Transfer sheet comprising a fluororesin layer containing reflective particles,and exterior laminate sheet comprising a fluororesin layer containing reflective particles, and method for manufacturing t

A technology of light-reflecting particles and fluororesin layer, applied in the direction of copying/marking method, patterns and coatings characterized by light projection effect, can solve problems such as difficulty in dissolving or melting, maximize decorative effect, and easily form curved surfaces. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

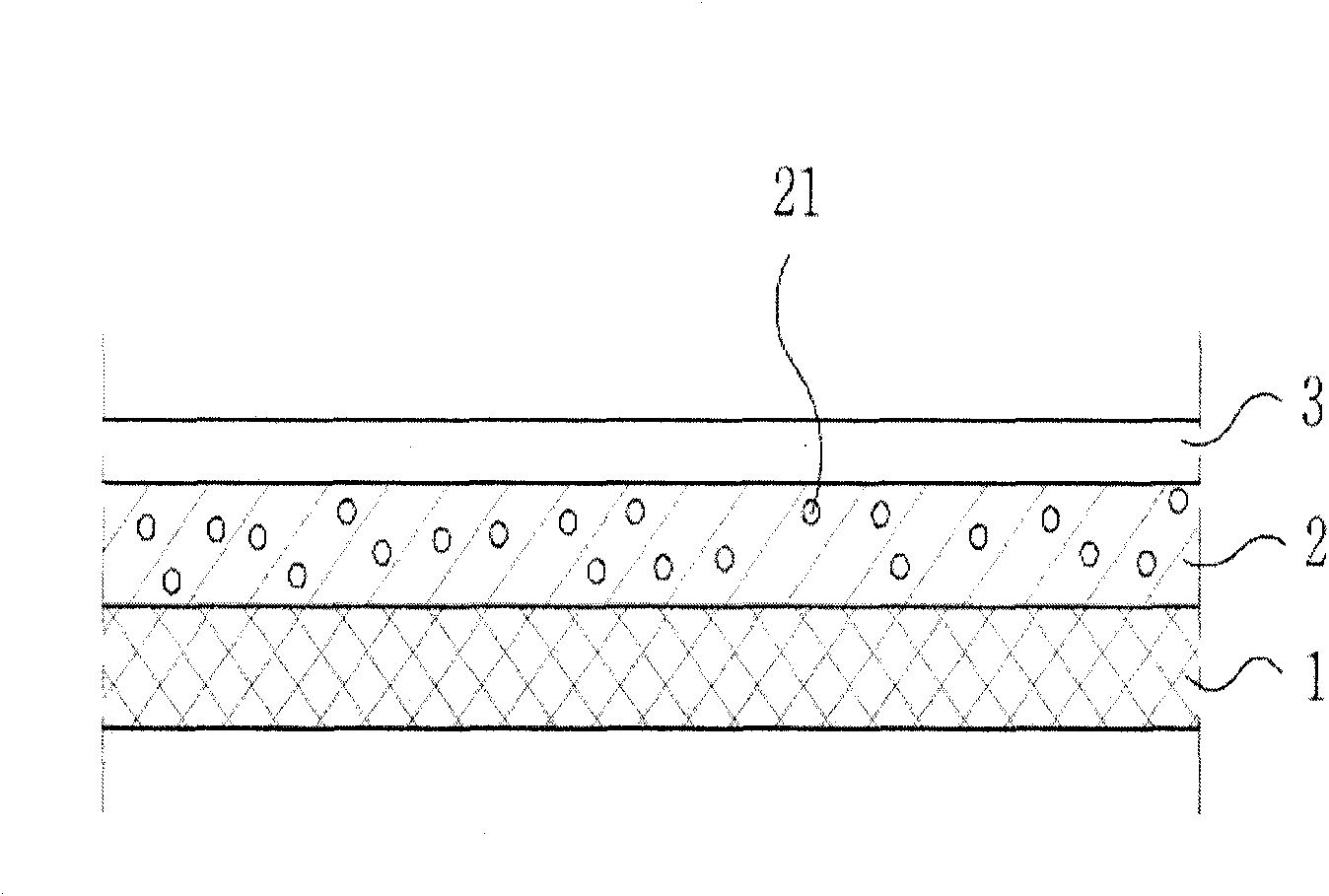

[0046] A transfer sheet according to the present invention was prepared by dissolving 300 g of a fluoropolyisocyanate resin as a fluororesin in 700 g of toluene to prepare a fluororesin solution, mixing 50 g of glass particles having an average particle diameter of 20 μm with 1 kg of the fluororesin The solutions were mixed and uniformly dispersed therein to prepare a fluororesin coating solution, and then the fluororesin coating solution was coated on one side of a polyethylene terephthalate film having a thickness of 75 μm as a carrier film 1, so that The film was dried to a thickness of 1 μm to form a fluororesin layer 2 , dried at a temperature of 100° C. and coated with an acrylic adhesive in a thickness of 2 μm on top of the fluororesin layer to form an adhesive layer 3 .

Embodiment 2

[0048] In addition to dissolving 500 g of fluoropolyisocyanate resin as a fluororesin in 500 g of toluene to prepare a fluororesin solution, mixing 1 g of pearlescent particles having an average particle diameter of 20 μm with 1 kg of the fluororesin solution and uniformly dispersing therein to prepare a fluororesin coating layer solution, and on one side of a polyethylene terephthalate film with a thickness of 75 μm as the carrier film 1, coat the fluororesin coating solution so that the thickness of the film after drying is 5 μm to form the fluororesin layer 2. , the transfer sheet according to the present invention was prepared by the same conditions and method as in Example 1.

[0049]

Embodiment 3

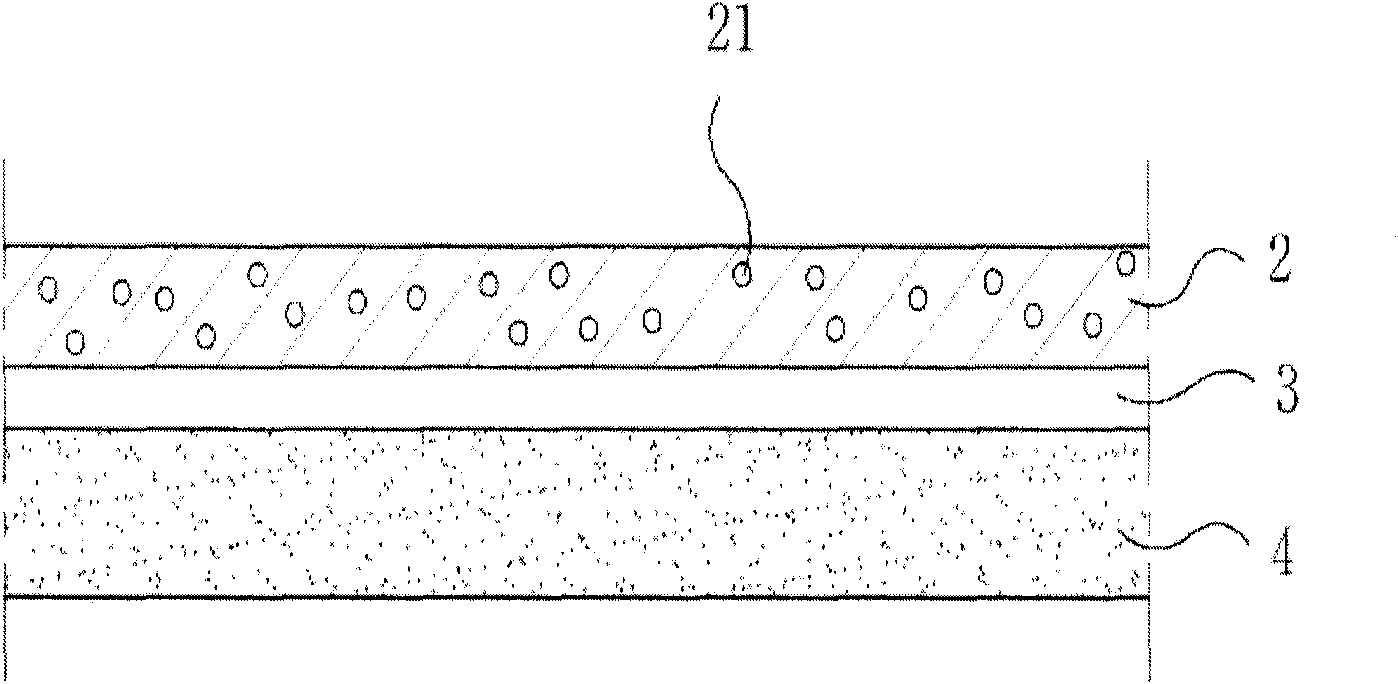

[0051] The exterior laminate sheet according to the present invention was prepared by thermally transferring the transfer sheet prepared in Example 1 above onto a synthetic resin film of vinyl chloride resin having a thickness of 100 μm as the colored synthetic resin film 4, This transfer sheet is adhered to a synthetic resin film so that the adhesive layer 3 of the transfer sheet is in contact with the synthetic resin film 4, it is heated and laminated, and the carrier film is removed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com