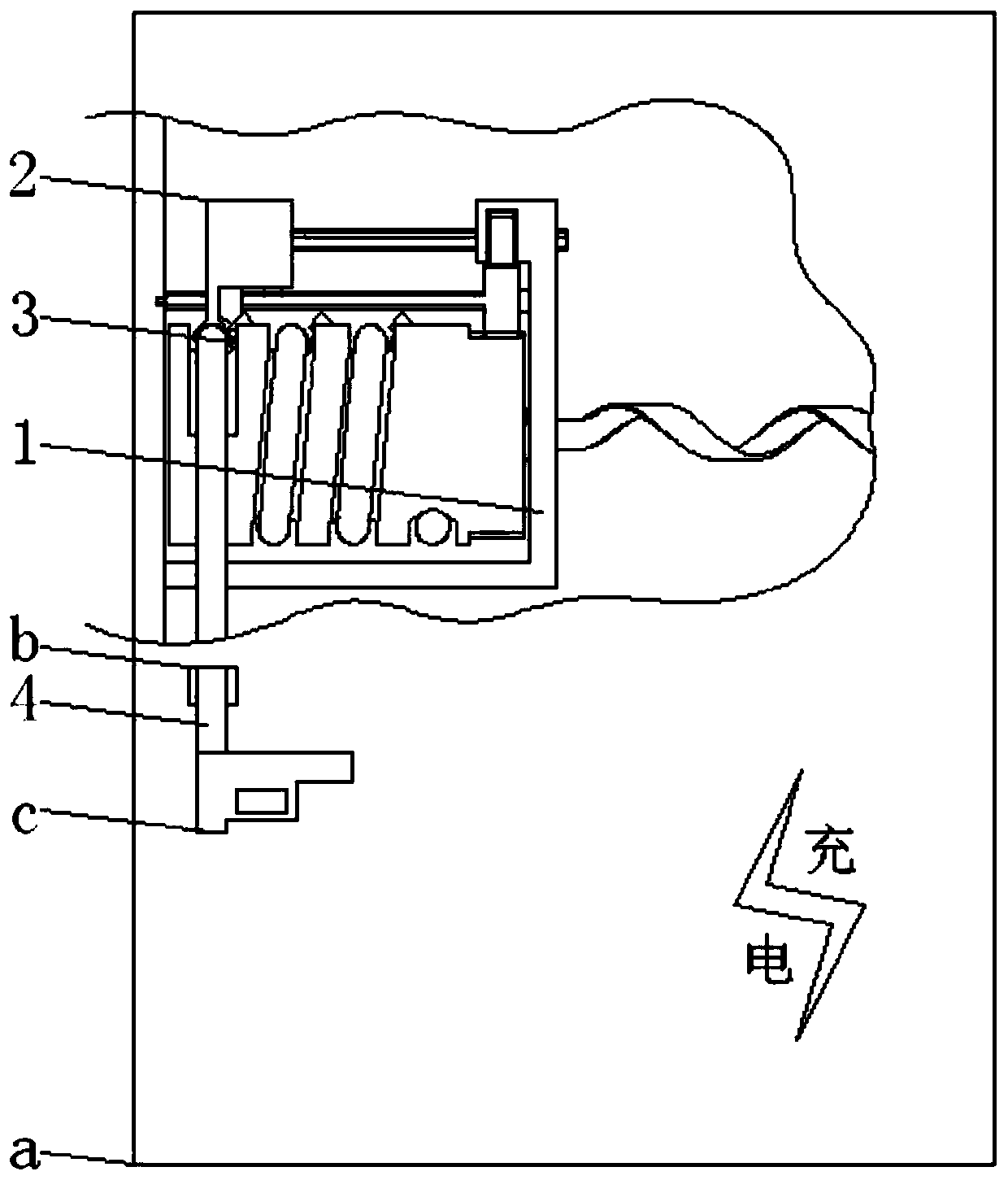

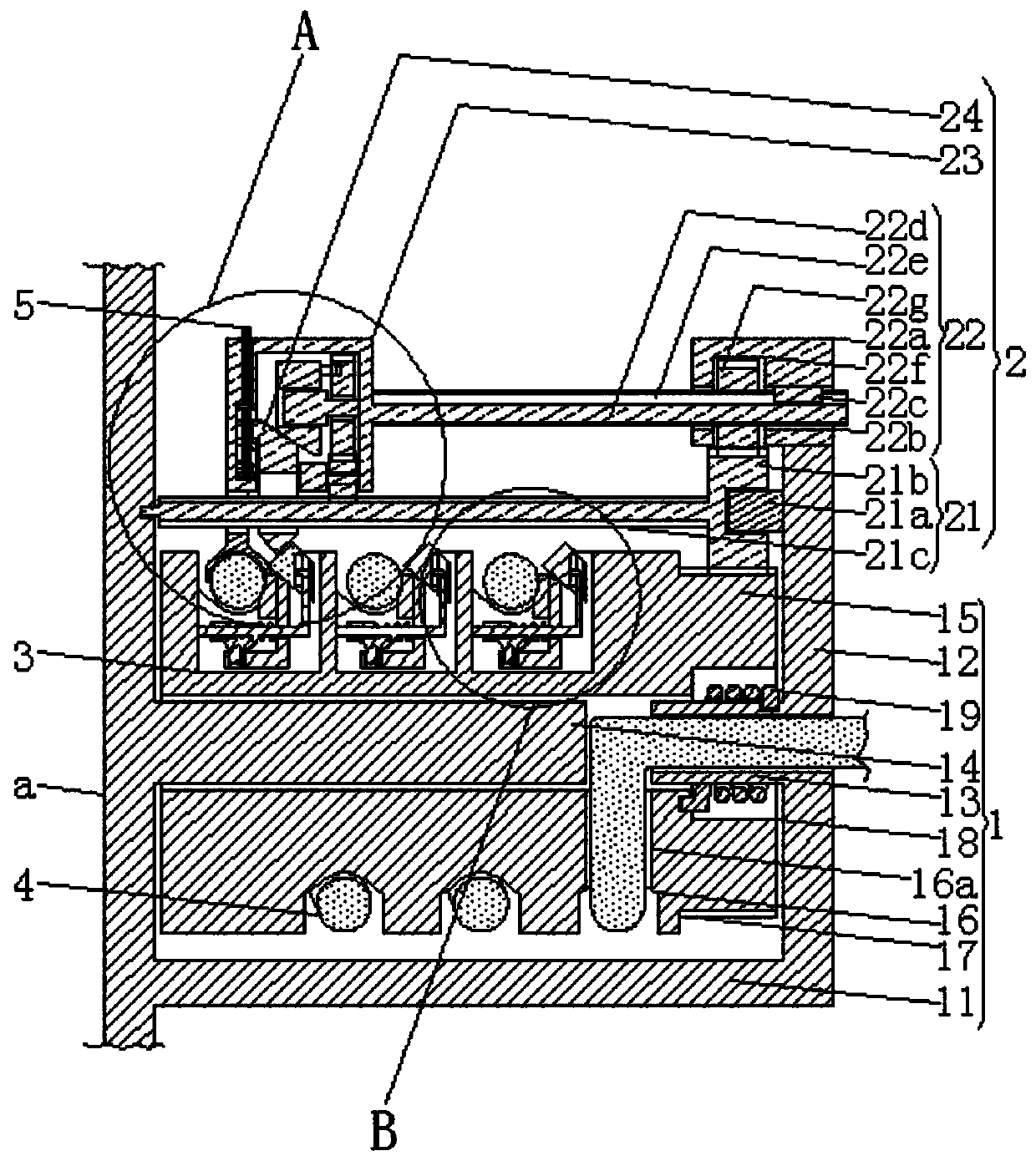

A pre-adjustment method for a new energy vehicle charging pile electric wire automatic winding device

InactiveCN110980448BEmbedded accuratelyAvoid forward and reverse switchingCharging stationsElectric vehicle charging technologyCircular discNew energy

This application discloses an automatic rewinding device for charging pile wires of new energy vehicles, which includes: an outer cylinder for winding or releasing the charging wire in a spiral shape, and an automatic device for restricting the distribution of the charging wire along the spiral trajectory on the outer cylinder for reeling. The wiring device, the automatic wire clamping device that clamps and fixes the charging wire that has been wound on the outer cylinder of the reel, and also includes a pre-adjustment device; the pre-adjustment method includes the following steps: rotating the active screw to be exposed above the machine head housing part; the active screw rod rotates to drive the square nut to move along the square longitudinal hole; the movement of the square nut adjusts the compression amount of the adjustment pressure spring under normal conditions; and then adjusts the adjustment pressure spring to the adjustment longitudinal rod The elastic force of the adjustment longitudinal rod and the pressing stress on the inclined end face to the right ensure that the adjustment disc and the left end of the pendulum block assembly are in close contact and maintain a certain pressing force and friction.

Owner:广州市南绅能源科技有限责任公司

A terminal post of a new energy vehicle motor

ActiveCN109038926BEffective winding and windingAvoid damageClamped/spring connectionsSupports/enclosures/casingsAqueous corrosionNew energy

The invention discloses a terminal of a motor of a new energy automobile, Including bottom plate, A take-up wheel is arrange on an outer wall of one side of that bottom plate, A support column is arrange on that outer wall of a side of the take-up wheel which is far away from the bottom plate, Threaded rings and support rods, the support column and the support rod are both positioned above the threaded ring, and the support column is positioned on one side of the support bar, one end of the support rod is provided with a fixing ring, a first splint is arranged on the inner wall of one side ofthe fixing ring, and a threaded rod is screwed on an outer wall of one side of the fixing ring, on one hand, the invention can effectively winding and winding excess wiring cables, On the other hand,it effectively reduces the contact amount between the terminal and air, avoids the damage and leakage caused by water corrosion of wiring ends in the air, improves the safety of the terminal connection and prolongs the service life of the terminal.

Owner:徐州徐汽汽车科技有限公司

An automatic elastic anti-loosening bolt

ActiveCN104500540BGuaranteed anti-loose performanceMaintain frictionNutsBoltsElastic componentContact force

The invention discloses an automatic elastic locking bolt. The automatic elastic locking bolt is characterized in that an accommodating groove is formed in a screw; the accommodating groove is communicated with a horizontal straight slot; a cylinder is arranged at the bottom of the accommodating groove, and a telescopic rod of the cylinder extends upwardly; a push block is arranged at an end of the telescopic rod of the cylinder; a switch for controlling the cylinder is arranged on the upper surface of a bolt head; 'I'-shaped portions of 'L'-shaped rotary blocks are accommodated in the accommodating groove, and the bottoms of the 'I'-shaped portions of the 'L'-shaped rotary blocks are in contact with the push block; gaps are reserved between the lower ends of protrusions and the bottom of the horizontal straight slot; the 'I'-shaped portions of the two 'L'-shaped rotary blocks can slide up and down in the accommodating groove; the 'I'-shaped portions of the two 'L'-shaped rotary blocks can be downwardly turned over when upwardly sliding to the highest positions; 'horizontal' portions of the 'L'-shaped rotary blocks comprise fixing blocks, connecting blocks and elastic components. The automatic elastic locking bolt has the advantages that the protrusions can be supported by the elastic components to be in contact with the surfaces of two sides of a plate, contact force and friction force of the protrusions and the surfaces of the two sides of the plate can be kept, and the automatic elastic locking bolt is small in occupied space and convenient to use and is portable.

Owner:南通通泰紧固件有限公司

Automatic drive belt biasing device

ActiveUS11072497B2Reduce fatigueReduce wearConveyorsControl devices for conveyorsControl theoryConveyor belt

An automatic belt biasing device is provided for biasing a drive belt into frictional contact with rollers of a conveyor. The belt biasing device maintains a drive belt in contact with rollers of a live roller conveyor to provide drive for the rollers to propel items or packages along the conveyor. A spring attached to a pivot arm or pair of scissoring pivot arms adjusts a biasing force applied by guide wheels of the belt biasing device to the drive belt due to changes in drive belt tension. The belt biasing device may be selectively adjustable based on required roller pitch distances. The belt biasing device is pivotably coupled to the roller conveyor allowing the guide wheels to apply equal pressure to the drive belt while allowing the pivot arms to actuate and increase or decrease the biasing force provided by the belt biasing device.

Owner:DEMATIC

Pre-adjusting method of new energy automobile charging pile wire automatic winding device

InactiveCN110980448AEmbedded accuratelyAvoid forward and reverse switchingCharging stationsElectric vehicle charging technologyCircular discNew energy

The invention discloses a pre-adjusting method of a new energy automobile charging pile wire automatic winding device. The new energy automobile charging pile wire automatic winding device comprises awire winding outer barrel for spirally winding or unwinding a charging wire, an automatic wiring device for limiting the charging wire to be distributed on the winding outer barrel along a spiral track, an automatic wire clamping device for clamping and fixing the charging wire wound on the wire winding outer barrel, and a pre-adjusting device. The pre-adjusting method comprises the steps that: the part, exposed out of the upper portion of a machine head shell body, of a driving screw is rotated; the driving screw rotates to drive a square nut to move along a direction longitudinal hole; themovement of the square nut causes the compression amount of a range adjusting pressure spring in a normal state; and an elastic force of the range adjusting pressure spring applied to a range adjusting longitudinal rod and extrusion stress of the range adjusting longitudinal rod applied to the right side of the inclined end surface are adjusted, the tight contact between an adjusting disc and theleft end of a swing block assembly is ensured, and certain pressing force and friction force are kept.

Owner:广州市南绅能源科技有限责任公司

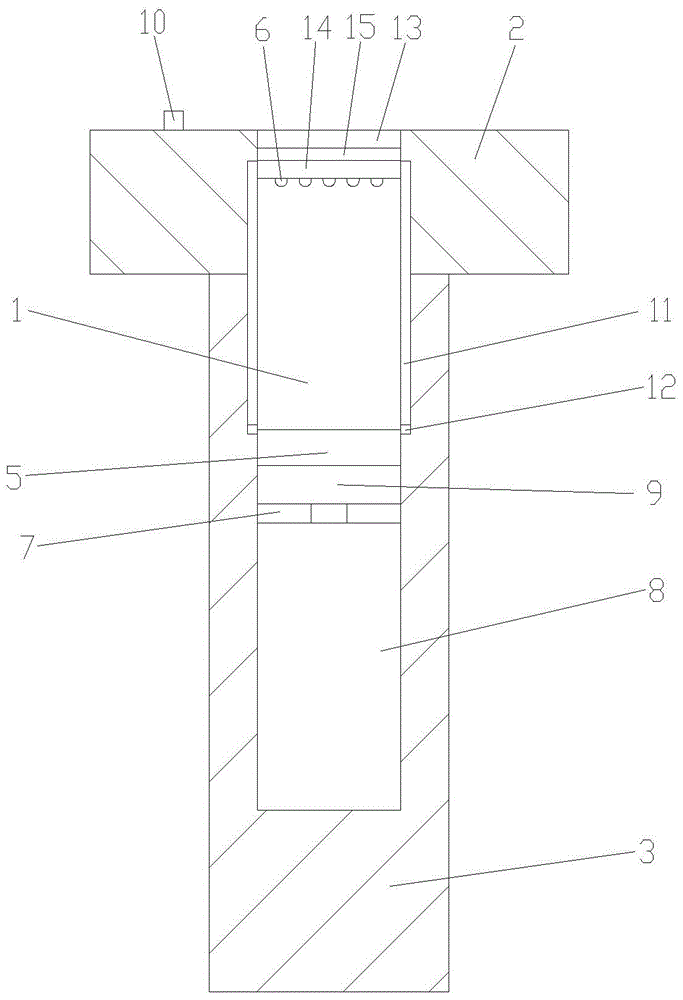

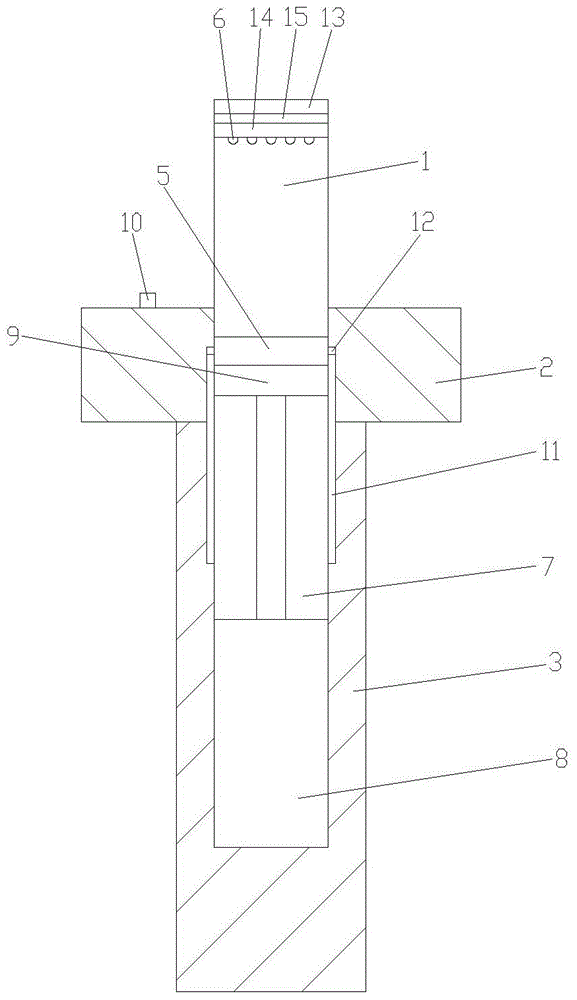

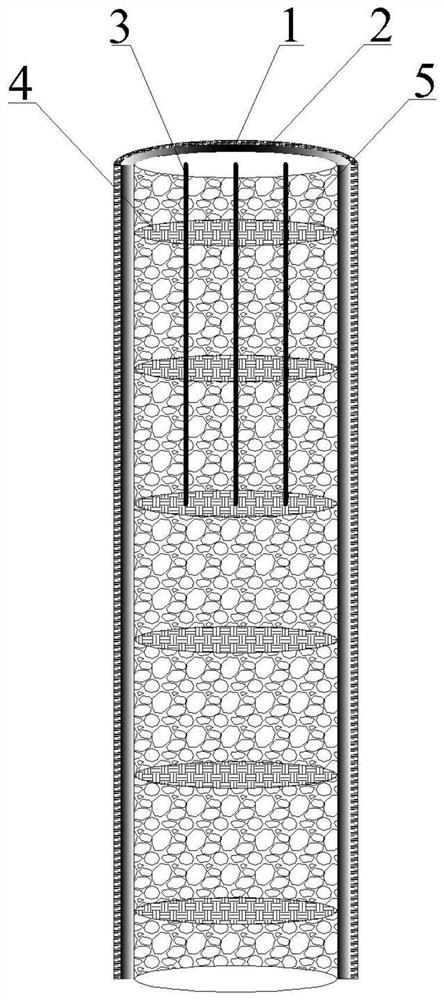

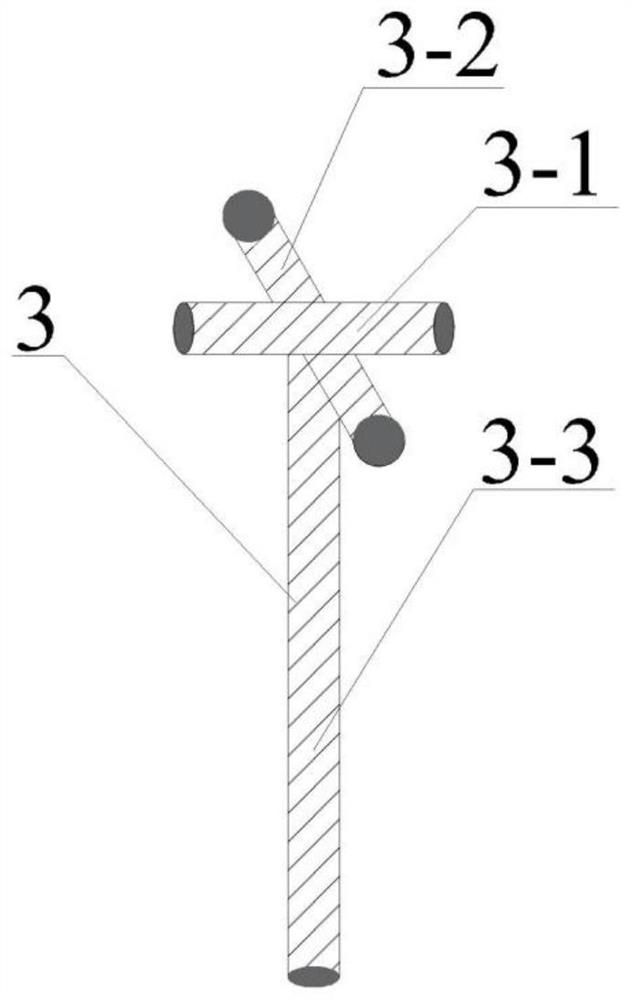

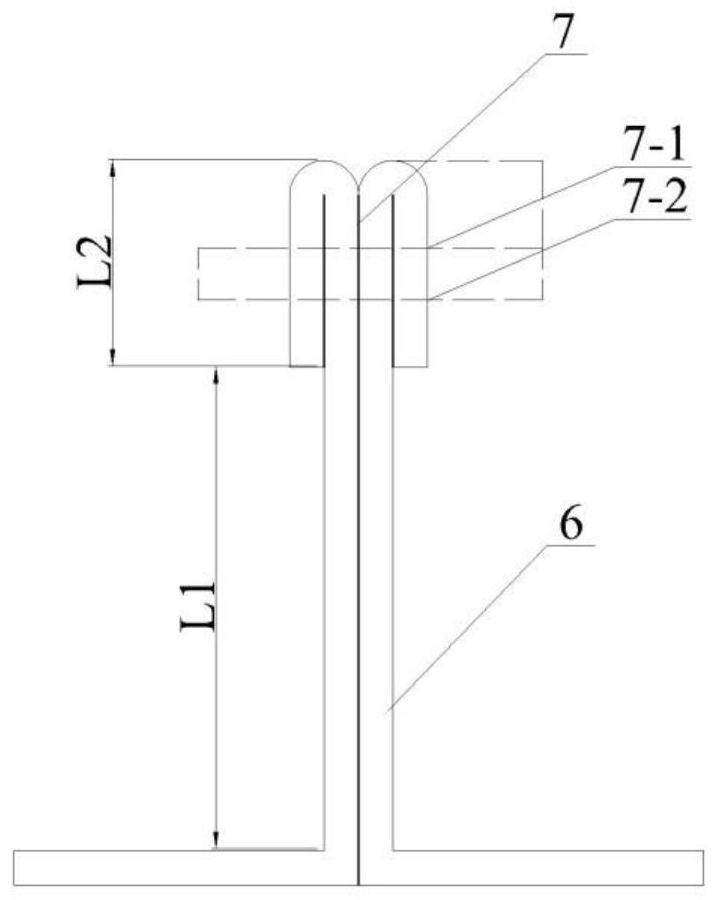

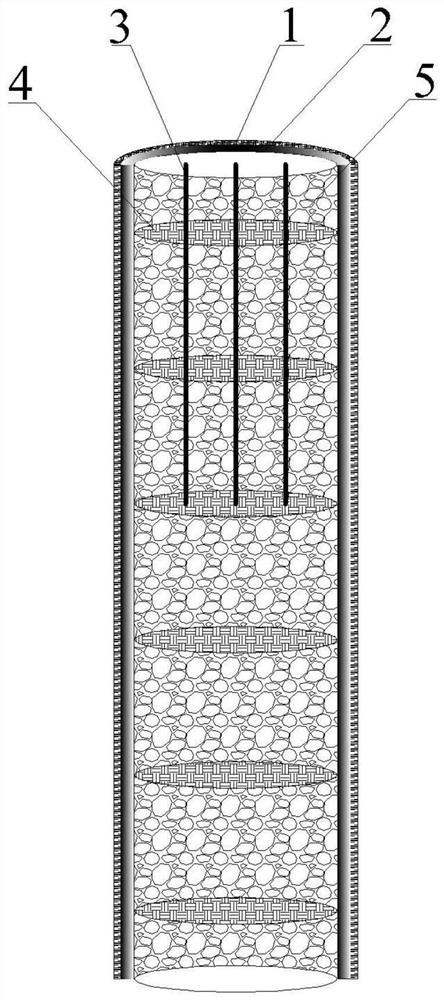

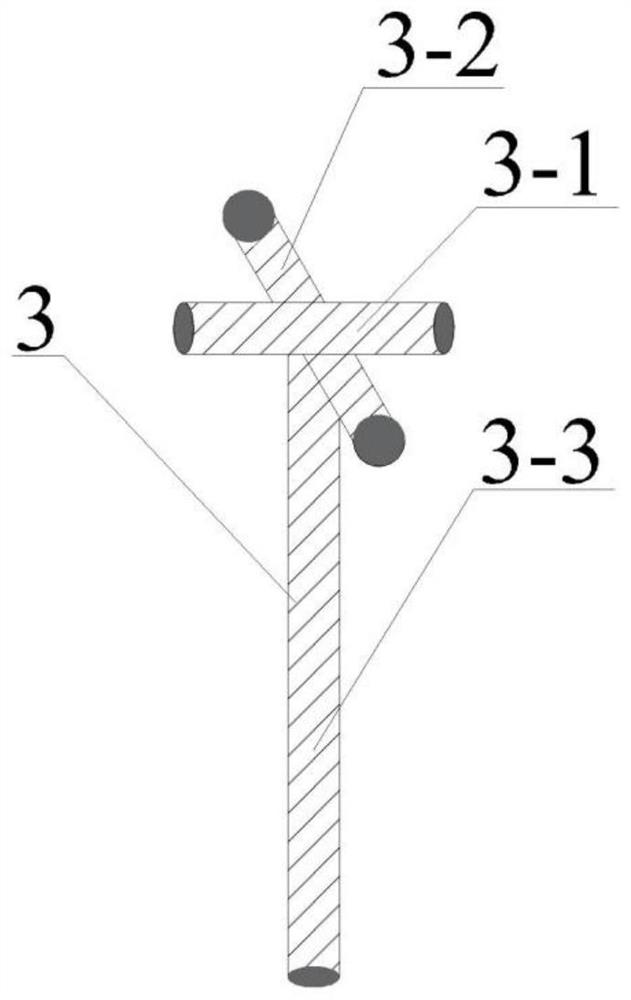

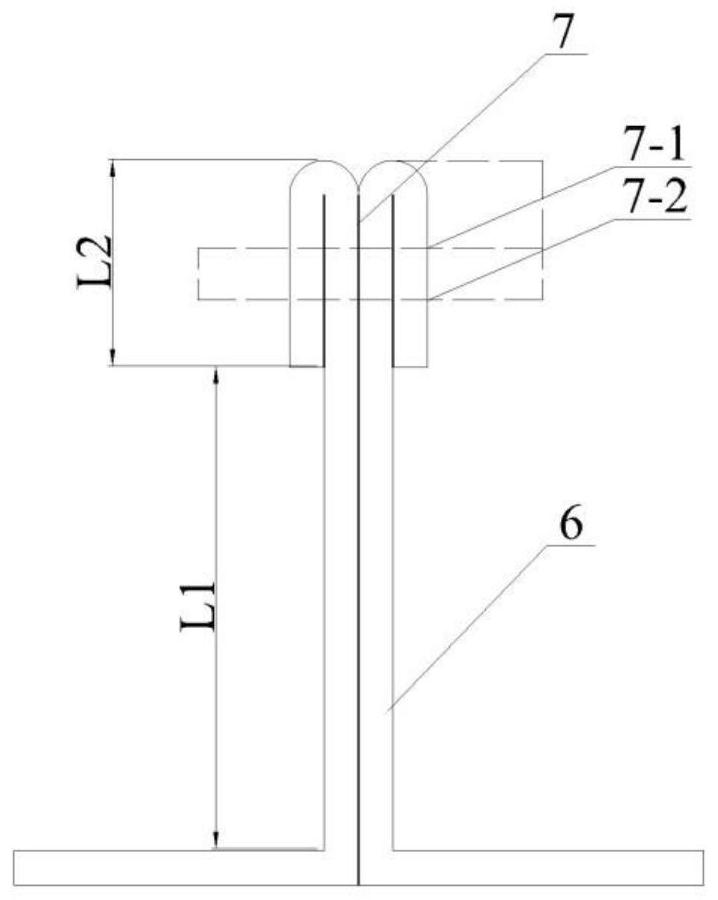

Multi-reinforced granular pile and its construction method

ActiveCN112663592BImprove carrying capacityKeep from drainingBulkheads/pilesSoil preservationStructural engineeringHollow core

The invention discloses a multi-reinforced granular material pile, which is arranged inside soft soil, and comprises hollow cylindrical vertical reinforcement and filler filled in the vertical reinforcement, and the vertical reinforcement circumferential surface in the filler is evenly arranged along the axial direction There are horizontal reinforcements, the horizontal reinforcements are placed between the fillers, and the axial reinforcements are evenly arranged along the radial direction of the vertical reinforcements. The multi-reinforced granular material pile of the present invention is more suitable for soft soil. The present invention also provides a construction method of the above-mentioned multi-reinforced granular pile.

Owner:HUBEI UNIV OF TECH

Multi-reinforced aggregate pile and construction method thereof

ActiveCN112663592AImprove carrying capacityKeep from drainingBulkheads/pilesSoil preservationStructural engineeringHollow core

The invention discloses a multi-reinforced aggregate pile. The multi-reinforced aggregate pile is arranged in soft soil, and comprises hollow cylindrical vertical reinforcements and fillers filled in the vertical reinforcements, horizontal reinforcements are uniformly arranged on the circumferential surfaces of the vertical reinforcements in the fillers in the axial direction, the horizontal reinforcements are placed among the fillers, and axial reinforcements are uniformly arranged in the radial direction of the vertical reinforcements. The multi-reinforced aggregate pile is more suitable for soft soil. The invention further provides a construction method of the multi-reinforced aggregate pile.

Owner:HUBEI UNIV OF TECH

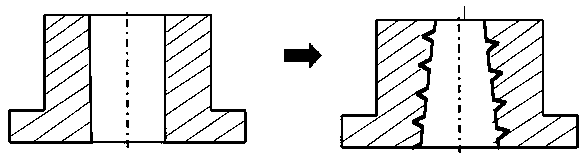

Non-slip plastic nut

The invention provides a thread slip preventive plastic nut. The screw-in end of the inner surface of a threaded hole of the plastic nut is provided with a slope; the diameter of the screw-in end of the threaded hole is less than that of an external thread of a tapping screw. The thread slip preventive plastic nut has the advantages that the nut is used for matching with the tapping screw, thread connection friction and pretension can be still retained for the nut under vibration, impact, variable load and sharp temperature fluctuation, loosening and thread slip are prevented for the nut and fitting safety of a fastener is improved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

A terminal of a motor of a new energy automobile

ActiveCN109038926AEffective winding and windingAvoid damageClamped/spring connectionsSupports/enclosures/casingsNew energyThreaded rod

The invention discloses a terminal of a motor of a new energy automobile, Including bottom plate, A take-up wheel is arrange on an outer wall of one side of that bottom plate, A support column is arrange on that outer wall of a side of the take-up wheel which is far away from the bottom plate, Threaded rings and support rods, the support column and the support rod are both positioned above the threaded ring, and the support column is positioned on one side of the support bar, one end of the support rod is provided with a fixing ring, a first splint is arranged on the inner wall of one side ofthe fixing ring, and a threaded rod is screwed on an outer wall of one side of the fixing ring, on one hand, the invention can effectively winding and winding excess wiring cables, On the other hand,it effectively reduces the contact amount between the terminal and air, avoids the damage and leakage caused by water corrosion of wiring ends in the air, improves the safety of the terminal connection and prolongs the service life of the terminal.

Owner:徐州徐汽汽车科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com