Tailored blank laser welding method for aluminum-silicon coating steel

A laser tailor welding and coating technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of increasing thermal deformation of plates, unfavorable for thin plate splicing, increased heat input, etc., and achieves excellent corrosion resistance The effect of sex and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

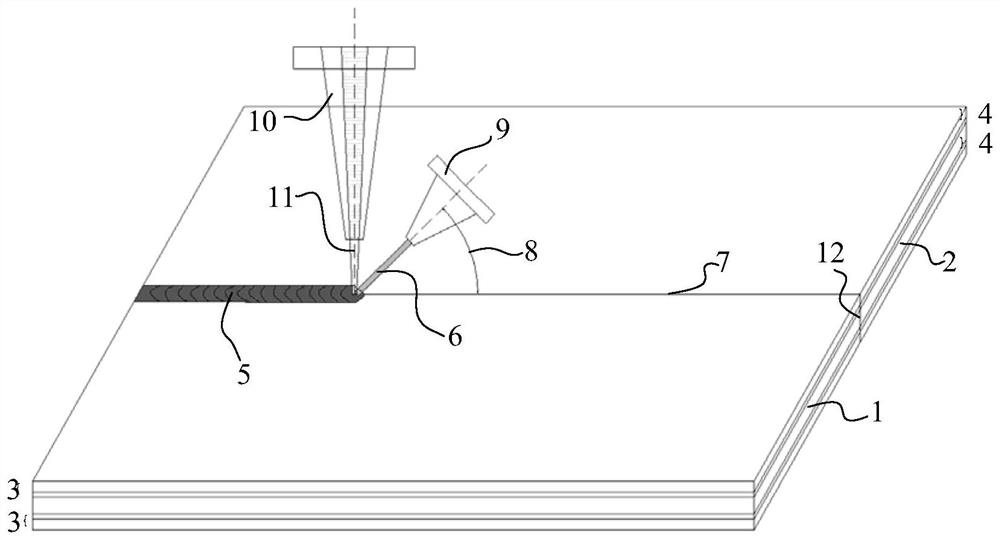

[0049] A laser tailor welding method for aluminum-silicon coated steel, comprising the following steps:

[0050] S1. Take two 1.4 mm thick aluminum-silicon-coated steel plates cut by a plate shearing machine. The microstructure of the steel plate is ferrite and pearlite. Use alcohol to clean the oil stains on the two steel plates for purification.

[0051] S2. Splicing and fixing the two steel plates on the welding table through clamps, and splicing them with zero gap.

[0052] S3. Use a fiber laser and set the welding parameters for wire filling: laser power 5500W, laser scanning speed 3.6m / min, laser spot diameter 0.98mm, no protective gas during welding, wire feeding speed 4m / min, wire feeding The angle is 45°.

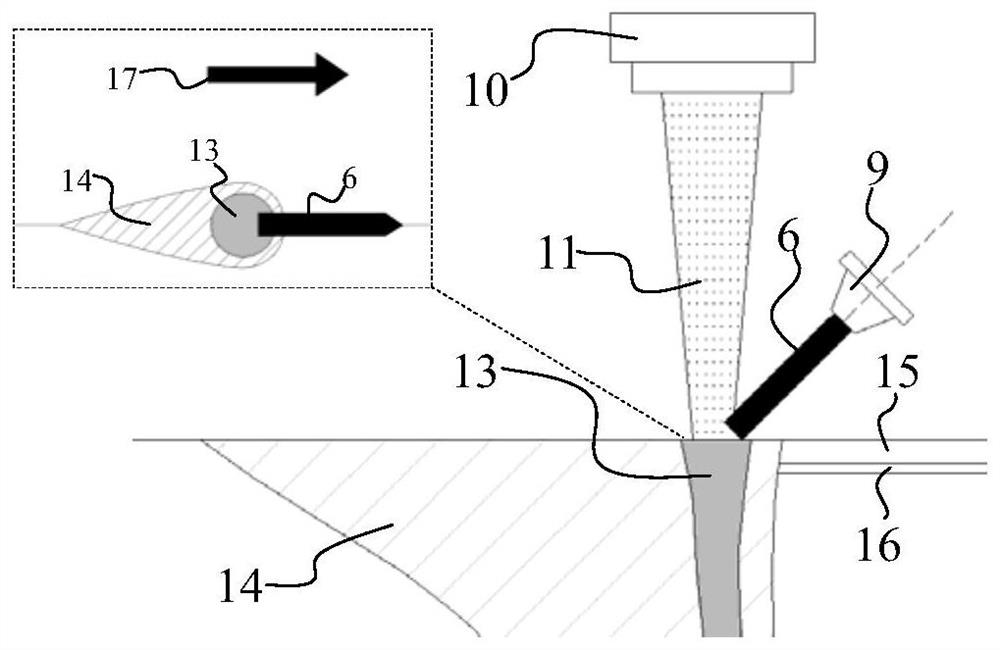

[0053] S5. The fiber laser emits laser light to irradiate the joint of two pieces of steel, and at the same time, the welding wire is fed to the molten pool by the wire feeding nozzle. The molten welding wire mixes with the molten butt joint area of the two pi...

Embodiment 2

[0057] A laser tailor welding method for aluminum-silicon coated steel, comprising the following steps:

[0058] S1. Take two 1.4 mm thick aluminum-silicon-coated steel plates cut by a plate shearing machine. The microstructure of the steel plate is ferrite and pearlite. Use alcohol to clean the oil stains on the two steel plates for purification.

[0059] S2. Splicing and fixing the two steel plates on the welding table through clamps, and splicing them with zero gap.

[0060] S3. Use a fiber laser and set welding parameters: laser power 5500W, laser scanning speed 4.2m / min, laser spot diameter 0.98mm, no shielding gas during welding. The wire feeding speed is 3m / min, and the wire feeding angle is 45°.

[0061] S5. The fiber laser emits laser light to irradiate the joint of two pieces of steel, and at the same time, the welding wire is fed to the molten pool by the wire feeding nozzle. The molten welding wire mixes with the molten butt joint area of the two pieces of ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com