Conveying mechanism for building glass processing

A technology of conveying mechanism and architectural glass, which is applied in the directions of conveyor objects, transportation and packaging, lighting and heating equipment, etc., can solve the problem of glass easily drifting and slipping, reduce the impact of the processing environment, simplify the device structure, strengthen the The effect of security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below through specific implementations:

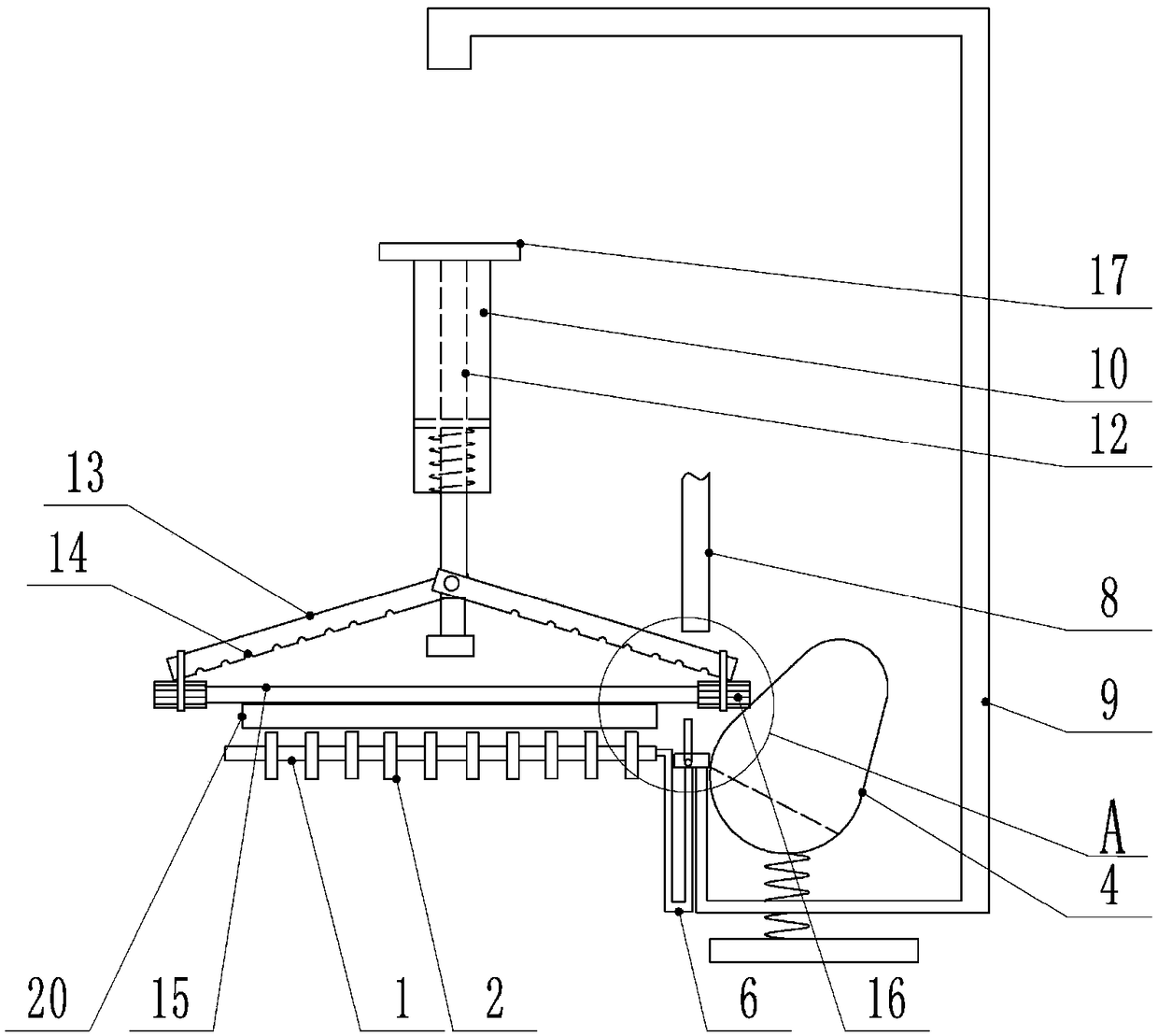

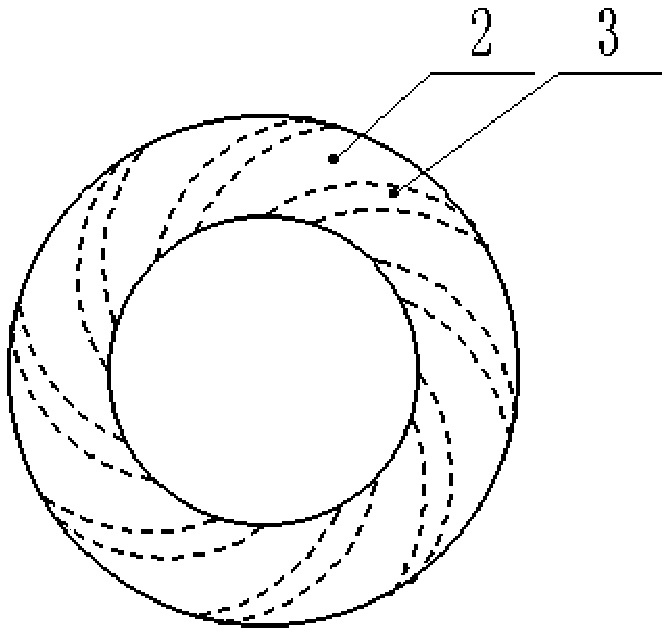

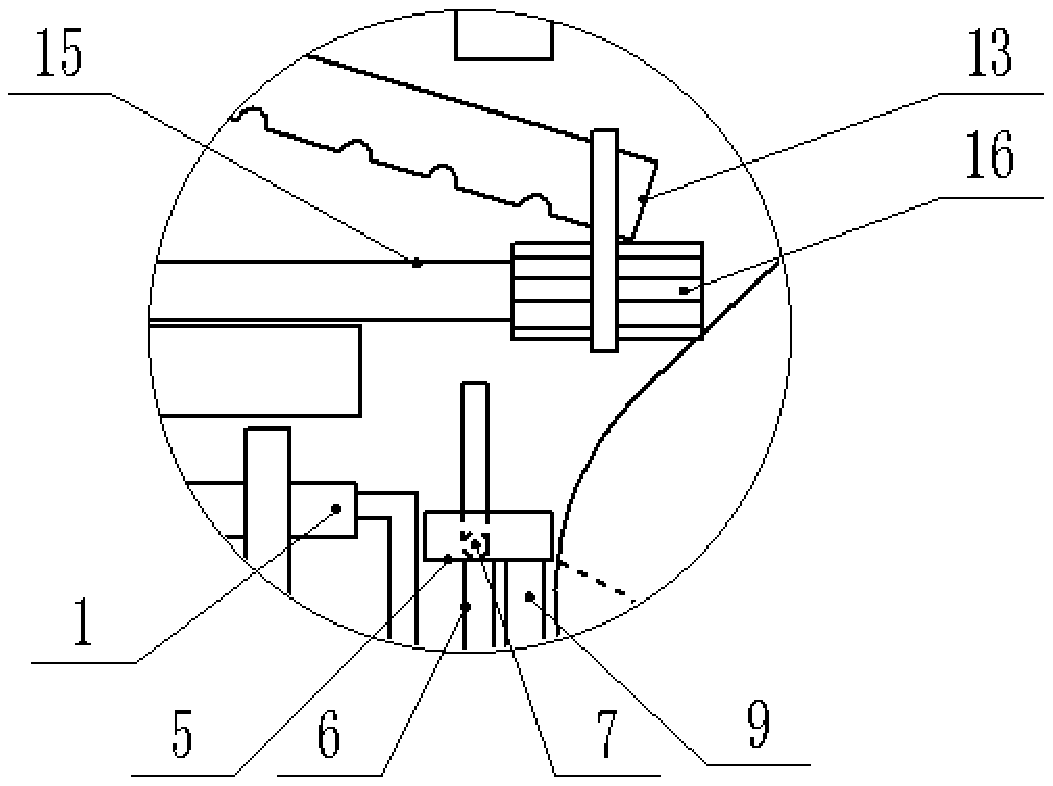

[0021] The reference signs in the drawings of the specification include: shaft tube 1, wheel 2, channel 3, toggle reset piece 4, air guide groove 5, blower pipe 6, stopper 7, air inlet pipe 8, air guide pipe 9, The sliding cylinder 10, the sliding shaft 12, the pendulum shaft 13, the blowing hole 14, the elastic rope 15, the wind wheel 16, the wind resisting plate 17, the vent 18, the grid plate 19, and the glass 20.

[0022] Implementation example figure 1 Shown: the transmission mechanism used for architectural glass processing, including the transmission roller set, reset mechanism, air power mechanism and push mechanism. Each reset mechanism, airflow power mechanism and push mechanism are correspondingly arranged in a group of structures.

[0023] The conveying roller group includes a plurality of groups of conveying rollers arranged in parallel, and the conveying rollers a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com