Graphene anticorrosion aqueous coating for magnesium alloy, and preparation method and application thereof

A water-based coating and graphene technology, applied in anti-corrosion coatings, coatings, devices for coating liquids on surfaces, etc., can solve the problems of physical health threats to constructors, poor dispersion stability of pigments and fillers, hindering metal protection applications, etc. The effect of high ecological value and popularization and application value, good dispersion and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

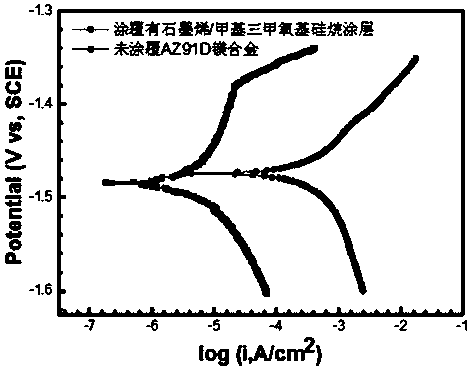

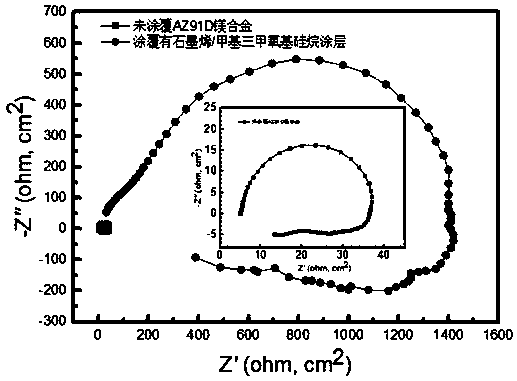

[0021] The invention relates to a method for preparing a graphene anti-corrosion water-based coating for magnesium alloys, which is characterized in that it comprises the following steps: firstly prepare a graphene / methyltrimethoxysilane dispersion, and then coat the surface of the AZ91D magnesium alloy with 2- The 3-layer graphene / methyltrimethoxysilane dispersion is coated by rod coating, and then dried and cured in a drying oven at 80-100°C to obtain a graphene anti-corrosion water-based coating for magnesium alloys.

[0022] Further, the preparation method of the graphene oxide / methyltrimethoxysilane dispersion comprises the following steps: uniformly mixing graphene oxide, methyltrimethoxysilane, absolute ethanol and deionized water to obtain a mixed material , and then add polyethylene glycol therein, and continue stirring for 20-30 minutes to obtain a graphene oxide / methyltrimethoxysilane dispersion.

[0023] Preferably, the volume ratio of graphene oxide, methyltrimeth...

Embodiment 1

[0030] Embodiment 1 provides a kind of preparation method of graphene anticorrosion water-based coating for magnesium alloy, comprises the steps:

[0031] 1) Pretreatment, the steps are as follows: grind the AZ91D magnesium alloy with sandpaper, polish, ultrasonically clean, then rinse with distilled water, and ultrasonically clean with absolute ethanol for 15 minutes.

[0032] 2) Preparation of graphene oxide / methyltrimethoxysilane dispersion: add 80ml of deionized water, 4ml of methyltrimethoxysilane and 12ml of absolute ethanol into a 100ml beaker, and stir magnetically for 15min at a temperature of 25°C , then add 0.8ml graphene oxide (1mg / ml) and 0.05% polyethylene glycol and continue to stir for 50min to obtain a mixed solution, and finally process the mixed solution by centrifugation to obtain graphene oxide / methyltrimethoxysilane Dispersions;

[0033] 3) Preparation of graphene oxide composite coating: apply graphene oxide / methyltrimethoxysilane dispersion on the surf...

Embodiment 2

[0036] Embodiment 2 provides a kind of preparation method of graphene anticorrosion water-based coating for magnesium alloy, comprises the steps:

[0037] 1) Pretreatment, the steps are as follows: The sample material used in Example 2 is AZ91D magnesium alloy, which is ground, polished, and ultrasonically cleaned with 2000# sandpaper, then rinsed with distilled water, and ultrasonically cleaned with absolute ethanol for 10 minutes.

[0038] 2) Preparation of graphene oxide / methyltrimethoxysilane dispersion: add 80ml of deionized water, 4ml of methyltrimethoxysilane and 12ml of absolute ethanol into a 100ml beaker, and stir magnetically for 15min at a temperature of 25°C , then add 2ml graphene oxide (1mg / ml) and 0.05% polyethylene glycol and continue to stir for 50min to obtain a mixed solution, and finally process the mixed solution by an off-method to obtain a graphene oxide / methyltrimethoxysilane dispersion body;

[0039] 3) Preparation of graphene oxide composite coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com