Friction spot joining method

A joint method and friction point technology, which is applied to welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve the problems of corrosion resistance decline, and achieve the suppression of corrosion resistance decline, not easy to slide, and restrain the joining time lengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment -

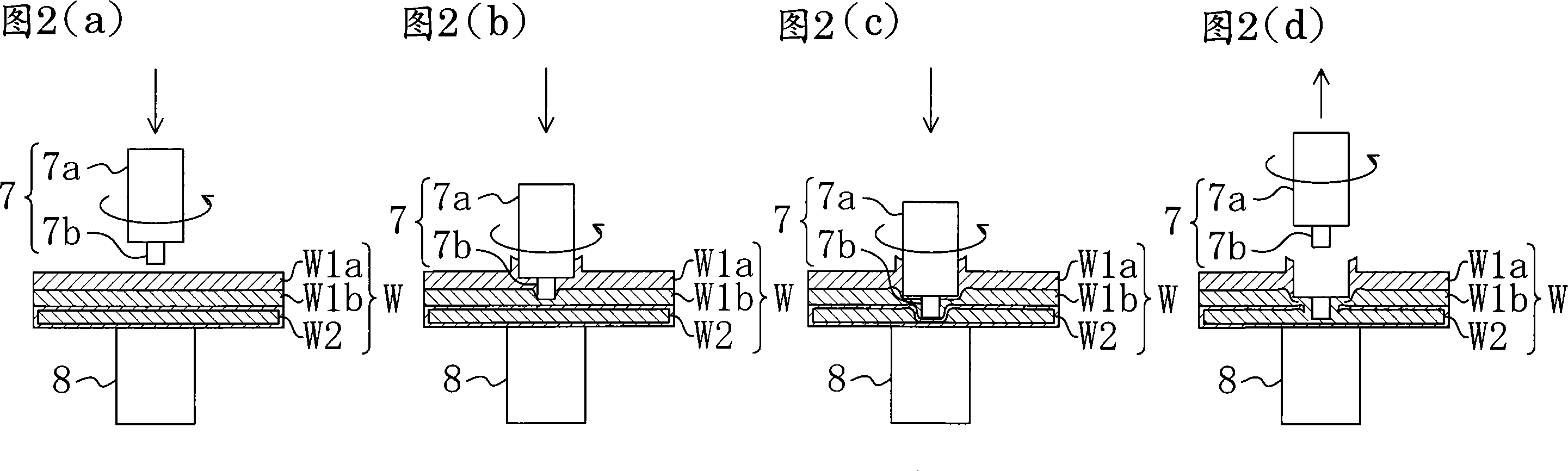

[0053] Next, examples of the present invention will be described.

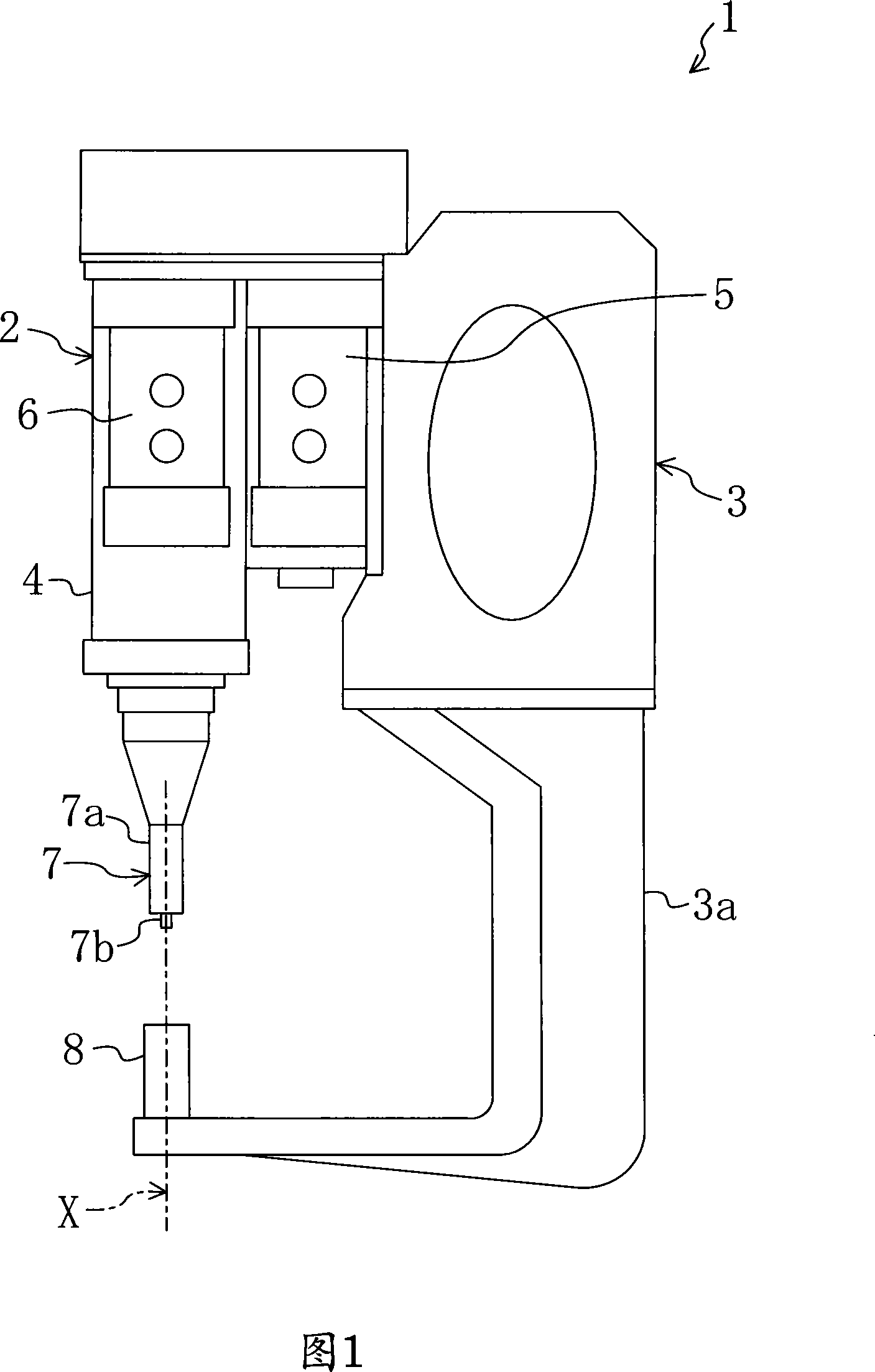

[0054] (joint unit)

[0055] The engaging unit is a fixed-position pressurizing unit in which the pressing shaft motor is a servo motor.

[0056] The rotary tool was made of ceramics; the diameter of the shoulder portion of the rotary tool was 10 mm; the diameter of the pin portion of the rotary tool was 3 mm, and the length of the pin portion was 1.27 mm.

[0057] (steel plate)

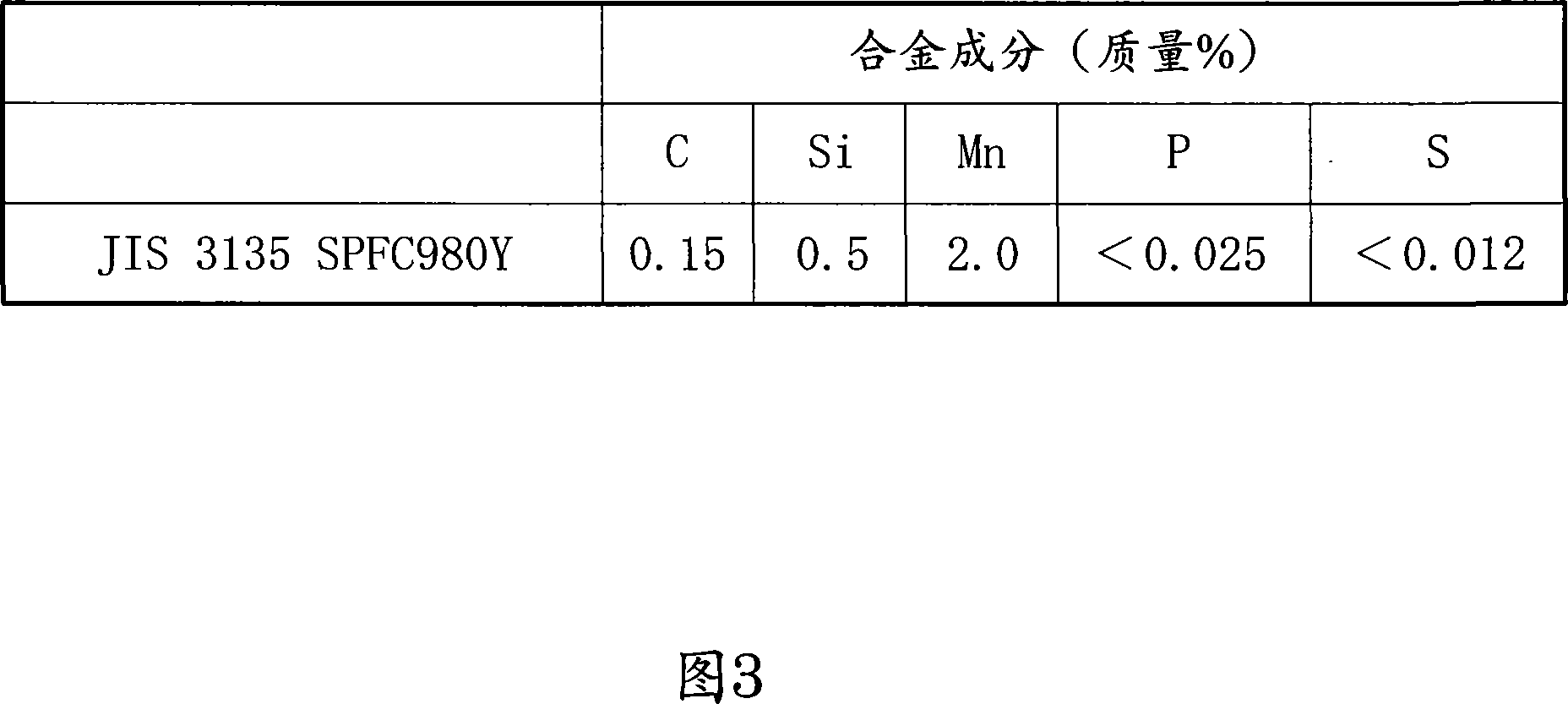

[0058] The first steel sheet was a 980 MPa-class high-tensile steel sheet (JIS (Japanese Industrial Standard) 3135 SPFC980Y) having a thickness of 1.0 mm. The composition of the first steel sheet was set as shown in FIG. 3 .

[0059] The second steel plate was set as a 270 MPa grade mild steel plate. Carry out alloying treatment after galvanizing on the second steel plate, make this second steel plate that has galvanized become coating unit area mass 55g / m 2 , Alloyed molten zinc-coated steel plate with a thickness of 0.7mm. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com