Foamable resol-type phenolic resin molding material, preparation method thereof, and phenolic resin foam

A technology of resole phenolic resin and phenolic resin, which is applied in the field of foamable resole phenolic resin molding materials and its preparation and phenolic resin foam, which can solve the problems of foaming and curing obstacles, and achieve the implementation of mixing Operation, good metal corrosion resistance, cost reduction effect of supply equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

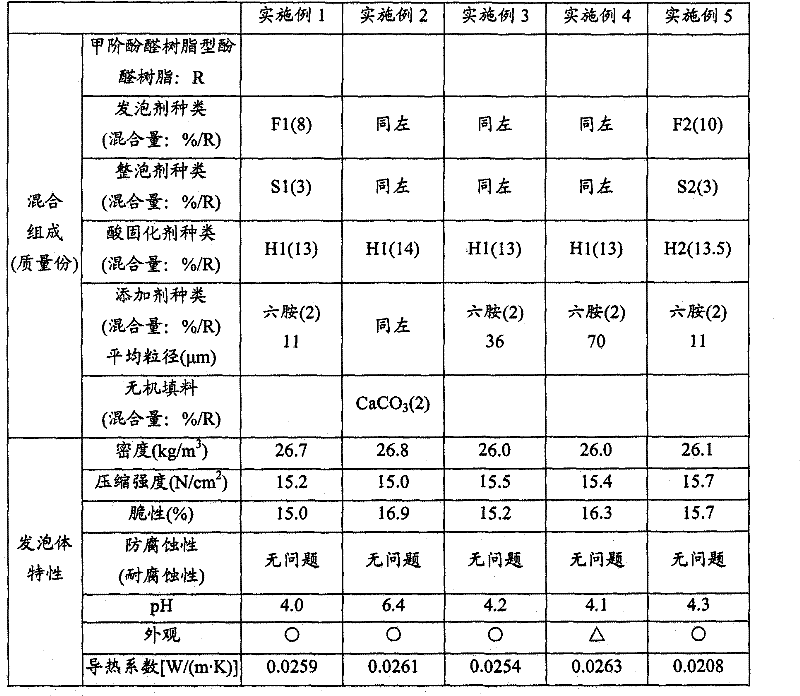

Embodiment 1

[0088] First, with respect to 100 parts by mass of the above-mentioned liquid resole type phenolic resin, add 3 parts by mass of a silicone-based foam stabilizer (trade name "L-5420", manufactured by Japan Unica Co., Ltd.) as a foam stabilizer and 8 parts by mass of n-pentane (manufactured by Eskei Sangyo Co., Ltd.) as a foaming agent were mixed, and the temperature of the mixture was adjusted to 5°C. The total amount of the resulting mixture, and 2 parts by mass of hexamethylenetetramine (average particle diameter 11 μm) as an additive and 13 parts by mass of xylenesulfonic acid as an acid curing agent (trade name "TEIKATOX 110", Teika Co., Ltd. Production) Stirring and mixing with a paddle mixer to prepare a foamable resol-type phenolic resin molding material. Next, pour the molding material into a metal mold frame (length 300mm x width 300mm x height 50mm) covered with glass non-woven fabric, and then immediately place the same glass non-woven fabric to make a sandwich stru...

Embodiment 2

[0090] In embodiment 1, with respect to 100 mass parts of liquid resole type phenolic resins, further add 2 mass parts of calcium carbonate as inorganic filler, and change acid curing agent to 14 mass parts, except that it is the same as embodiment 1 A phenolic resin foam was prepared in the same manner. Table 1 shows the physical properties of this foam.

Embodiment 3

[0092] In Example 1, except having changed the average particle diameter of hexamethylenetetramine into 36 micrometers, it carried out similarly to Example 1, and prepared the phenolic resin foam. Table 1 shows the physical properties of this foam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com