High-solid surface-tolerant epoxy zinc-rich primer and preparation method and application thereof

A technology of epoxy zinc-rich primer and low surface treatment, applied in the field of coatings, can solve the problems of inconvenient construction, zinc fever, blistering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

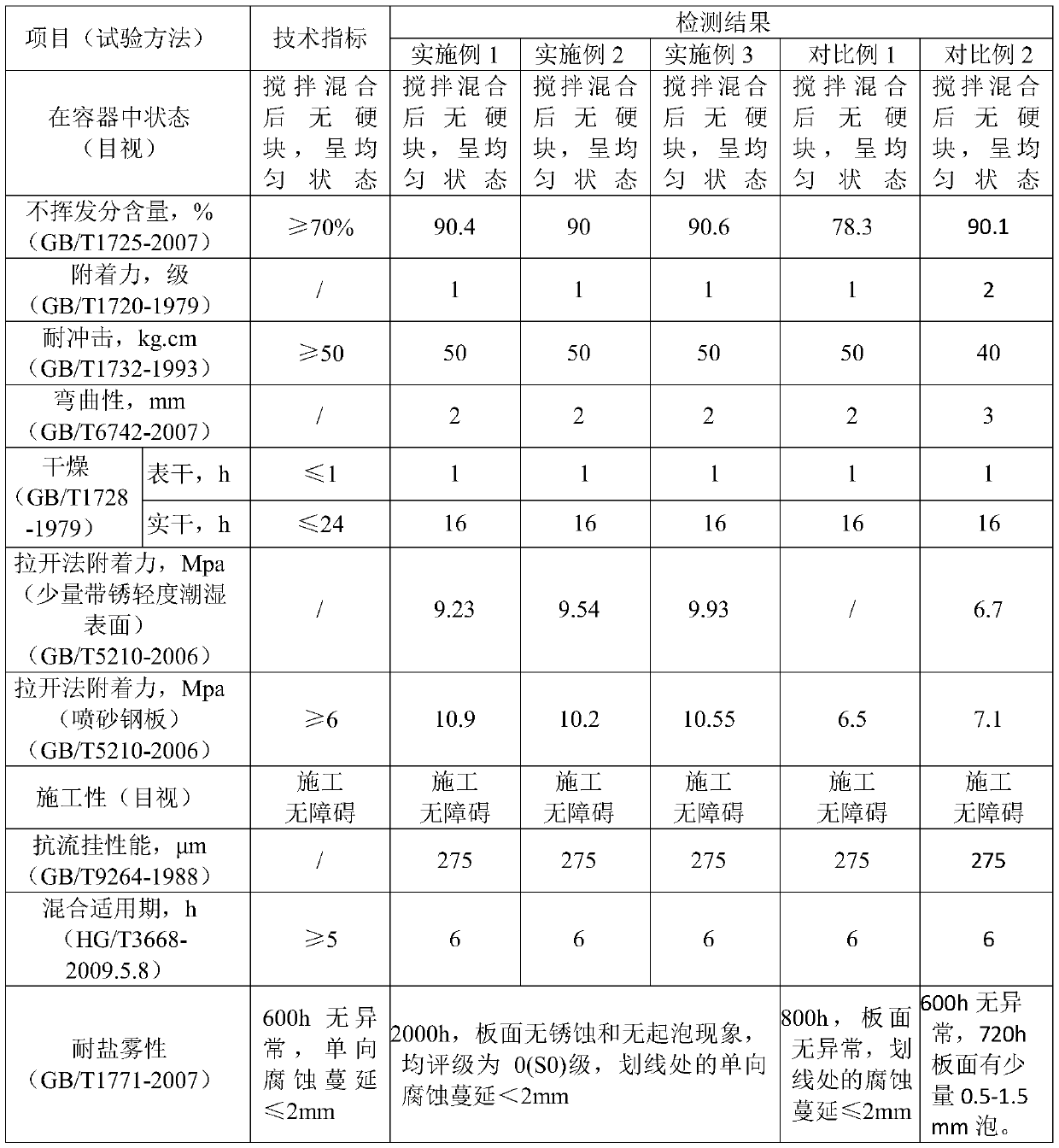

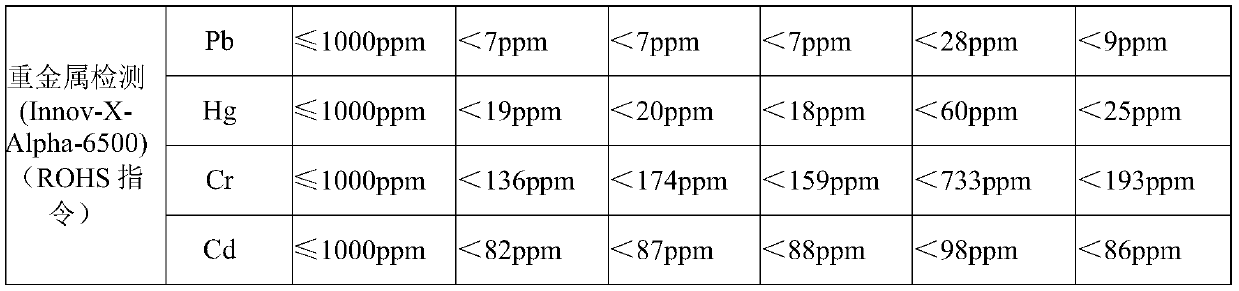

Examples

Embodiment 1

[0104] S1. Preparation of organic mixed solvent

[0105] Mix 25 parts of xylene, 25 parts of butanol, 10 parts of isopropanol, 20 parts of methyl isobutyl ketone and 20 parts of dipropylene glycol methyl ether to obtain an organic mixed solvent.

[0106] S2, preparation of epoxy resin slurry

[0107] First, 5 parts of F44-80 liquid novolac epoxy resin, 1 part of AGE reactive diluent, 11 parts of SM601-60 epoxy resin, 0.5 part of BENTONE SD-2 organic bentonite, 1.3 parts of MONORAL3300 polyamide wax paste, 0.2 parts of EFKA4010 dispersant 1 part, 1 part of TC-GC zinc phosphate, 3 parts of APW aluminum tripolyphosphate, 3 parts of organic mixed solvent prepared by S1, add them to the batching container in turn, stir and disperse evenly at a speed of 1000r / min, then inhale the horizontal sand Grind and disperse to a fineness of 35 μm in a mill to obtain epoxy resin slurry.

[0108] S3, preparation of component A

[0109] Add 62 parts of 1000-mesh zinc powder to the epoxy resin...

Embodiment 2

[0115] S1. Preparation of organic mixed solvent

[0116] Mix 25 parts of xylene, 25 parts of butanol, 10 parts of isopropanol, 20 parts of methyl isobutyl ketone and 20 parts of dipropylene glycol methyl ether to obtain an organic mixed solvent.

[0117] S2, preparation of epoxy resin slurry

[0118] First, 6.5 parts of F44-80 liquid phenolic epoxy resin, 1 part of AGE reactive diluent, 9 parts of SM601-60 epoxy resin, 0.5 part of BENTONE SD-2 organic bentonite, 1.3 parts of MONORAL3300 polyamide wax paste, 0.2 parts of EFKA4010 dispersant Parts, 1.5 parts of TC-GC zinc phosphate, 2.5 parts of TC-1 aluminum tripolyphosphate, 4 parts of organic mixed solvent prepared by S1, add them to the batching container in turn, stir and disperse evenly at a speed of 1000r / mim, inhale Grinding and dispersing to a fineness of 35 μm with a type sand mill to obtain epoxy resin slurry.

[0119] S3, preparation of component A

[0120] Add 61 parts of 1000-mesh zinc powder to the epoxy resin ...

Embodiment 3

[0126] S1. Preparation of organic mixed solvent

[0127] Mix 25 parts of xylene, 25 parts of butanol, 10 parts of isopropanol, 20 parts of methyl isobutyl ketone and 20 parts of dipropylene glycol methyl ether to obtain an organic mixed solvent.

[0128] S2, preparation of epoxy resin slurry

[0129] First, 7.5 parts of F44-80 liquid novolac epoxy resin, 1 part of AGE reactive diluent, 9 parts of SM601-60 epoxy resin, 0.5 part of BENTONE SD-2 organic bentonite, 1.3 parts of MONORAL3300 polyamide wax paste, 0.2 parts of EFKA4010 dispersant 2 parts, 2 parts of Nubirox 106 modified zinc phosphate, 2 parts of APW aluminum polyphosphate, 3 parts of organic mixed solvent prepared by S1, add them to the batching container in turn, stir and disperse evenly at a speed of 1000r / min, then inhale the horizontal sand Grind and disperse to a fineness of 35 μm in a mill to obtain epoxy resin slurry.

[0130] S3, preparation of component A

[0131] Add 62 parts of 1000-mesh zinc powder to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com