Flame retardant polyamide resin composition

A polyamide resin, flame retardant technology, applied in the field of flame retardant polyamide resin composition, can solve the problems of low glow wire and tensile strength, poor conduction, corrosion of metal contact terminals, etc. Excellent traceability, excellent metal corrosion resistance, and excellent mechanical strength

Active Publication Date: 2010-08-11

MITSUBISHI ENG PLASTICS CORP

View PDF7 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

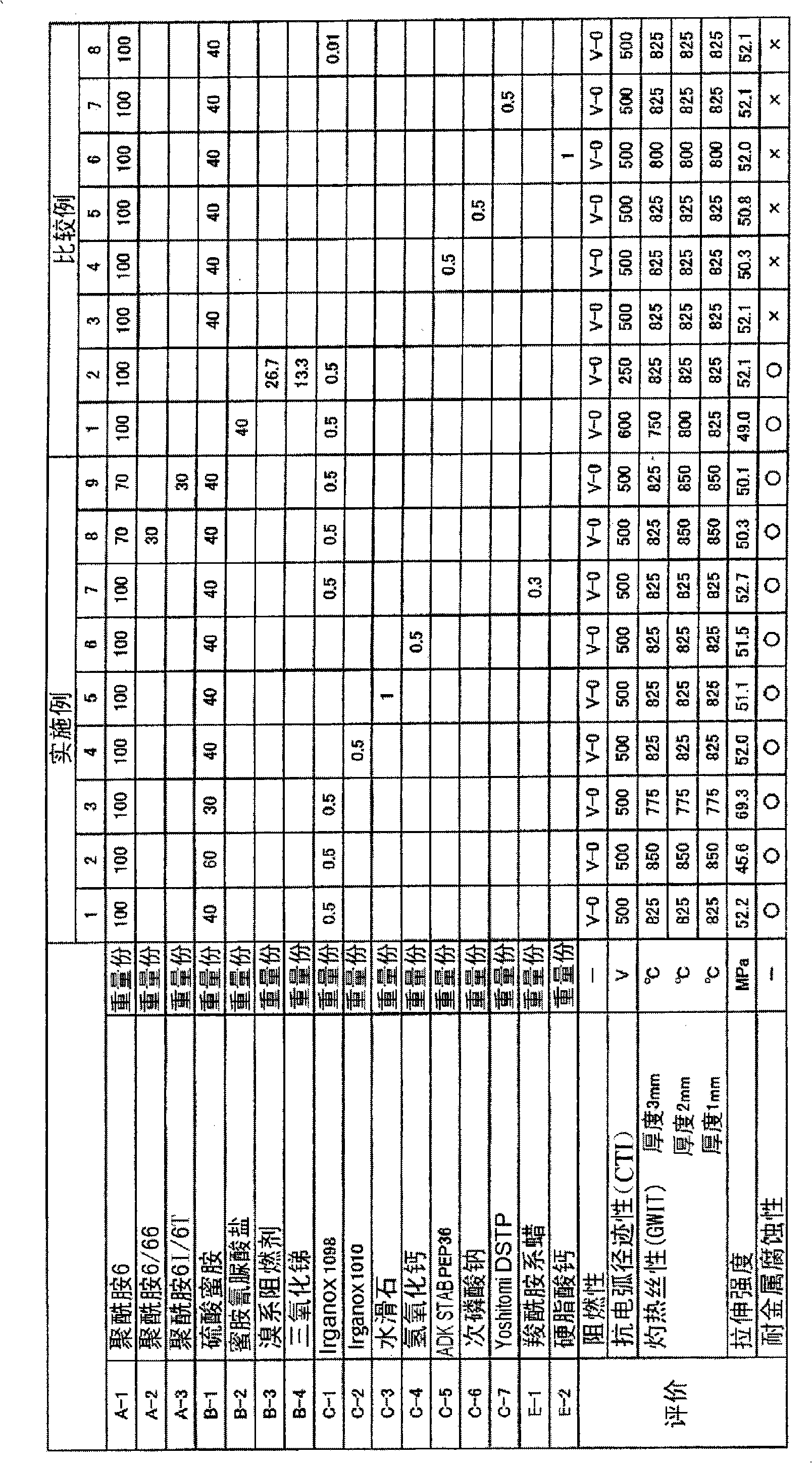

As described in Patent Document 2, when flame retardants such as melamine polyphosphate, melam (Melam) and melem (Melem) double salt, polymetaphosphate melamine, polyphosphate amide, etc. are used, there is a glow wire low sex problem

In addition, the thermoplastic resin composition described in the examples of Patent Document 3 may have low glow thread property and low tensile strength.

In addition, according to studies by the inventors of the present invention, it has been found that when electrical and electronic components are manufactured using a resin composition containing a sulfur-containing melamine-based flame retardant such as melamine sulfate, due to the heat generated during energization, etc., the Produce sulfate ions, sulfur dioxide, hydrogen sulfide and other metal corrosive gases, corrode metal contacts and terminals, resulting in poor conduction and other problems

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

reference example 1

reference example 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melt viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

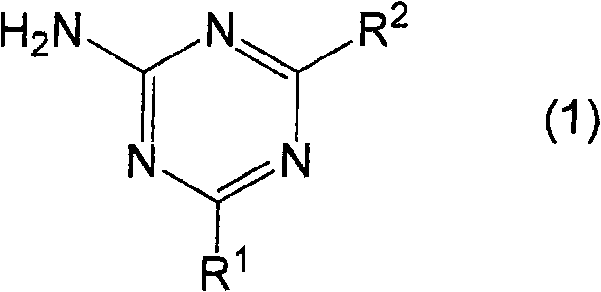

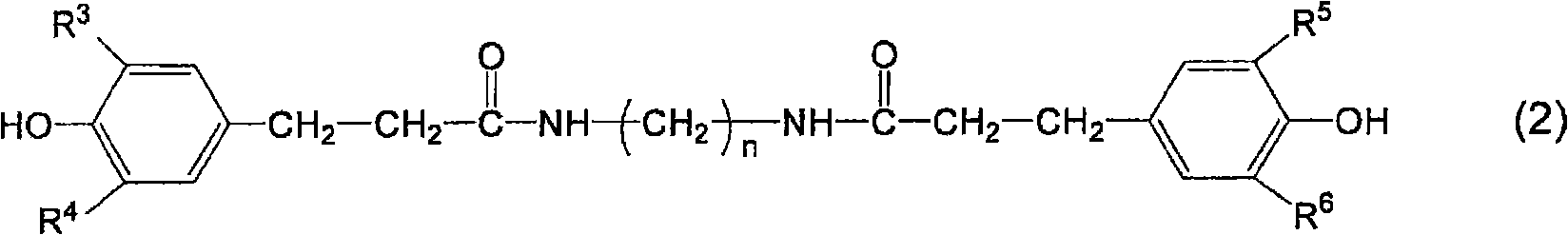

A flame retardant polyamide resin composition that excels in all of flame retardance, glow wire and antitracking characteristics and mechanical strength and excels in metal corrosion suppression, finding suitable application in electrical / electronic parts with metal contact point / terminal, such as connectors. The flame retardant polyamide resin composition is characterized by containing 100 partsby weight of polyamide resin (A), 10 to 60 parts by weight of salt (B) formed from an aminotriazine compound and at least one compound selected from the group consisting of sulfuric acid, pyrosulfuric acid and an organic sulfonic acid and at least one compound (C) selected from the group consisting of a hindered phenol compound, hydrotalcite and a hydroxide of alkaline earth metal, the mixing ratio of component (C) to component (B), (C) / (B), being in the range of 0.0005 to 0.2.

Description

Flame retardant polyamide resin composition technical field The present invention relates to a flame-retardant polyamide resin composition. In detail, it relates to a flame-retardant polyamide resin composition which is excellent in arc tracking resistance and glow wire characteristic as one of electrical safety of electric parts and electronic parts, and which is resistant to metal corrosion Also excellent, suitable for electrical and electronic components with metal contacts, metal terminals. Background technique Polyamide resins have been used in automotive parts, mechanical parts, electrical and electronic parts, and the like due to their excellent mechanical strength, heat resistance, and the like. Especially in recent years, in the use of electrical and electronic components such as connectors and plugs with metal terminals, switches and circuit breakers with metal contacts, the level of flame retardancy requirements has gradually increased, and the requirements are...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L77/00C08K3/22C08K3/24C08K5/13C08K5/3492

CPCC08L77/00C08L2201/02C08K5/34928C08L51/06C08K5/20C08L2666/06C08L2666/24C08K5/13C08K3/22C08K5/3492

Inventor 角田守男山中康史

Owner MITSUBISHI ENG PLASTICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com