Preparation method of magnesium alloy micro-arc oxidation black super-hydrophobic film layer

A micro-arc oxidation, magnesium alloy technology, applied in anodizing, coating, surface reaction electrolytic coating, etc., can solve the problems of affecting the stability of the solution system, high toxicity of metal oxides, polluting the environment and human body, etc. Corrosion, reduce direct contact, improve the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

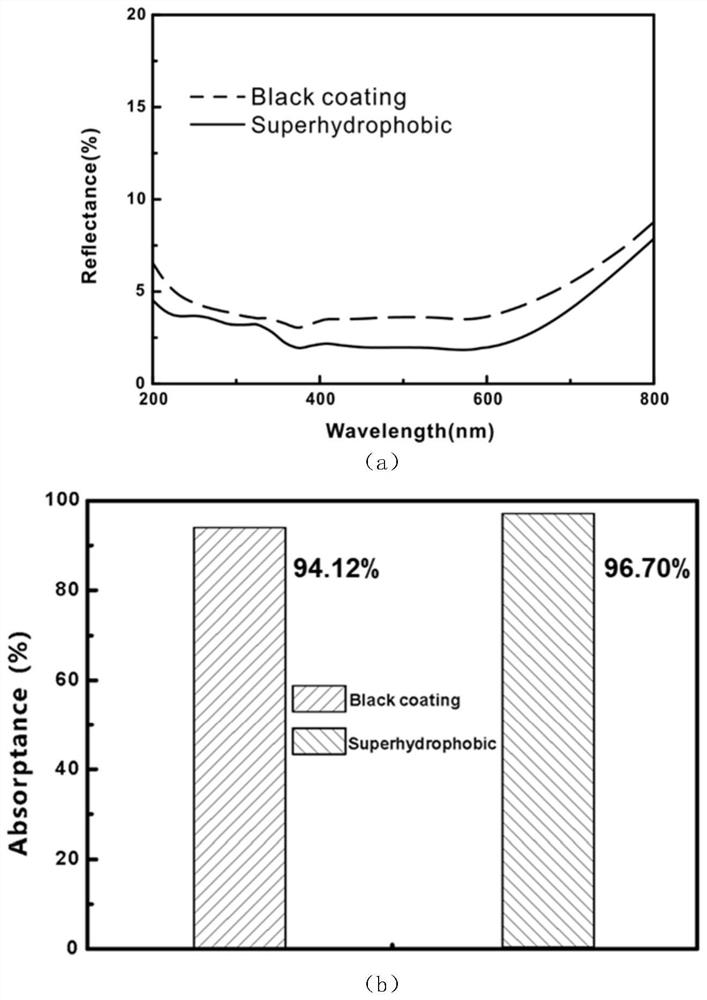

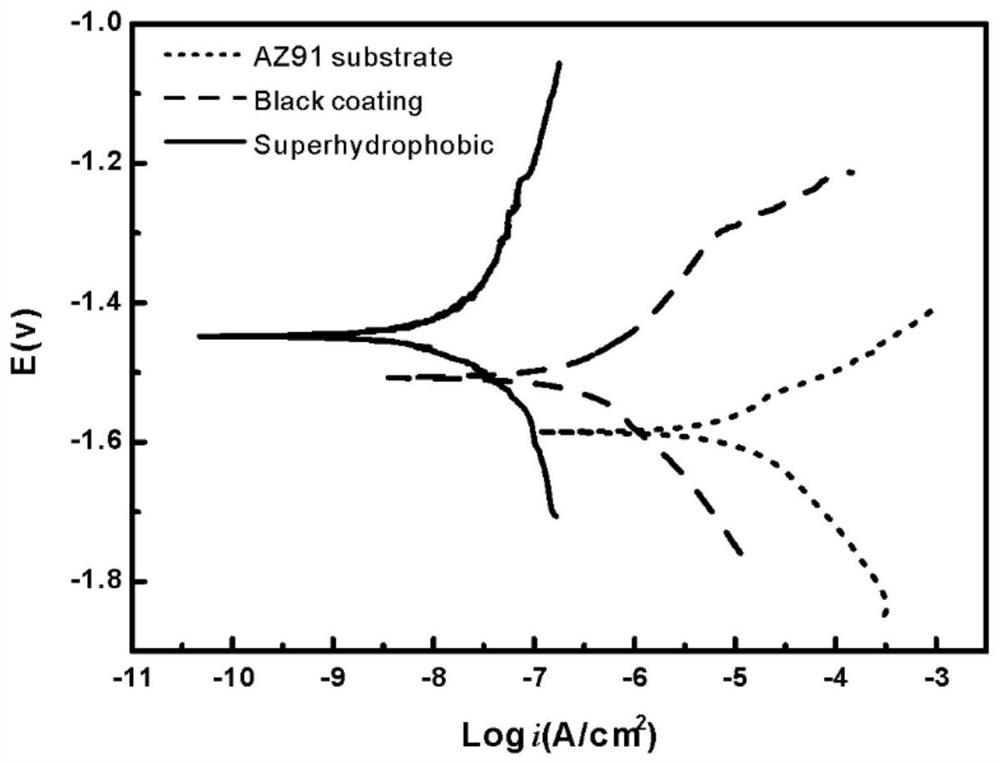

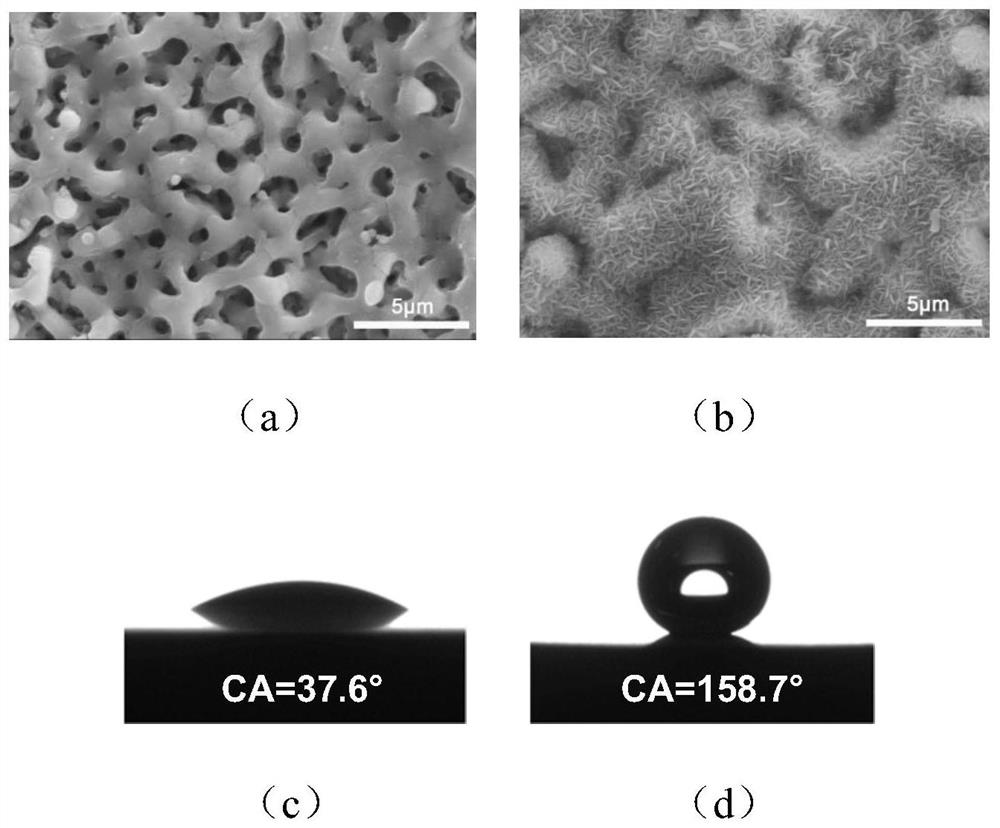

Embodiment 1

[0038] Grind the magnesium alloy to be treated to 1200# sandpaper, ultrasonically wash it in acetone for 1 min, and dry it for later use. Prepare the basic electrolyte first, add sodium silicate 8g / L, potassium fluoride 0.5g / L, and potassium hydroxide 2g / L sequentially in distilled water at room temperature. Take another beaker filled with distilled water and add the corresponding complexing agent potassium sodium tartrate 8g / L, stir and dissolve and add the coloring salt copper pyrophosphate 10g / L. Finally, add the prepared coloring salt solution into the basic electrolyte at a volume ratio of 1:1, and stir evenly. Subsequently, with the magnesium alloy as the anode and the stainless steel plate as the cathode, the dried magnesium alloy is immersed in the electrolyte, and the magnesium alloy is subjected to micro-arc oxidation treatment in a constant voltage mode. Before the start of the micro-arc oxidation, set the electrical parameters, the forward voltage is 280V, the neg...

Embodiment 2

[0040] Grind the magnesium alloy to be treated to 1200# sandpaper, ultrasonically wash it in acetone for 1 min, and dry it for later use. Prepare the basic electrolyte first, add sodium silicate 10 / L, potassium fluoride 0.5g / L, and potassium hydroxide 3g / L in order in distilled water at room temperature. Take another beaker with distilled water and add the corresponding complexing agent potassium sodium tartrate 5g / L, stir and dissolve and add the coloring salt copper pyrophosphate 6g / L. Finally, add the prepared coloring salt solution into the basic electrolyte at a volume ratio of 1:1, and stir evenly. Subsequently, with the magnesium alloy as the anode and the stainless steel plate as the cathode, the dried magnesium alloy is immersed in the electrolyte, and the magnesium alloy is subjected to micro-arc oxidation treatment in a constant voltage mode. Before the start of the micro-arc oxidation, set the electrical parameters, the forward voltage is 300V, the negative voltag...

Embodiment 3

[0042] Grind the magnesium alloy to be treated to 1200# sandpaper, ultrasonically wash it in acetone for 1 min, and dry it for later use. Prepare the basic electrolyte first, add sodium silicate 12g / L, potassium fluoride 0.5g / L, and potassium hydroxide 4g / L sequentially in distilled water at room temperature. Take another beaker filled with distilled water and add the corresponding complexing agent potassium sodium tartrate 7g / L, stir and dissolve and add the coloring salt copper pyrophosphate 8g / L. Finally, add the prepared coloring salt solution into the basic electrolyte at a volume ratio of 1:1, and stir evenly. Subsequently, with the magnesium alloy as the anode and the stainless steel plate as the cathode, the dried magnesium alloy is immersed in the electrolyte, and the magnesium alloy is subjected to micro-arc oxidation treatment in a constant voltage mode. Before the start of the micro-arc oxidation, set the electrical parameters, the forward voltage is 250V, the neg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com