Chromium-free self-lubricating passivation solution and preparation method thereof

A technology of self-lubricating and passivating liquid, which is applied in the fields of chemistry and metallurgy, and can solve problems such as unsatisfactory, low friction of galvanized sheet, anti-oxidation and anti-wear extreme pressure, corrosion resistance and fingerprint resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Component Mass parts

[0038] Water-based epoxy resin 10%

[0039] Curing agent 1%

[0040] Silane coupling agent KH550 10%

[0041] Ce(NO 3 ) 3 1%

[0042] Polyethylene wax 2%

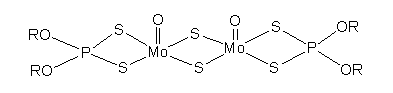

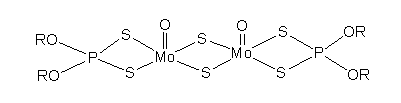

[0043] Oxymolybdenum Dialkyl Dithiophosphate 2%

[0044] Nano silica 1%

[0045] Attapulgite 1%

[0046] Ethanol 12%

[0047] water 60%

[0048] First weigh 1g of curing agent and add it to 10g of water-based epoxy resin, and stir on a magnetic stirrer for 2h, weigh 1g of Ce(NO 3 ) 3 Add to 10g of silane coupling agent KH550, and add 2~3 drops of hydrogen peroxide, put it on a magnetic stirrer and stir for 2-3h, add the above-mentioned stirred water-based epoxy resin and silane coupling agent into 60g of water; Weigh 2g of polyethylene wax and 2g of dialkyldithiooxymolybdenum and add it to 12g of ethanol for ultrasonic dispersion for 30min, stir on a mechanical stirrer for 60min, and add 1g of attapulgite and 1g of ...

Embodiment 2

[0050] Component Mass parts

[0051] Water-based epoxy resin 10%

[0052] Curing agent 1%

[0053] Silane coupling agent KH792 15%

[0054] Ce(NO 3 ) 3 0.5%

[0056] Polyethylene wax 4%

[0057] Oxymolybdenum Dialkyl Dithiophosphate 2%

[0058] Nano silica 1%

[0059] Attapulgite 1%

[0060] Ethanol 10%

[0061] water 55%

[0062] Take by weighing 1g of curing agent and join in the water-based epoxy resin of 10g, and be placed on the magnetic stirrer and stir for 2h, take by weighing 0.5g of Ce(NO 3 ) 3 Add 0.5g of sodium molybdate to 15g of silane coupling agent 792, add 1~2 drops of hydrogen peroxide, stir on a magnetic stirrer for 2-3h, mix the above-mentioned stirred water-based epoxy resin and silane coupling agent Add KH792 to 55g of water and stir; weigh 4g of polyethylene wax and 2g of dialkyldithiooxymolybdenum, add it to 10g of ethanol and ultrasonicall...

Embodiment 3

[0064] Component Mass parts

[0065] Water-based epoxy resin 10%

[0066] Curing agent 1%

[0067] Silane coupling agent KH902 10%

[0068] Ce(NO 3 ) 3 0.5%

[0069] Sodium molybdate 0.5%

[0070] Polyethylene wax 2%

[0071] Molybdenum disulfide 2%

[0072] Oxymolybdenum Dialkyl Dithiophosphate 2%

[0073] Nano silica 1%

[0074] Attapulgite 1%

[0075] Ethanol 10%

[0076] water 60%

[0077] The curing agent that takes by weighing 1g joins in the water-based epoxy resin of 10g, stirs 2h on the magnetic stirrer, then the Ce(NO of 0.5g 3 ) 3Add 0.5g of sodium molybdate to 10g of silane coupling agent 902, and add 1~2 drops of hydrogen peroxide, stir on a magnetic stirrer for 2-3h, mix the above-mentioned stirred water-based epoxy resin and silane coupling agent Add KH902 to 60g of water; add 2g of polyethylene wax, 2g of molybdenum disulfide and 2g of dialkyldithiooxymolybdenum to 10g of eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com