Additive compositions with a friction modifier and a metal dialkyl dithio phosphate salt

A technology of dialkyl dithiophosphoric acid and metal salts, which can be used in additives, lubricating compositions, petroleum industry, etc., and can solve problems such as changing the friction characteristics of lubricants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

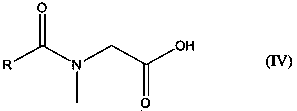

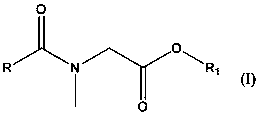

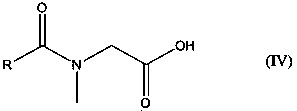

Method used

Image

Examples

Embodiment 1

[0293] Embodiment 1: Butyl oleoyl sarcosinate (BuOS)

[0294] 281 g (0.8 mol) oleoyl sarcosine, 237 g butanol and 0.38 g Amberlyst 15 acid resin were added to a 1 L resin pot equipped with overhead stirrer, Dean Stark separator and thermocouple. The reaction mixture was heated at reflux under nitrogen with stirring for 3 hours, removing 25 mL aliquots every 30 minutes. The reaction mixture was then concentrated under vacuum and filtered to obtain 310 g of product.

Embodiment 2

[0295] Embodiment 2: Ethyl oleoyl sarcosinate (EtOS)

[0296] 281 g (0.8 mol) oleoyl sarcosine and 295 g ethanol were added to a 1 L resin pot equipped with overhead stirrer, Dean Stark separator and thermocouple. The reaction mixture was heated at reflux under nitrogen with stirring for 3 hours, removing 25 mL aliquots every 30 minutes. The reaction mixture was then concentrated under vacuum to obtain 280 g of product.

Embodiment 3

[0297] Example 3: Ethyl lauroyl sarcosinate (EtLS)

[0298] 128.5 g (0.5 mol) lauroyl sarcosine and 345.5 g ethanol were added to a 1 L resin pot equipped with overhead stirrer, Dean Stark separator and thermocouple. The reaction mixture was heated at reflux under nitrogen with stirring for 3 hours, removing 25 mL aliquots every 30 minutes. The reaction mixture was then concentrated under vacuum to obtain 126.2 g of product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com