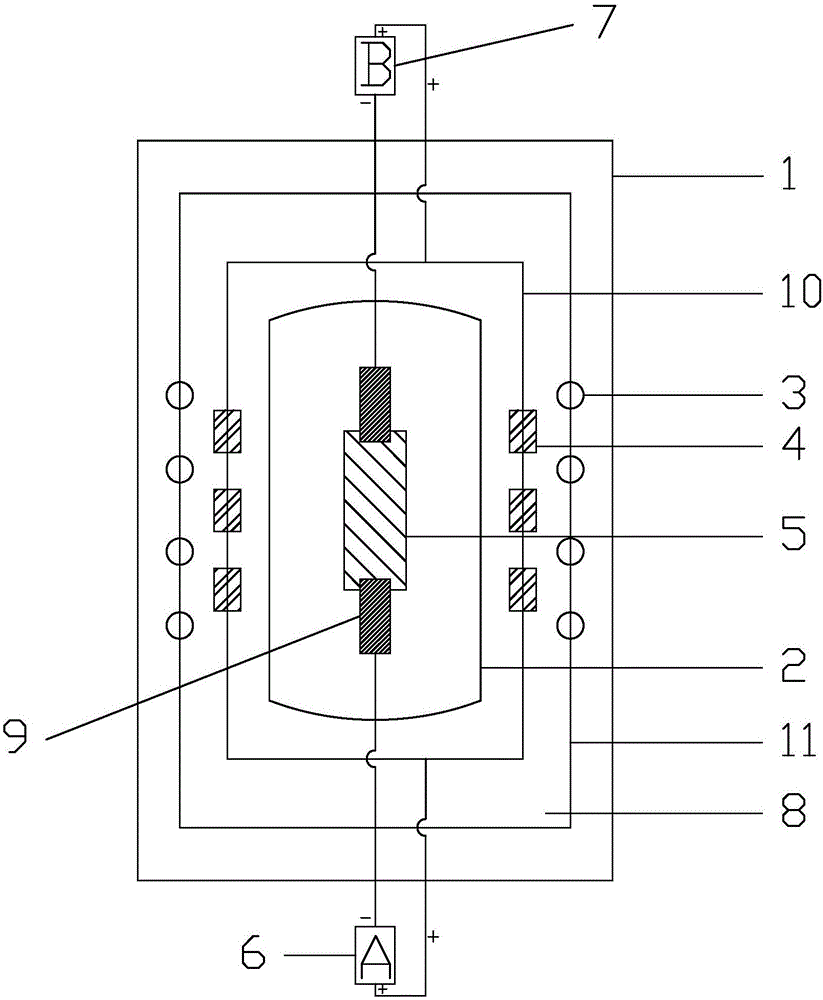

Tin-zinc alloy plating device and technology with barrel plating bath

A technology for alloy electroplating and barrel plating tanks, which is applied in the direction of plating tanks, electrodes, and electrolytic processes, and can solve the problems of reduced corrosion resistance of alloy electroplating layers, imbalance of tin and zinc ion ratios, and uneven content of tin-zinc alloys, etc., to achieve Good gloss, stable content ratio, corrosion resistance and good welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] After the workpiece is pretreated, the electroplating treatment is carried out under the following plating bath conditions:

[0045] pH: 6.2;

[0046] Divalent tin: 0.8g / L;

[0047] Divalent zinc: 15g / L;

[0048] Tin-zinc anode current: 120A;

[0049] Graphite anode current: 21.3A;

[0050] The temperature of the plating bath is 18°C;

[0051] The cathode current density is 0.5A / dm 2 .

Embodiment 2

[0053] After the workpiece is pretreated, the electroplating treatment is carried out under the following plating bath conditions:

[0054] pH: 6.5;

[0055] Divalent tin: 1.2g / L;

[0056] Divalent zinc: 18g / L;

[0057] Tin-zinc anode current: 135A;

[0058] Graphite anode current: 48.3A;

[0059] The temperature of the plating bath is 22°C;

[0060] The cathode current density is 0.65A / dm 2 .

Embodiment 3

[0062] After the workpiece is pretreated, the electroplating treatment is carried out under the following plating bath conditions:

[0063] pH: 7.0;

[0064] Divalent tin: 1.5g / L;

[0065] Divalent zinc: 22g / L;

[0066] Tin-zinc anode current: 160A;

[0067] Graphite anode current: 66A;

[0068] The temperature of the plating bath is 24°C;

[0069] The cathode current density is 0.8A / dm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com