High-ductility, corrosion-resistant and ultra/extra-thick crystalline cemented carbide and preparation method thereof

A cemented carbide, corrosion-resistant technology, applied in the field of powder metallurgy materials, can solve problems such as reducing the fracture toughness of alloys, and achieve the effect of good acid/alkali resistance and oxidation corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

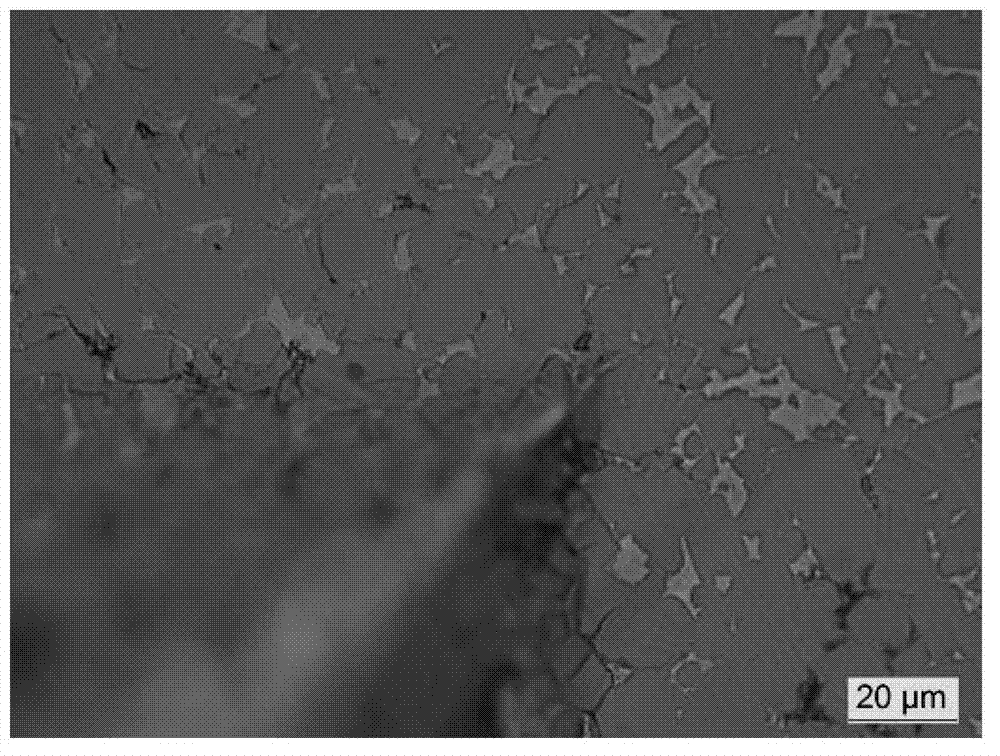

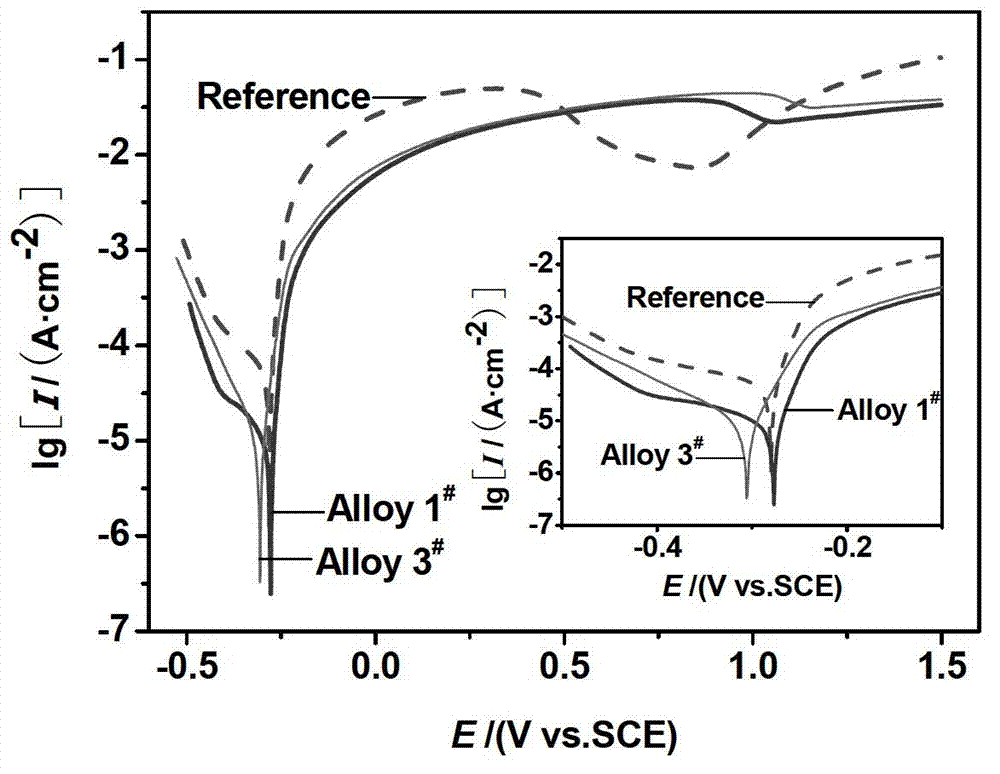

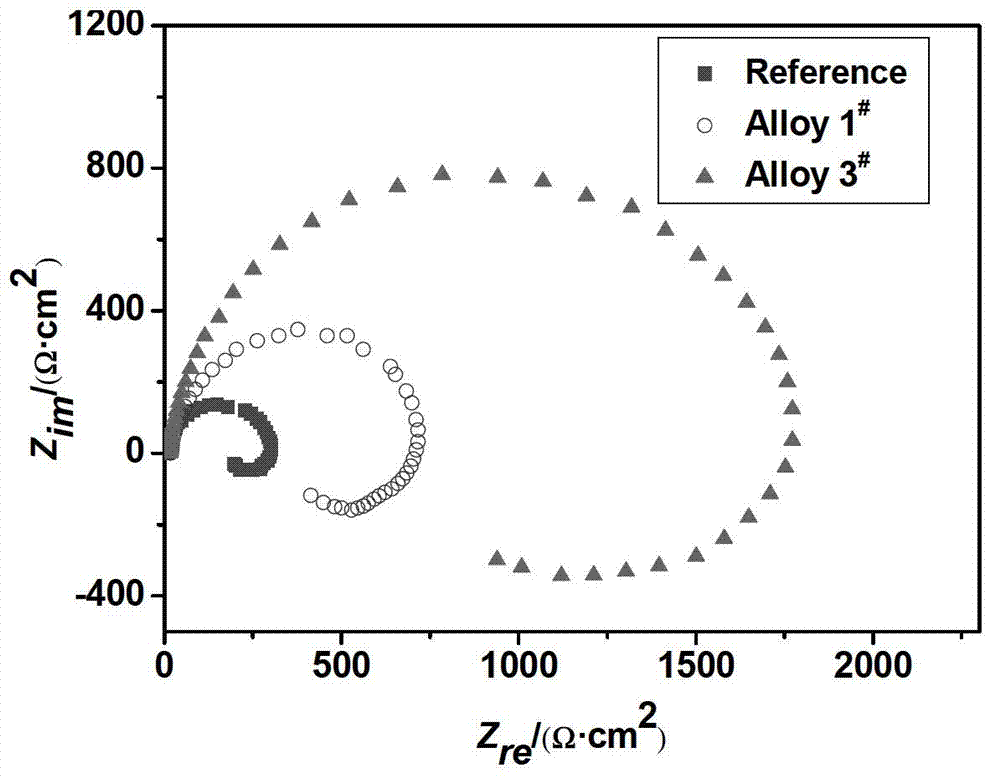

[0016] Using WC powder with a grain size of 7 μm and Cr with a Fischer grain size of 1.02 μm 3 C 2 powder as raw material, according to the mass fraction of WC-8%Co-0.4%Cr 3 C 2 (1# alloy) composition ratio, using stirring method to make the containing WC and Cr 3 C 2 The raw material powder is suspended in the cobalt hydroxide alkaline slurry with an initial pH value of 10.5, and the cobalt hydroxide alkaline slurry is reduced at 150°C for 8 hours under a hydrogen pressure of 4.5MPa to prepare a nano-assembly structure Co-coated WC Compound powder. Then, in a hydrogen atmosphere at 650 °C, the nano-assembled Co-coated WC composite powder was subjected to diffusion homogenization and Co-coated densification to form Co densely coated WC composite powder. Then, 2.0% PEG forming agent was added to the Co densely coated WC composite powder, and the composite powder mixed with the forming agent was dried and granulated. Liquid phase sintering was carried out at 1430°C in a pr...

Embodiment 2

[0024] Using WC powder with a grain size of 7 μm and Cr with a Fischer grain size of 1.02 μm 3 C 2 powder and La with a specific surface area average diameter of 73.1nm 2 o 3 Powder is the raw material, according to the mass fraction, it is WC-8%Co-0.4%Cr 3 C 2 -0.048%La 2 o 3 (2# alloy) composition ratio, using stirring method to make the containing WC, Cr 3 C 2 and La 2 o 3 The raw material powder is suspended in the cobalt hydroxide alkaline slurry with an initial pH value of 11.5, and the cobalt hydroxide alkaline slurry is reduced at 180°C for 2 hours under a hydrogen pressure of 2.5MPa to prepare a nano-assembly structure Co-coated WC Compound powder. Then, in a hydrogen atmosphere at 600 °C, the nano-assembled Co-coated WC composite powder was subjected to diffusion homogenization and Co-coated densification to form a Co densely coated WC composite powder. Then, a paraffin wax forming agent accounting for 2.5% of the total mass fraction of the composite powde...

Embodiment 3

[0026] Using WC powder with a grain size of 7 μm and Cr with a Fischer grain size of 1.02 μm 3 C 2 Rare earth (RE)-Co pre-alloyed powder of -200 mesh, containing 65% Co with a mass fraction of Co of 65% as raw materials, according to the mass fraction of WC-8%Co-0.4% Cr 3 C 2 – 0.048% RE (3# alloy) composition ratio, using stirring method to make the containing WC, Cr 3 C 2 and RE–Co pre-alloyed powders were suspended in cobalt hydroxide aqueous slurry with initial pH value of 11.5, hydrazine hydrate N 2 h 4 ·H 2 O is the reducing agent, select N 2 h 4 ·H 2 O:Co 2+ The molar ratio of the cobalt hydroxide is 3:1, and the cobalt hydroxide aqueous slurry is reduced at 60 °C under normal pressure to prepare a nano-assembly structure Co-coated WC type composite powder. Then, in a hydrogen atmosphere at 700 °C, the nano-assembly structure Co-coated WC composite powder was diffused and homogenized, and the Co coating was densified to form a Co densely coated WC composite p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com