Welding and welding joint surface layer performance improvement double-heat-source combined effect method

A joint action, dual heat source technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of corrosion resistance and wear resistance of the weld position, and achieve weld performance improvement, repair and corrosion resistance performance, enhance the effect of using functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

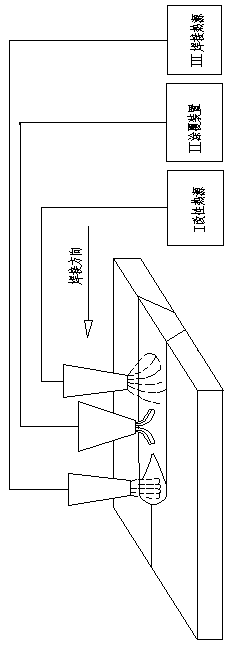

[0016] combine figure 1 This embodiment is described. The joint action method of welding and weld surface performance improvement with dual heat sources in this embodiment is mainly composed of welding heat source, weld surface performance improvement heat source and weld performance improvement material coating device. Along the welding direction, the welding heat source is at In the front, the material coating device for improving weld performance is in the middle, and the heat source for improving weld surface performance is behind. The movement speed of the three is the same during welding, and the relative position does not change.

Embodiment 2

[0018] combine figure 1 To illustrate this embodiment, during the action process, the front heat source completes the welding of the weld seam according to the welding process, and after the weld seam is formed; the intermediate coating device coats the performance material on the surface of the weld seam; role, thereby improving weld performance.

Embodiment 3

[0020] combine figure 1 In this embodiment, the material coated by the material coating device is determined according to the process requirements. It can be a solid powder, a sticky soft layer, or a thin strip plate. When the heat source heats the coated material, a layer with good stability is formed. Preferably, the heating method and energy density are determined according to the process requirements. Generally, the heat source can be argon arc heat, laser, plasma heat, induction heat, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com