Flame retardant polyamide resin composition

一种聚酰胺树脂、组合物的技术,应用在阻燃性聚酰胺树脂组合物领域,能够解决导通不良等问题,达到耐金属腐蚀性优异、抗电弧径迹性优异、机械强度优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

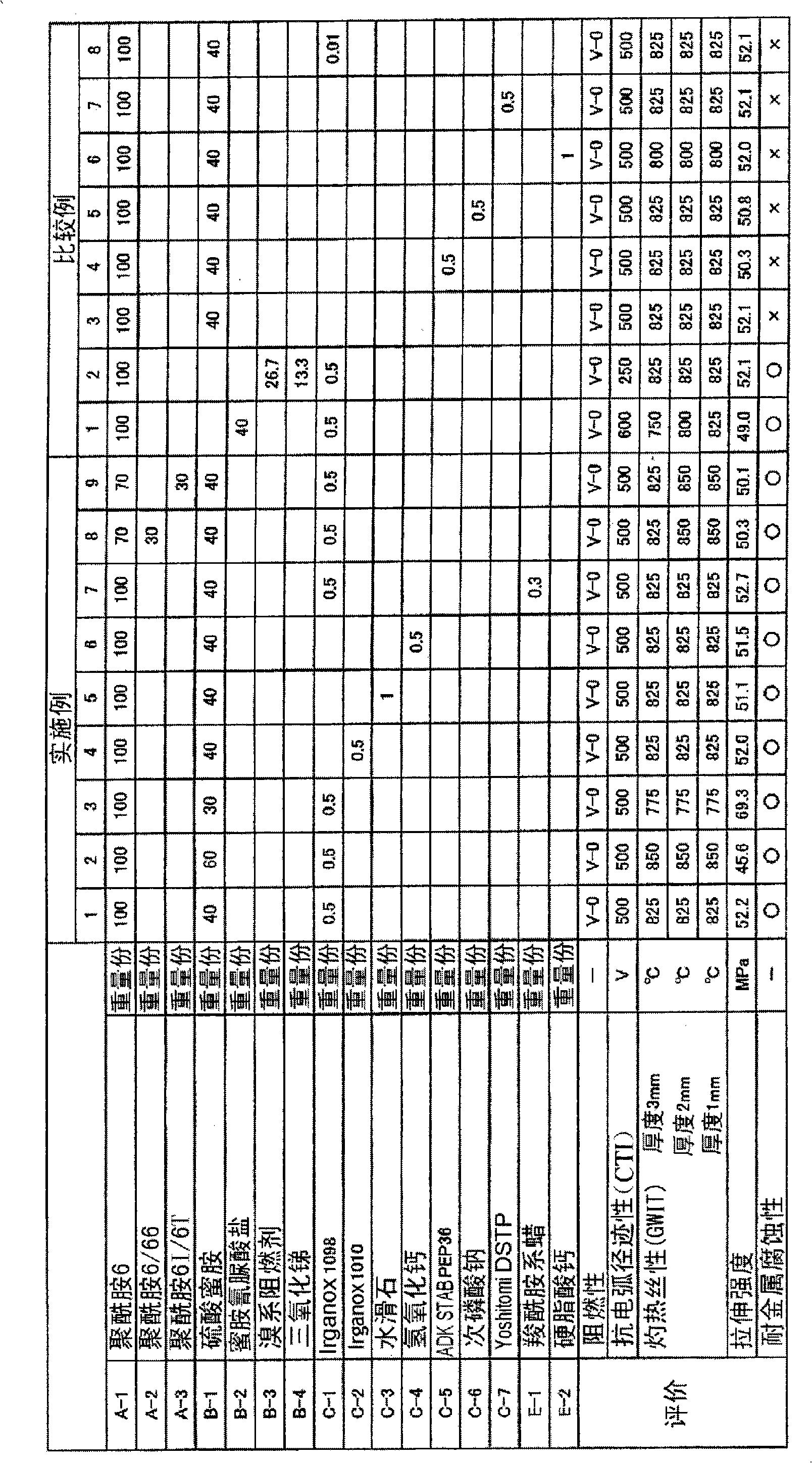

[0118] Hereinafter, although this invention is demonstrated based on an Example, this invention is not limited to these Examples at all. In addition, each component used in the following Example is specifically as follows. In addition, the evaluation of the polyamide resin composition which consists of these components was performed by the method described below.

[0119] [ingredients used in examples]

[0120] Polyamide resin (A)

[0121] (A-1) Polyamide 6: manufactured by Mitsubishi Engineering-Plastics Co., Ltd., "trade name: Novamid (registered trademark) 1010J", viscosity number 118ml / g (according to ISO307 standard, at a temperature of 25°C, in 96% by weight sulfuric acid, The value measured at a polyamide resin concentration of 0.5% by weight), and a melting point of 224°C.

[0122] (A-2) Polyamide 6 / 66 copolymer: manufactured by Mitsubishi Engineering-Plastics Co., Ltd., "Novamid (registered trademark) 2010J", viscosity number 118 ml / g (measured by the same method...

reference example 1

[0145] 100 parts by weight of polypropylene (manufactured by Mitsubishi Chemical Corporation, MVR 1 cm 3 / 10 minutes), 2 parts by weight of maleic anhydride (manufactured by Mitsubishi Chemical Corporation), and 3.5 parts by weight of benzoyl peroxide (manufactured by NOF Corporation, "trade name: Nyper BMT-K-40") were mixed with a super mixer Mix for 1 minute to obtain a mixture. Next, the obtained mixture was extruded with a twin-screw extruder (manufactured by Japan Steel Works, "Model: TEX30HCT", barrel inner diameter 30mm, L / D=42) at a barrel set temperature of 230°C and a screw speed of 300rpm 1. Melt-kneading was carried out under the condition of a discharge rate of 15 kg / hour, extruded into a thread shape through a die, and then cut by a cutting machine to obtain pellets of modified propylene polymer-1.

[0146] (D-6) Maleic anhydride-modified polypropylene-2: maleic anhydride-modified polypropylene produced by the method described below. MVR 300cm 3 / 10 minutes, t...

reference example 2

[0148] 100 parts by weight of polypropylene (manufactured by Mitsubishi Chemical Corporation, MVR=1cm 3 / min), 3 parts by weight of maleic anhydride (same as reference example 1), 4 parts by weight of benzoyl peroxide (same as reference example 1), melt and knead in the same way as reference example 1, carry out granulation, Granules of Modified Propylene Polymer-2 were obtained.

[0149](D-7) Maleic anhydride-modified polypropylene-3: maleic anhydride-modified polypropylene produced by the method described below. MVR 400cm 3 / 10 minutes, the added amount of maleic anhydride unit is 2.0 parts by weight

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com