Wear-resisting chain

A technology of chain and wear-resistant layer, applied in the chain field, to achieve the effect of good surface lubricity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The foregoing and other technical content, features, and effects of the present invention will be clearly presented in the following detailed description of a preferred embodiment with reference to the drawings.

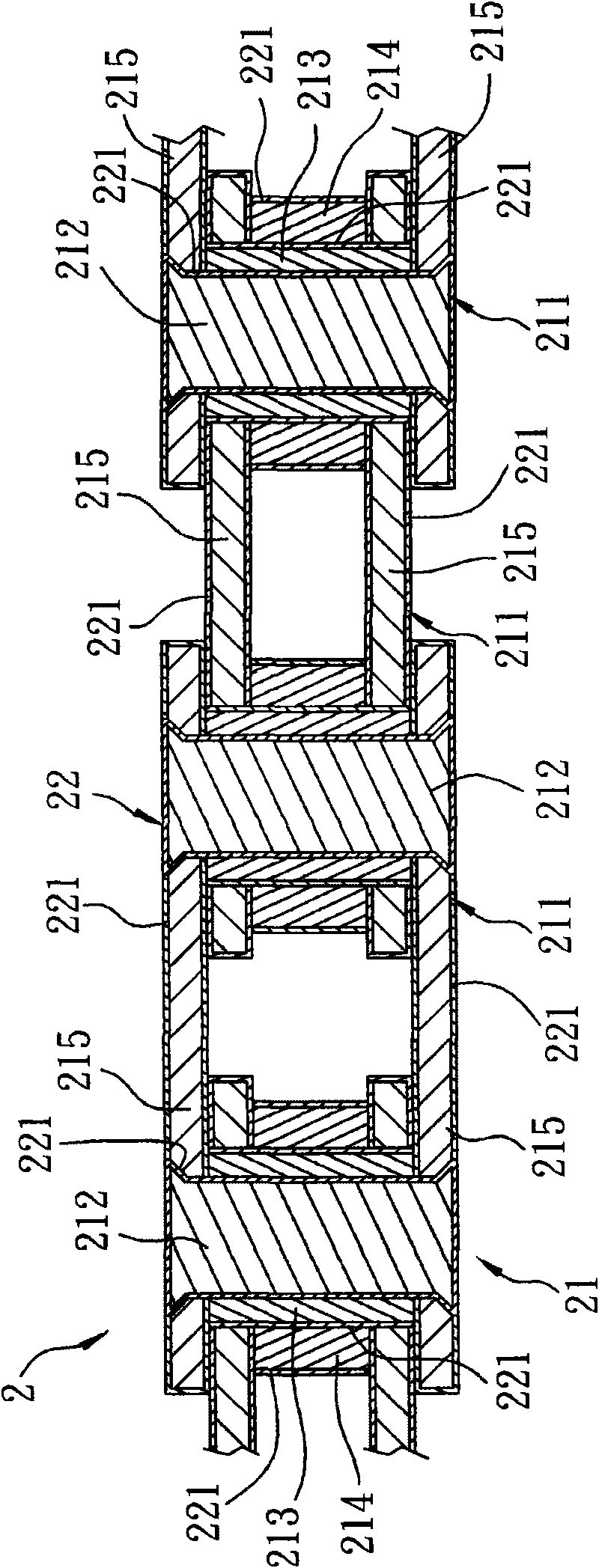

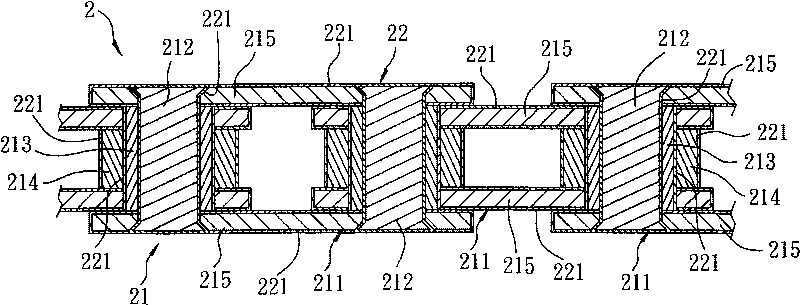

[0009] Such as figure 1 As shown, the preferred embodiment of the wear-resistant chain 2 of the present invention includes a chain body 21 and a wear-resistant layer unit 22. The chain body 21 includes a plurality of chain links 211 that are stacked inside and outside, a plurality of chain pins 212 used to connect the plurality of chain links 211 in series, and a plurality of bushings respectively looped on a circumferential surface of the plurality of chain pins 212 213. A plurality of chain rollers 214 respectively looped on a peripheral surface of the plurality of bushes 213, and a wear-resistant layer unit 22.

[0010] Each chain link 211 has two chain pieces 215 facing away from each other. Each chain pin 212 is used to combine two adjacent chain links 211 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com