Biodegradable magnesium alloy free of rare earth elements as well as preparation method and application of biodegradable magnesium alloy

A rare earth element and magnesium alloy technology, applied in the field of medical materials, can solve the problems of corrosion resistance decline, strength decline, rapid deterioration, etc., and achieve the effect of reducing the area and controlling the degradation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

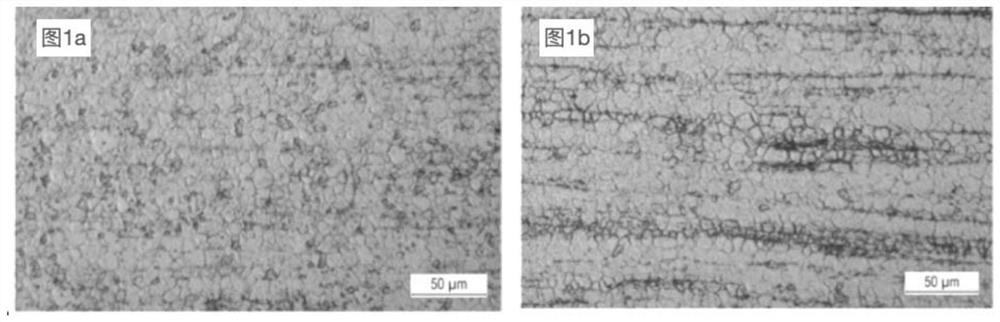

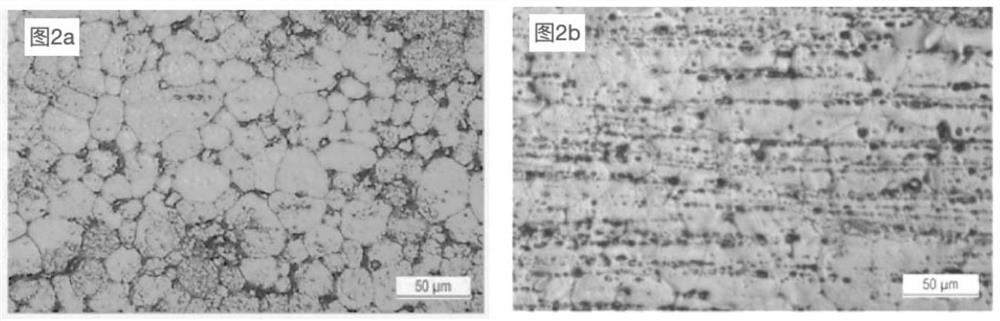

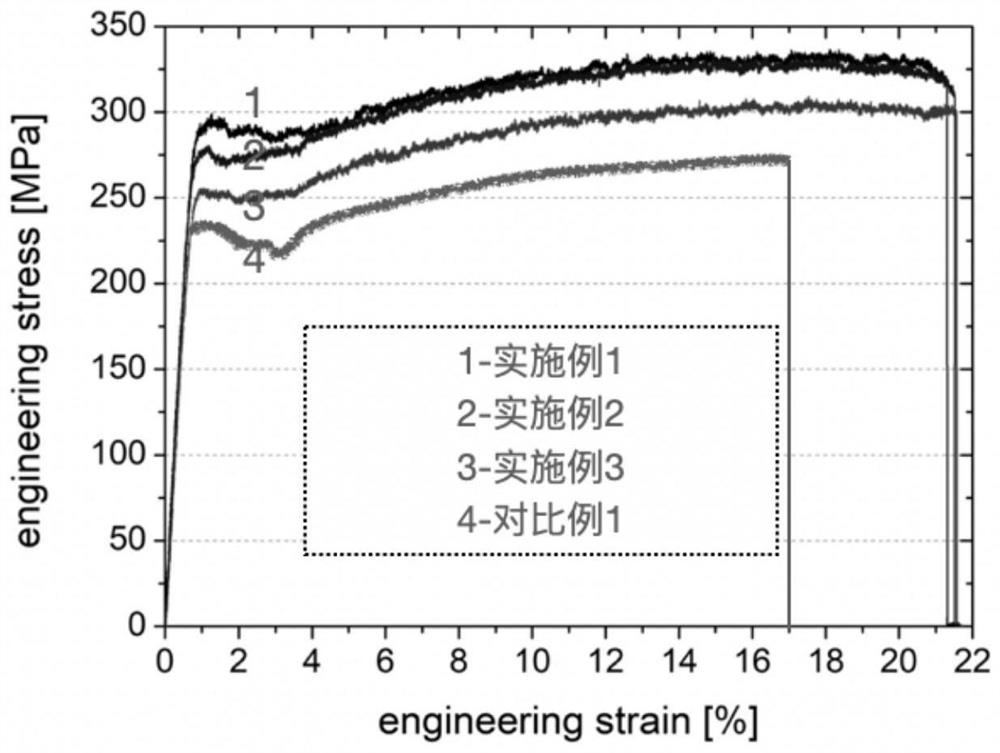

Embodiment 1

[0044] This embodiment provides a biodegradable magnesium alloy that does not contain rare earth elements. The metal powder is fully mixed, and then melted at 700 ℃ and then cast into shape; heat treatment: heat the alloy obtained by casting, control the temperature to 200 ℃, anneal for 1 min, and cool; hot extrusion: put the alloy after heat treatment into the hot extrusion In the pressed die, the temperature is controlled at 300°C, the extrusion rate is controlled at 5mm / s, and the extrusion ratio is set at 10:1; rolling forming: rolling at 350°C, the speed is controlled at 30m / min, and each pass is rolled. The down-pressure amount of the system is controlled at 60%, and the number of passes is no more than 10 times, so as to obtain a formed biodegradable magnesium alloy.

Embodiment 2

[0046] This embodiment provides a biodegradable magnesium alloy that does not contain rare earth elements, and the preparation method is as follows: The metal powder is fully mixed, and then melted at 750 ℃ and cast into shape; heat treatment: heat the alloy obtained by casting, control the temperature to 250 ℃, anneal for 2 minutes, and cool; hot extrusion: put the alloy after heat treatment into the hot extrusion In the pressed die, the temperature is controlled at 300°C, the extrusion rate is controlled at 5mm / s, and the extrusion ratio is set to 15:1; rolling forming: rolling at 350°C, the speed is controlled at 20m / min, and each pass is rolled. The down pressure of the pass is controlled at 50%, and the pass is not more than 10 times to obtain a formed biodegradable magnesium alloy.

Embodiment 3

[0048] This embodiment provides a biodegradable magnesium alloy without rare earth elements. The preparation method is as follows: 90 parts of Mg, 5 parts of Zn, 1 part of Ca, 1 part of Mn, 0.8 parts of Zr, 1.2 parts of Sn, 1 part of Sr The metal powder is fully mixed, and then melted at 700 ℃ and then cast into shape; heat treatment: heat the alloy obtained by casting, control the temperature to 200 ℃, anneal for 1 min, and cool; hot extrusion: put the alloy after heat treatment into the hot extrusion In the pressed die, the temperature is controlled at 250°C, the extrusion rate is controlled at 5mm / s, and the extrusion ratio is set at 15:1; rolling forming: rolling at 320°C, the speed is controlled at 30m / min, and each pass is rolled. The down pressure of the pass is controlled at 80%, and the pass does not exceed 10 times to obtain a formed biodegradable magnesium alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com