Patents

Literature

35results about How to "Decreased corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

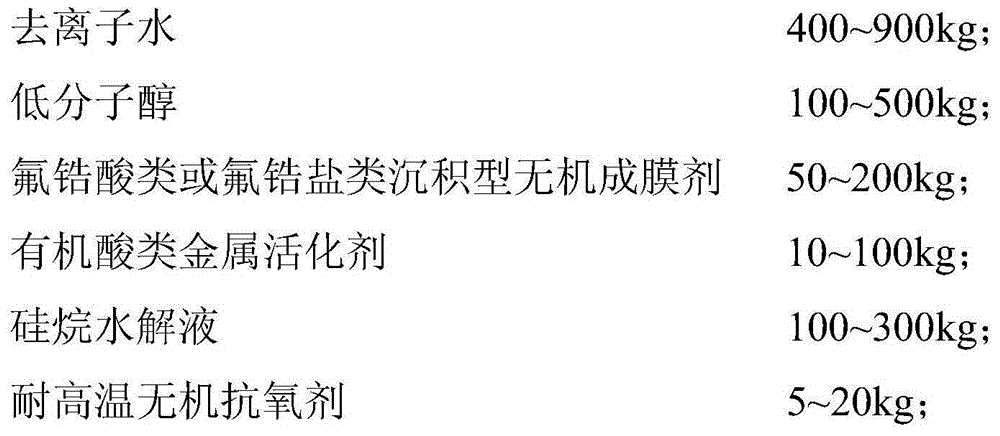

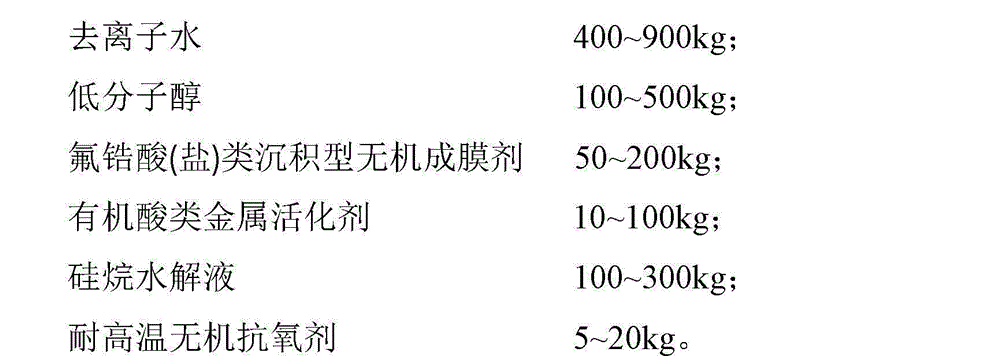

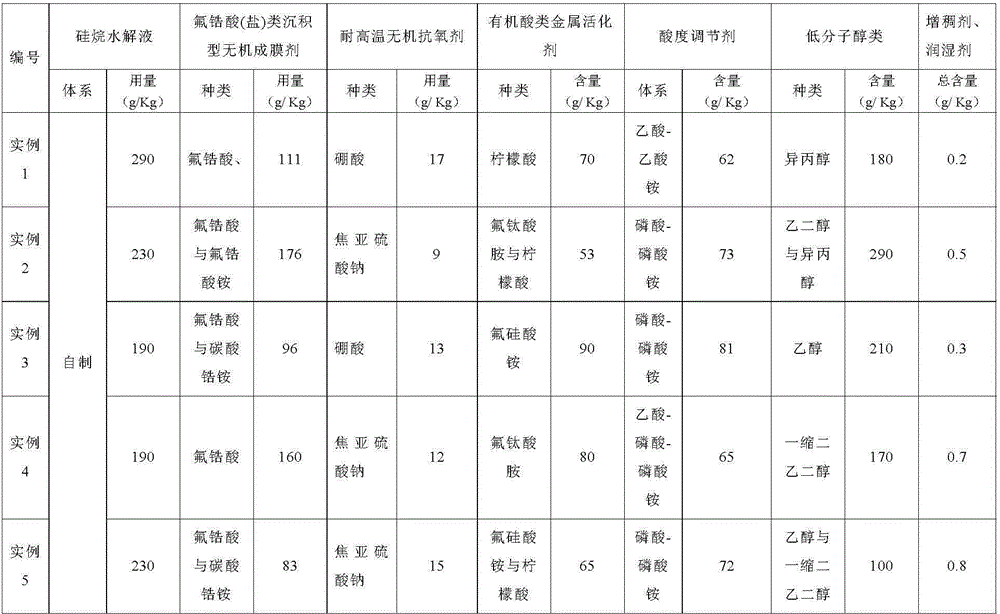

Non-chrome purified liquid

ActiveCN103205738AImprove corrosion resistanceGood resistance to high temperature yellowing propertiesMetallic material coating processesAntioxidantSilanes

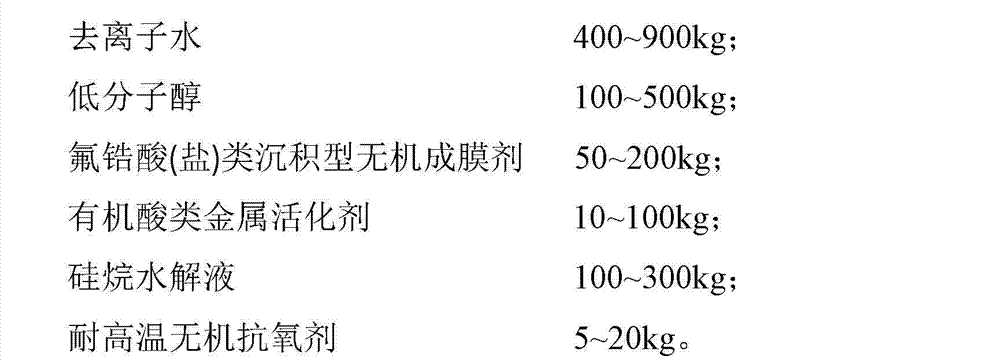

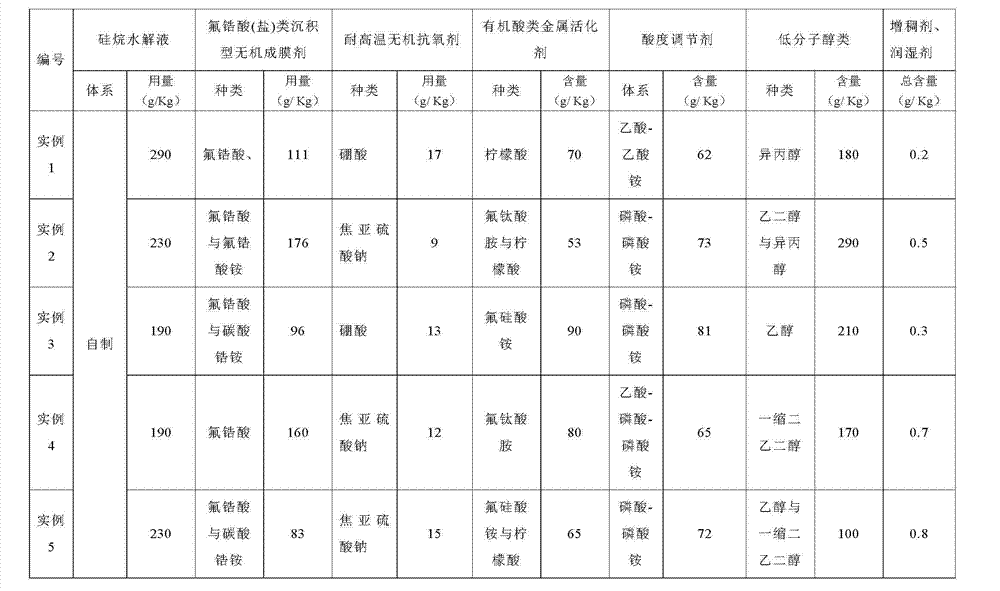

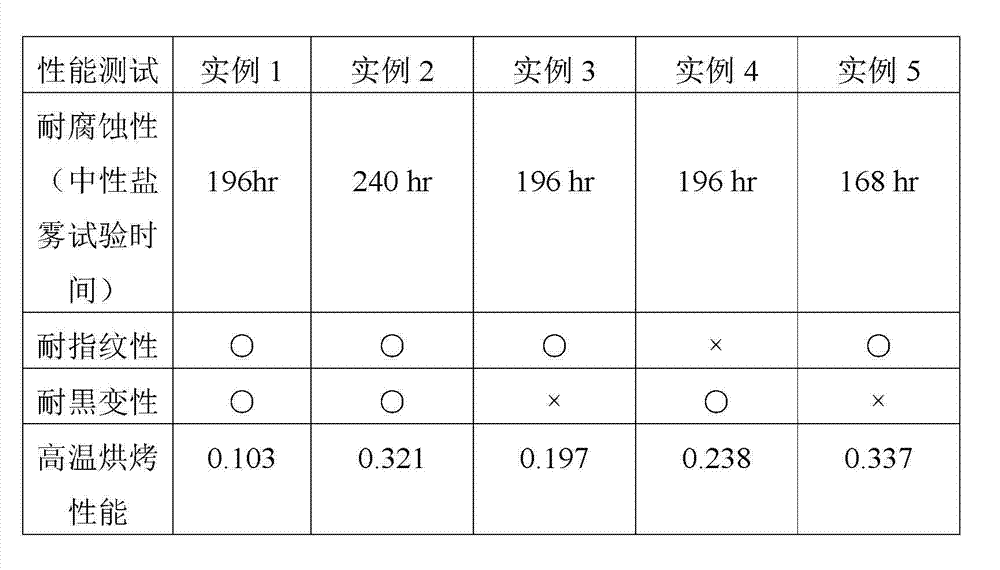

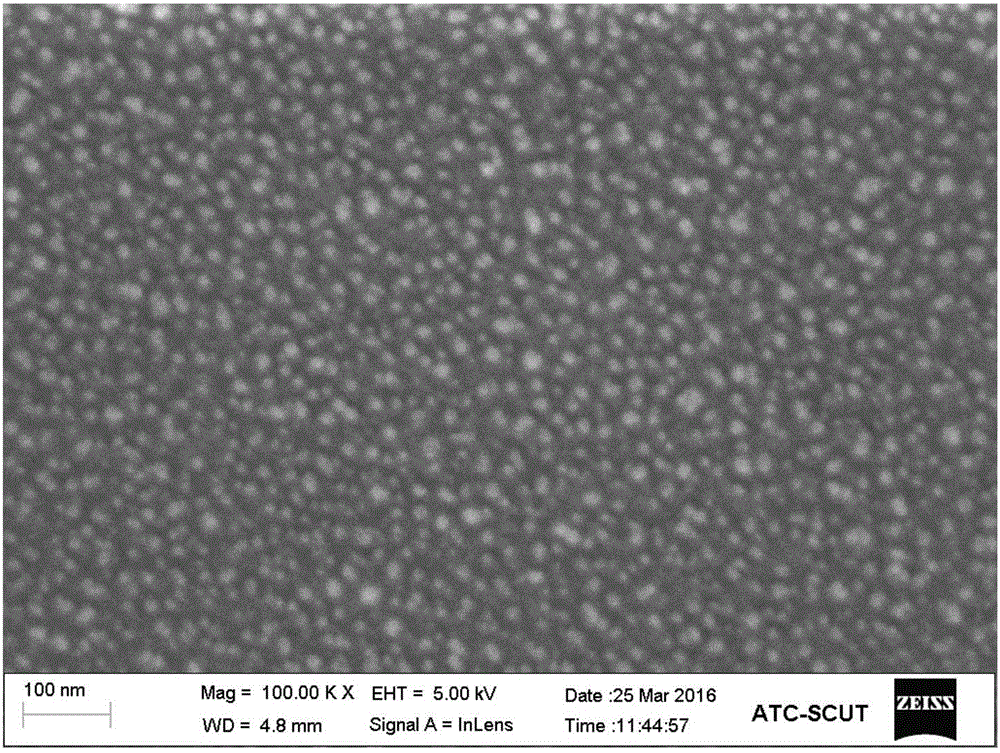

The invention discloses a non-chrome purified liquid. Components of each 1000kg of the non-chrome purified liquid include: 400-900kg of deionized water, 100-500kg of low molecular weight alcohol, 50-200kg of zirconium-fluoride-acid (salt) type sedimentary inorganic film-forming agent, 10-100kg of organic-acid type metal activator, 100-300kg of silane hydrolyzate and 5-20kg of high-temperature-resistant inorganic antioxidant. The non-chrome purified liquid is good in corrosion resistance, has good high-temperature and xanthochroia resisting features since the high-temperature-resistant inorganic antioxidant is added in without organic aqueous resin, is adaptable to surface passivation processing of galvanized and aluminum-zinc alloy plated type metal products, and is further adaptable to surface passivation processing of galvanized plates (the galvanized plates for computer cases and the like) with special requirements for high-temperature and xanthochroia resisting features.

Owner:武汉钢实硅钢浩源润滑油有限公司

Air-permeability aluminum foil and preparation method thereof

ActiveCN101628644AGood corrosionGood corrosion resistanceFlexible coversWrappersMaximum diameterCorrosion

The invention relates to an air-permeability aluminum foil and a preparation method thereof, wherein the aluminum foil is mainly suitable for air-permeability packaging in requirements of agricultural production and daily life. The aluminum foil is characterized by being made of 3003 alloy, the thickness of the aluminum foil is 0.03-0.05 mm, pinholes which can reach more than 10,000 every square meter are densely distributed on the surface of the aluminum foil, and the maximum diameter of each pinhole is not more than 0.05 mm. The preparation method comprises the following process steps: batching, smelting, cast-rolling, cold-rolling, interannealing, cold-rolling, and foil-rolling to reach the finished thickness, slitting into a finished specification, and finished annealing. The invention has the advantages of good air permeability, strong corrosion resistance and strong oxidation resistance.

Owner:新疆生产建设兵团第八师天山铝业有限公司

Sliding sprue tile for smelting high-oxygen steel and calcium treated steel

InactiveCN1335281AGood chemical stabilityImprove mechanical propertiesMelt-holding vesselsBrickOxidation resistant

The refractory material for the sliding tap-hole block consists of magnesite and / or magnesia alumina spinel refractory material 90-100 % with the rest being zirconia or titanium oxide refractory material. The sliding tap-hole block of the present invention has excellent mechanical performance, chemical stability, corrosion resistance, metal burn-out resistance and oxidation resistance at high temperature, and when it is used in smelting high-oxygen steel and calcium treated steel, it has long service life, light weight and low cost.

Owner:BAOSHAN IRON & STEEL CO LTD

Chromium-free passivating liquid for surface treatment of electrogalvanized steel plate and use method thereof

InactiveCN101289741AImprove stabilityLong storage timeMetallic material coating processesChromium freeElectrogalvanization

The invention discloses a chromium-free passivating solution for the surface treatment of electro-galvanized steel plates, as well as a method for using the same. The mass percentages of the composition of the chromium-free passivating solution are: 0.2-20 percent of gamma-glycidyl ether oxygen propyl trimethoxy silane, 0.01-1.0 percent of polyvinyl alcohol, 0.1-3.0 percent of ammonium zirconium carbonate, water as a solvent, and the balance. The application method comprises the following steps that: the surface of a clean electro-galvanized steel plate is coated with the passivating solution, and then the passivating solution is baked to become a film; the thickness of a film layer is between 0.2 and 2.0 g / m<2>. The process treatment of the invention remarkably improves the corrosion resistance of the electro-galvanized steel plate, which is equivalent to chromate color passivation. In addition, through the treatment of the process, the coating performance of the electro-galvanized steel plate is remarkably improved as well.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Water-based polyurethane anti-glare coating material and preparation method thereof

ActiveCN106380569ABrittleReduced polishing resistancePolyurea/polyurethane coatingsWater basedOrganometallic catalysis

The invention discloses a water-based polyurethane anti-glare coating material and a preparation method thereof. The preparation method mainly comprises the following steps: first stage: by using polyoxytetramethylene glycol and dihydroxymethyl eicosanoic acid as raw materials, adding an organic metallic catalyst and diisocyanate to react, and adding a tertiary amine neutralizer to generate an isocyanate-terminated water-based polyurethane prepolymer; and second stage: two-step chain extension and emulsification: simultaneously carrying out emulsification and chain extension reaction on the prepolymer in a sulfonate-chain-extender-containing water solution under high-speed shearing actions until the prepolymer can be uniformly emulsified in water, and dropwisely adding a hydrazine chain extender to obtain the water-based polyurethane anti-glare emulsion. The coated film of the polyurethane anti-glare emulsion has the characteristics of low glossiness and high light transmittance, and is applicable to the fields of architectural lighting, road traffic, display screens, textile leather and the like.

Owner:QINGYUAN YAKOO CHEM CO LTD

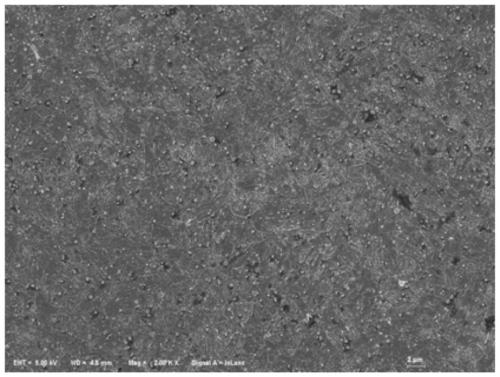

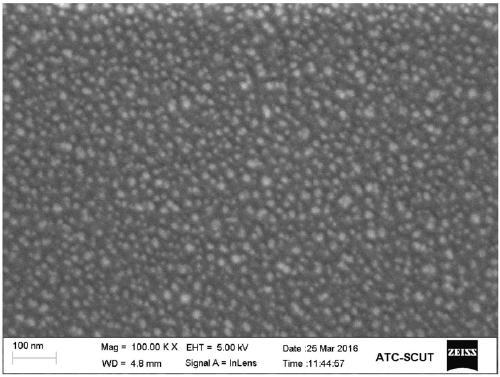

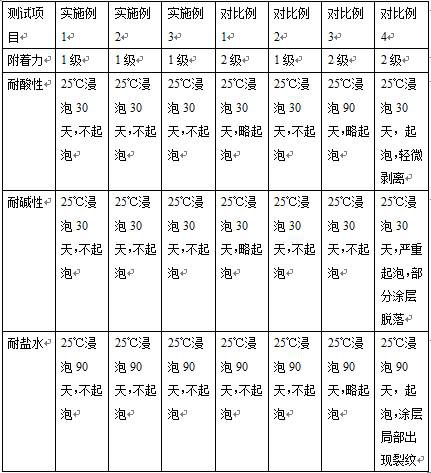

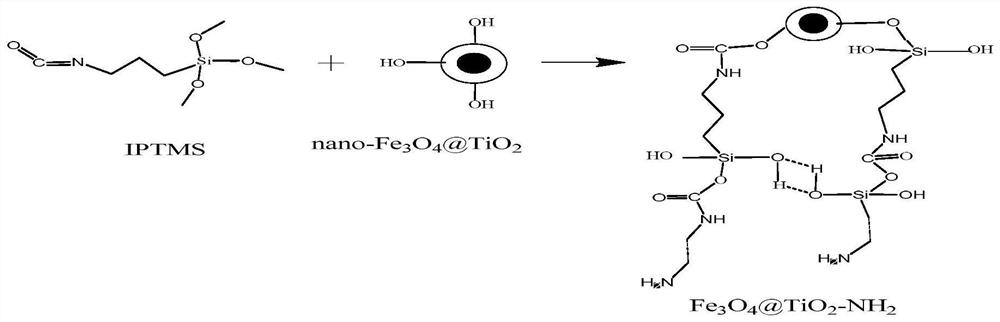

Nanometer composite ocean anticorrosion coating and preparation method thereof

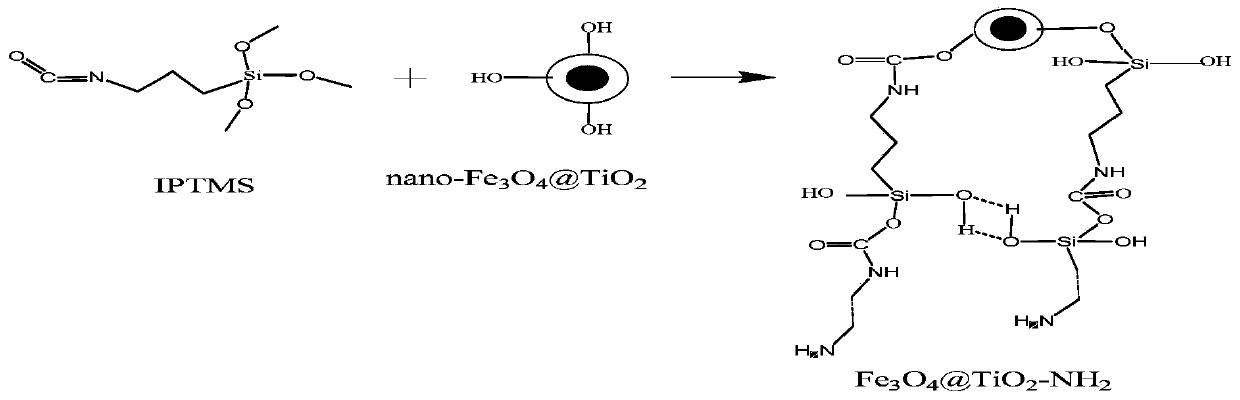

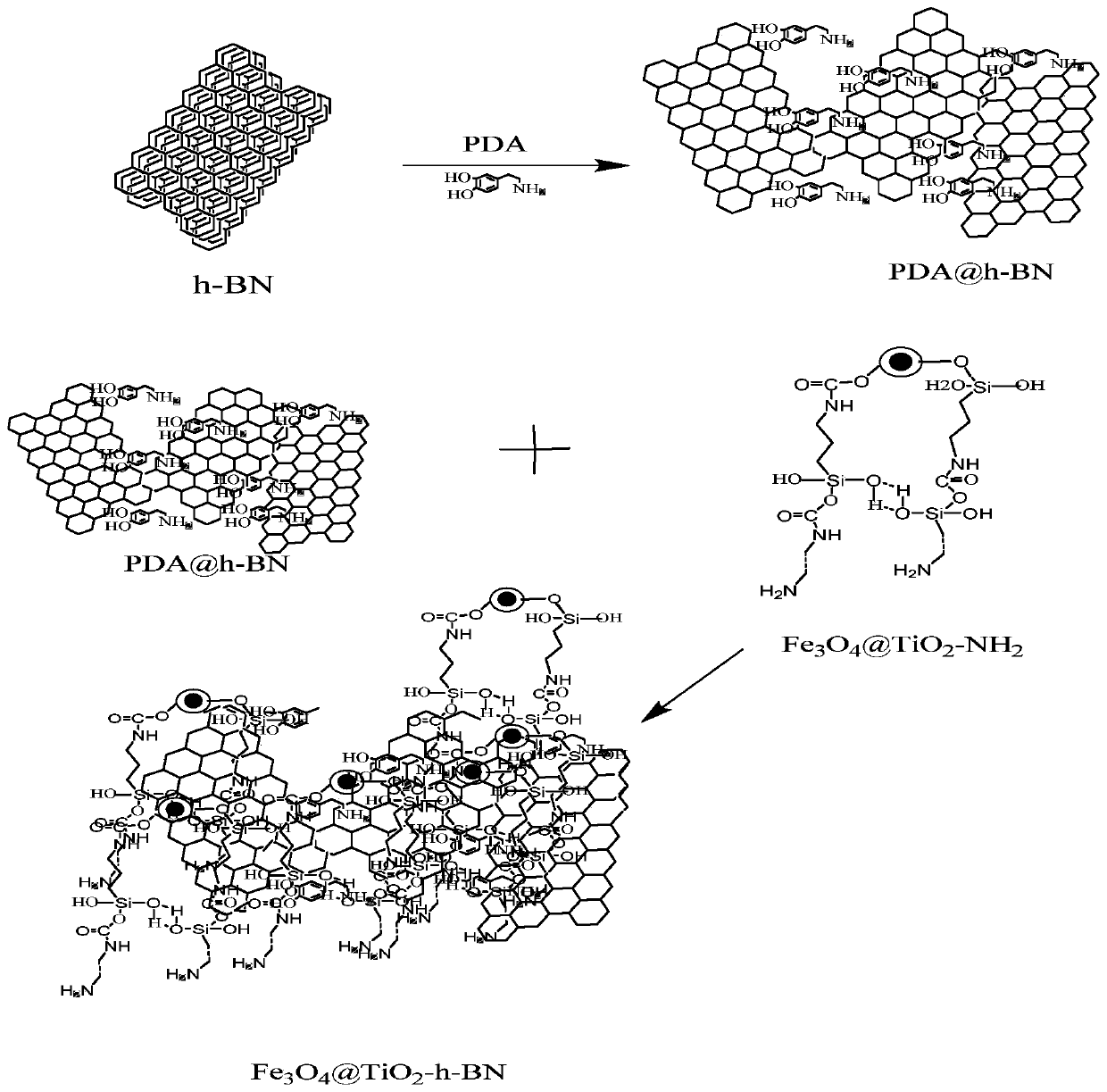

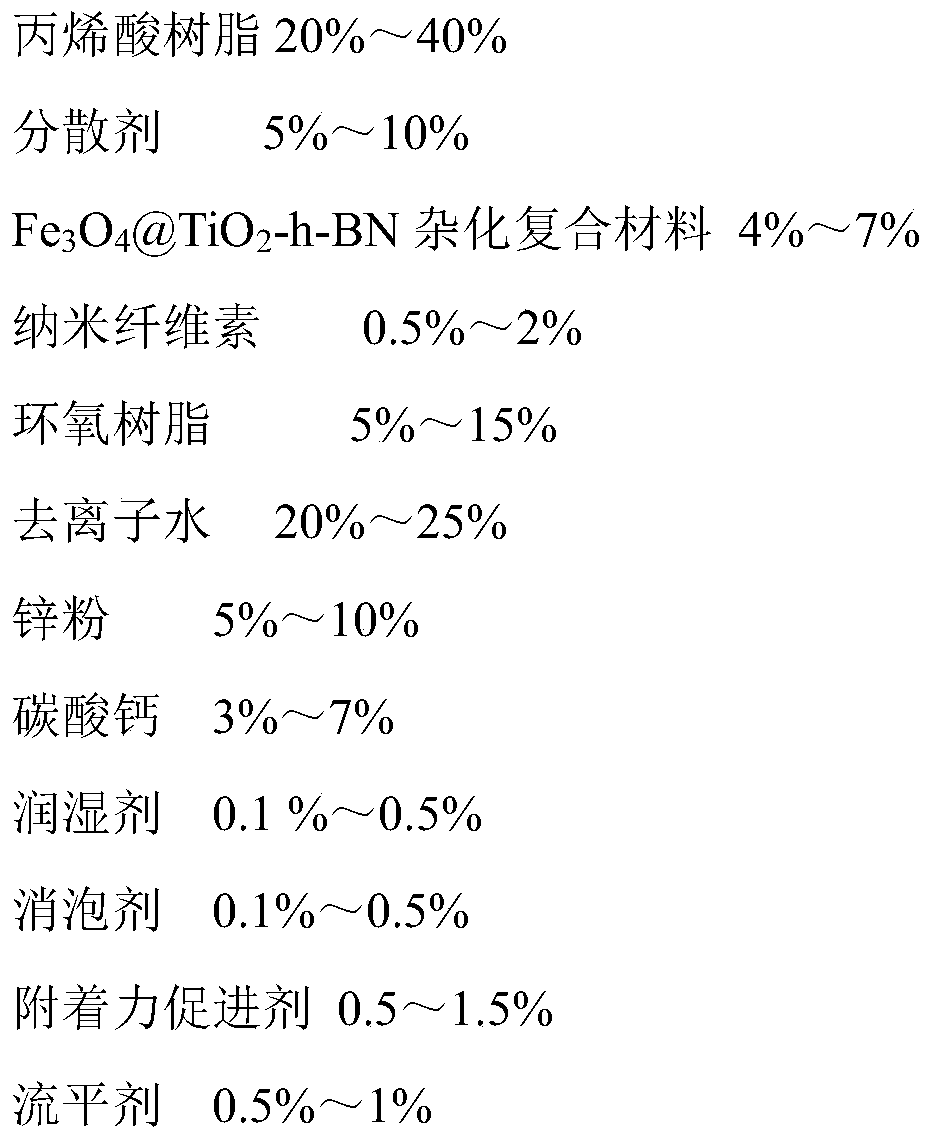

ActiveCN109943169AReduce biocorrosion hazardsLarge specific surface areaAntifouling/underwater paintsPaints with biocidesWater basedEpoxy

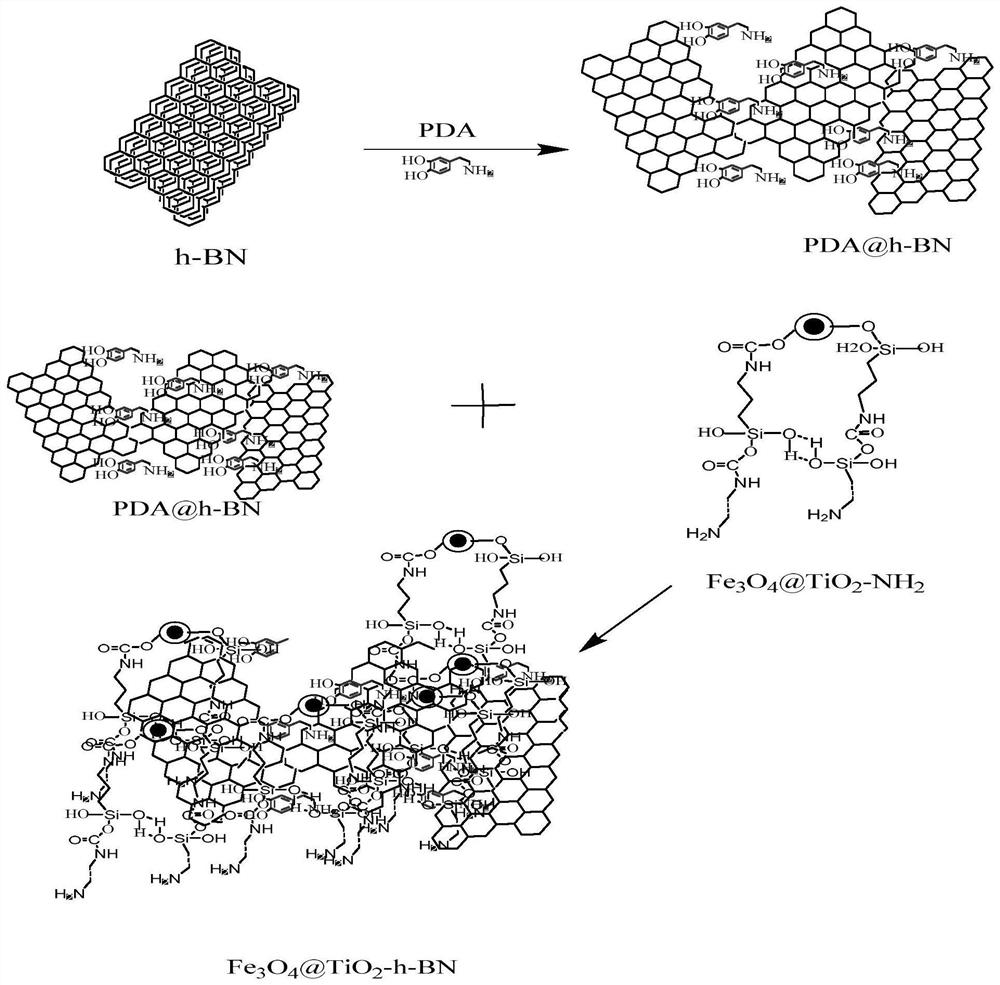

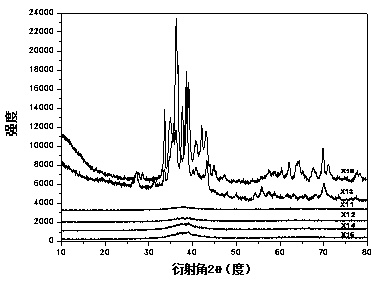

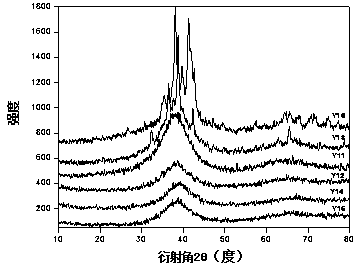

The invention discloses a nanometer composite ocean anticorrosion coating and a preparation method thereof, belonging to the field ofcorrosion prevention of coatings. The coating contains the following components in percentage by weight: a component A: 20%-40% of acrylic resin, 5%-10% of a hydroxyl epoxy phosphate dispersing agent, 4%-7% of a Fe3O4@TiO2-h-BN hybridized composite material, 0.5%-2%of nano-crystalline cellulose, 5%-15% of epoxy resin, 1.2%-3.5% of other aids, 20%-25% of deionized water, 5%-10% of zinc powder and 3%-7% of calcium carbonate; and a component B: a curing agent, namely 15%-25% of a water-based isocyanate curing agent. The coating prepared by virtue of the preparation method has good wear resistance, fouling resistance and corrosion resistance, is mainly applied to the fouling prevention and corrosion prevention of petroleum steel-frame structure platforms in an ocean atmospheric region environment and is also suitable for the fields of fouling prevention andcorrosion prevention of ships and underwater pipelines.

Owner:CHANGZHOU UNIV

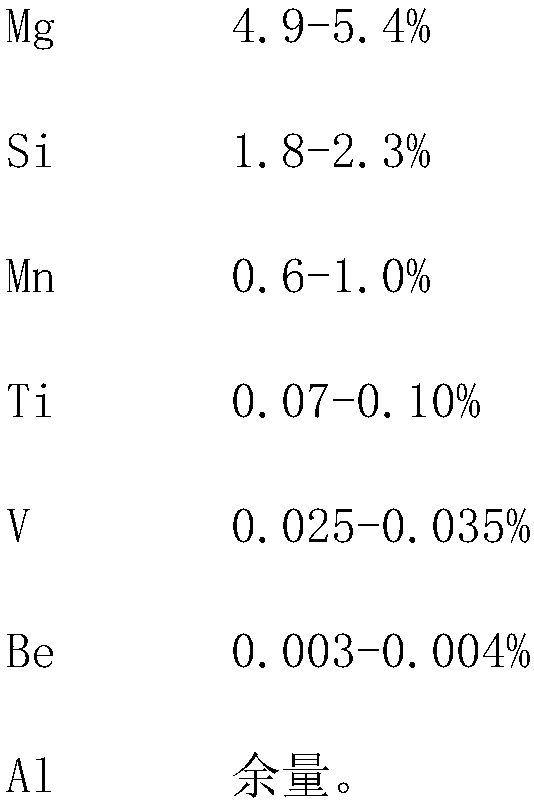

Aluminum magnesium alloy for casting two-breadth-type steering wheel framework and preparation method thereof

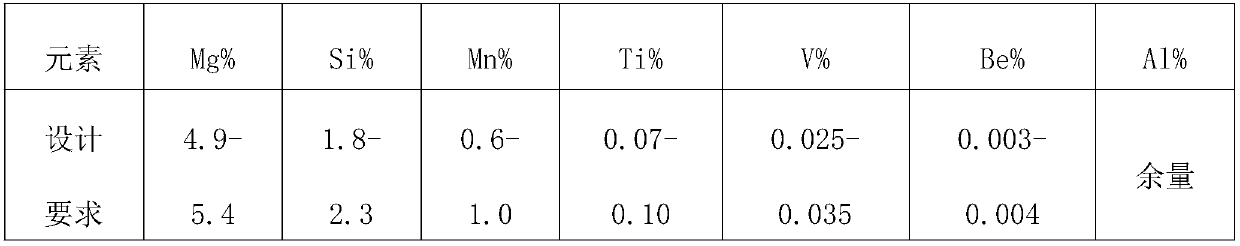

The invention belongs to the field of metal materials and relates to the field of preparation of aluminum magnesium alloys, in particular to an aluminum magnesium alloy for casting a two-breadth-typesteering wheel framework and a preparation method thereof. The alloy comprises the following components in percentages by weight: 4.9-5.4% of Mg, 1.8-2.3% of Si, 0.6-1.0% of Mn, 0.07-0.10% of Ti, 0.025-0.035% of V, 0.003-0.004% of Be and the balance of Al; impurity elements are controlled as follows: less than or equal to 0.13% of Fe, less than or equal to 0.03% of Zn, less than or equal to 0.01%of Cu, less than or equal to 0.0005% of Cr, less than or equal to 0.001% of P, less than or equal to 0.0005% of Na, less than or equal to 0.0005% of Ca, less than or equal to 0.01% of Li and the balance of Al.

Owner:保定隆达铝业有限公司 +1

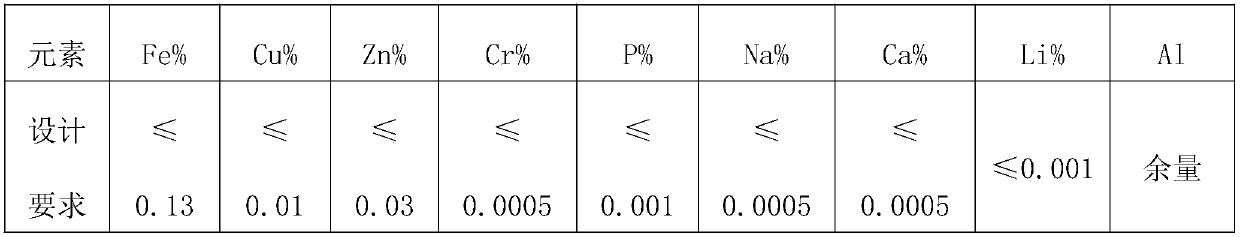

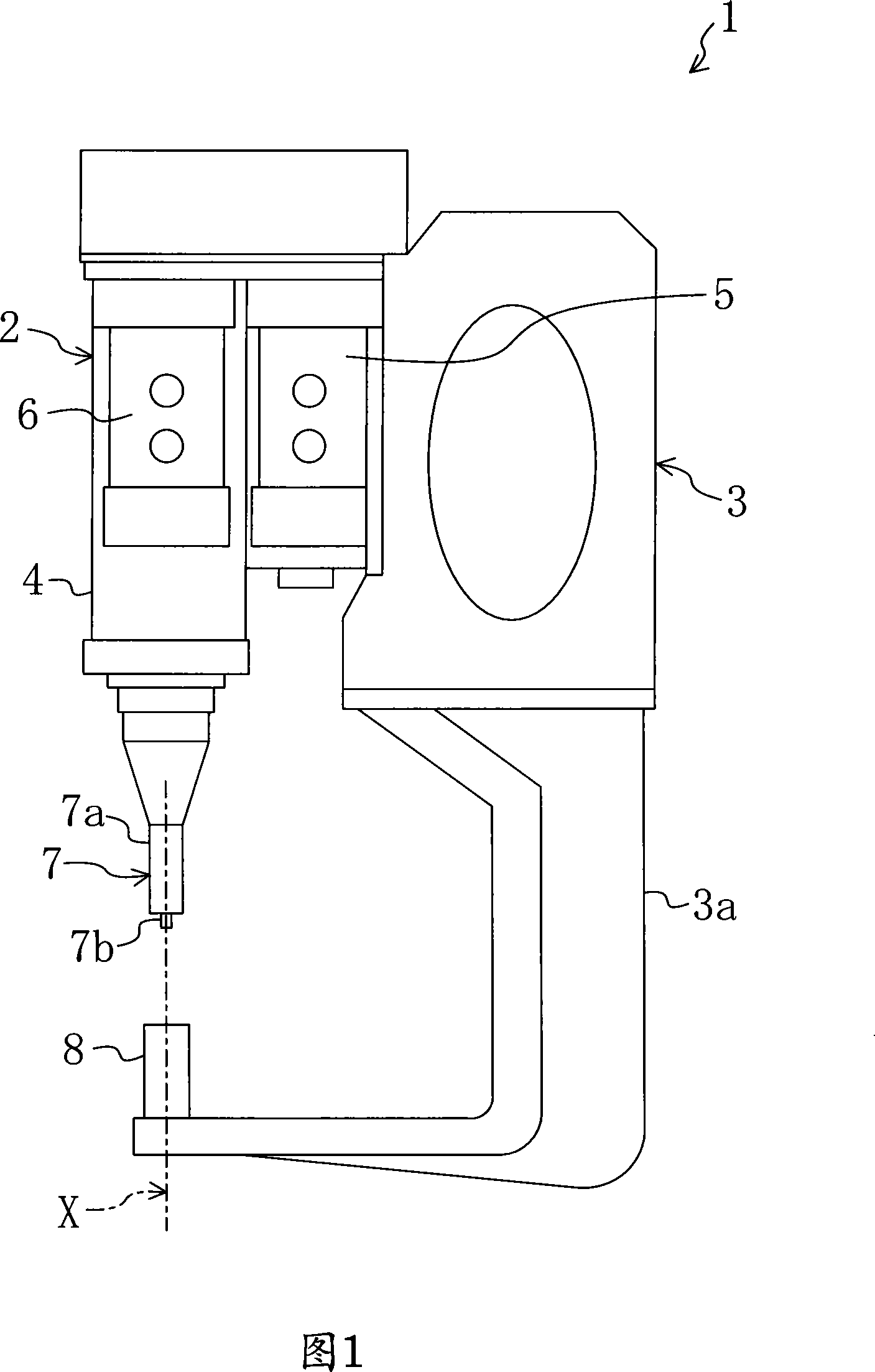

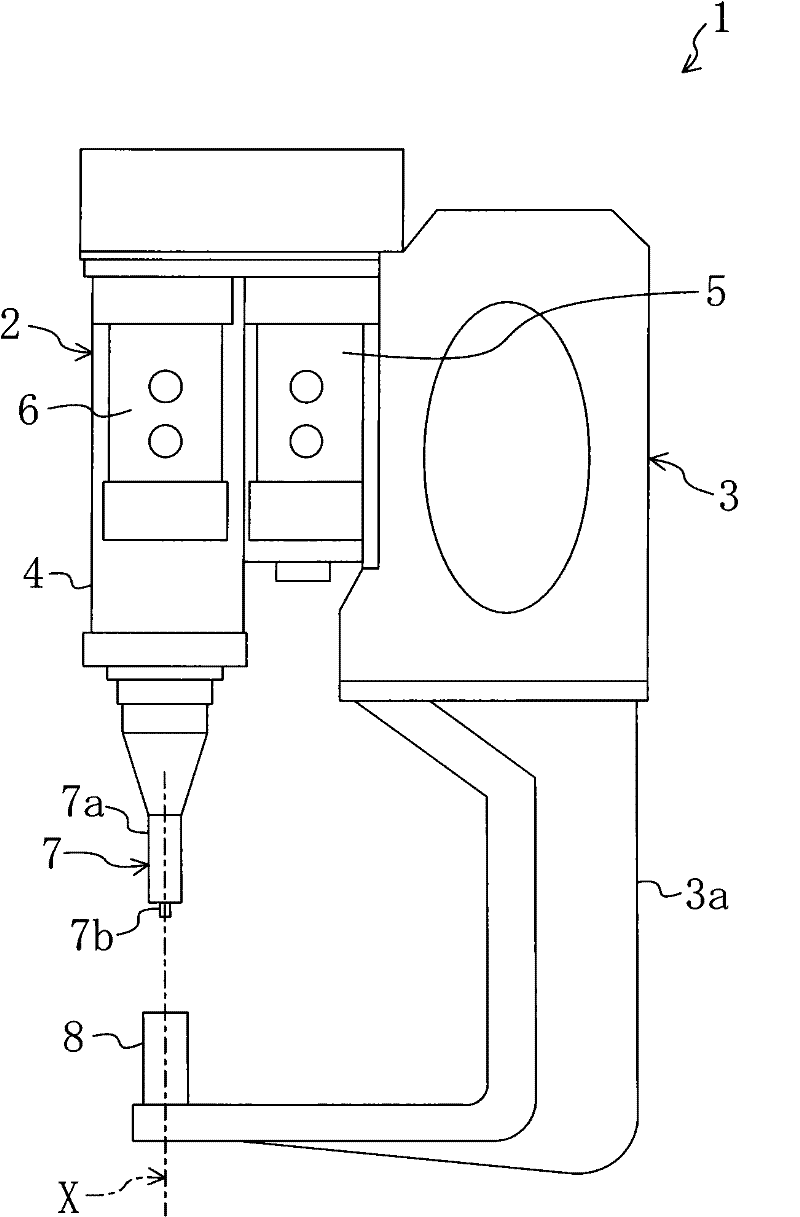

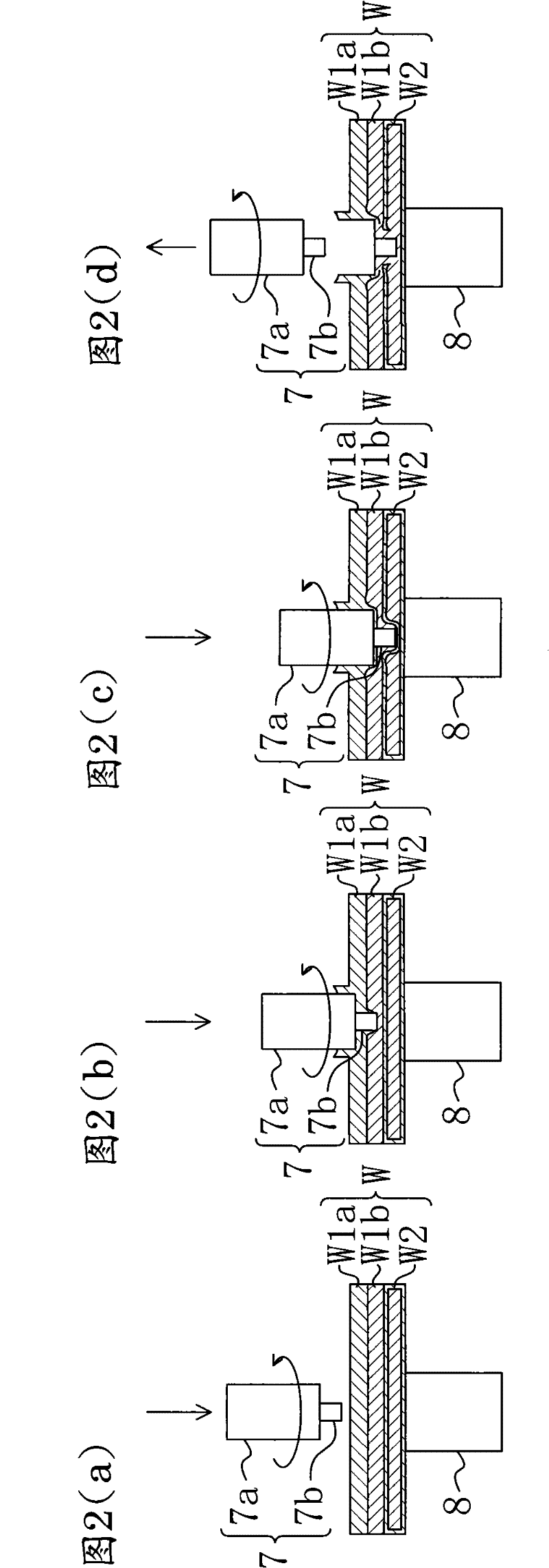

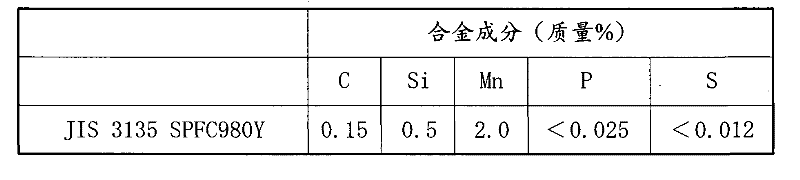

Friction spot joining method

InactiveCN101147999ADecreased corrosion resistanceNot easy to slideWelding/soldering/cutting articlesMetal working apparatusSheet steelMetal

A plurality of steel plates including at least one first non-coated steel plate (W1) and at least one metal-coated steel plate (W2) are prepared. The plurality of steel plates are overlaid in such a fashion that at least one of the two steel plates located on the respective sides in the overlaying direction is the first non-coated steel plate. A rotary tool (7) is rotated and allowed to press a to-be-joined part of the plurality of overlaid steel plates from the first non-coated steel plate side to friction-spot-join the to-be-joined part in a solid state by causing plastic flow at the to-be-joined part by generated frictional heat. Whereby, both elongation of time required for joining and lowering of the corrosion resistance of the metal-coated steel plate are suppressed. Whereby, both elongation of time required for joining and lowering of the corrosion resistance of the metal-coated steel plate are suppressed.

Owner:MAZDA MOTOR CORP

Air-permeability aluminum foil and preparation method thereof

ActiveCN101628644BImprove corrosion resistanceDecreased corrosion resistanceFlexible coversWrappersMaximum diameterAlloy

The invention relates to an air-permeability aluminum foil and a preparation method thereof, wherein the aluminum foil is mainly suitable for air-permeability packaging in requirements of agricultural production and daily life. The aluminum foil is characterized by being made of 3003 alloy, the thickness of the aluminum foil is 0.03-0.05 mm, pinholes which can reach more than 10,000 every square meter are densely distributed on the surface of the aluminum foil, and the maximum diameter of each pinhole is not more than 0.05 mm. The preparation method comprises the following process steps: batching, smelting, cast-rolling, cold-rolling, interannealing, cold-rolling, and foil-rolling to reach the finished thickness, slitting into a finished specification, and finished annealing. The invention has the advantages of good air permeability, strong corrosion resistance and strong oxidation resistance.

Owner:新疆生产建设兵团第八师天山铝业有限公司

Copper piece surface passivating treatment fluid

InactiveCN106555181AExcellent heat and humidity resistanceImprove passivation effectMetallic material coating processesEnvironmental resistancePolyvinyl alcohol

The invention relates to a copper piece surface passivating treatment fluid. The passivating treatment fluid is composed of 3-7 g / L of benzotriazole, 180-220 mg / L of sodium phosphate, 6-12 g / L of citric acid, 60-90 mg / L of colloidal silicon dioxide and 5-7 ml / L of a wetting agent; and the wetting agent is formed by mixing polyethylene glycol and polyving akohol, and the mass ratio of polyethylene glycol to the polyving akohol is (1.7-2.3):1. The copper piece surface passivating treatment fluid has the beneficial effects that through the synergistic effect of all components, the hydrothermal resisting property of the passivating treatment fluid is greatly improved; in addition, during passivating treatment, chromium ions are not contained, and the environmental protection performance is greatly strengthened; and meanwhile, expensive raw materials are not contained, and the cost of the passivating treatment fluid is greatly reduced.

Owner:NANTONG BOTAO CHEM

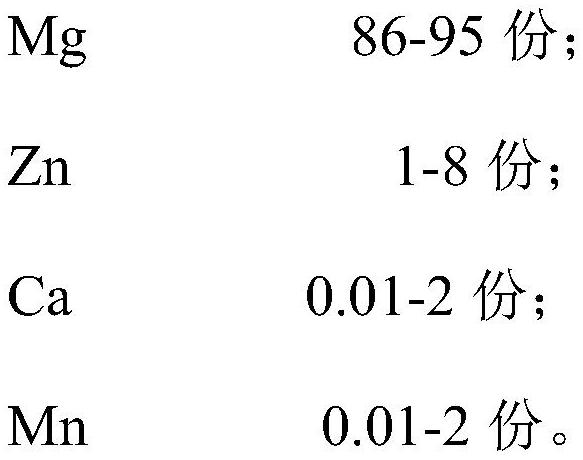

Biodegradable magnesium alloy free of rare earth elements as well as preparation method and application of biodegradable magnesium alloy

PendingCN114561579AControllable degradation rateHigh mechanical strengthSurgeryProsthesisRare-earth elementHuman body

The invention provides a biodegradable magnesium alloy without rare earth elements. The magnesium alloy comprises the following elements in percentage by mass: 1.0-5.0% of Zn; 0.1 to 1.0 percent of Mn; 0.1 to 1.0 percent of Ca; 0.1 to 1.0 percent of Sr; 0.1 to 3.0% of Sn; 0.1 to 0.8 percent of Zr; impurities in the magnesium alloy do not contain rare earth. The invention further provides a preparation method of the biodegradable magnesium alloy and application of the biodegradable magnesium alloy in preparation of medical instruments. According to the invention, Mg is taken as a main body and is mixed with Zn, Ca and Mn in a specific proportion to prepare the alloy, the degradation speed is controllable, the alloy has relatively high mechanical strength, elements harmful to a human body do not exist, and the alloy is degraded in the human body and does not influence the human body.

Owner:SHANGHAI KINDLY MEDICAL INSTR CO LTD +1

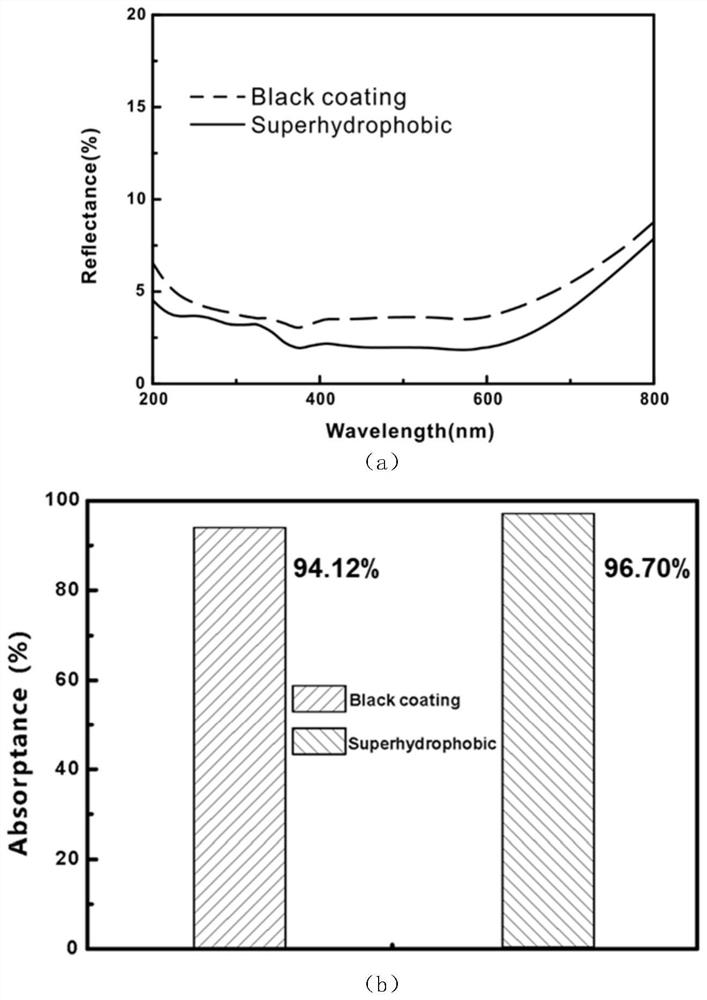

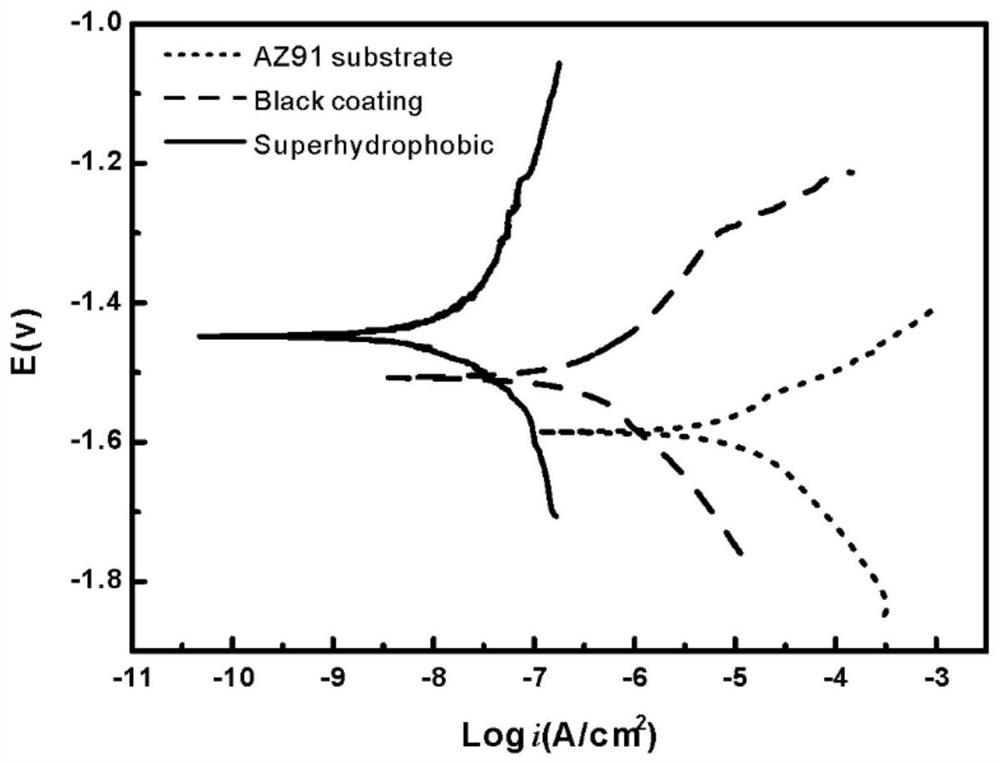

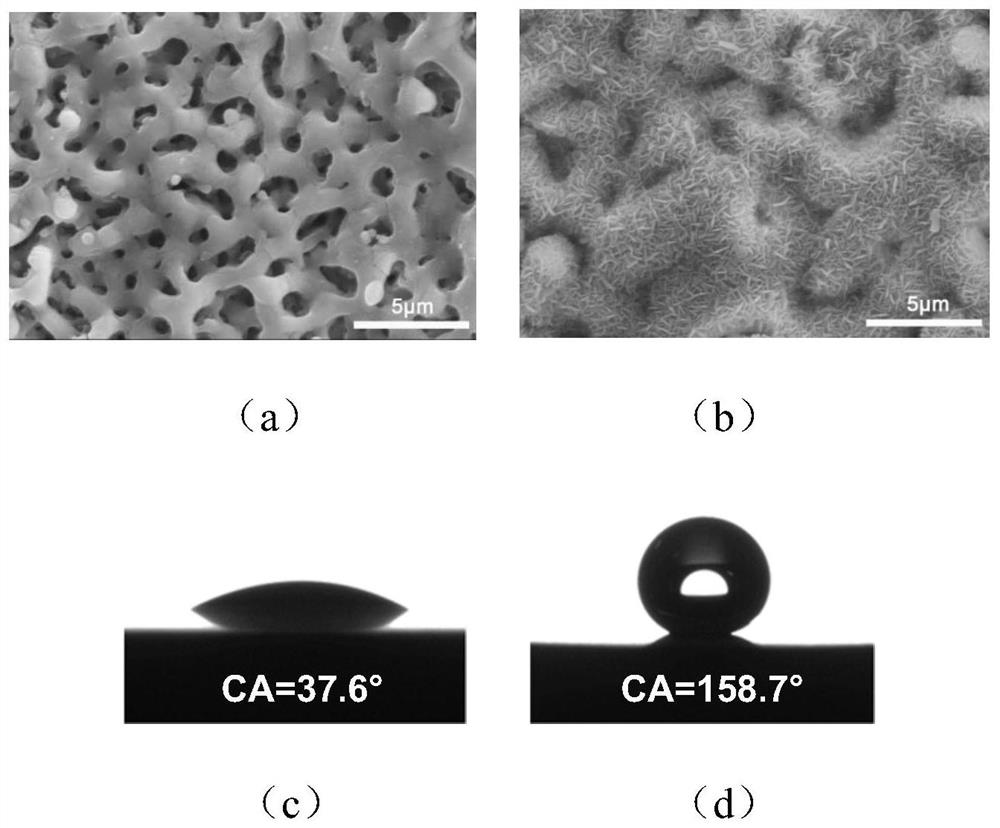

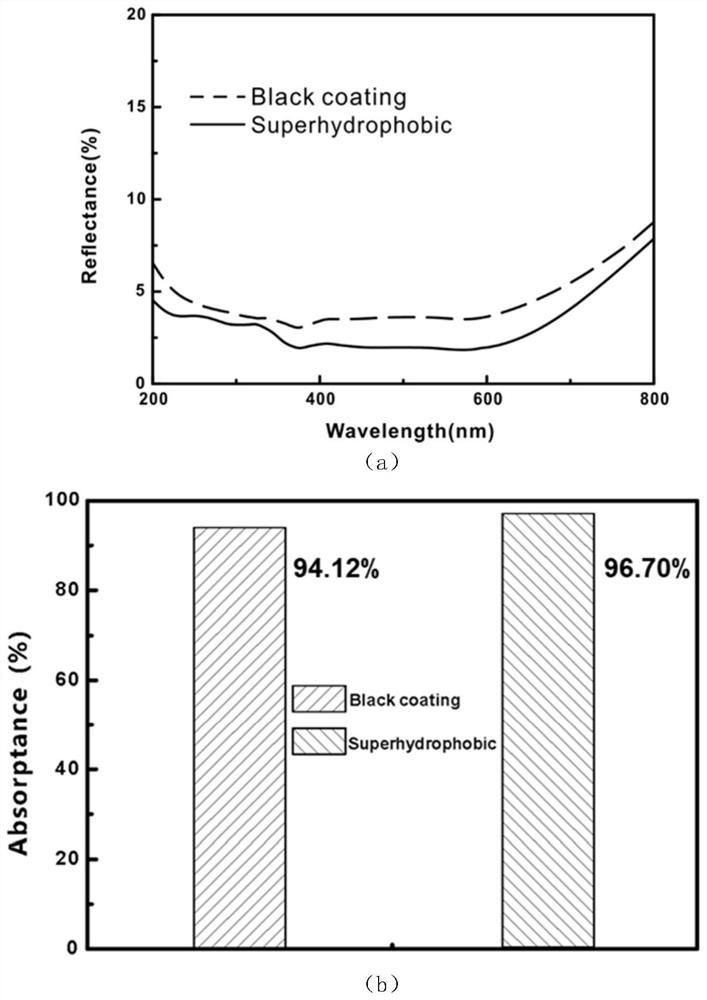

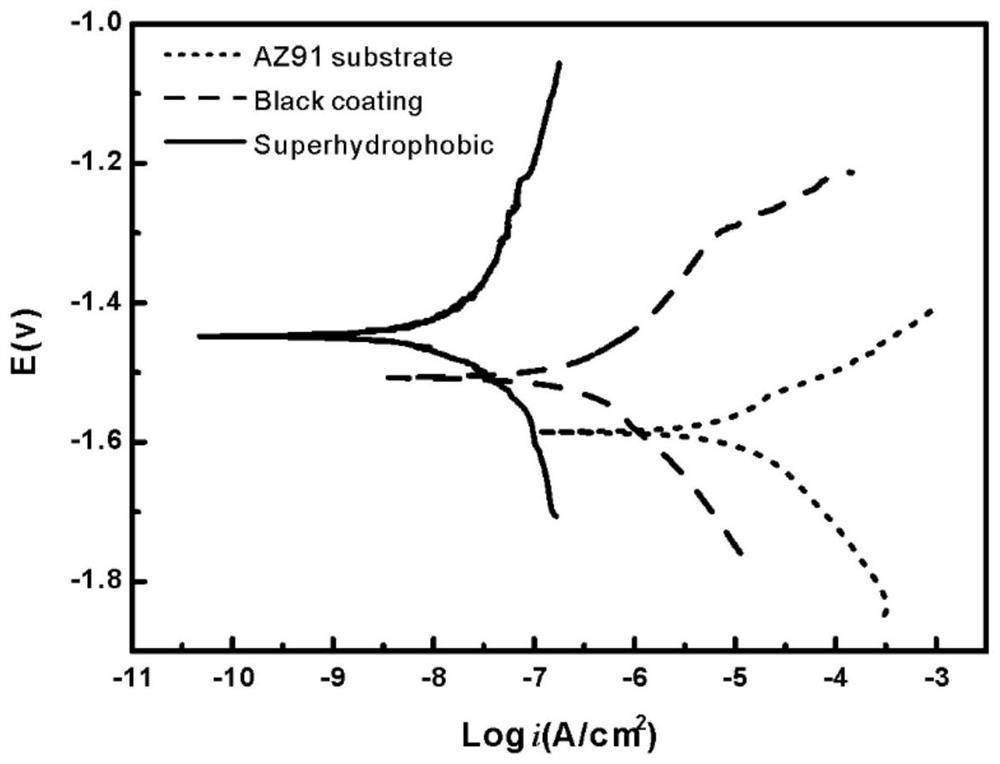

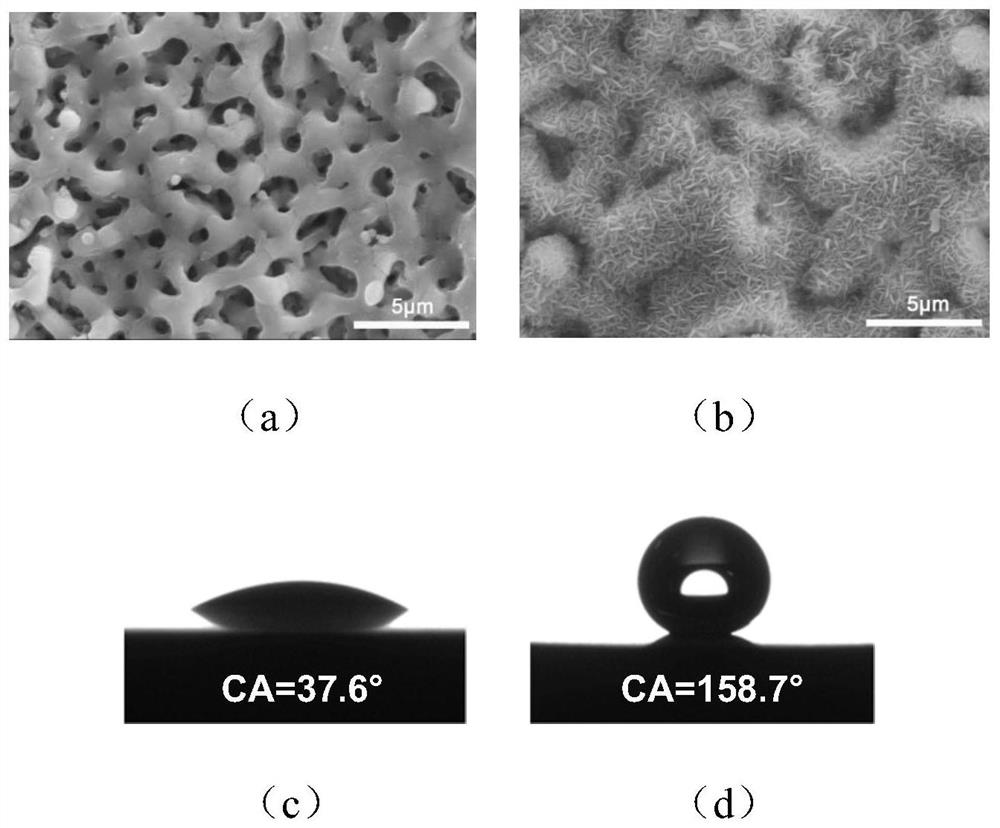

Preparation method of magnesium alloy micro-arc oxidation black super-hydrophobic film layer

ActiveCN112458512AImprove corrosion resistanceWith extinctionAnodisationElectrolytic agentMicro arc oxidation

The invention discloses a preparation method of a magnesium alloy micro-arc oxidation black super-hydrophobic film layer. The preparation method comprises the following steps that a coloring salt solution containing copper pyrophosphate and sodium potassium tartrate is mixed with a basic electrolyte taking silicate as a main salt, a magnesium alloy is taken as a matrix to be immersed into the electrolyte, and a black ceramic film is prepared on the surface of the magnesium alloy in a micro-arc oxidation mode; secondly, the black ceramic film is immersed into an aluminum nitrate nonahydrate solution, and LDH treatment is carried out; and finally, the obtained object is immersed into a lauric acid ethanol solution for modification and drying is carried out to obtain the magnesium alloy micro-arc oxidation black super-hydrophobic film layer. According to the preparation method, the micro-arc oxidation black ceramic film and super-hydrophobicity are combined to prepare the functionalized film layer, so that the corrosion resistance of the magnesium alloy is remarkably improved, meanwhile, the magnesium alloy has the properties of high light absorption rate, self-cleaning, pollution prevention and the like, and the application fields of the magnesium alloy and a micro-arc oxidation technology are broadened.

Owner:XI AN JIAOTONG UNIV

A chrome-free passivation solution

ActiveCN103205738BHigh temperature yellowing resistanceReduce corrosion resistanceMetallic material coating processesChromium freeOrganic acid

Owner:武汉钢实硅钢浩源润滑油有限公司

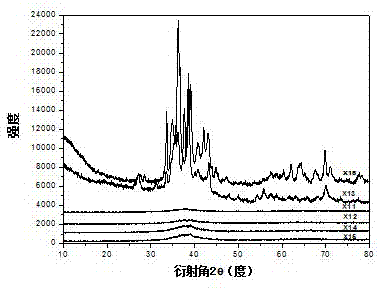

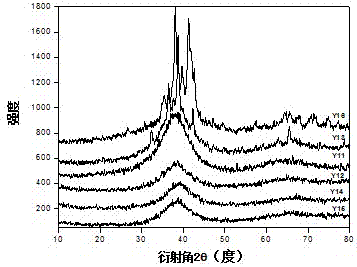

Method for determining crystallization of amorphous alloy

The invention provides a method for determining crystallization of an amorphous alloy. The method comprises the following steps: preparing at least four round amorphous alloy bars with different diameters by using a casting method and preparing at least two sample strips by using a die-casting method; then determining the Vickers hardness and bending strength of above amorphous alloys, analyzing the bending strength of the amorphous alloys and ranking the amorphous alloys according to a sequence of from higher bending strength to lower bending strength; if the bending strength of a certain amorphous alloy is less than 70% of the bending strength of adjacent amorphous alloys, setting the mean value of the Vickers hardness of the amorphous alloy and the Vickers hardness of the adjacent amorphous alloys as reference critical Vickers hardness for a crystalline alloy; and determining to-be-determined alloys with Vickers hardness greater than the reference critical Vickers hardness as amorphous alloys and determining to-be-determined alloys with Vickers hardness less than the reference critical Vickers hardness as crystalline alloys. The determination method provided by the invention is convenient to operate, fast in detection speed and low in cost; and the method is a nondestructive testing method and especially applicable to quality monitoring of workshop production.

Owner:BYD CO LTD

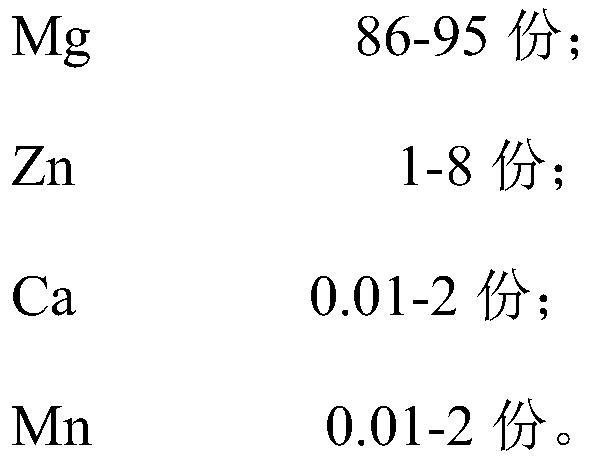

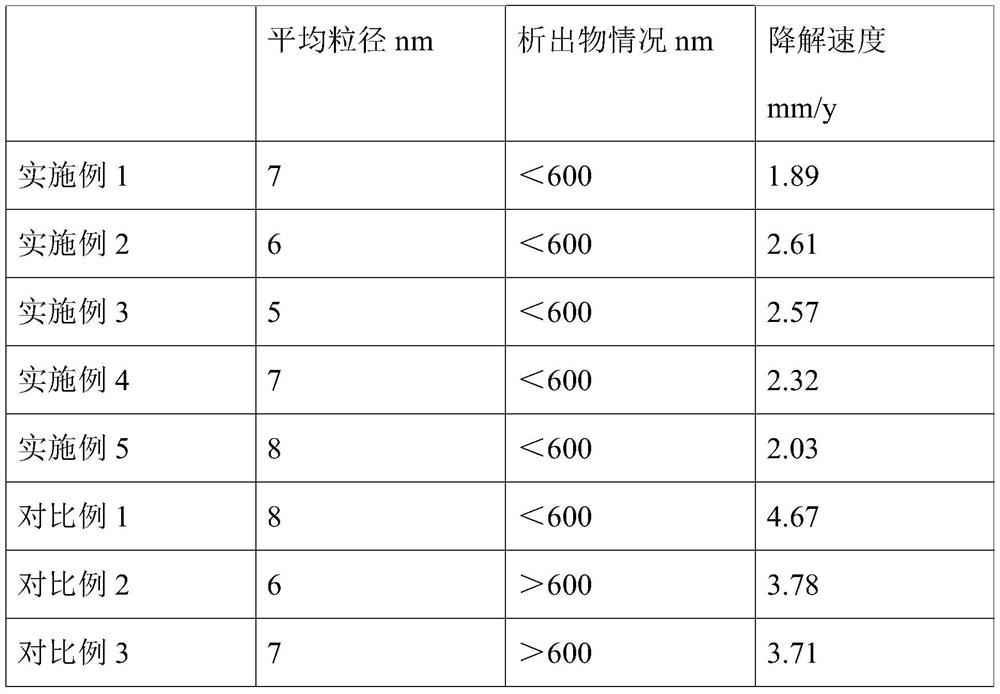

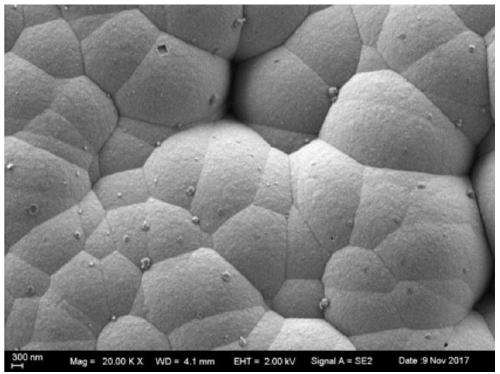

Biodegradable magnesium alloy without rare earth elements and preparation method of biodegradable magnesium alloy

InactiveCN112695237AControllable degradation rateHigh mechanical strengthRare-earth elementHuman body

The invention discloses a biodegradable magnesium alloy without rare earth elements. The magnesium alloy is prepared from 90-97 parts of Mg, 2-6 parts of Zn, 0.01-2 part of Ca and 0.01-2 part of Mn, and impurities of the magnesium alloy do not contain rare earth. The invention further discloses a preparation method of the biodegradable magnesium alloy and application of the biodegradable magnesium alloy to preparation of medical instruments. Mg serves as a main body and is mixed with Zn, Ca and Mn in a specific proportion to prepare the alloy, the degradation speed is controllable, the alloy has high mechanical strength, elements harmful to the human body do not exist, and the alloy does not influence the human body when degraded in the human body.

Owner:SHANGHAI KINDLY MEDICAL INSTR CO LTD +1

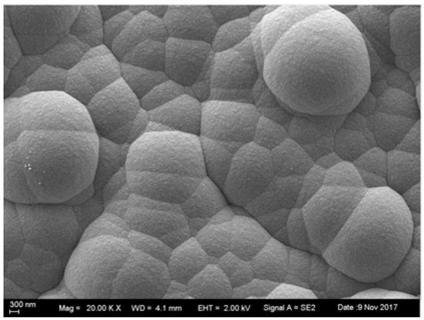

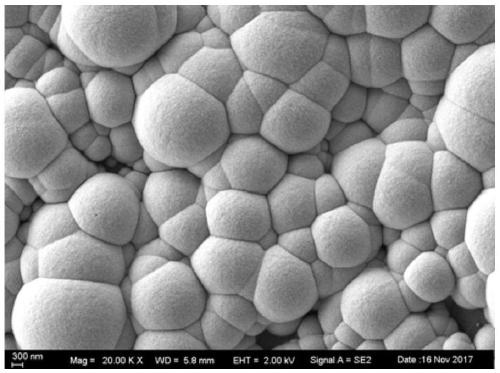

Microcrystalline nickel-phosphorus alloy chemical plating solution and preparation method thereof

InactiveCN108950527AGood weldabilityFew holes per unit areaLiquid/solution decomposition chemical coatingChemical platingSolvent

The invention relates to a microcrystalline nickel-phosphorus alloy chemical plating solution and a preparation method thereof. The microcrystalline nickel-phosphorus alloy chemical plating solution is characterized by talking deionized water as a solvent and comprising the following raw materials of, by weight, 60-120 parts of nickel sources, 90-150 parts of pH value balancing agents, 30-100 parts of reducing agents, 90-250 parts of complexing agents, 0.05-3.0 parts of surfactants, 0.01-5.0 parts of stabilizers. The preparation method of the microcrystalline nickel-phosphorus alloy chemical plating solution comprises the following steps that firstly, the components such as nickel chloride, ammonium chloride and citric acid are metered by mass and poured into a dissolving reaction kettle with stirring; the deionized water is added, and stirring and dissolving are carried out; then sodium hypophosphite is added, and stirring and dissolving are carried out; and finally additives such asthe stabilizers and the surfactants are added. The microcrystalline nickel-phosphorus alloy chemical plating solution and the preparation method thereof are mainly applied to metallization of monocrystalline silicon and polycrystalline silicon chips. Compared with the prior art, the microcrystalline nickel-phosphorus alloy chemical plating solution and the preparation method thereof have the advantages that the plating speed is high, the binding force between coatings and silicon bases of the chips is good, the coatings are fine, and the number of pores per unit area is small.

Owner:SHANGHAI RES INST OF CHEM IND

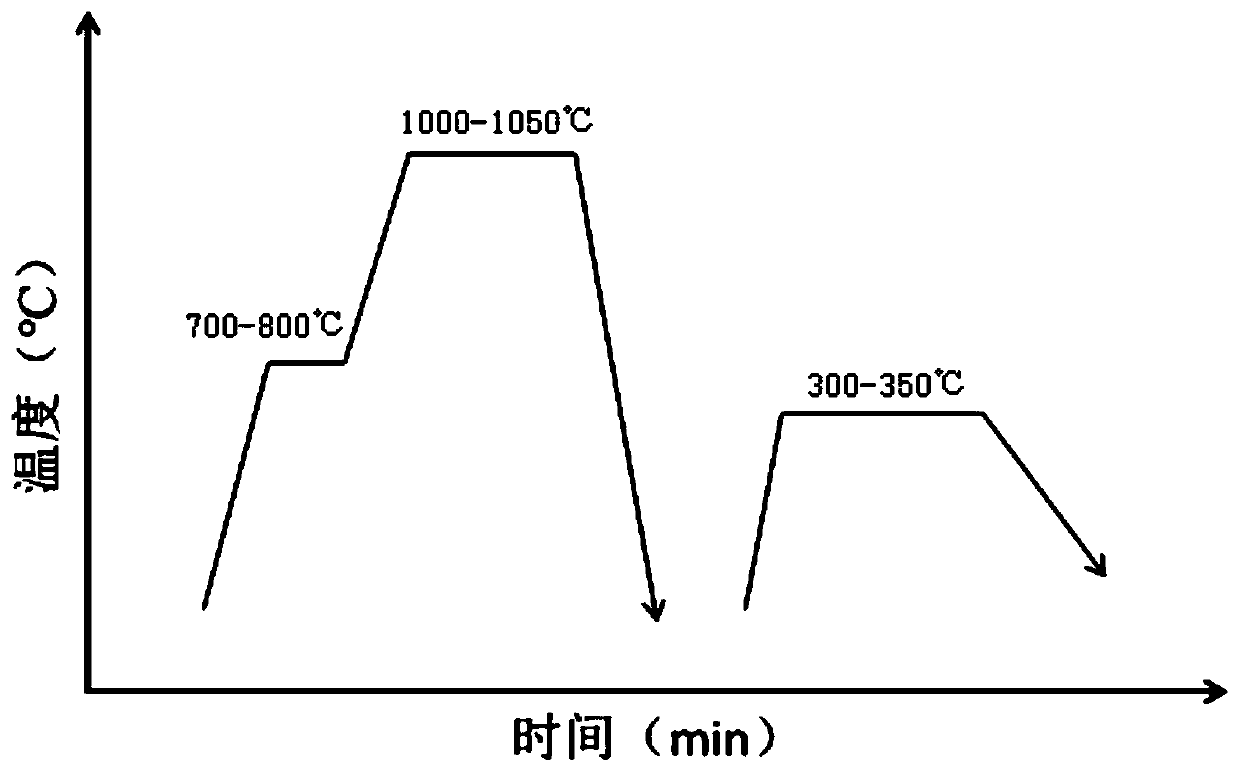

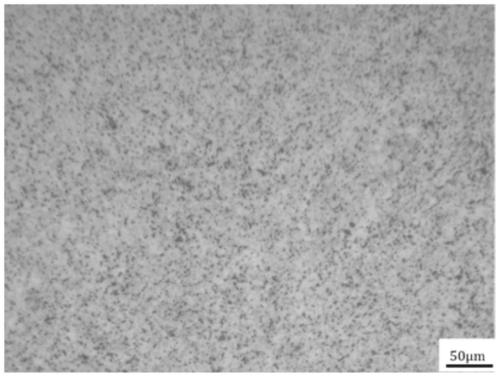

Heat treatment method for stainless steel products formed by SLM

InactiveCN110157862ADecreased corrosion resistanceImprove unevennessAdditive manufacturing apparatusIncreasing energy efficiencyHardnessInternal stress

The invention relates to a heat treatment method for stainless steel products formed by SLM. The method comprises the following steps of firstly, heating the 40Cr13 stainless steel products formed bythe SLM to about 800 DEG C and holding for a period of time; heating to about 1000 DEG C and holding for a period of time; then quenching with oil at about 50 DEG C; and finally, tempering and air cooling at about 300 DEG C. According to the method, the anisotropy of the stainless steel products formed by the SLM is basically eliminated, the hardness, strength and toughness of the stainless steelproducts are improved, and the internal stress of the products is reduced; and the heat treatment method is simple, efficient and convenient to operate, and has good application prospects.

Owner:WUHAN UNIV OF TECH

A kind of waterborne polyurethane anti-glare coating material and preparation method thereof

ActiveCN106380569BBrittleReduced polishing resistancePolyurea/polyurethane coatingsWater basedOrganometallic catalysis

The invention discloses a water-based polyurethane anti-glare coating material and a preparation method thereof. The preparation method mainly comprises the following steps: first stage: by using polyoxytetramethylene glycol and dihydroxymethyl eicosanoic acid as raw materials, adding an organic metallic catalyst and diisocyanate to react, and adding a tertiary amine neutralizer to generate an isocyanate-terminated water-based polyurethane prepolymer; and second stage: two-step chain extension and emulsification: simultaneously carrying out emulsification and chain extension reaction on the prepolymer in a sulfonate-chain-extender-containing water solution under high-speed shearing actions until the prepolymer can be uniformly emulsified in water, and dropwisely adding a hydrazine chain extender to obtain the water-based polyurethane anti-glare emulsion. The coated film of the polyurethane anti-glare emulsion has the characteristics of low glossiness and high light transmittance, and is applicable to the fields of architectural lighting, road traffic, display screens, textile leather and the like.

Owner:QINGYUAN YAKOO CHEM CO LTD

A kind of ultra-low carbon magnesia-carbon brick for stainless steel ladle bottom and preparation method thereof

Owner:北京利尔高温材料股份有限公司 +2

Sliding sprue tile for smelting high-oxygen steel and calcium treated steel

InactiveCN1209317CGood chemical stabilityImprove mechanical propertiesMelt-holding vesselsBrickOxidation resistant

The invention relates to a sliding nozzle brick for high-oxygen steel and calcium-treated steel. The refractory material consists of 90-100% of one or both of the refractory materials of magnesia and aluminum-magnesium spinel in terms of weight percentage , and the balance is a refractory material of zirconia or titania. The sliding nozzle brick provided by the invention is a refractory material containing more than 90% of magnesia and aluminum-magnesium spinel, which has good mechanical properties at high temperature, high chemical stability, corrosion resistance, and strong resistance to molten metal and oxidation , for high-oxygen steel and calcium-treated steel, the sliding nozzle brick has a long life, and has the advantages of light weight and low price.

Owner:BAOSHAN IRON & STEEL CO LTD

A kind of anticorrosion and antirust paint and preparation method thereof

ActiveCN109021782BEasy curingImprove adhesionAnti-corrosive paintsEpoxy resin coatingsTriethoxysilaneTitanium powder

Owner:福建省艺邦新材料科技有限公司

A kind of nanocomposite marine anticorrosion coating and preparation method thereof

ActiveCN109943169BReduce biocorrosion hazardsLarge specific surface areaAntifouling/underwater paintsPaints with biocidesCelluloseAcrylic resin

The invention discloses a nanometer composite ocean anticorrosion coating and a preparation method thereof, belonging to the field ofcorrosion prevention of coatings. The coating contains the following components in percentage by weight: a component A: 20%-40% of acrylic resin, 5%-10% of a hydroxyl epoxy phosphate dispersing agent, 4%-7% of a Fe3O4@TiO2-h-BN hybridized composite material, 0.5%-2%of nano-crystalline cellulose, 5%-15% of epoxy resin, 1.2%-3.5% of other aids, 20%-25% of deionized water, 5%-10% of zinc powder and 3%-7% of calcium carbonate; and a component B: a curing agent, namely 15%-25% of a water-based isocyanate curing agent. The coating prepared by virtue of the preparation method has good wear resistance, fouling resistance and corrosion resistance, is mainly applied to the fouling prevention and corrosion prevention of petroleum steel-frame structure platforms in an ocean atmospheric region environment and is also suitable for the fields of fouling prevention andcorrosion prevention of ships and underwater pipelines.

Owner:CHANGZHOU UNIV

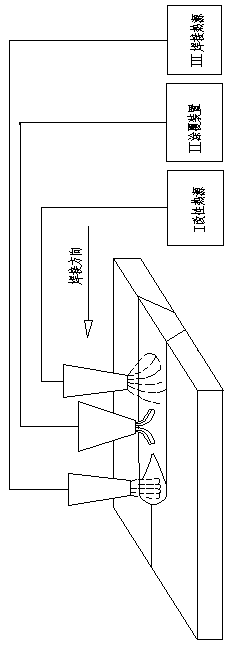

Welding and welding joint surface layer performance improvement double-heat-source combined effect method

InactiveCN110877165ADecreased corrosion resistanceDecreased wear resistanceWelding/cutting auxillary devicesPretreated surfacesCorrosion resistantUndermatching

The invention relates to a welding and welding joint surface layer performance improvement double-heat-source combined effect method. When materials such as stainless steel and abrasion-resistant steel are welded, due to the heat effect in the welding process, welding joint components, structures and the like are changed, original corrosion resistance, abrasion resistance and the like are loweredor even disappear, consequently, performance of a welding joint part is not matched with that of a base material, and the application range is limited. According to the welding and welding joint surface layer performance improvement double-heat-source combined effect method, a welding heat source, a welding joint surface layer performance improvement heat source and a welding joint performance improvement material coating device are mainly included. In the welding direction, the welding heat source conducts connector welding to form a welding joint; the performance improvement material coatingdevice is arranged behind for material coating; and the welding joint surface layer performance improvement heat source is arranged behind to provide heat to heat the coated material which acts withthe welding joint surface layer to form the welding joint surface layer meeting the requirements.

Owner:TAIYUAN UNIV OF TECH

A method for judging whether an amorphous alloy is crystallized

Owner:BYD CO LTD

Chromium-free passivating liquid for surface treatment of electrogalvanized steel plate and use method thereof

InactiveCN101289741BImprove stabilityLong storage timeMetallic material coating processesChromium freeElectrogalvanization

The invention discloses a chromium-free passivating solution for the surface treatment of electro-galvanized steel plates, as well as a method for using the same. The mass percentages of the composition of the chromium-free passivating solution are: 0.2-20 percent of gamma-glycidyl ether oxygen propyl trimethoxy silane, 0.01-1.0 percent of polyvinyl alcohol, 0.1-3.0 percent of ammonium zirconium carbonate, water as a solvent, and the balance. The application method comprises the following steps that: the surface of a clean electro-galvanized steel plate is coated with the passivating solution,and then the passivating solution is baked to become a film; the thickness of a film layer is between 0.2 and 2.0 g / m<2>. The process treatment of the invention remarkably improves the corrosion resistance of the electro-galvanized steel plate, which is equivalent to chromate color passivation. In addition, through the treatment of the process, the coating performance of the electro-galvanized steel plate is remarkably improved as well.

Owner:BAOSHAN IRON & STEEL CO LTD +1

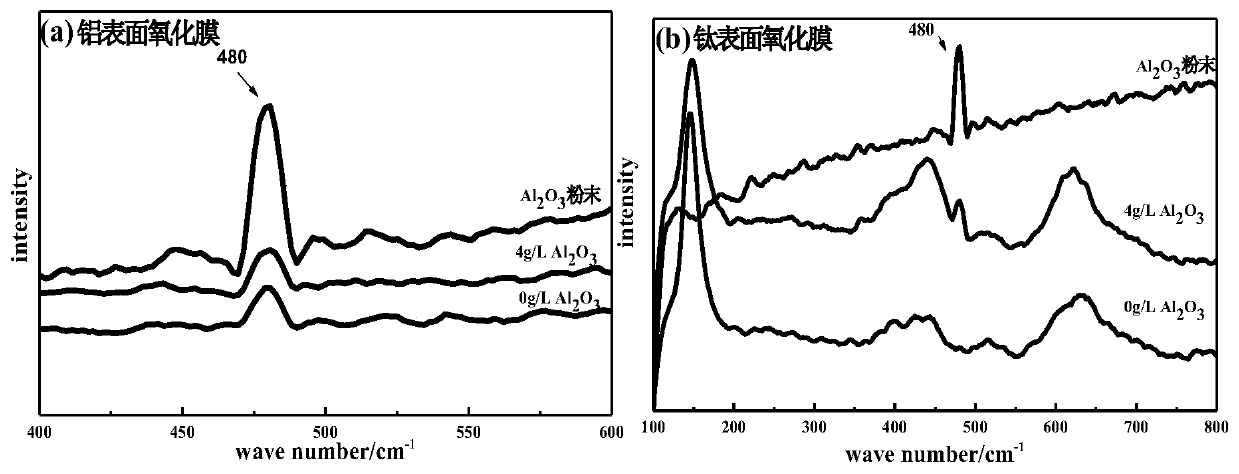

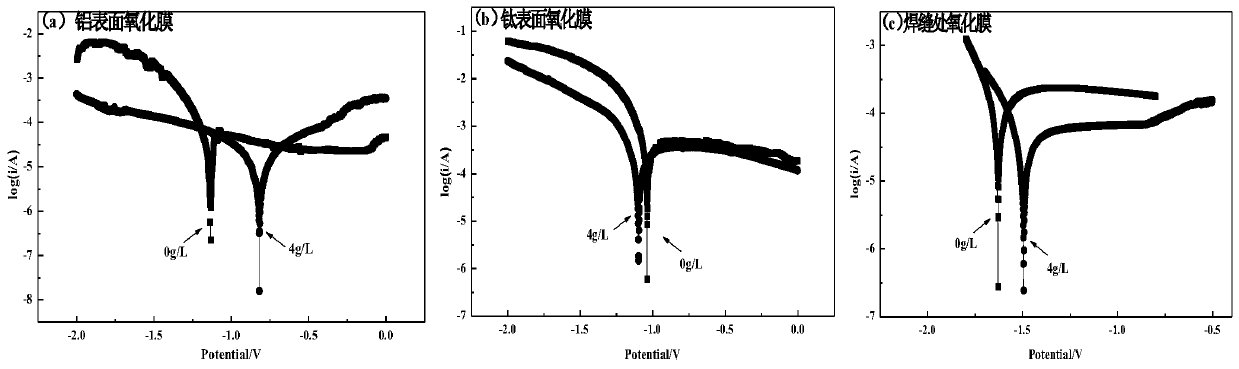

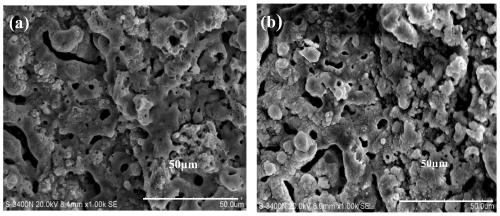

Method for preparing micro-arc oxidation film of aluminum titanium composite plate

ActiveCN110257878AIncreased electrical energyLow dielectric constantAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention discloses a method for preparing a micro-arc oxidation film of an aluminum titanium composite plate. According to the method, titanium serving as a base plate and aluminum serving as a composite plate are subjected to explosive welding to form the aluminum titanium composite plate, an aluminum titanium composite plate sample is polished step by step through abrasive paper until the surface is smooth, and the aluminum titanium composite plate sample is subjected to ultrasonic washing in ethyl alcohol or acetone and dried in air at the room temperature; the aluminum titanium composite plate sample is immersed in electrolyte to serve as an anode, a stainless steel electrolyte tank serves as a cathode, an alternating current constant voltage mode is adopted for carrying out micro-arc oxidation treatment, after treatment is finished, a micro-arc oxidation sample is flushed with cold water, residue on the surface is removed, the micro-arc oxidation sample is dried at the room temperature, and the micro-arc oxidation film on the surface of the aluminum titanium composite plate is obtained; and the electrolyte comprises inorganic salt and aluminum oxide particles. According to the method, by adding Al2O3 particles and optimizing electrolyte, the prepared micro-arc oxidation film of the aluminum titanium composite plate can improve the problems of poor thickness of a transition area of the micro-arc oxidation film on the surface and the weld joint of the aluminum titanium composite plate, corrosion resistance and heat impact resistance.

Owner:GUANGXI UNIV +1

A kind of preparation method of magnesium alloy micro-arc oxidation black super-hydrophobic film layer

ActiveCN112458512BImprove corrosion resistanceReduce direct contactAnodisationElectrolytic agentMicro arc oxidation

The invention discloses a method for preparing a black super-hydrophobic film layer by micro-arc oxidation of magnesium alloy. First, a coloring salt solution containing copper pyrophosphate and potassium sodium tartrate is mixed with a basic electrolyte containing silicate as the main salt, and a magnesium alloy In order to immerse the substrate in the electrolyte, a black ceramic film was prepared on the surface of the magnesium alloy by micro-arc oxidation; secondly, the black ceramic film was immersed in aluminum nitrate nonahydrate solution for LDH treatment; finally, it was immersed in lauric acid ethanol solution for modification and drying. That is, a black super-hydrophobic film layer of magnesium alloy micro-arc oxidation is obtained. The invention combines the micro-arc oxidation black ceramic film with the super-hydrophobicity to prepare the functionalized film layer, which not only significantly improves the corrosion resistance of the magnesium alloy, but also has the properties of high light absorption rate, self-cleaning, anti-fouling and the like, and broadens the scope of the magnesium alloy. And the application field of micro-arc oxidation technology.

Owner:XI AN JIAOTONG UNIV

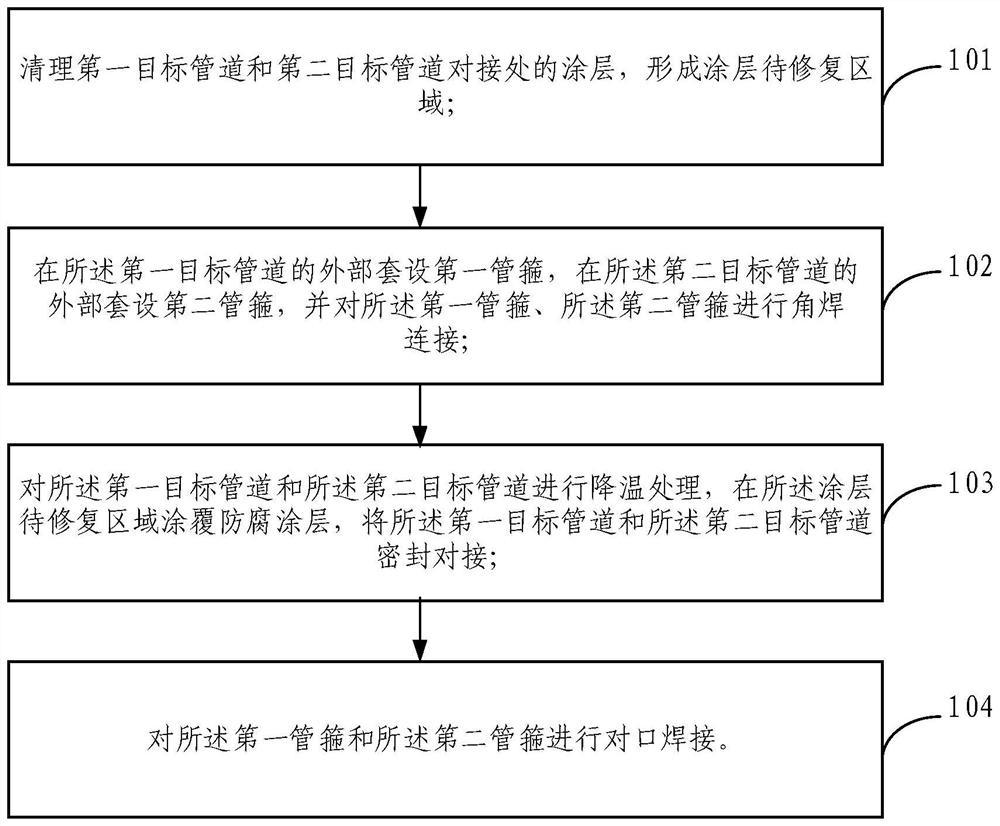

Lossless welding process for repairing ground internal coating anticorrosion pipeline

PendingCN113828894AAvoid influenceDecreased corrosion resistanceMetal working apparatusTubular articlesButt weldingLine tubing

The invention relates to the technical field of coating pipeline repair, and provides a lossless welding process for repairing a ground internal coating anticorrosion pipeline, the lossless welding process comprises the following steps that a coating at the joint of a first target pipeline and a second target pipeline is cleaned to form a coating to-be-repaired area; the first target pipeline is sleeved with a first pipe hoop, the second target pipeline is sleeved with a second pipe hoop, and angle welding connection is conducted on the first pipe hoop and the second pipe hoop; the first target pipeline and the second target pipeline are cooled, the coating to-be-repaired area is coated with an anticorrosion coating, and the first target pipeline and the second target pipeline are in sealed butt joint; and butt welding is conducted on the first pipe hoop and the second pipe hoop. According to the lossless welding process for repairing the ground internal coating anticorrosion pipeline, the coating in the pipeline is cleaned up before the pipe hoops are welded, and the inner wall of the pipeline is coated with the anticorrosion coating again after the pipe hoops are welded, so that the situation that the anticorrosion performance of the pipeline is reduced due to high temperature in the welding process is avoided.

Owner:BEIJING SINOPERM TECH

Friction spot joining method

InactiveCN101147999BDecreased corrosion resistanceNot easy to slideWelding/soldering/cutting articlesMetal working apparatusSheet steelMetal

A plurality of steel plates including at least one first non-coated steel plate (W1) and at least one metal-coated steel plate (W2) are prepared. The plurality of steel plates are overlaid in such a fashion that at least one of the two steel plates located on the respective sides in the overlaying direction is the first non-coated steel plate. A rotary tool (7) is rotated and allowed to press a to-be-joined part of the plurality of overlaid steel plates from the first non-coated steel plate side to friction-spot-join the to-be-joined part in a solid state by causing plastic flow at the to-be-joined part by generated frictional heat. Whereby, both elongation of time required for joining and lowering of the corrosion resistance of the metal-coated steel plate are suppressed. Whereby, both elongation of time required for joining and lowering of the corrosion resistance of the metal-coated steel plate are suppressed.

Owner:MAZDA MOTOR CORP

Aluminum alloy material for forming aluminum pipe

InactiveCN102978482AImprove mechanical propertiesRaise the recrystallization temperatureManganeseTitanium

The invention discloses an aluminum alloy material for forming an aluminum pipe, which is characterized by consisting of the following components in percentage by mass: 1.0-1.3% of manganese, 0.35-0.37% of iron, 0.06-0.08% of silicon, 0.07-0.08% of titanium, not greater than 0.005% of trace impurity elements and the balance of aluminum. The aluminum alloy material for forming the aluminum pipe has the advantages of good ductility and excellent corrosion resistance.

Owner:WENZHOU TIANDI ALUMINUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com