Non-chrome purified liquid

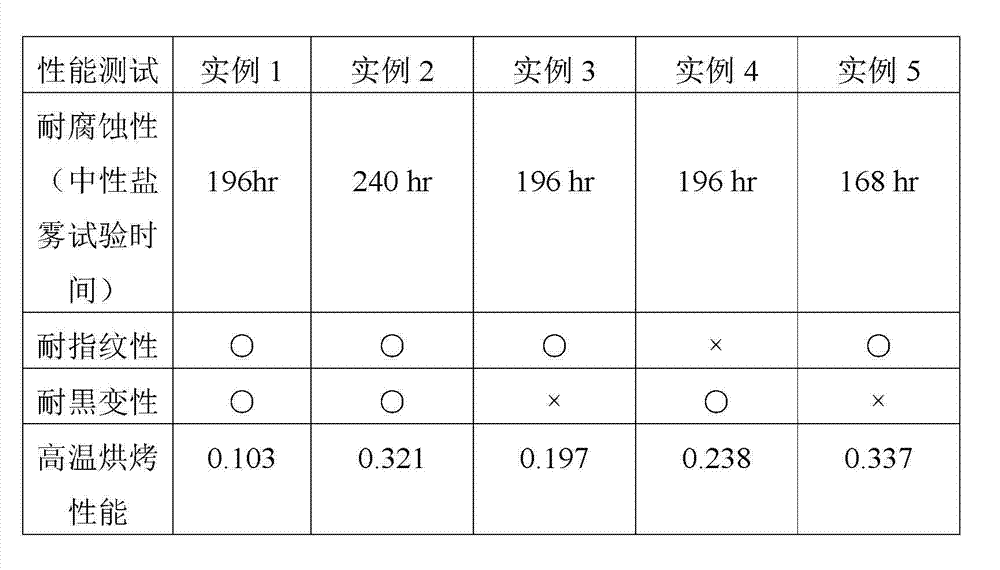

A chromium-free purification solution and chromium-free passivation technology, which is applied in the coating process of metal materials, etc., can solve the problems of general corrosion resistance, system stability decline, and limited application, and achieve good high-temperature yellowing resistance, resistance Good corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

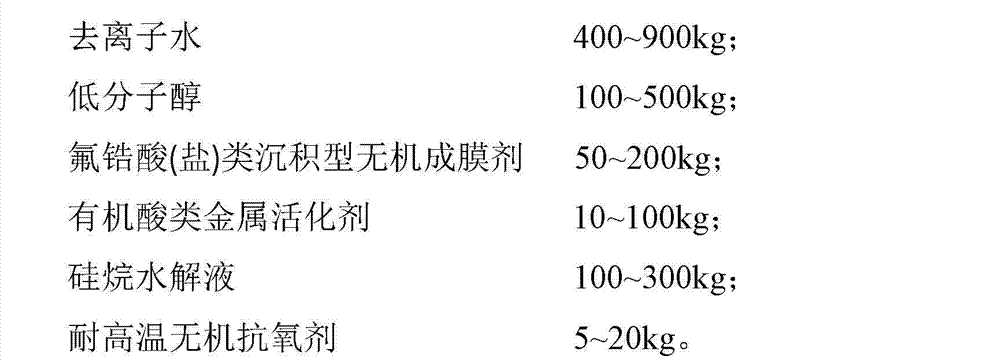

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with embodiment, the present invention is further described.

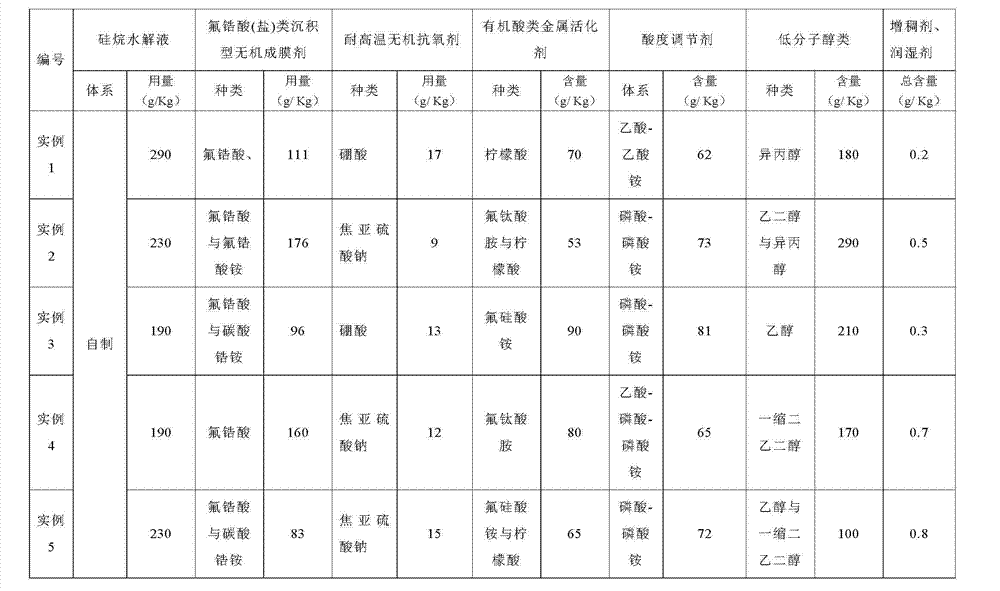

[0039] Specific examples are shown in Table 1

[0040] Each embodiment column in the table all adds the Viscalex HV-30 type thickener of Swiss Ciba Company, and the addition amount is 0.2g / Kg; The PE100 type wetting agent of Germany Corning Company 0.7 g / Kg; The balance uses deionized water to make up .

[0041] The preparation method of the silane hydrolyzate listed in the table is: add 500ml deionized water to a 1000ml three-neck flask, add glacial acetic acid to adjust the pH value to 5, slowly add 75g of N-2-aminoethyl-3-aminopropyl The mixture of trimethoxysilane and 228g of bis-triethoxysilethane was continued to stir for 5h after dropping. Due to exothermic loss of the system, 749 g of silane hydrolyzate product was finally obtained.

[0042] Table 1 chrome-free passivation solution concrete embodiment composition

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com