Heat treatment method for stainless steel products formed by SLM

A heat treatment method, stainless steel technology, applied to the improvement of process efficiency, additive manufacturing, additive processing, etc., can solve the problems of workpiece composition and structure differences, and achieve the effects of improving strength and toughness, eliminating anisotropy, and increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A 40Cr13 stainless steel heat treatment process formed by SLM, the specific steps are as follows:

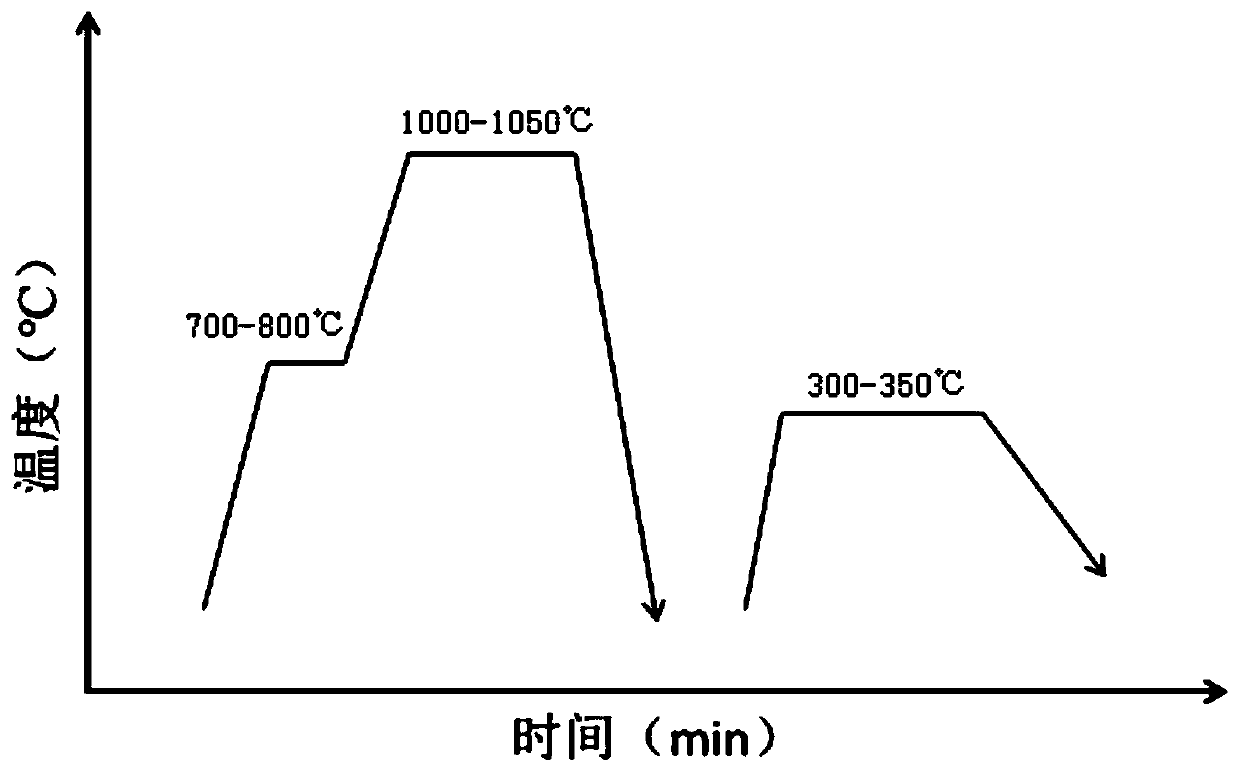

[0024] (1) Clean and dry the stainless steel sample formed by SLM, put it into a vacuum heat treatment furnace, and start heating in sections after the vacuum degree of the heat treatment furnace is stabilized within 5Pa (such as figure 1 shown);

[0025] (2) The heating rate in the first stage is set at 30°C / min, heated from room temperature to 800°C, and kept at this temperature for 10 minutes;

[0026] (3) After the first stage of heating and heat preservation is completed, the second stage of heating starts. The heating rate is set at 10°C / min, heated from 800°C to 1000°C, and kept at this temperature for 25 minutes;

[0027] (4) After the second stage of heating and heat preservation is completed, the stainless steel test piece is oil-quenched with 25°C vacuum quenching oil (THIF-517, the same below);

[0028] (5) Temper the stainless steel specimen within one hour...

Embodiment 2

[0031] A 40Cr13 stainless steel heat treatment process formed by SLM, the specific steps are as follows:

[0032] (1) Clean and dry the stainless steel sample formed by SLM, put it into a vacuum heat treatment furnace, and start segmental heating after the vacuum degree of the heat treatment furnace is stabilized within 5Pa;

[0033] (2) The heating rate in the first stage is set at 35°C / min, heated from room temperature to 700°C, and kept at this temperature for 15 minutes;

[0034] (3) After the first stage of heating and heat preservation is completed, the second stage of heating starts. The heating rate is set at 10°C / min, heated from 700°C to 1000°C, and kept at this temperature for 30 minutes;

[0035] (4) After the second stage of heating and heat preservation is completed, the stainless steel specimen is oil-quenched with vacuum quenching oil at 25°C;

[0036] (5) Temper the stainless steel test piece within one hour after the oil quenching is completed. The tempering...

Embodiment 3

[0038] A 40Cr13 stainless steel heat treatment process formed by SLM, the specific steps are as follows:

[0039] (1) Clean and dry the stainless steel sample formed by SLM, put it into a vacuum heat treatment furnace, and start segmental heating after the vacuum degree of the heat treatment furnace is stabilized within 5 Pa;

[0040] (2) The heating rate in the first stage is set at 40°C / min, heated from room temperature to 800°C, and kept at this temperature for 20 minutes;

[0041] (3) After the first stage of heating and heat preservation is completed, the second stage of heating starts. The heating rate is set at 10°C / min, heated from 800°C to 1050°C, and kept at this temperature for 35 minutes;

[0042] (4) After the second stage of heating and heat preservation is completed, the stainless steel specimen is oil-quenched with 50°C vacuum quenching oil;

[0043] (5) Temper the stainless steel test piece within one hour after the oil quenching is completed. The tempering t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com