Patents

Literature

52results about How to "Good corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air-permeability aluminum foil and preparation method thereof

ActiveCN101628644AGood corrosionGood corrosion resistanceFlexible coversWrappersMaximum diameterCorrosion

The invention relates to an air-permeability aluminum foil and a preparation method thereof, wherein the aluminum foil is mainly suitable for air-permeability packaging in requirements of agricultural production and daily life. The aluminum foil is characterized by being made of 3003 alloy, the thickness of the aluminum foil is 0.03-0.05 mm, pinholes which can reach more than 10,000 every square meter are densely distributed on the surface of the aluminum foil, and the maximum diameter of each pinhole is not more than 0.05 mm. The preparation method comprises the following process steps: batching, smelting, cast-rolling, cold-rolling, interannealing, cold-rolling, and foil-rolling to reach the finished thickness, slitting into a finished specification, and finished annealing. The invention has the advantages of good air permeability, strong corrosion resistance and strong oxidation resistance.

Owner:新疆生产建设兵团第八师天山铝业有限公司

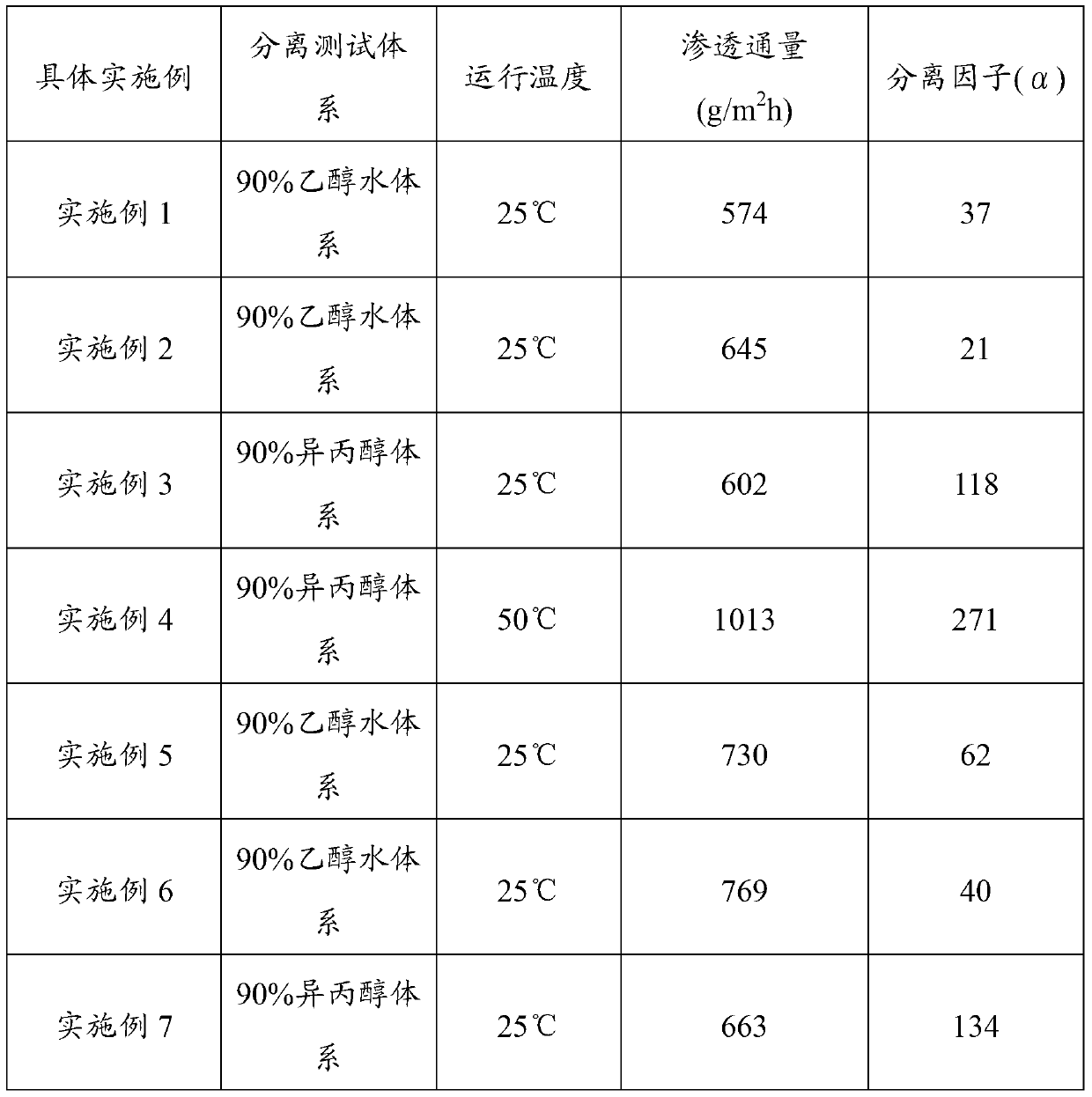

Fluorinated acrylate copolymer pervaporation composite film and preparation method thereof

ActiveCN103341328AImprove adhesionGood chemical stabilitySemi-permeable membranesComposite filmHeat resistance

The invention discloses a fluorinated acrylate copolymer pervaporation composite film which comprises a supporting layer and an active separating layer, wherein the active separating layer is uniformly distributed on the supporting layer which is a polytetrafluoroethylene microporous supporting film. The active separating layer is a fluorinated acrylate copolymer. The surface composition and body structure of the fluorinated acrylate copolymer pervaporation composite film are controllable, and the fluorinated acrylate copolymer pervaporation composite film has better stability, heat resistance, corrosive resistance, and long service life. The invention further discloses a preparation method of the fluorinated acrylate copolymer pervaporation composite film. The preparation method has the advantage of effectively solving the problem of non-uniformity and crack in the film coating process, and the preparation method is simple and low in cost, and easy to realize industrialized production.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

Heat-insulation type concrete for civil construction and preparation method thereof

The invention discloses heat-insulation type concrete for civil construction and belongs to the technical field of concrete. The heat-insulation type concrete is prepared from the following raw materials in parts by weight: 90 to 100 parts of cement, 20 to 25 parts of fly ash, 40 to 50 parts of fine sand, 10 to 20 parts of ceramsite, 5 to 8 parts of cast stone powder, 6 to 9 parts of zeolite powder, 60 to 70 parts of water, 1 to 2 parts of fiber, 0.5 to 1 part of a waterproof agent, 1 to 3 parts of a de-foaming agent, 0.2 to 0.8 part of a suspension agent and 0.1 to 0.2 part of an activating agent. The invention further discloses a preparation method of the heat-insulation type concrete for the civil construction. The heat-insulation type concrete for the civil construction is simple to prepare and has relatively excellent waterproof, fireproof and heat-insulation capabilities.

Owner:山东励仙电力工程有限公司

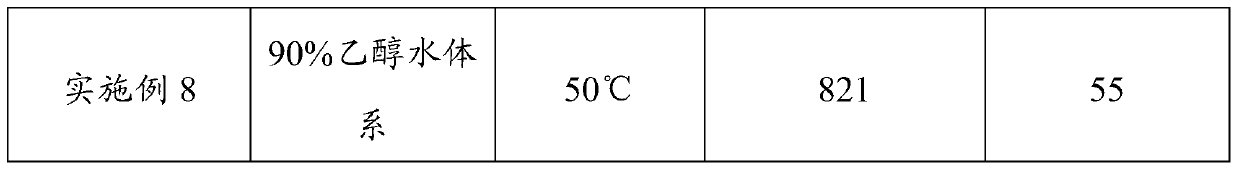

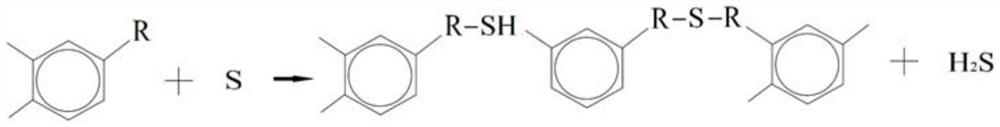

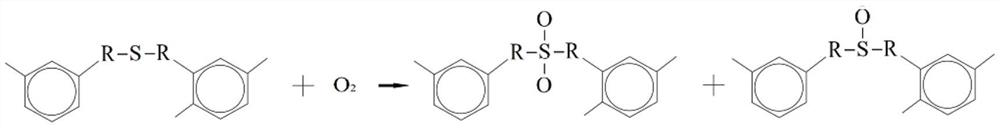

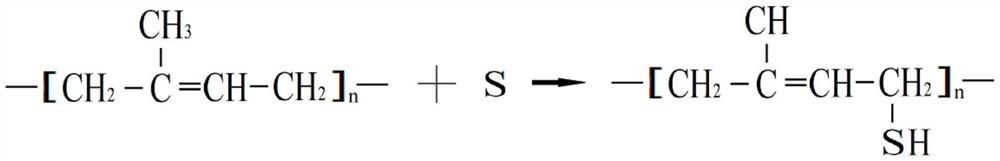

Novel anti-aging compound rubber and preparation method thereof

InactiveCN105566779AIncrease crosslink densityImprove anti-aging propertiesPolymer scienceTriallyl isocyanurate

The invention discloses an anti-aging compound rubber sealing strip. The anti-aging compound rubber sealing strip is prepared from, by weight, 50-200 parts of ethylene propylene rubber, 10-70 parts of fast extruding furnace black, 1-15 parts of indirect zinc oxide, 1-10 parts of antiager, 1-15 parts of paraffin oil, 1-10 parts of lubricant, 1-10 parts of vulcanizing agent and 1-8 parts of accelerant. The accelerant is triallyl isocyanurate and / or trifunctional acrylic ester. The invention further discloses a preparation method of the anti-aging compound rubber sealing strip. The anti-aging compound rubber sealing strip has the advantages of being long in service life, resistant to aging and pressure changes and stable in hardness, and the preparation method is simple and easy to operate.

Owner:ANHUI ZHONGDING SEALING PARTS

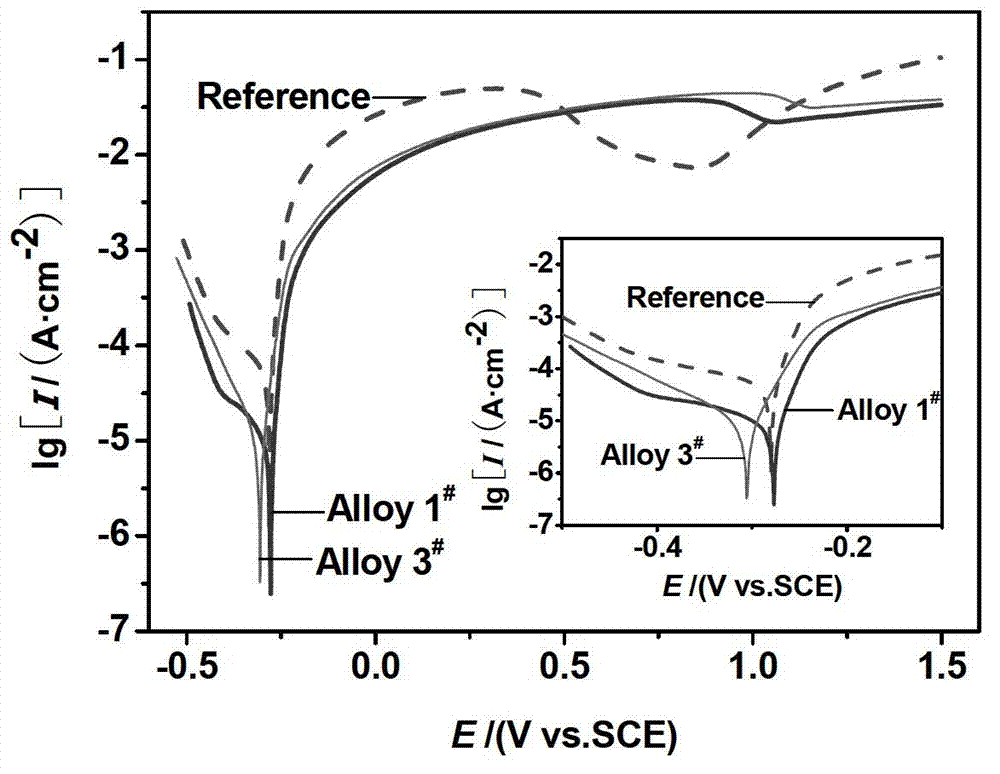

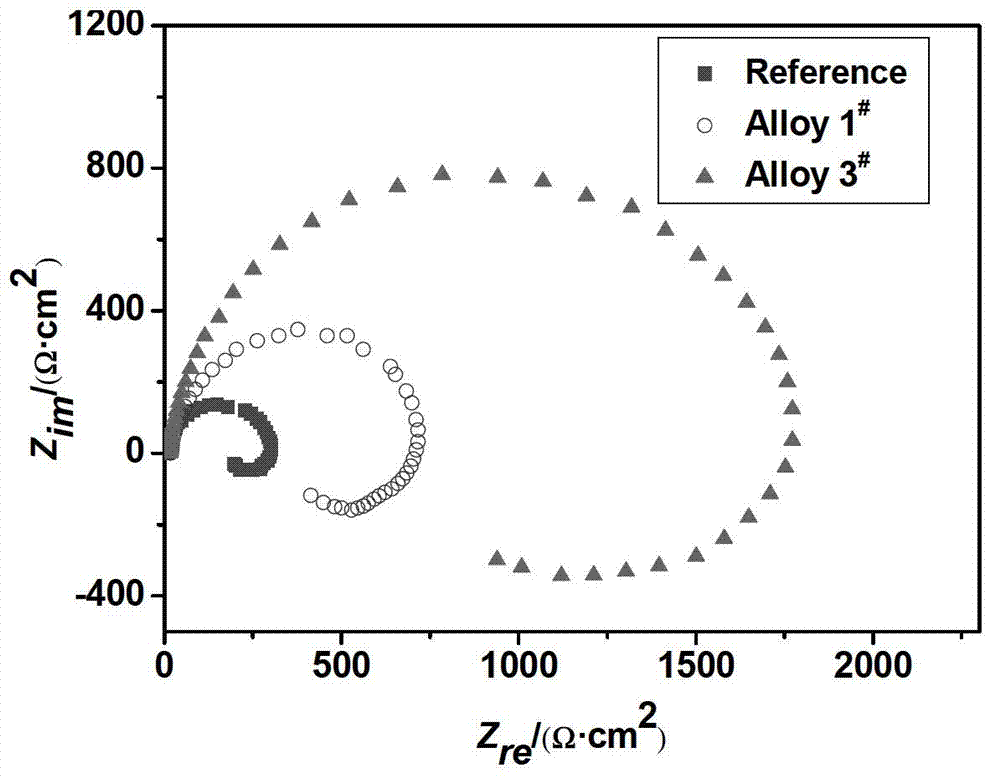

Medical absorbable Mg-Si alloy

The invention relates to a biologically absorbable magnesium alloy applied to medical implant materials and particularly suitable to be used as a corrodible and degradable bone implant material and adegradable scaffold material under human body environment. The biologically absorbable magnesium alloy comprises the following components in percentage by weight: 0.5 to 5.0 percent of silicon (Si) and the balance of magnesium (Mg), and possibly comprises a small amount of microelements such as manganese (Mn), calcium (Ca), rare earth (RE) and yttrium (Y); and the content of each microelement is not more than 1.5 percent, and the total content of the microelements is not more than 2.0 percent. The material has good biological compatibility and mechanical property, and has application value inthe medical field, such as intravascular interventional treatment of scaffolds, absorbable bone fixing instruments such as bone pegs, bone lammelae and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

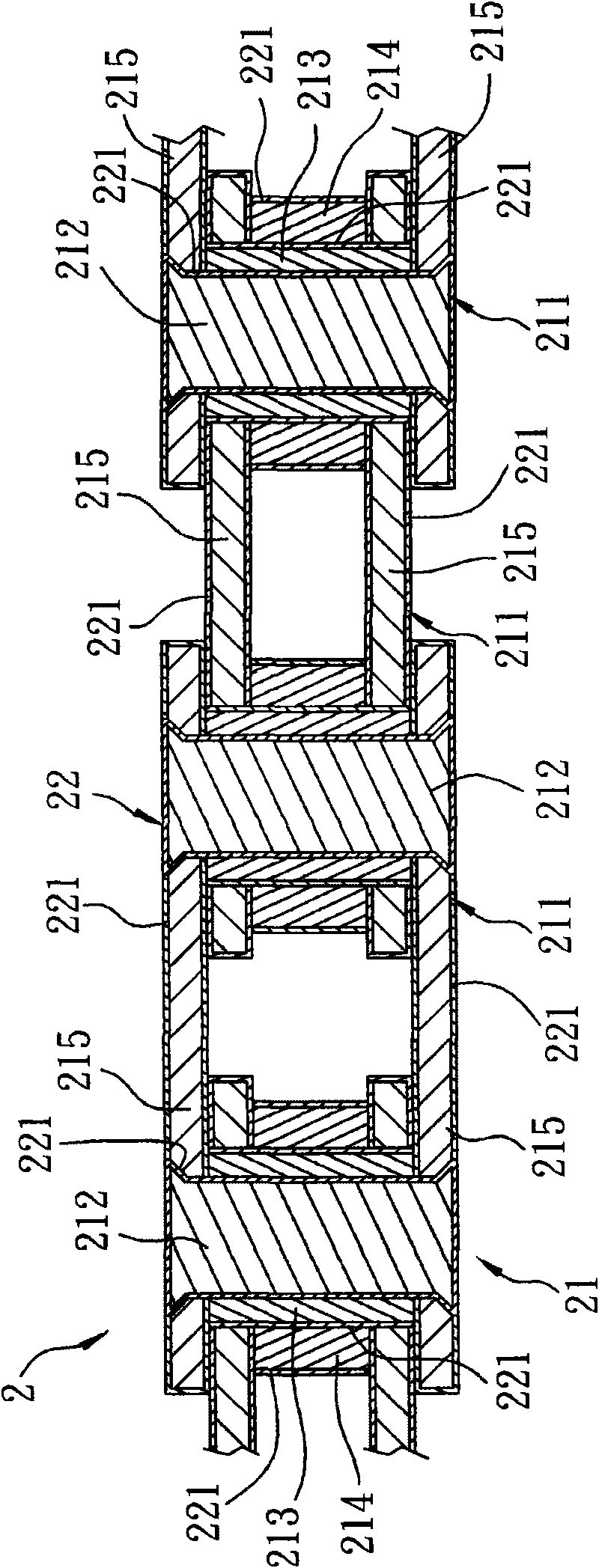

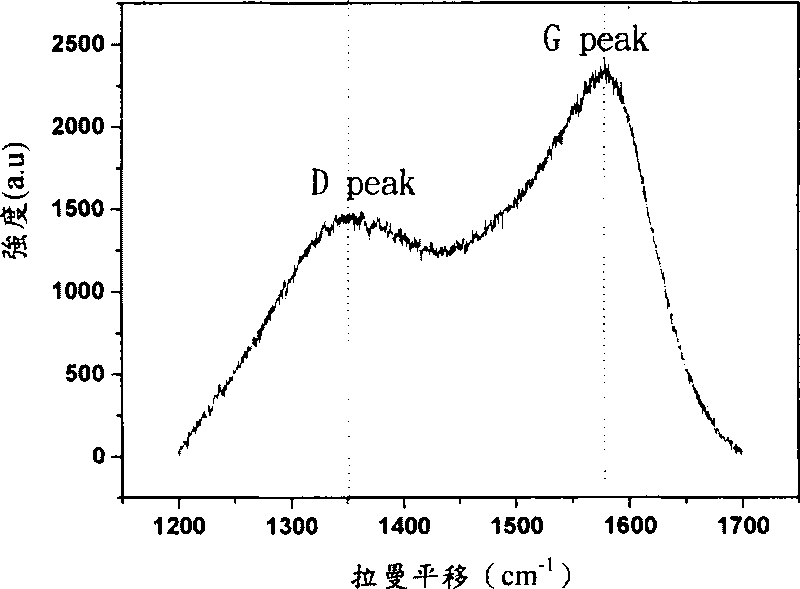

Wear-resisting chain

InactiveCN101737454AImprove the lubrication effectAccelerated corrosionDriving chainsGraphiteSpectral analysis

The invention relates to a wear-resisting chain which comprises a chain body and a wear-resisting layer unit which covers a local part or the total part of the chain body. The wear-resisting layer unit can generate a graphite characteristic peak and a disordered characteristic peak by Raman spectral analysis. By utilizing the structural characteristics of the wear-resisting layer unit, the wear-resisting chain can generate the efficacy of abrasion and corrosion resistance, high lubrication degree and long service life, and the like.

Owner:超汇桂盟传动(苏州)有限公司

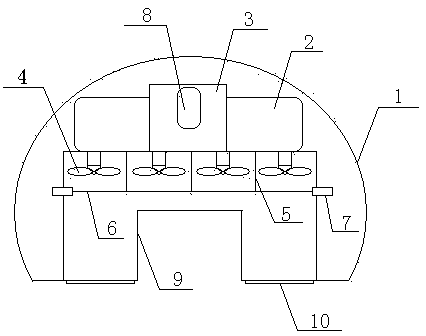

Cooling fan device for LED streetlamp

InactiveCN103712193ANo cloggingStable internal structurePoint-like light sourceLighting heating/cooling arrangementsGratingEngineering

The invention relates to a cooling fan device for an LED streetlamp. The cooling fan device comprises an outer shell, a large motor, a photothermic sensor and a plurality of multi-head fans. The multi-head fans are arranged in the outer shell and are separated through gratings, the lower portion of each grating is provided with a fixing plate, the two sides of each fixing plate are fixed to the inner wall of the outer shell through dismountable reinforcing strips, the large motor is arranged on the upper portions of the multi-head fans, the photothermic sensor is further arranged on the front upper portion of the large motor and is further provided with a temperature gauge, an LED streetlamp installation tank is arranged in the lower portions of the multi-head fans, and the two sides of the LED streetlamp installation tank are respectively provided with a drain outlet. Through the improvements, the cooling fan device has the advantages that adjustment is carried out to achieve cooling according to the internal temperature of the outer shell, the internal structure is firm, protective measures are taken among the multi-head fans so that the multi-head fans do not interfere with one another, the cooling fan device can be used under high-temperature and low-temperature environments and other severe environments and is high in strength, resistant to corrosion, excellent in fire resistance and good in venting practice, and pollution and blocking caused by dirt cannot be caused.

Owner:SUZHOU CHENGTENG ELECTRONICS TECH

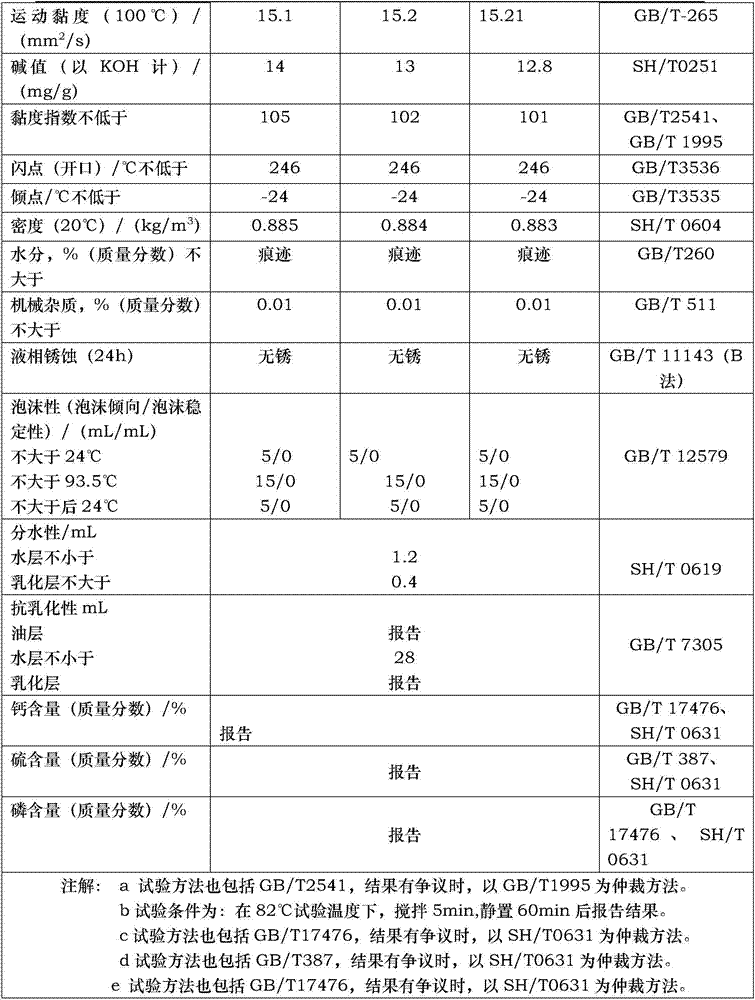

Medium-high speed trunk-piston diesel and engine oil

InactiveCN107164053AGood dispersionGood heat resistanceLubricant compositionAntioxidantLinear alkylbenzene

The invention discloses medium-high speed trunk-piston diesel and engine oil, which is prepared from the following components in parts by weight: 80-90 parts of 500SN base oil, 50 parts of 150BS base oil, 1-2.5 parts of polyisobutyl butylene diimide T155A, 1.0-2.0 parts of an over-based sulfurized calcium alkyl phenolate clearing agent T115B, 0.4-0.6 part of nitrogen-containing borate, 2-4 parts of long-chain linear alkylbenzene ultra-high alkali synthesis calcium sulfonate T106D, 1-2 parts of a high-molecular weight polyisobutyl butylene diimide dispersing agent T161A, 1-5 parts of a disimberyl sulfide zinc salt oxidation and corrosion inhibitor T203, 0.2-0.5 part of a phenolic ester antioxidant, 0.1-0.3 part of a dinonyl diphenylamine antioxidant, 0.1-0.3 part of a polymethacrylate pour point depressant T602 and 0.2-0.5 part of a friction modifier oxymolybdenum dialkydithiophosphate T462. Compared with the prior art, the medium-high speed trunk-piston diesel and engine oil has excellent cleaning dispersibility, heat resistance and antioxidative stability, excellent anti-rust and anti-corrosion properties, acid neutralization capacity and alkali value retentivity.

Owner:烟台艾西特润滑科技有限公司

Palladium-silver alloy material for dental department

InactiveCN103205594AImprove corrosion resistanceGuaranteed ductilityImpression capsDentistry preparationsGold alloysMechanical property

The invention discloses palladium-silver alloy for repairing an oral cavity. Alloy ingredients are optimized by an alloy material. Compared with the prior art, the obtained material has the advantages of good mechanical property, good corrosion resistance, low sensitization, and beautiful color and luster under the premise of not reducing the alloy property and clinical use effect; and the cost is just 1 / 4 to 1 / 3 of gold alloy.

Owner:SICHUAN QIHE PRECIOUS METALS CO LTD

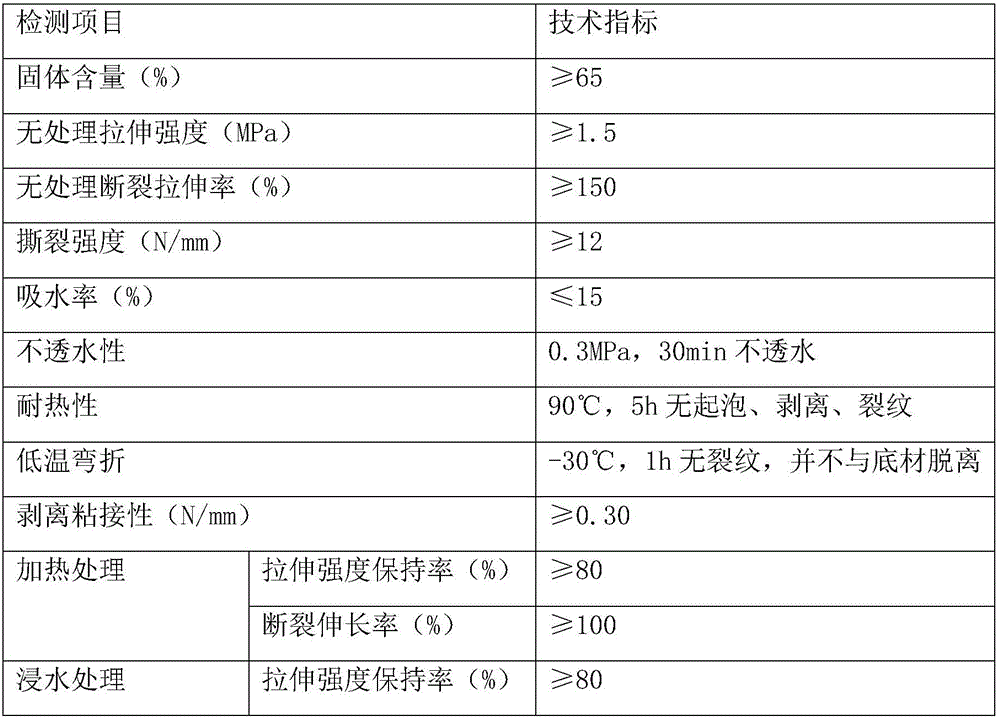

Special roof-spraying waterproof material

ActiveCN106221450AImprove adhesionImprove sealingFireproof paintsAntifouling/underwater paintsEpoxyLow speed

The invention discloses a special roof-spraying waterproof material. The special roof-spraying waterproof material is prepared from, by weight, 400-550 parts of emulsion, 80-120 parts of silica powder, 300-400 parts of calcite powder, 40-60 parts of rutile titanium dioxide, 30-50 parts of deionized water, 2-4 parts of dispersing agent, 2-4 parts of defoaming agent, 1.5-2.5 parts of preservative, 0.8-1.2 parts of ultraviolet light absorber and 0.8-1.2 parts of anti-aging agent. A preparing method of the special roof-spraying waterproof material includes the steps that the silica powder, the calcite powder, the rutile titanium dioxide, the deionized water, the dispersing agent, the defoaming agent, the preservative, the ultraviolet light absorber and the anti-aging agent are stirred to be even at a high speed, the emulsion is added at a low speed, the mixture is stirred to be even, and the special roof-spraying waterproof material is obtained through filtering. The emulsion is acrylic emulsion or a mixture of acrylic emulsion and aliphatic-series waterborne polyurethane emulsion or a mixture of acrylic emulsion and waterborne epoxy resin emulsion. The special roof-spraying waterproof material is mainly used for water resisting of roofs.

Owner:成都市嘉洲新型防水材料有限公司

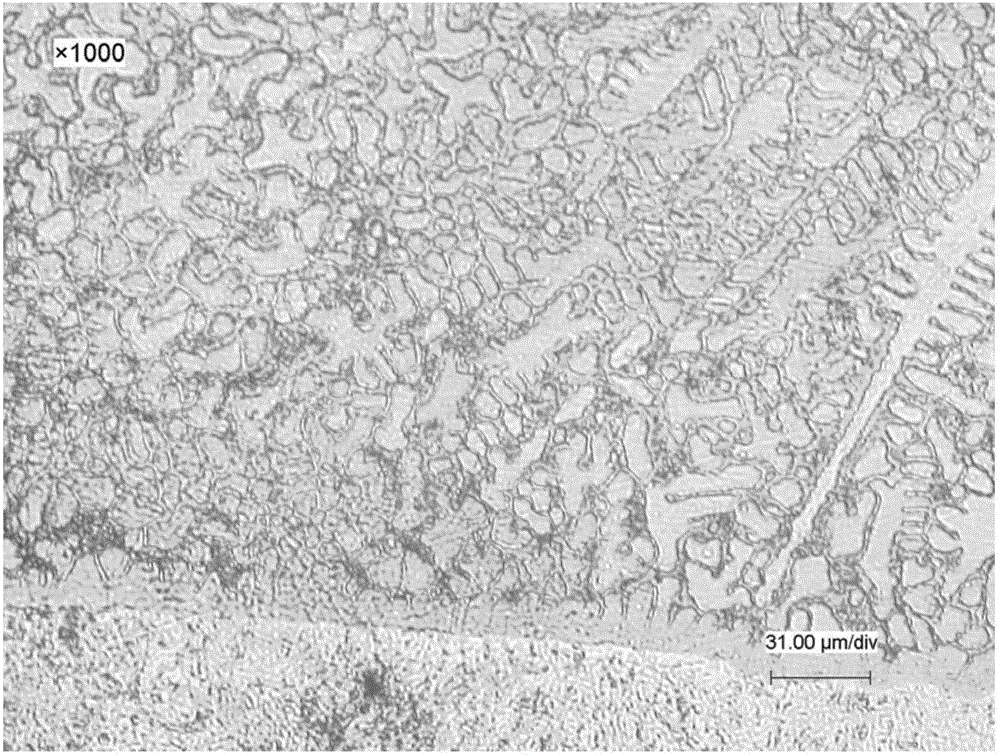

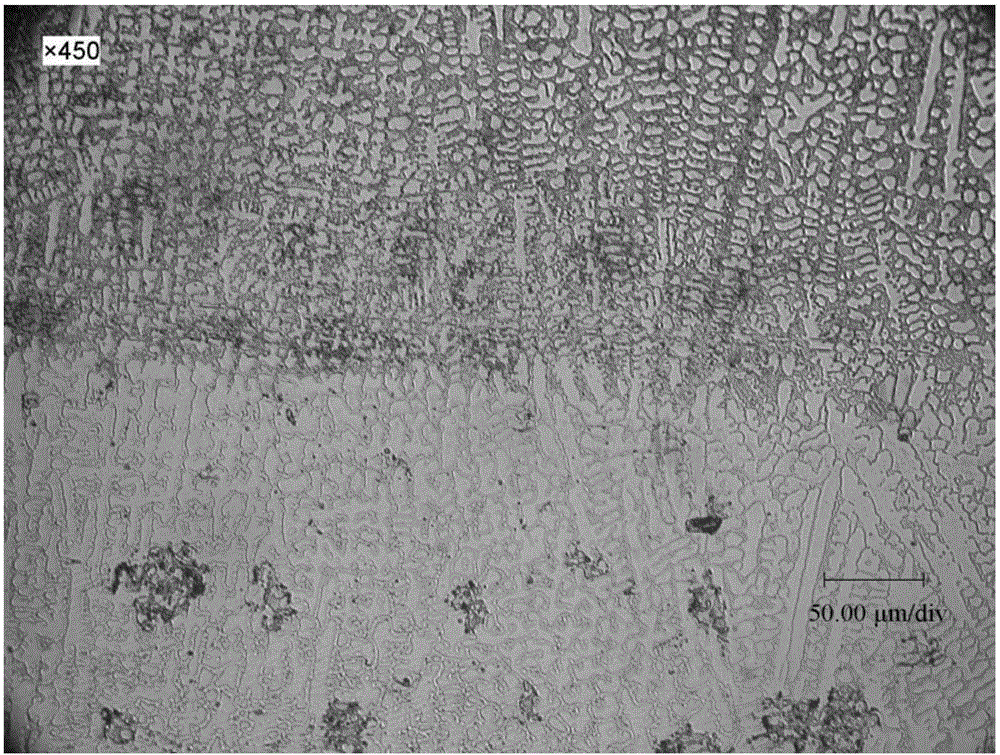

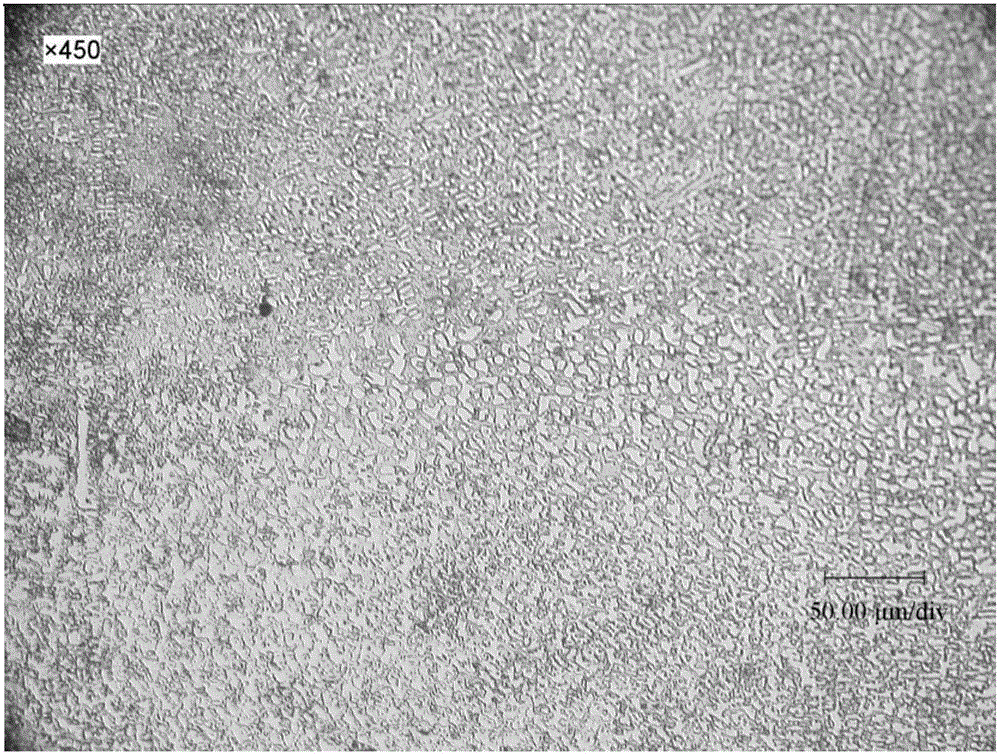

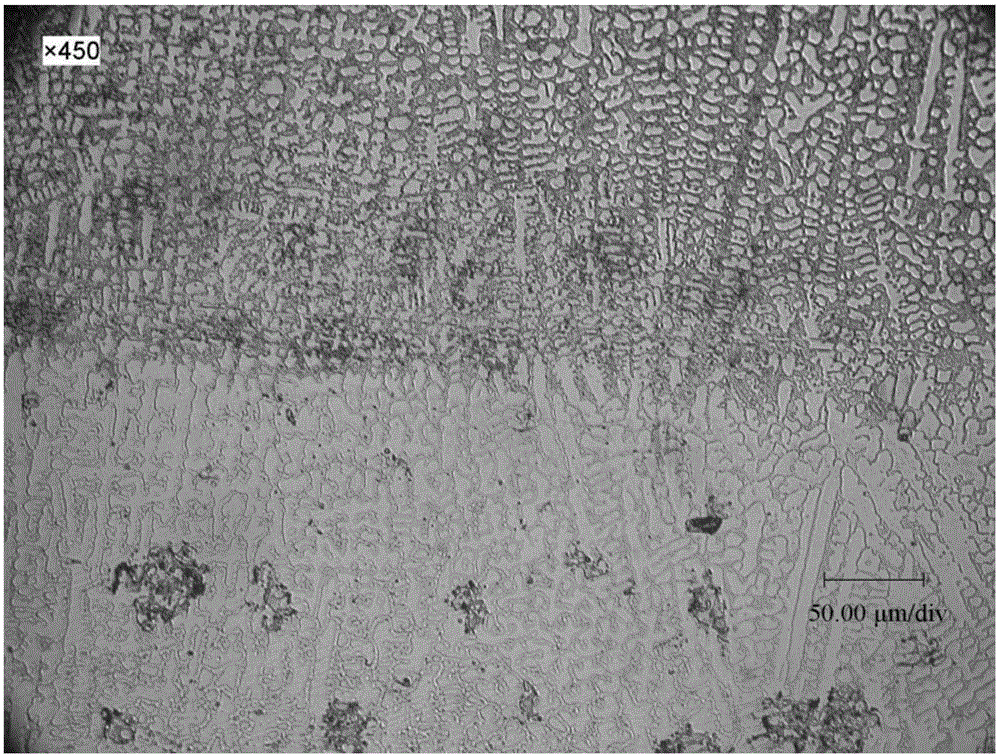

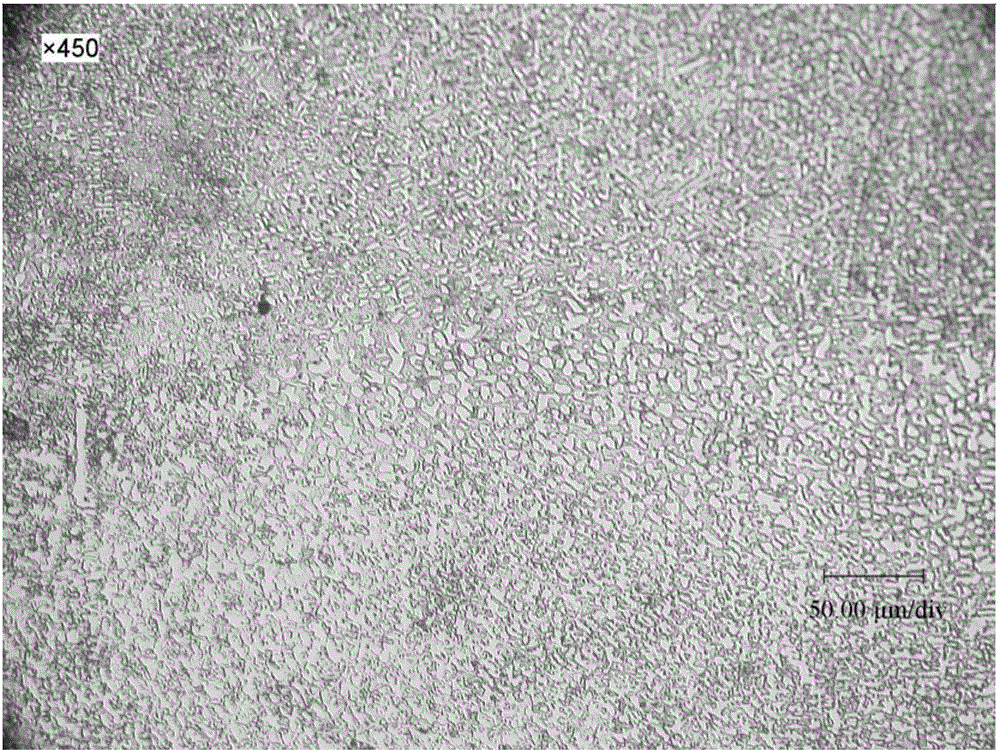

High-ductility, corrosion-resistant and ultra/extra-thick crystalline cemented carbide and preparation method thereof

The invention discloses a high-ductility, corrosion-resistant and ultra / extra-thick crystalline cemented carbide and a preparation method thereof. By taking Coarse WC (wolfram carbide) powder as raw materials, and through separately adding Cr3C2 or adding Cr3C2 and rare earth in a combined mode, and adopting a Co / Ni densely-cladded WC-type composite powder process, ultra / extra-thick crystalline cemented carbides with high ductility and better acid / alkali-resistance and oxidation / corrosion resistance are prepared. The adding amounts of the Cr3C2 and the rare earth are respectively 5-8% and 0.4-0.6% of the total mass fraction of Co / Ni in the cemented carbide. The rare earth can be added in rare earth-cobalt pre-alloyed powder form or in oxide form, and when the rare earth is added in oxide form, the adding amount is calculated by oxides. The composite powder process refers to prepare nano assembling structured Co / Ni densely-cladded WC-type composite powder by using a hydrothermal high pressure hydrogen reduction or hydrazine hydrate aqueous-phase normal-pressure reduction process, and then carry out thermal diffusion homogenization and Co / Ni cladded densification processing on the composite powder in a hydrogen atmosphere by using a nano diffusion sintering effect.

Owner:CENT SOUTH UNIV

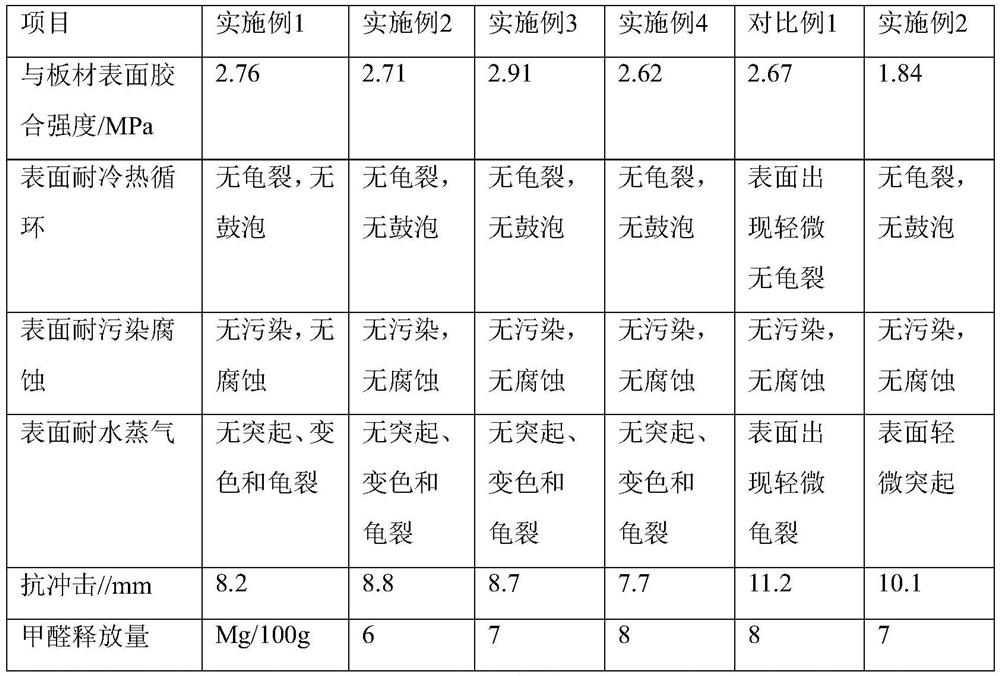

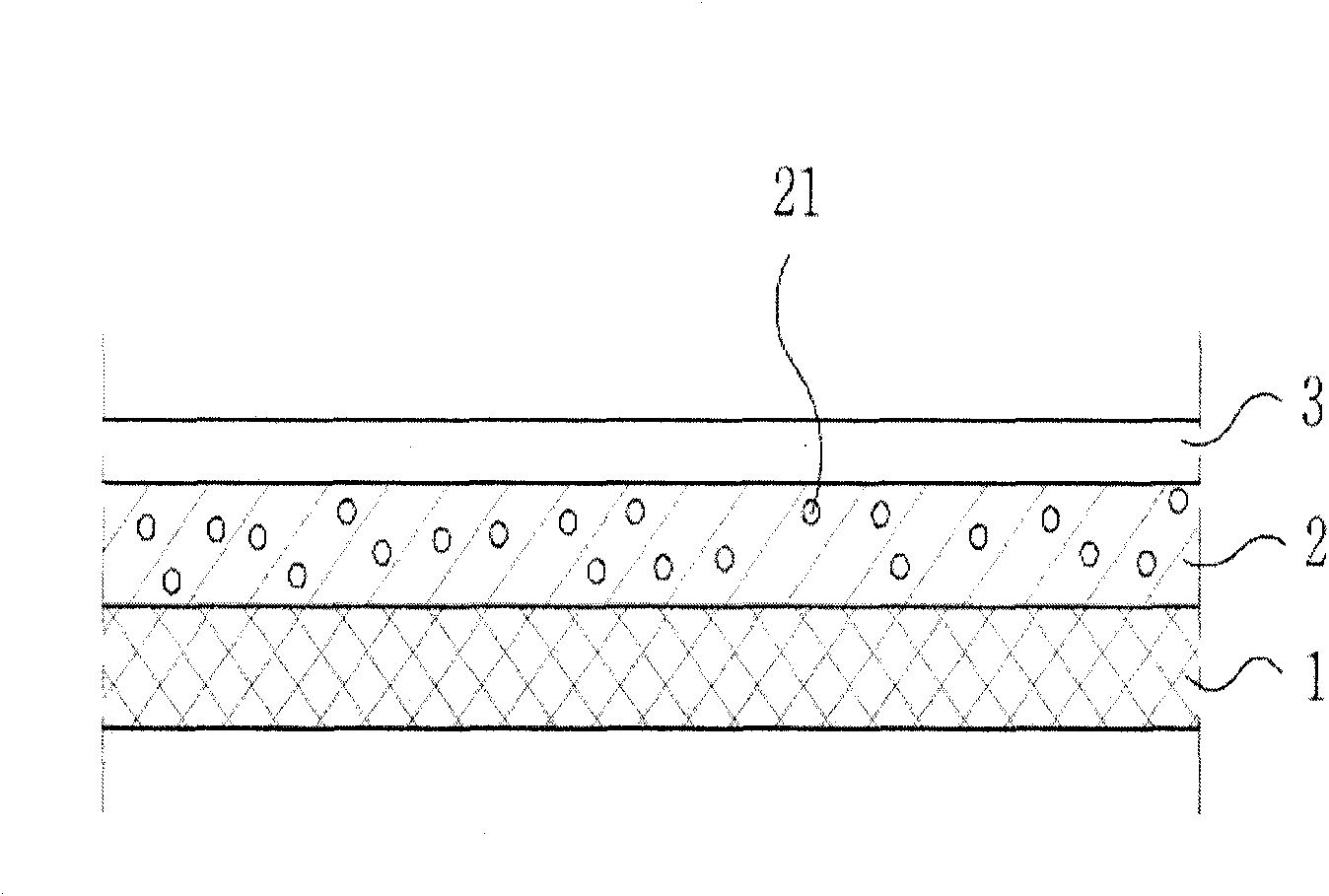

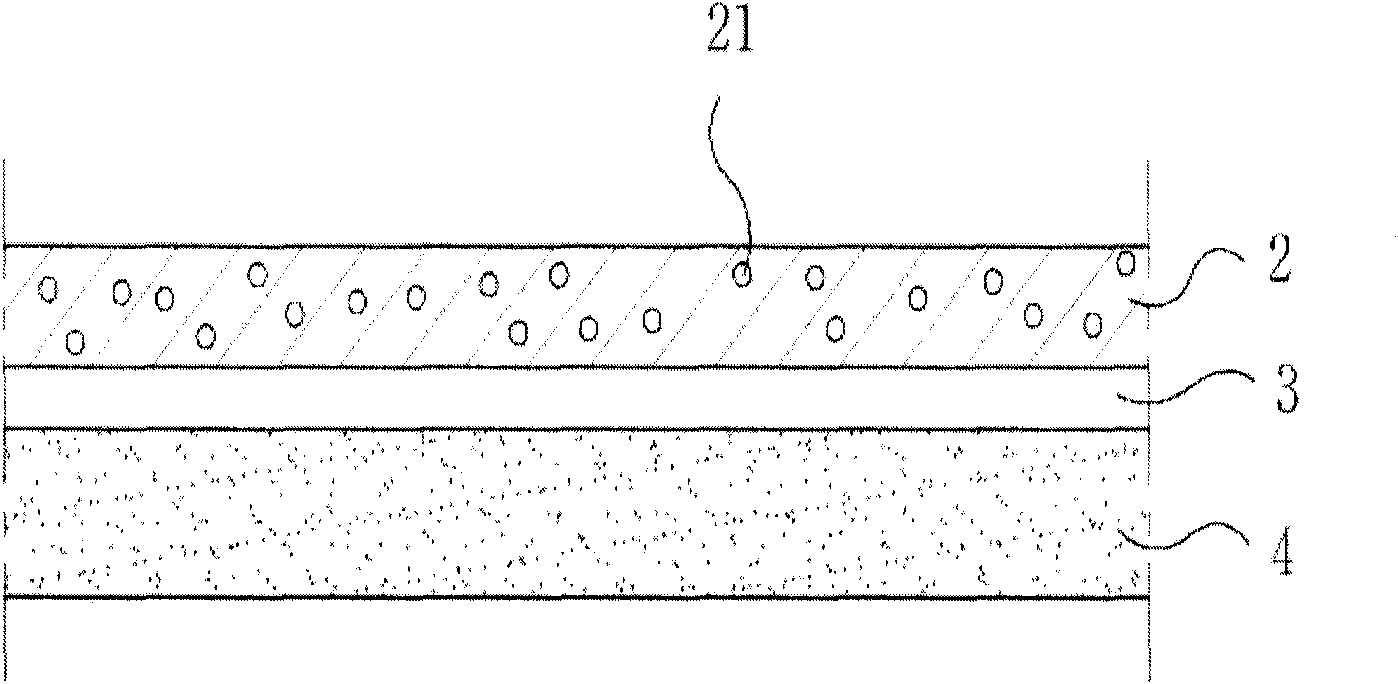

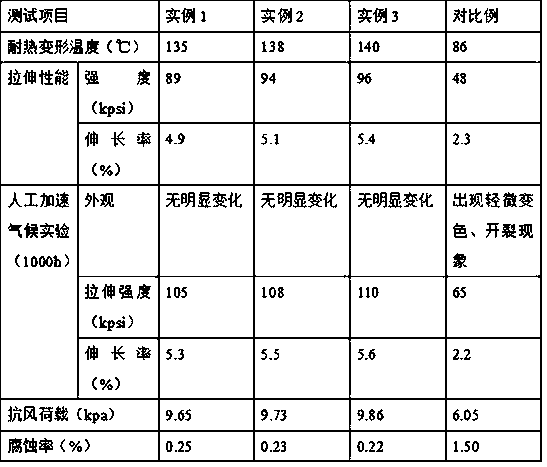

Weather-proof decorative paper and preparation method thereof

PendingCN112301797AGood weather resistanceAccelerated corrosionSpecial paperNon-macromolecular organic additionWeather resistanceProcess engineering

The invention relates to the technical field of decorative paper, in particular to weather-proof decorative paper and a preparation method thereof. The decorative paper comprises a base paper layer, an impermeable adhesive layer coating the surface of the base paper layer and a protective adhesive layer attached to the upper surface of the impermeable adhesive layer, and the base paper layer is provided with an ink pattern layer. The decorative paper has excellent weather resistance, corrosion resistance and mechanical properties, and is long in service life, good in appearance effect and highin practicability. The preparation method of the weather-proof decorative paper is simple, efficient, convenient to operate and control, stable in product quality and beneficial to industrial production.

Owner:GUANGDONG FUMEI NEW MATERIAL TECH CO LTD

Method for manufacturing wires and bar of rare earth metal with high lanthanum being mixed into and wires and bar of rare earth alloy containing aluminum, barium, calcium and magnesium

A technology for preparing the high-La RE metal mixture wire or rod and RE alloy wire or rod containing Al, Ba, Ca and Mg includes such steps as loading the cast RE ingot or block and KCl as convering agent into the crucible in RE electric furnace, adding Al, Ba, Ca and Mg in intermediate alloy mode, removing slag, casting ingot at 1000-1150 deg.C, preheating the ingot and die, and die pressing by hydraulic press.

Owner:武钢集团有限公司

Transfer sheet comprising a fluororesin layer containing reflective particles,and exterior laminate sheet comprising a fluororesin layer containing reflective particles, and method for manufacturing t

InactiveCN101557942AGood weather resistanceGood corrosionFilm/foil adhesivesDecorative surface effectsWeather resistanceSurface layer

The present invention relates to a transfer sheet characterized in that a fluororesin layer, wherein reflective particles such as pearl particles or glass particles for giving metal texture are dispersed, is formed on a carrier film and an adhesive layer is formed on said fluororesin layer, and an exterior laminate film characterized in that by transferring said transfer film on a synthetic resin film, the fluororesin layer containing reflective particles forms a surface layer, and an adhesive layer and a synthetic resin film are in turn laminated under said fluororesin layer. The exterior laminate sheet according to the present invention can easily give physical properties, such as excellent weather resistance, corrosion resistance and stain resistance, resulting from the fluororesin to windows / doors and panels, and it is so flexible that it has an effect of easily constructing curved surfaces. In addition, the exterior laminate sheet according to the present invention is allowed to use pearl particles or glass particles having large particle size by adopting formation of a fluororesin layer containing reflective particles as a coating method, whereby it has an effect that a decoration effect may be maximized.

Owner:LG CHEM LTD

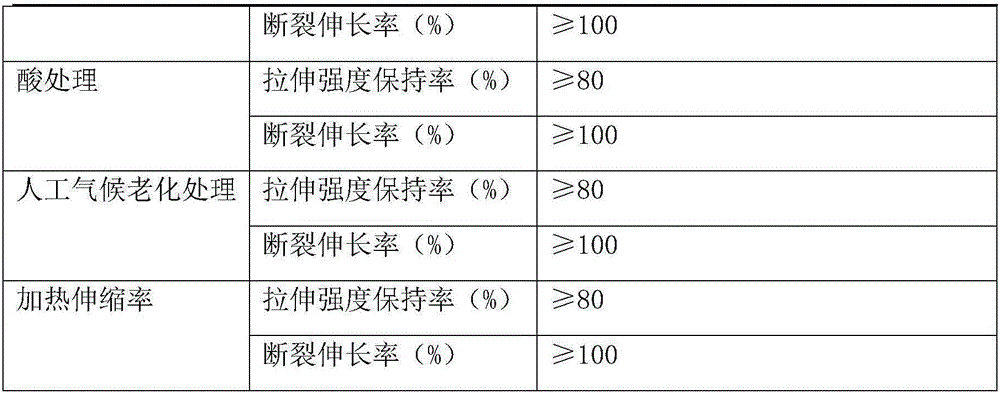

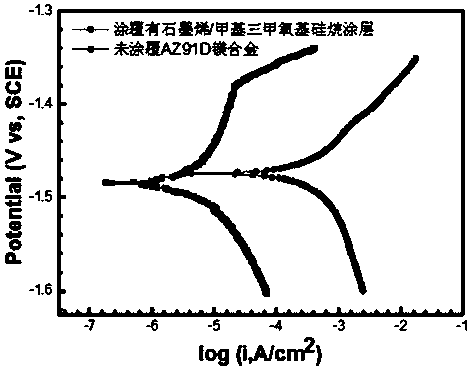

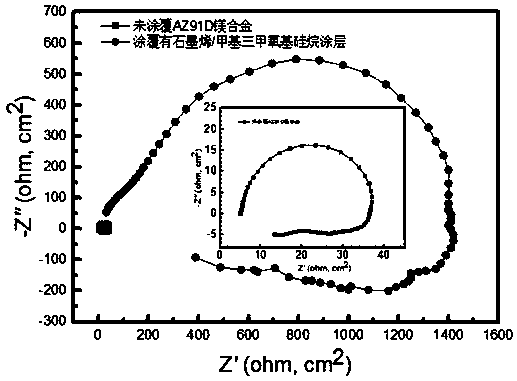

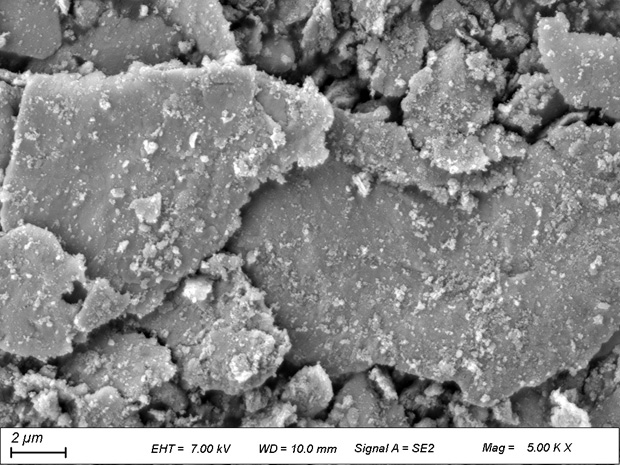

Graphene anticorrosion aqueous coating for magnesium alloy, and preparation method and application thereof

PendingCN110938372AReduce corrosionLow costLiquid surface applicatorsAnti-corrosive paintsOxide coatingMagnesium alloy

The invention relates to a preparation method of a graphene anticorrosion aqueous coating for magnesium alloy, which includes steps of: preparing a graphene / methyltrimethoxysilane dispersion, coatingthe surface of AZ91D magnesium alloy with the graphene / methyltrimethoxysilane dispersion by 2-3 layers particularly in a rod-coating manner, and drying and curing the coating in a drying box at 80-100DEG C. The invention further discloses the graphene anticorrosion aqueous coating for magnesium alloy, which is prepared through the method, and the applications of the coating on a magnesium alloy product surface. In the coating, the methyltrimethoxysilane is bonded to the graphene oxide lamella, so that the composite graphene oxide coating has better anticorrosion effect. The product greatly improves the anticorrosion effect of the magnesium alloy, is low in cost, is simple in preparation method, is free of heavy metal ions and satisfies ecological and environmental protection.

Owner:JIANGSU ANNATAI ENVIRONMENTAL PROTECTION TECH CO LTD

Polyvinyl chloride fluorine-containing Yingdan paint

ActiveCN101265380AGood temperature resistanceGood aging resistanceWax coatingsPolyurea/polyurethane coatingsHigh resistancePolyvinyl chloride

The invention discloses a polyvinyl chloride fluoric ferrophosphorus coating, which consists of components A and B. Component A is divided into A1 and A2. A1 is a polyvinyl chloride fluoric ferrophosphorus primer; and A2 is a polyvinyl chloride fluoric ferrophosphorus finish coat. Component B is a polyurethane curing agent. Before use, a primer is prepared with A1 and B in the ratio of 12 to 1 by weight; and a finish coat is prepared with A2 and B in the ratio of 12 to 1 by weight. The coating film thickness is 180 Mu m, and the service life of the coating can be more than 15 years under the heavy-duty anticorrosive condition. The coating can be widely applied in anticorrosion engineering of industrial architecture, petroleum, chemical engineering, medicine, process pipes, equipment, steel components, bridges, and shipbuilding, as well as protection of strong, medium and weak corrosive media on surfaces of indoor and outdoor steel structures and concrete. The coating has the characteristics of efficient corrosion prevention, high ratio of performance to price, high resistance to temperature and weatherability, excellent oil resistance, convenient construction, and long service life.

Owner:台州龙化科技有限公司

Coal tar modified durable sulfur concrete and preparation method thereof

InactiveCN111875323ASolve the land environmentSolve the pollution of the environmentSlagCrushed stone

The invention discloses coal tar modified durable sulfur concrete and a preparation method thereof. Each cubic meter of the coal tar modified durable sulfur concrete comprises the following componentsby mass: 1080 kg of industrial sulfur particles; 600 kg of granular crushed stone; 72 kg of fly ash; 41 kg of granulated blast furnace slag; 342 kg of quartz sand; 29 kg of waste ceramic fine aggregate; 24 kg of waste glass micro powder; 36kg of stone chip powder; 36kg of volcanic ash; 65 kg of rubber particles; and 30kg of glass fiber; wherein the mass of the modifier is 1-5% of the mass of theindustrial sulfur particles; the mass of the thickening agent is 0.1-0.5% of the total mass of the sulfur concrete; and the mass of the coupling agent is 0.3-2% of the mass of the industrial sulfur particles. According to the invention, the durability problem caused by material embrittlement and volume shrinkage due to sulfur solid-phase transformation is solved, the cost problem that the traditional sulfur concrete is generally high in price is solved, and the problems that wastes occupy land and pollute the natural environment are also solved.

Owner:INNER MONGOLIA UNIV OF TECH

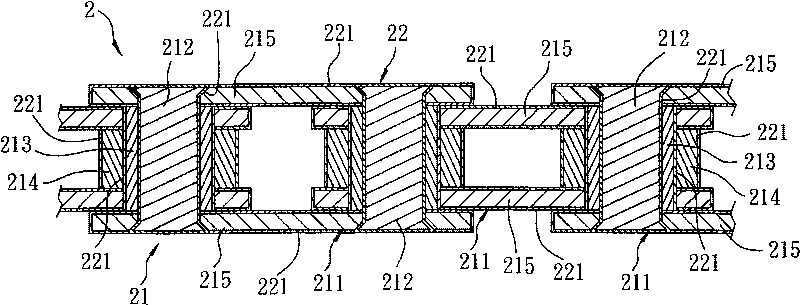

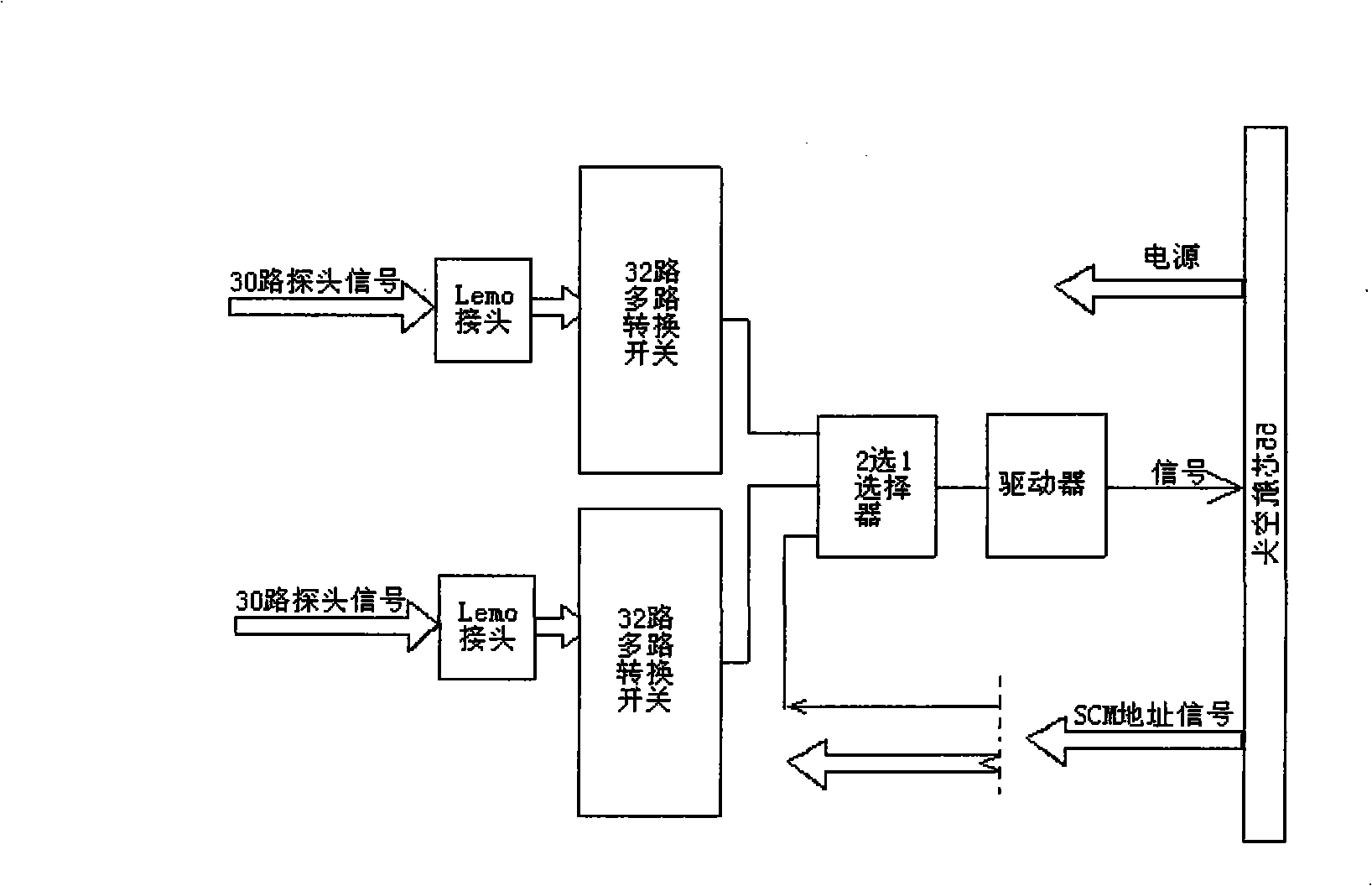

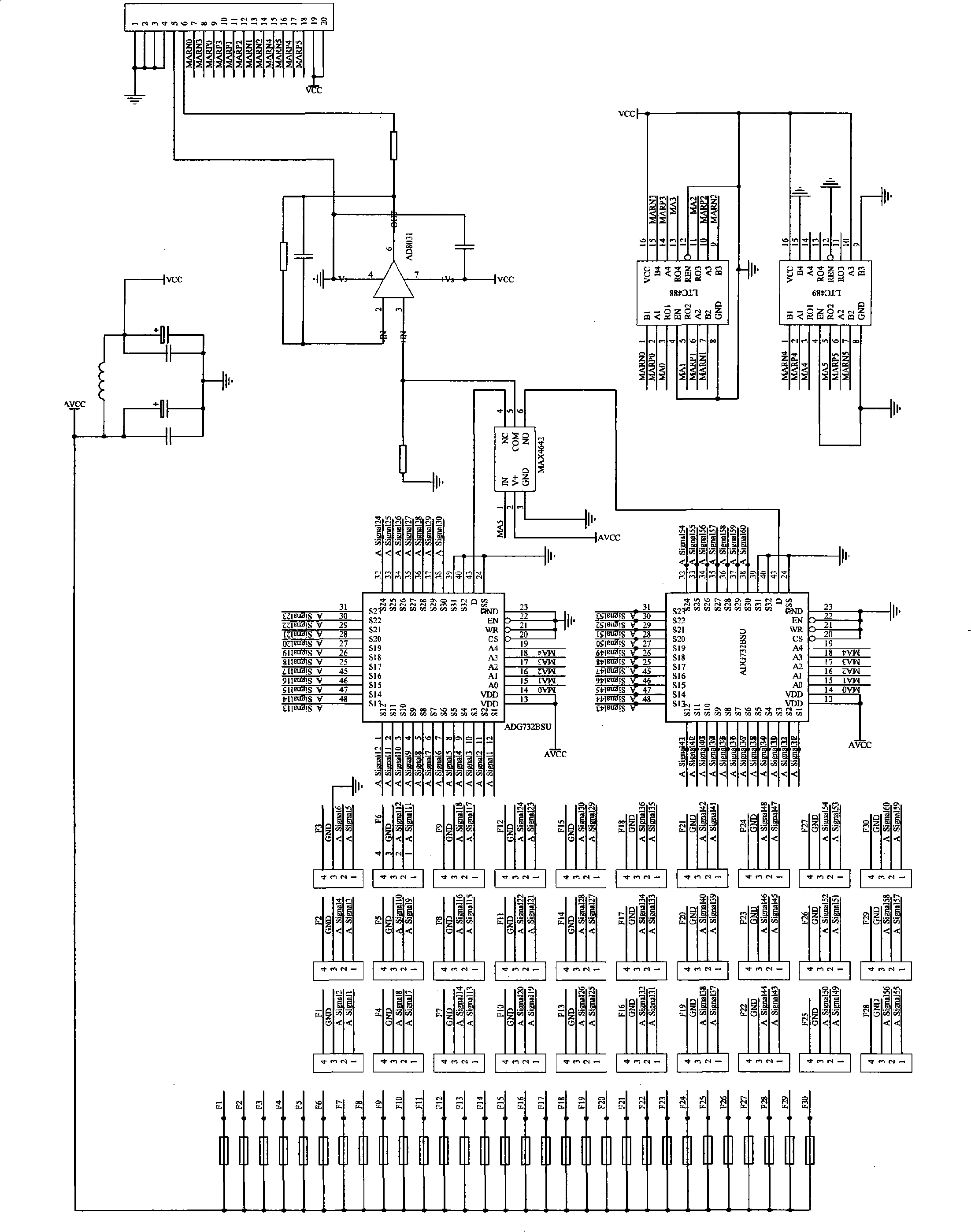

Pipeline leakage detector probe electric cable connection circuit

ActiveCN101334351AReliable degree of corrosionGood corrosionWeather/light/corrosion resistancePipeline systemsAviationComputer module

The invention discloses a buried steel pipeline magnetic-leakage corrosion detector probe cable connecting circuit (SCM) for the online detection of the corrosion degree of buried steel pipelines, which relates to the technical field of the measurement of magnetic variable, the measurement of the linear size of thickness, and pipeline systems, and is characterized in that a plurality of groups of 30-way probe wires are connected on the 32-way multi-way switch of a signal concentration module by a Lemo adaptor, every two outputs of the 32-way multi-way switch are connected with an alternative selector, the output of which is connected with a 55 or 20-core aviation head by a drive, while the 55 or 20-core aviation head is provided with SCM address signal wires respectively connected to the alternative selector, and a power wire connected to a plurality of 32-way multi-way switches, the alternative selector and the drive. The invention overcomes the deficiency of the prior art, and provides a reliable and simple and convenient pipeline magnetic-leakage corrosion detector probe cable connecting circuit for the online detection of the corrosion degree of the pipelines.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

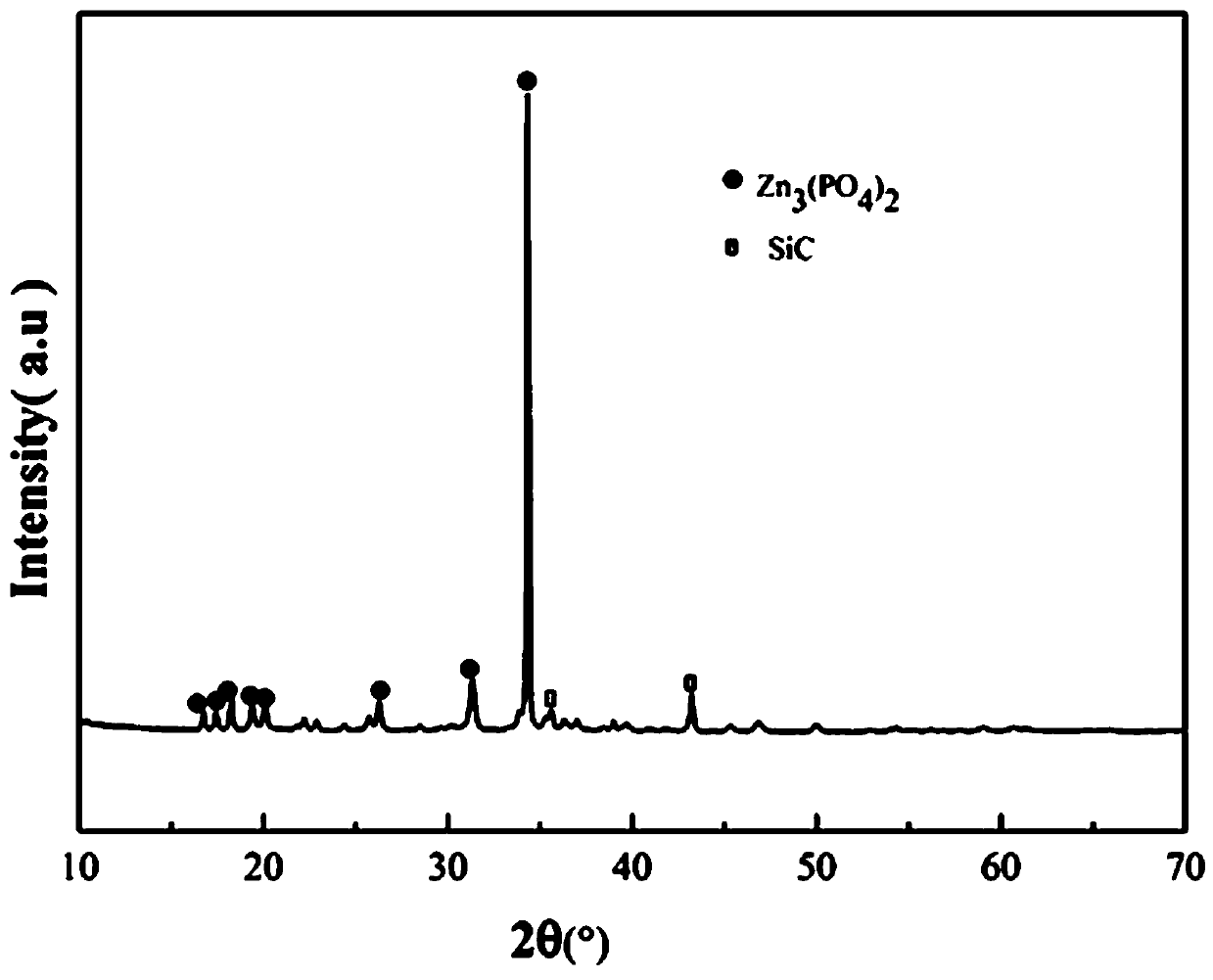

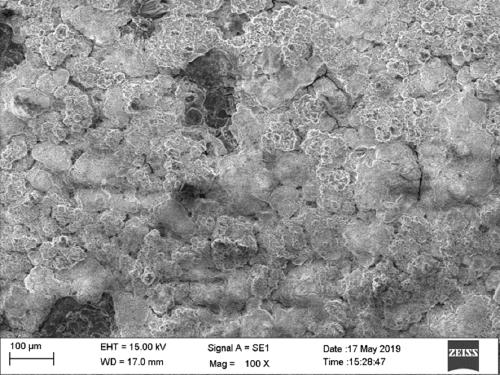

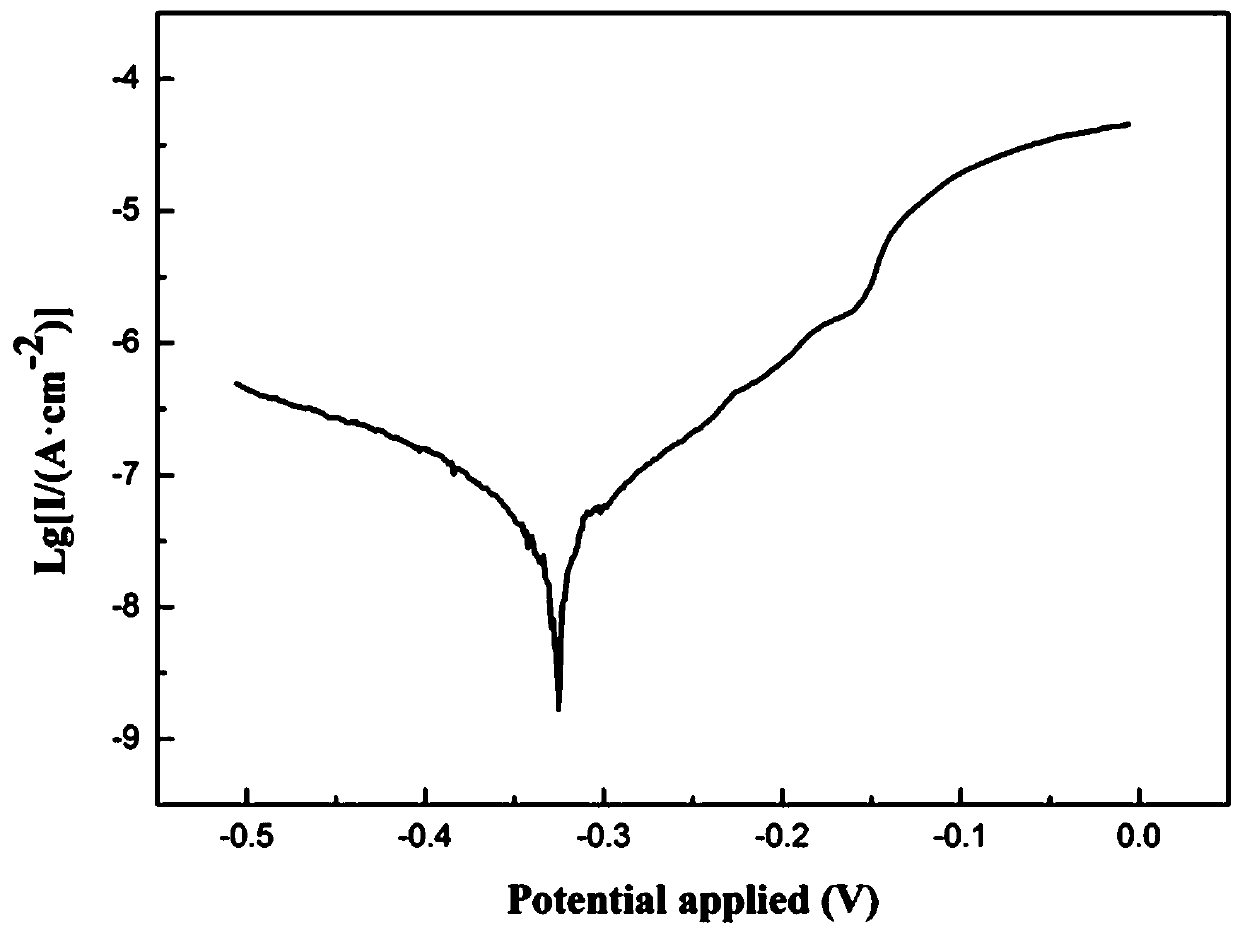

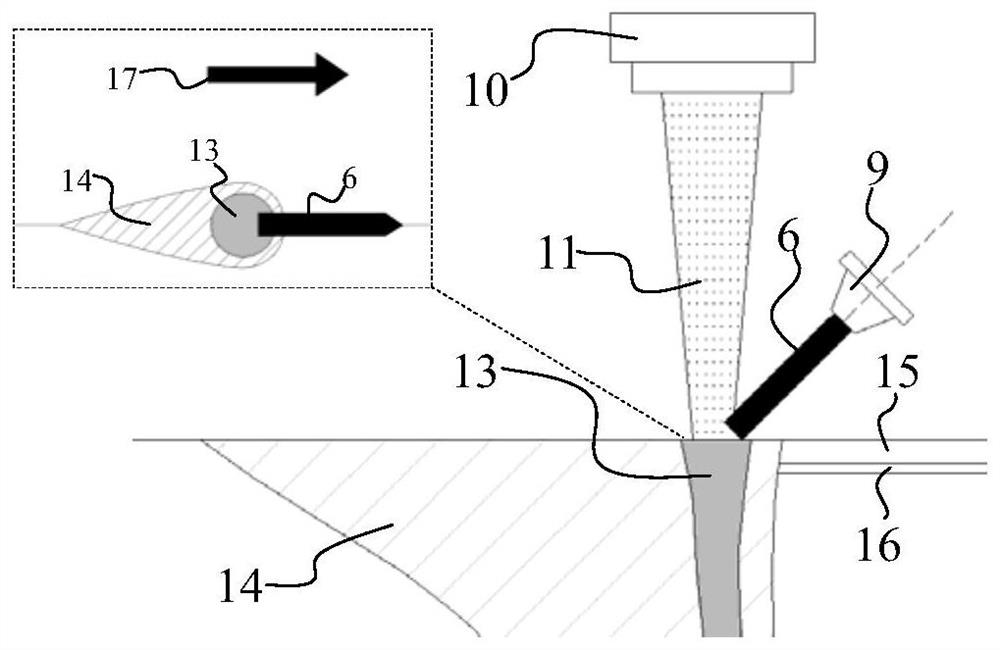

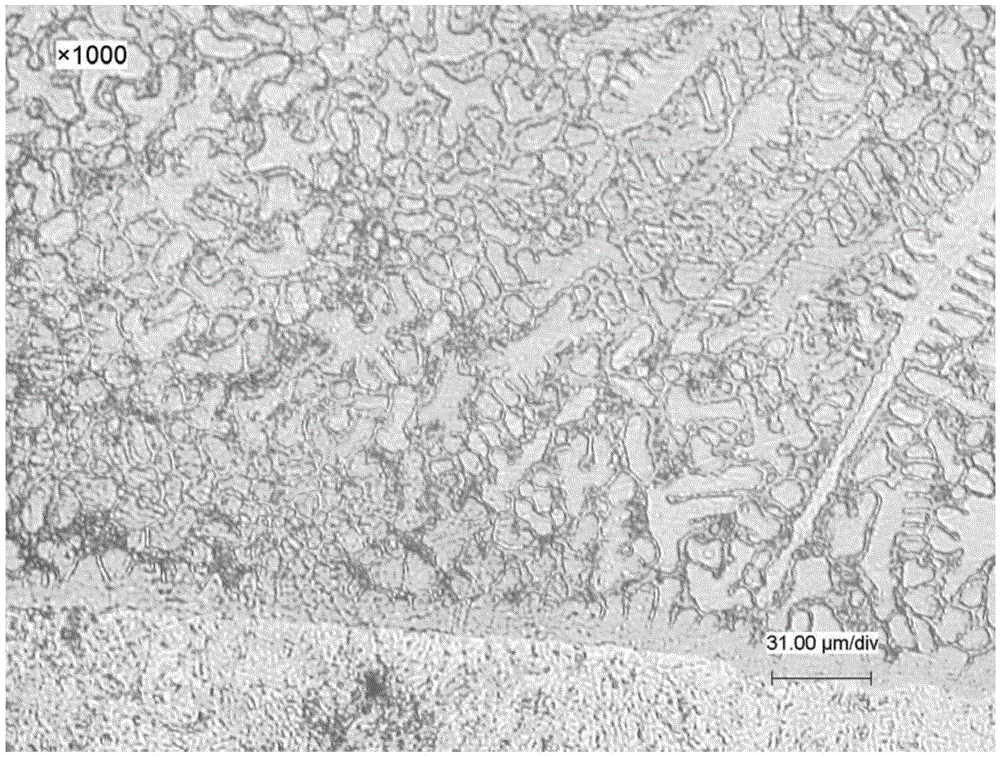

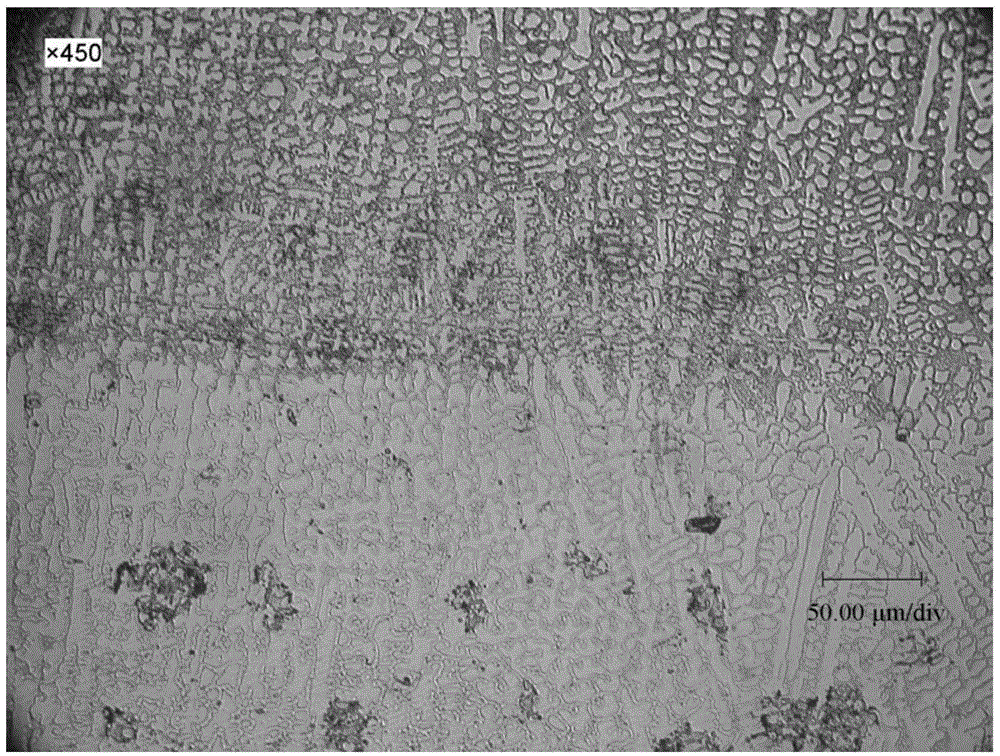

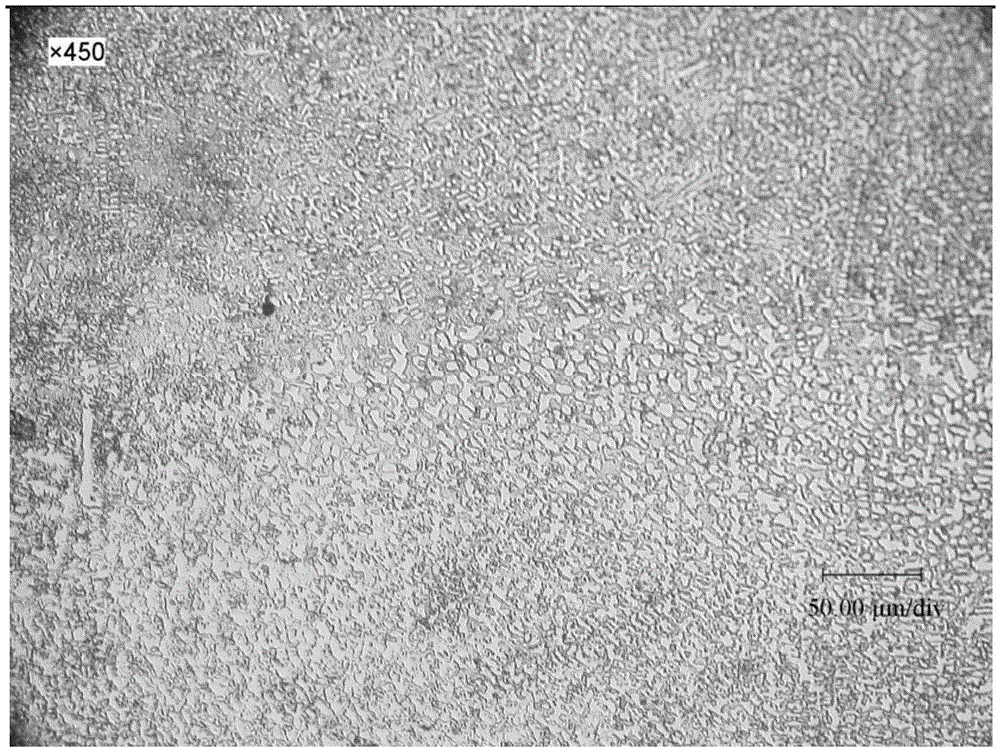

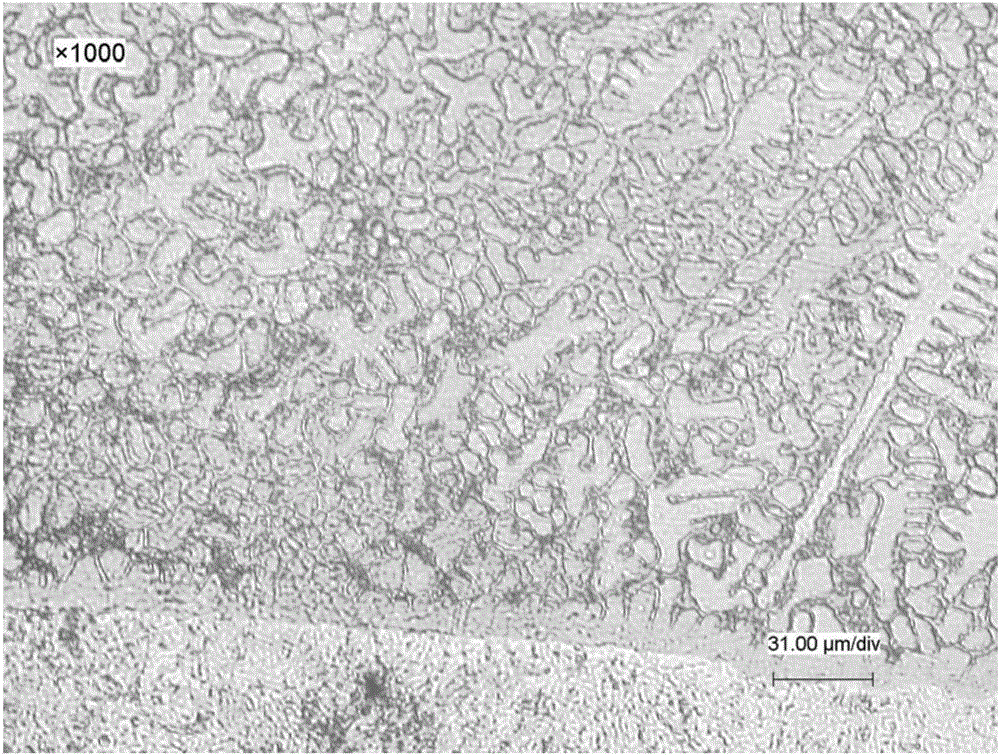

Phosphorizing liquid doped with silicon carbide nanoparticles or hydroxyapatite particlesas well as phosphorizing treatment method of magnesium or magnesium alloy

ActiveCN110423997AEvenly distributedGood corrosionMetallic material coating processesNitratePhosphate

The invention relates to phosphorizing liquid doped with silicon carbide nanoparticles or hydroxyapatite particles. The phosphorizing liquid doped with the silicon carbide nanoparticles or the hydroxyapatite particles comprises the following components includingzinc nitrate, zinc dihydrogen phosphate, phosphoric acid and the 0.001-1 g / Lof silicon carbide nanoparticles or hydroxyapatiteparticles. The phosphorizing liquid is prepared by the following method ofS1, ultrasonically cleaning the silicon carbide nanoparticles or the hydroxyapatite particles and conducting drying; S2, dissolving the zinc nitrate and the zinc dihydrogen phosphate into water, conducting mixing, adding a phosphoric acid solution, adding the silicon carbide nanoparticles or the hydroxyapatite particles, putting a mixture in an ultrasonic environment, mixing for 4-6 minutes, and then obtaining the phosphorizing liquid. A phosphorizing treatment method of magnesium or magnesium alloy comprises the following steps ofperforming pretreatment; immersing the magnesium or magnesium alloy into the phosphorizing liquid and starting ultrasonic waves, wherein the deposition time is 1-20 minutes and the temperature is 40-80 DEG C; and blow-drying after complete washing with water. The phosphorizing liquid is used for performing phosphorizing treatment on the magnesium or magnesium alloy and can effectively increase thenucleation rate and promote grain refinement of a phosphorizing film; and the generated phosphorizing film has excellent corrosion resistance and wear resistance.

Owner:HUNAN INST OF TECH

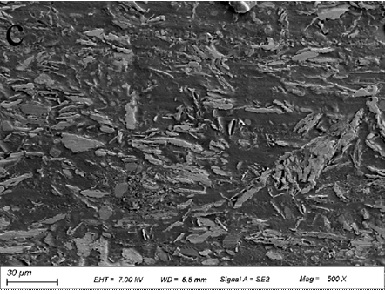

Laser repairing method for allowing roller surface of hot roller to have good thermal hardness after repairing

InactiveCN106567065APositive effectSmall amount of deformationMetallic material coating processesAlloyHardness

The invention relates to a laser repairing method for allowing the roller surface of a hot roller to have good thermal hardness after repairing. A transitional alloy layer, an intermediate alloy layer and a surface alloy layer are arranged on the surface of the hot roller in a laser cladding mode from inside one by one. The alloy powder adopted by the transitional alloy layer comprises, by mass, 0.21%-0.31% of C, 3.2%-3.6% of Si, 1.0%-1.1% of B, 2.2%-2.6% of Fe, 7%-8% of Cr and the balance Ni. The alloy powder adopted by the intermediate alloy layer comprises, by mass, 0.4%-0.5% of C, 3.8%-4.3% of Si, 11.2%-11.93% of B, 2.5%-3.2% of Fe, 10%-12% of Cr and the balance Ni. The alloy powder adopted by the surface alloy layer comprises, by mass, 0.05%-0.1% of C, 3.2%-3.6% of Si, 2%-4% of Fe, 16%-19% of Cr, 27%-30% of Mo and the balance Co. The surface of the hot roller repaired by using the laser repairing method for the hot roller has good abrasion resistance, corrosion resistance and thermal hardness, toughness and strength are taken into account in the interior, and the effect of laser cladding is good.

Owner:DANYANG HONGTU LASER TECH

Cable sheath material used for electric engineering and preparation method of material

InactiveCN107266778AEasy to makeLittle environmental pollutionPlastic/resin/waxes insulatorsAluminium hydroxideAntioxidant

The invention discloses a cable sheath material used for electric engineering, and belongs to the technical field of cable sheath materials. The cable sheath material comprises the following raw materials in parts by weight: 10-20 parts of high-density polyethylene, 70-80 parts of an ethylene-vinyl acetate copolymer, 12-16 parts of fluorosilicone rubber, 8-12 parts of ethylene-propylene-diene-terpolymer rubber, 1-3 parts of stearic acid, 6-8 parts of brominated polystyrene, 7-9 parts of syderolite, 2-4 parts of a phosphate, 5-7 parts of aluminium hydroxide, 6-8 parts of nano-silica, 1-3 parts of an antioxidant, 0.5-1.5 parts of an ultraviolet light absorber, 17-19 parts of a plasticizer and 1-2 parts of an antistatic agent. The invention also discloses a preparation method of the cable sheath material used for electric engineering. The cable sheath material used for electric engineering provided by the invention is simple in preparation, low in environmental pollution, and has good mechanical strength and flame retardance.

Owner:HEFEI SHANGQIANG ELECTRIC TECH CO LTD

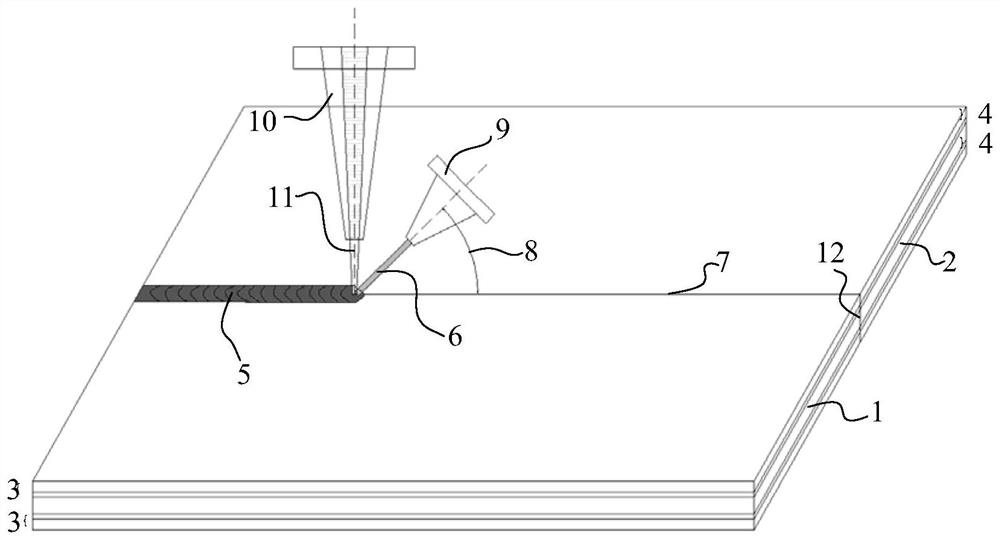

Tailored blank laser welding method for aluminum-silicon coating steel

PendingCN113967789AImprove efficiencyQuality improvementLaser beam welding apparatusStainless steel weldingSteel plates

The invention discloses a tailored blank laser welding method for aluminum-silicon coating steel. The tailored blank laser welding method comprises the following steps that a stainless steel welding wire with the high molybdenum content is selected; two steel plates with aluminum-silicon coatings are taken; butt-joint laser filler wire tailored welding is carried out; and hot stamping is performed after welding. According to the method, the coating does not need to be removed, and splicing of the aluminum-silicon coating steel can be achieved only by filling the welding wires. After hot stamping, a welding head is consistent with a base material in toughness, so that the product quality and the production efficiency are improved.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Preparation method of modified phenolic resin based anti-glare panel

InactiveCN108424665AHigh temperature resistantWith acid and alkali corrosion resistanceFlat articlesChemical reactionOxygen

Owner:常州五荣化工有限公司

Low roller deformation hot roller laser repair method

InactiveCN106567071APositive effectSmall amount of deformationMetallic material coating processesAlloyUltimate tensile strength

The present invention relates to a low roller deformation hot roller laser repair method, wherein a transition alloy layer, an intermediate alloy layer and a surface alloy layer are sequentially subjected to laser cladding on the surface of a hot roller from the inner layer, the components of the alley powder used by the transition alloy layer comprise, by mass, 0.2-0.3% of C, 3.2-3.6% of Si, 1.2-1.8% of B, 2.2-2.6% of Fe, 7-8% of Cr and the balance of Ni, the components of the alley powder used by the intermediate alloy layer comprise, by mass, 0.4-0.5% of C, 3.8-4.3% of Si, 12-13% of B, 2.5-3.2% of Fe, 10-12% of Cr and the balance of Ni, and the components of the alley powder used by the surface alloy layer comprise, by mass, 0.05-0.1% of C, 3.0-3.16% of Si, 2-4% of Fe, 16-19% of Cr, 27-30% of Mo, and the balance of Co. According to the present invention, the hot roller repaired by using the hot roller laser repair method of the present invention has good abrasion resistance, good corrosion resistance and good thermal rigidity of the surface, has good toughness and good strength of the internal, and has good laser cladding effect.

Owner:DANYANG HONGTU LASER TECH

Automobile trim environmental-friendly material and preparation method thereof

InactiveCN106750590AMaterial with better tensile strength and highHigh tensile strengthFiberFlexural strength

The invention discloses an automobile trim environmental-friendly material and a preparation method thereof. The automobile trim environmental-friendly material comprises the following raw materials in parts by weight: 20-35 parts of natural rubber, 10-15 parts of cotton fiber, 10-20 parts of alginate fiber, 2-10 parts of hemp fiber, 20-40 parts of tangerine oil, 4-10 parts of a corrosion inhibitor, 5-15 parts of nano-grade molybdenum trioxide, 2-5 parts of a flame retardant and 5-10 parts of PPA, wherein the corrosion inhibitor comprises the following raw materials in parts by weight: 10-15 parts of zinc carbonate, 2-10 parts of tuff and 5-10 parts of vermiculite; the flame retardant comprises the following raw materials in parts by weight: 6-15 parts of sepiolite powder, 5-8 parts of stearic acid, 2-5 parts of molybdenum trioxide, 1-5 parts of ruthenium oxide and 50-100 parts of water. The automobile trim environmental-friendly material is relatively good in tension strength, bending strength and impact strength, is good in product appearance and relatively good in corrosion resistance and flame retardancy, is relatively safe and is easy in raw material obtaining, simple in production process and low in production cost.

Owner:ZHENGZHOU LIFUAI BIOLOGICAL TECH CO LTD

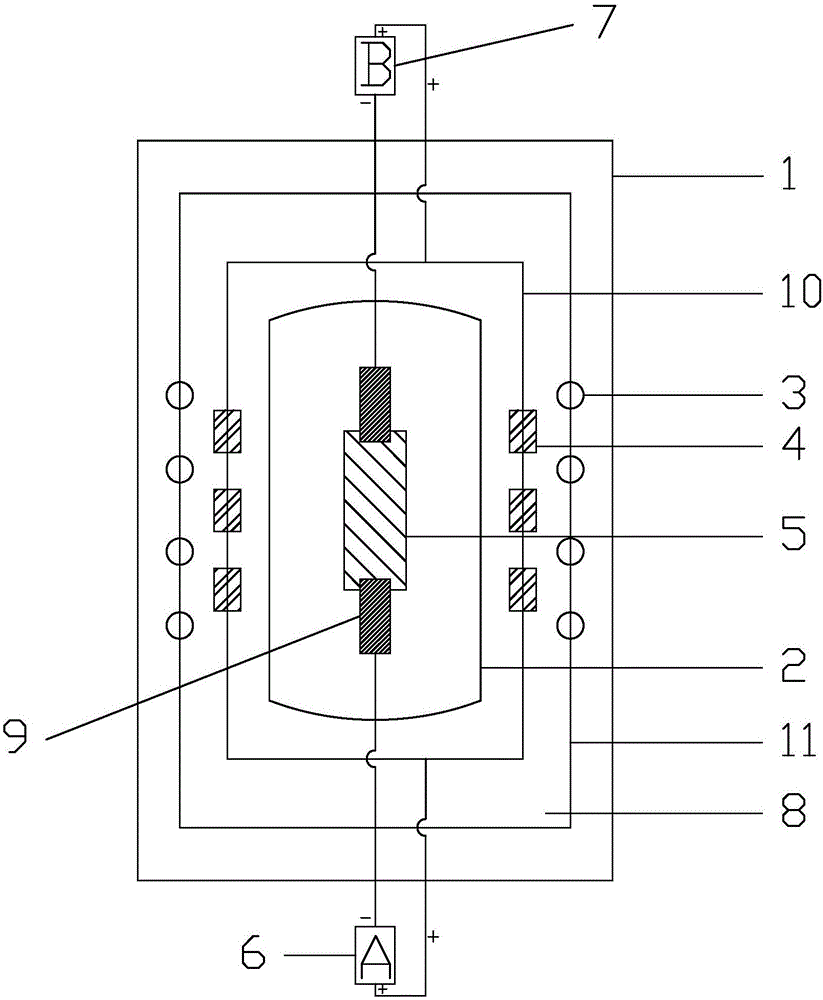

Tin-zinc alloy plating device and technology with barrel plating bath

The invention discloses a tin-zinc alloy plating device and technology with a barrel plating bath. The device comprises the plating bath, a rolling barrel, at least two power rectifiers, anode assemblies electrically connected to positive electrodes of the power rectifiers and cathode work-pieces connected to negative electrodes of the power rectifiers, wherein the anode assemblies and the cathode work-pieces are oppositely arranged inside the plating bath; each anode assembly comprises at least one soluble anode and at least one insoluble anode; and the soluble anodes are composed of one or two kinds of tin sheets and tin-zinc plates. According to the plating device and technology, the tin content in plating layers can be effectively controlled to be 70+ / -12%, crystals are fine, the tin-zinc alloy content proportion is stable after work-pieces are plated, the corrosion resistance and the welding performance are good, and the electric conductivity and the electrical resistance are low.

Owner:厦门同恒金属有限公司

Multifunctional heavy anti-corrosion coating as well as preparation method and application thereof

ActiveCN114106679AHas a negative moisture-sensitive characteristicResists scour and abrasionAntifouling/underwater paintsPaints with biocidesFirming agentN-Butyl Alcohol

The invention discloses a multifunctional heavy anti-corrosion coating which consists of a component A and a component B. The component A is prepared from the following components in percentage by weight: 60 to 70 percent of waterborne epoxy emulsion, 5.5 to 8.3 percent of MgCr2O4-TiO2 ceramic powder, 0.6 to 1.0 percent of polymer nonionic dispersant, 0.9 to 1.2 percent of organic silicon defoaming agent, 0.5 to 0.8 percent of polyether modified polydimethylsiloxane, 0.3 to 0.4 percent of DP-10 adhesion promoter, 0.8 to 1.1 percent of bentonite and 15 to 30 percent of deionized water; and the component B comprises the following components in percentage by weight: 40-55% of seashell powder composite zinc-aluminum flake powder, 35-40% of a polyurethane curing agent and 5-25% of n-butyl alcohol. The invention further discloses a preparation method and application of the multifunctional heavy anti-corrosion coating. Good mechanical properties of the coating are guaranteed, and seawater erosion and abrasion are effectively resisted.

Owner:NANJING INST OF TECH

A hot roller laser restoration method capable of prolonging the service lifetime of a hot roller

InactiveCN106567064APositive effectSmall amount of deformationMetallic material coating processesRestoration methodWear resistance

The invention relates to a hot roller laser restoration method capable of prolonging the service lifetime of a hot roller. A transitional alloy layer, a middle alloy layer and a surface alloy layer are cladded with laser layer by layer from the inside on the surface of the hot roller. Alloy powder adopted by the transitional alloy layer includes components by mass: 0.12-0.19% of C, 3.2-3.6% of Si, 1.2-1.8% of B, 2.2-2.6% of Fe, and 7-8% of Cr, with the balance being Ni. Alloy powder adopted by the middle alloy layer includes components by mass: 0.4-0.5 % of C, 3.8-4.3% of Si, 12-13% of B, 2.5-3.2% of Fe, and 10-12% of Cr, with the balance being Ni. Alloy powder adopted by the surface alloy layer includes components by mass: 0.05-0.1% of C, 3.0-3.16% of Si, 2-4% of Fe, 16-19% of Cr and 27-30% of Mo, with the balance being Co. The surface of the hot roller restored by the method has good wear resistance, corrosion resistance and hot hardness, both toughness and strength of the inside of the hot roller are taken into account, and laser cladding effects are good.

Owner:DANYANG HONGTU LASER TECH

Laser repairing method of hot roll good in laser cladding effect

InactiveCN106567069APositive effectSmall amount of deformationSuperimposed coating processToughnessRepair method

The invention relates to a laser repairing method of a hot roll good in laser cladding effect. The surface of the hot roll is laser-cladded with a transition alloy layer, an intermediate alloy layer and a surface alloy layer from the inside layer by layer; alloy powder adopted by the transition alloy layer comprises, by mass, 0.21-0.31% of C, 3.2-3.6% of Si, 1.0-1.1% of B, 2.2-2.6% of Fe, 7-8% of Cr and the balance Ni; alloy powder adopted by the intermediate alloy layer comprises, by mass, 0.4-0.5% of C, 3.8-4.3% of Si, 11.2-11.93% of B, 2.5-3.2% of Fe, 10-12% of Cr and the balance Ni; and alloy powder adopted by the surface alloy layer comprises, by mass, 0.05-0.1% of C, 3.0-3.16% of Si, 2-4% of Fe, 16-19% of Cr, 27-30% of Mo and the balance Co. The hot roll repaired by the laser repairing method of the hot roll good in laser cladding effect has good abrasion resistance, corrosion resistance and hot hardness in surface, integrates toughness and strength inside, and is good in laser cladding effect.

Owner:DANYANG HONGTU LASER TECH

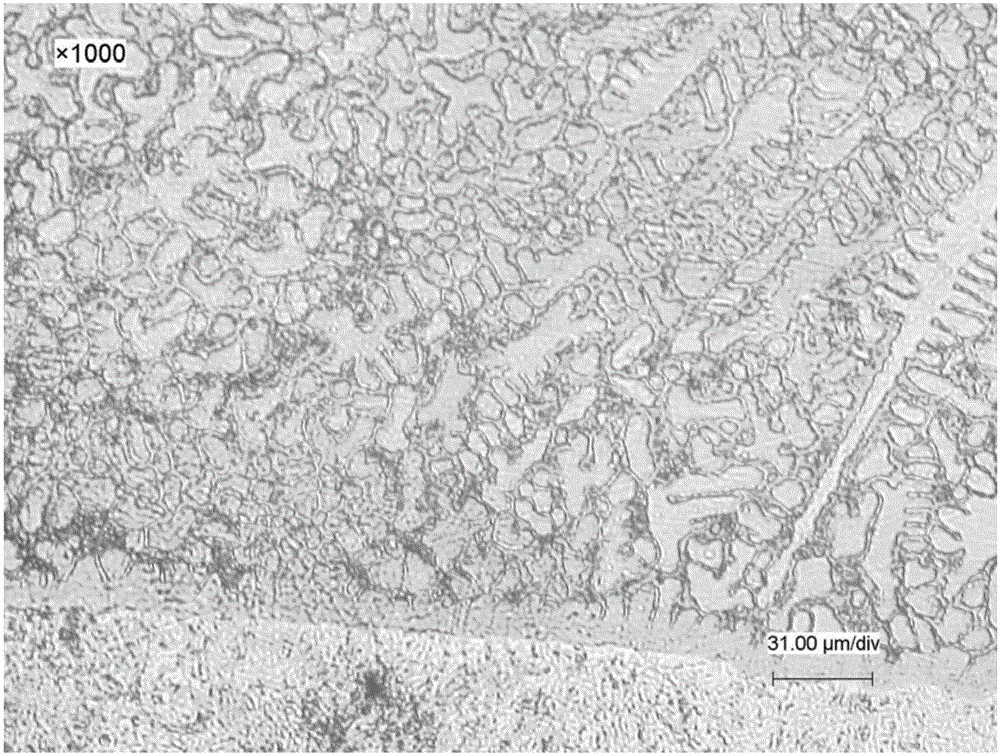

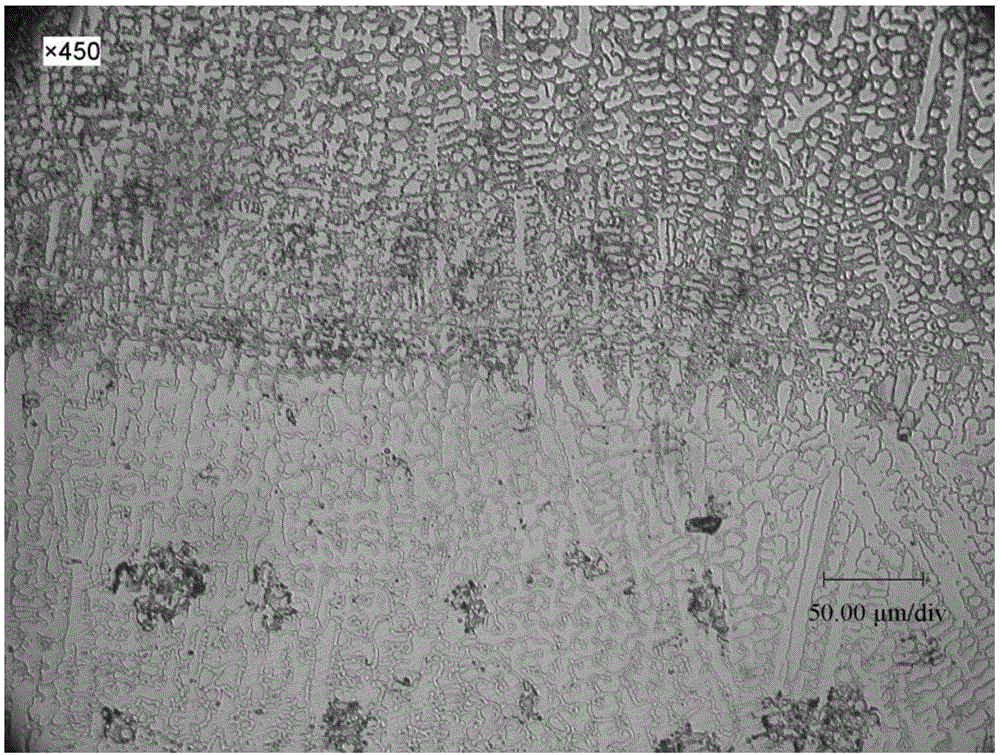

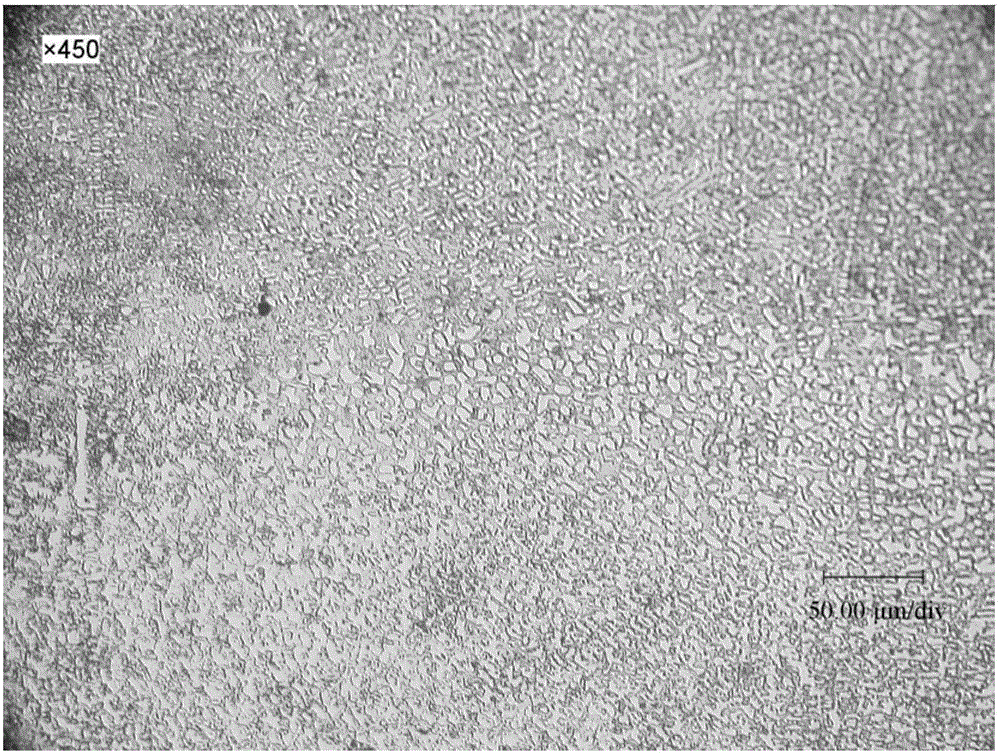

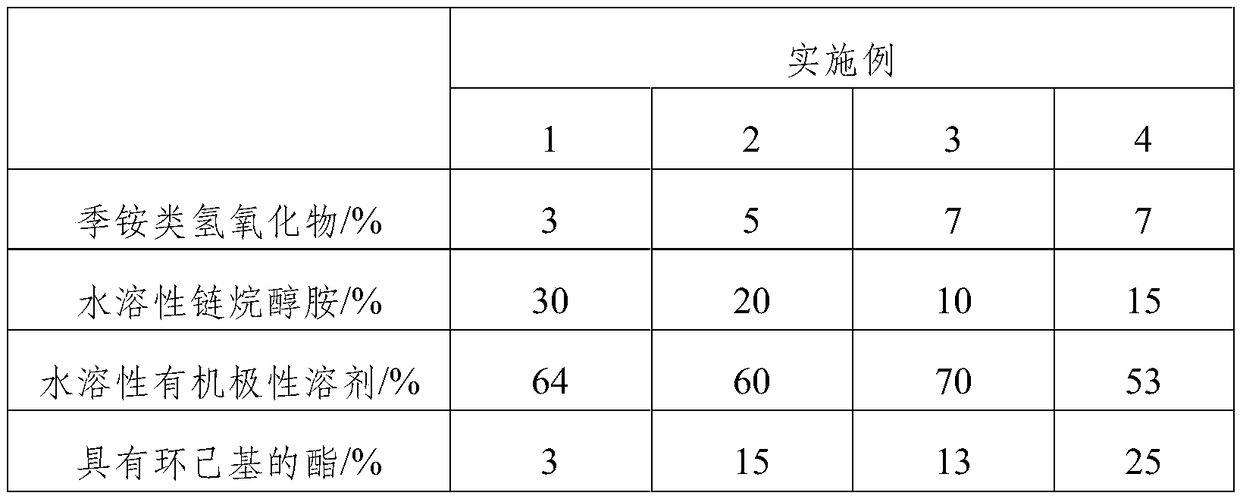

A positive photoresist stripping cleaning composition and application thereof

ActiveCN109164686AImprove performanceGood corrosionPhotosensitive material processingAlcoholWater soluble

A positive photoresist stripping cleaning composition is disclosed and is composed of quaternary ammonium hydroxide, water-soluble alkanolamine, water-soluble organic polar solvent and ester compoundwith cyclohexyl group. A positive photoresist stripping cleaning composition contains an ester compound having a cyclohexyl group, the esters are stable in alkaline organic phase, The quaternary ammonium hydroxide ionizes in the aqueous washing solution to form hydroxide ion, the aqueous washing solution is alkaline, and the ester compound with cyclohexyl group hydrolyzes in alkaline condition toform acid and alcohol and keep the reaction balance, the acid can neutralize hydroxide ion in the alkaline solution quickly, and improve the corrosion degree of the metal layer on the wafer surface inthe washing process. The invention also discloses the application of a positive photoresist stripping cleaning composition in a substrate photoresist stripping process.

Owner:JIANGYIN JIANGHUA MICROELECTRONICS MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com