Seaport engineering concrete chloride ion penetration resistant reinforcing agent

A chloride ion penetration and concrete technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as deficiencies, performance complementarity and optimization of high-strength concrete, to reduce penetration speed and improve chlorine resistance. Ion permeability, the effect of reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The development steps of the present invention are as follows:

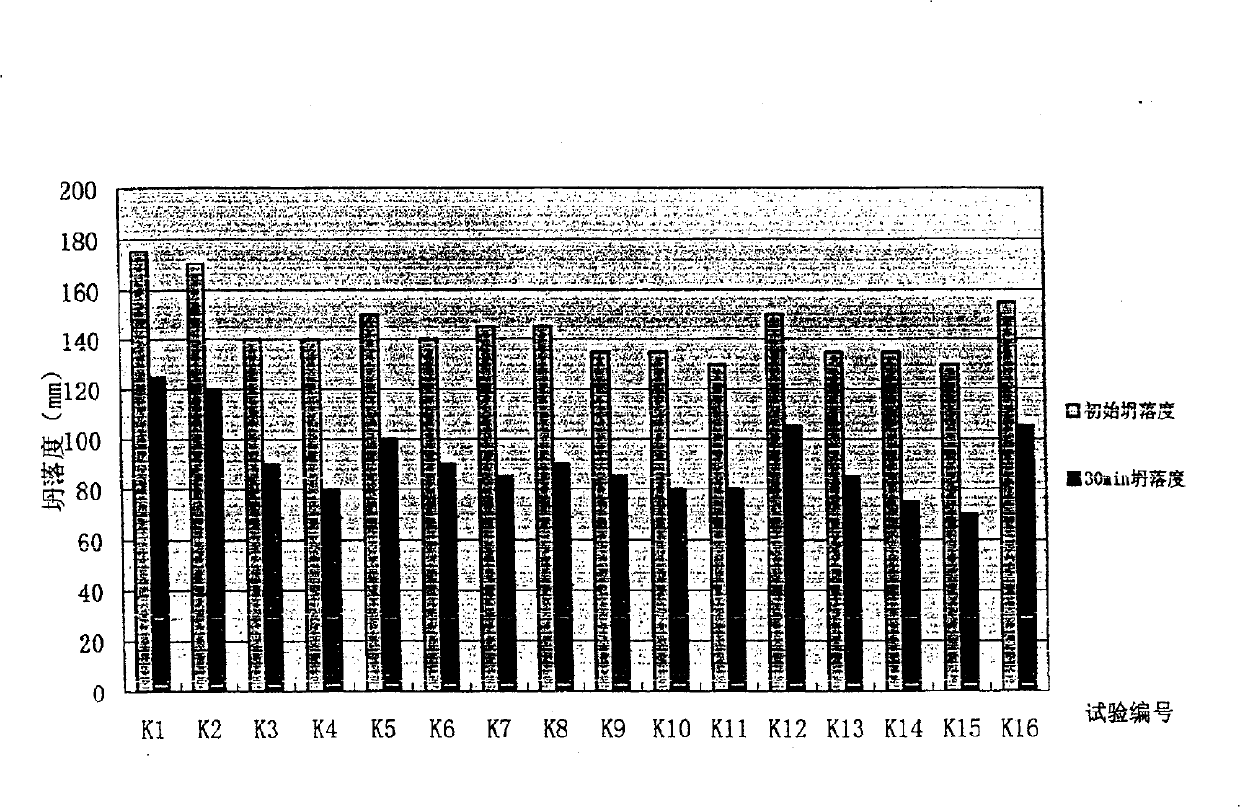

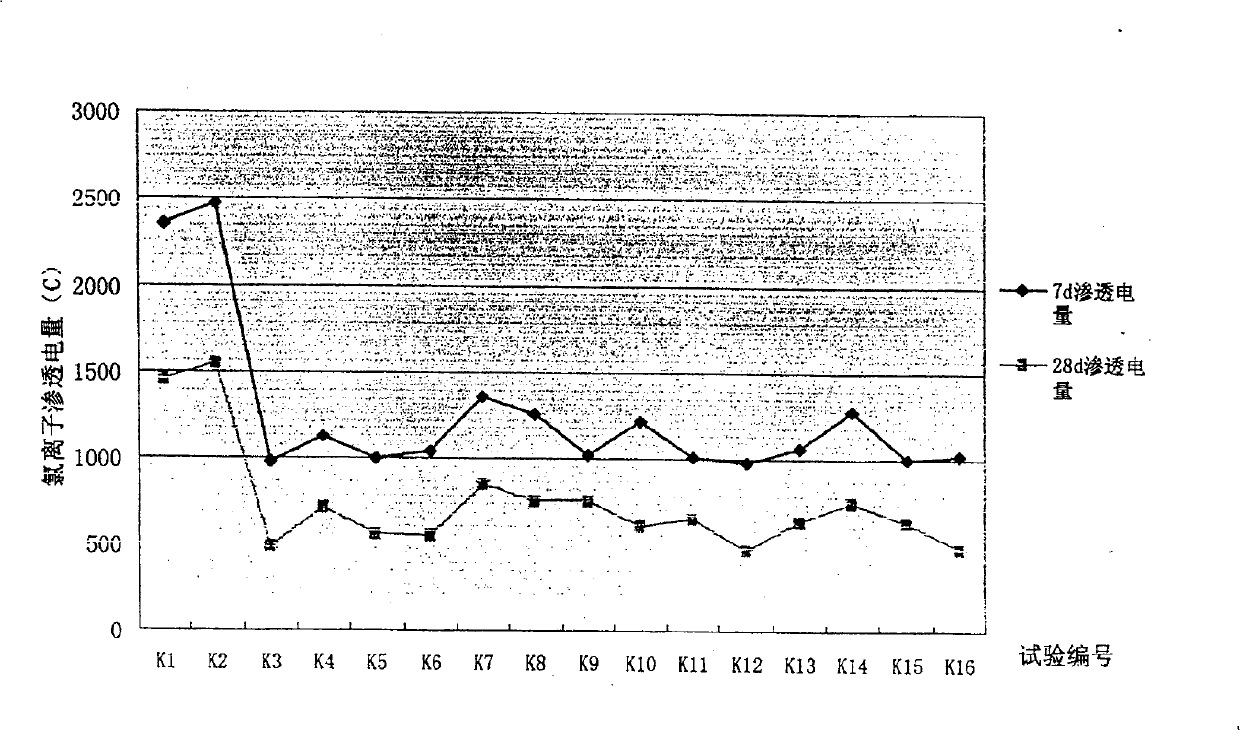

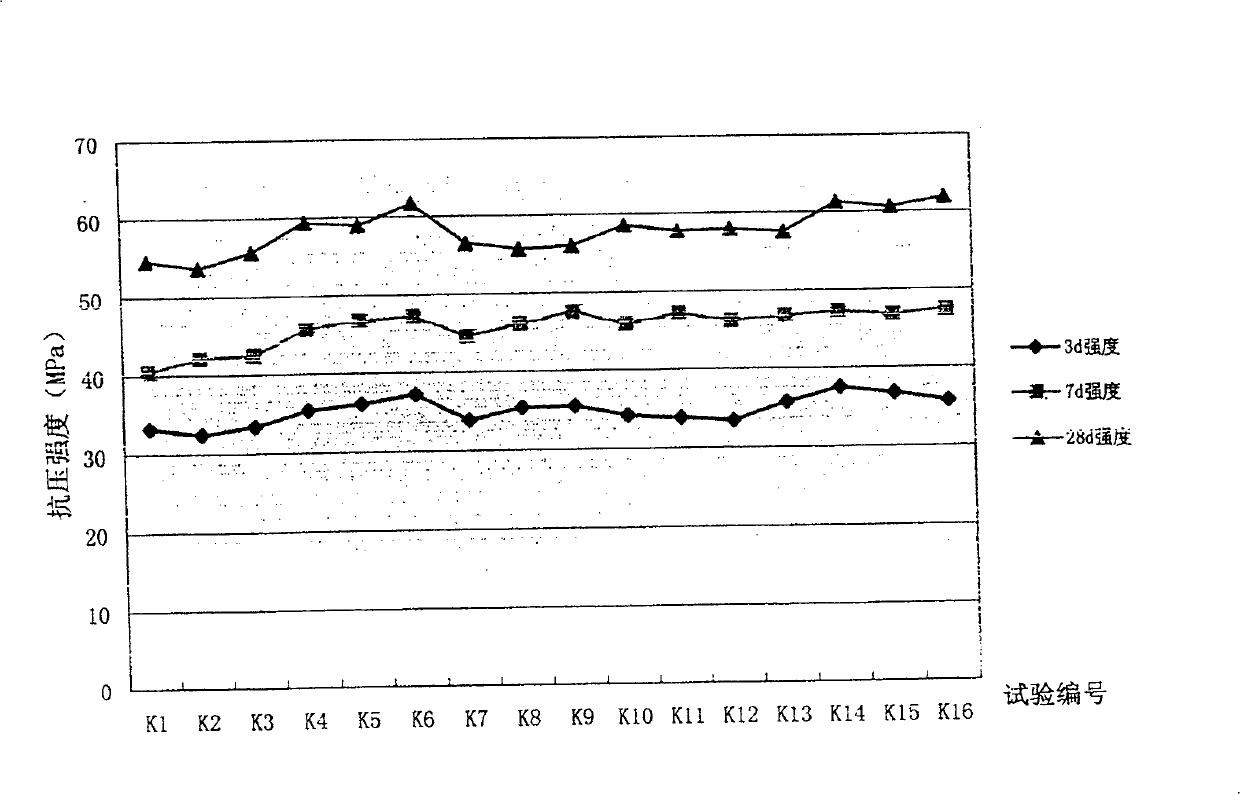

[0024] (1) Analyze the influence of various inorganic functional components (IPM) on the anti-chloride ion penetration performance of concrete: the inorganic functional components are divided according to their functions, including nano-scale high-efficiency compact components, anti-crack and anti-seepage components, early volume Stable components, crystalline components, etc., mainly include high-quality fly ash (FA), high-quality ground slag (SL), ultra-fine high-quality silica powder (SF), washed and calcined kaolin (AL-1, AL-2), Ultrafine nanofiber (AL-3), etc.;

[0025] (2) Analyze the influence of various organic functional components (SPM) on the chloride ion penetration resistance of concrete: organic functional components mainly include high-efficiency plasticizing components (SP-1, JM-B high-concentration and high-efficiency water reducers) , high-efficiency slump-preserving components (SP-2, Po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com