A method for judging whether an amorphous alloy is crystallized

An amorphous alloy and crystallization technology, which is used in the field of quickly judging whether amorphous alloy products are qualified or not, and can solve the problems of long detection cycle, complex judgment, and troublesome sample preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

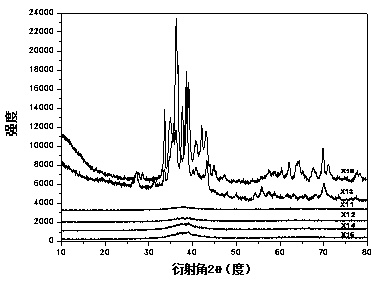

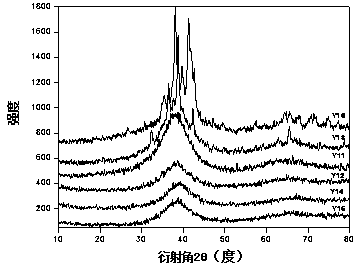

Image

Examples

Embodiment 1

[0038] Zr, Al, Cu, Ni with a purity of 99.0% by weight are used as Zr 55 Al 10 Ni 5 Cu 30 For proportioning, argon with a purity of 99.0% by volume is used as a shielding gas and melted for 4 minutes at 1100° C. to completely melt the alloy raw material. The melt is cast into a copper mold for water cooling at a cooling rate of 102K / s. Five round rods with different diameters were produced by gravity casting, with diameters of 3mm, 5mm, 7mm, 9mm and 10mm respectively, marked as sample B1, sample B2, sample B3, sample B4, sample B5; induction melting, die casting method Three sample strips were prepared, with thicknesses of 0.5mm, 1.5mm, and 10mm respectively, labeled as sample B6, sample B7, and sample B8. These samples were subjected to Vickers hardness test and flexural strength test. A Vickers reference hardness W1 is calculated according to the test results.

Embodiment 2

[0040] Same as Example 1, the difference is that the sample B1, sample B2, sample B3, and sample B5 of the above-mentioned example 1 of gravity casting are taken, and the corresponding diameters are 3mm, 5mm, 7mm, and 10mm respectively; the spline 2 prepared by the die-casting method A sample B6 and a sample B7 have corresponding thicknesses of 0.5mm and 1.5mm respectively, and a Vickers reference hardness W2 is calculated according to the test results.

Embodiment 3

[0042] Same as in Example 1, the difference is that there are 4 sample bars prepared by the die-casting method, including sample B9 with a thickness of 3 mm. Vickers hardness test and flexural strength test were carried out on sample B9. A Vickers reference hardness W3 is calculated according to the test results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com