Fluorinated acrylate copolymer pervaporation composite film and preparation method thereof

A technology of acrylate and pervaporation, applied in the field of membrane separation, to achieve the effects of firm adhesion, loose network structure, good affinity and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

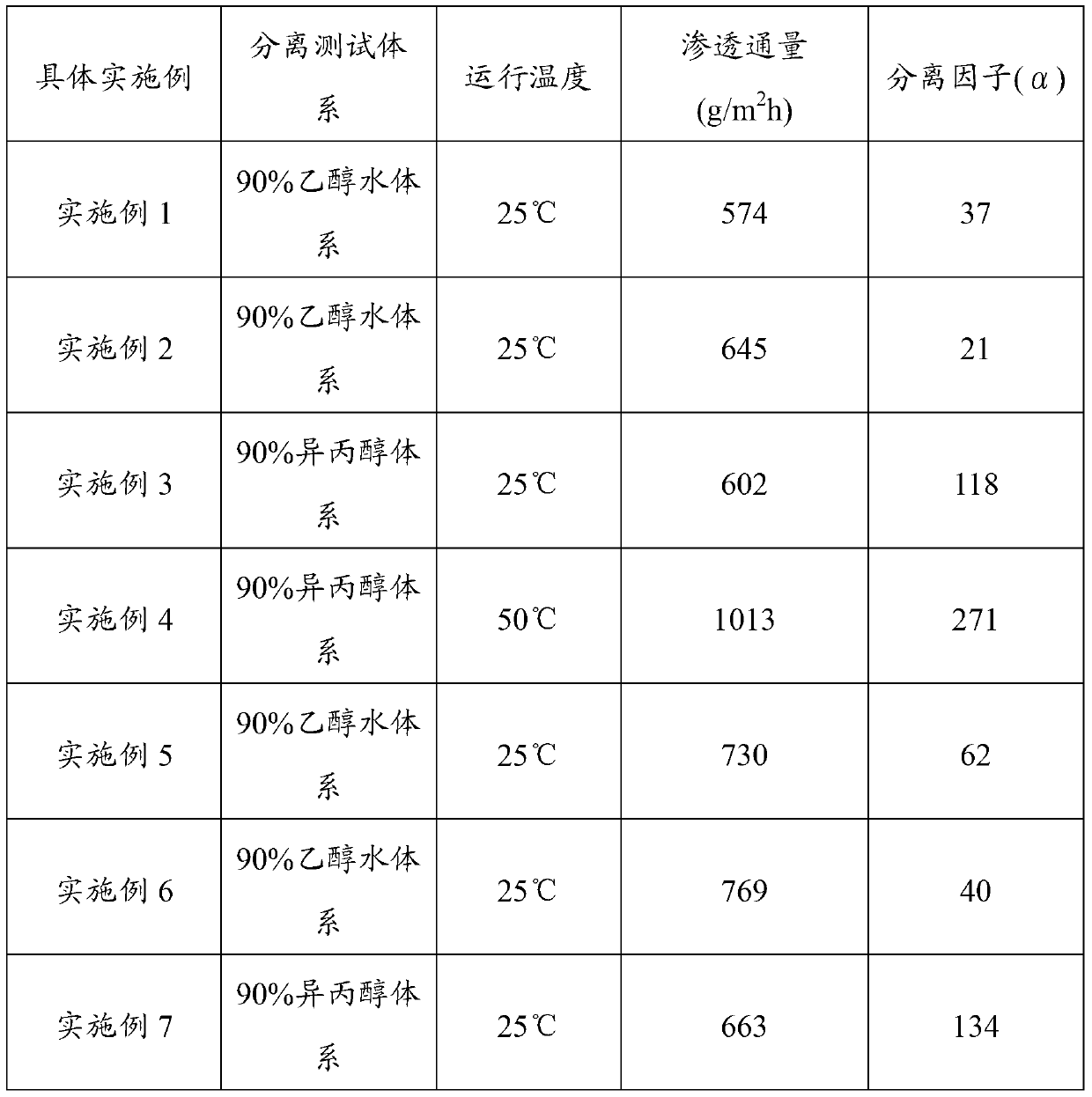

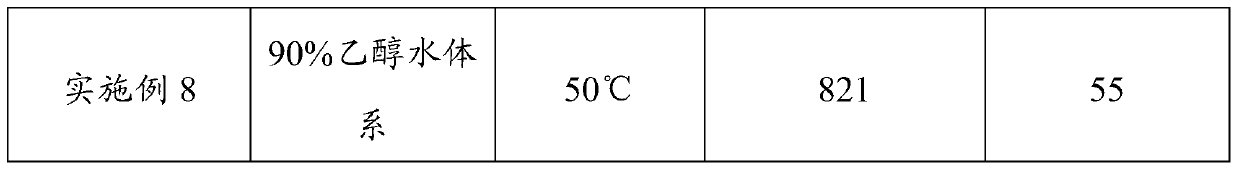

Examples

Embodiment 1

[0035] (1) Preparation of fluorine-containing acrylate copolymer microemulsion with nanoscale particles: Add 1.0 g of deionized water to a 25 ml reaction bottle (three-neck flask) equipped with a high-speed stirrer, and dissolve 1.2 g of trifluoroethyl methacrylate ester, 3.3 g isooctyl methacrylate, 0.2 g methacrylic acid, and 4.5 g polymerizable surfactant C 1 -PEO-C 11 -MA-40 was dissolved in deionized water, stirred at 15000rpm for 30min at a water bath temperature of 40°C, taken out, cooled to room temperature, and then ultrasonically dispersed for 10min to obtain a W / O microemulsion. Add 15 mM ammonium persulfate to the W / O microemulsion, stir at 15000 rpm for 10 min at room temperature, ultrasonically emulsify for 5 min, and pass nitrogen gas into the reaction bottle at a rate of 0.5 L / h for 10 min to ensure that the polymerization reaction is carried out under nitrogen protection. Add 15mM N,N,N',N'-tetramethylethylenediamine dropwise to the reaction flask while stirr...

Embodiment 2

[0038] (1) Preparation of fluorine-containing acrylate copolymer microemulsion with nanoscale particles: Add 1.5 g of deionized water to a 25 ml reaction bottle (three-necked flask) equipped with a high-speed stirrer, and dissolve 1 g of hexafluorobutyl methacrylate , 3.2g lauryl methacrylate, 0.2g N-methylolacrylamide and 4.2g polymerizable surfactant C 1 -PEO-C 11 -MA-40 was dissolved in deionized water, stirred at 18000 rpm for 20 minutes at a water bath temperature of 50°C, taken out, cooled to room temperature, and dispersed by ultrasonic for 15 minutes to obtain a W / O microemulsion. Add 10mM ammonium persulfate to the W / O microemulsion, stir at 18000rpm for 15min at room temperature, ultrasonically emulsify for 5min, and pass nitrogen gas into the reaction bottle at a rate of 0.5L / h for 10min to ensure that the polymerization reaction is carried out under nitrogen protection. While stirring at 300rpm, 10mM N,N,N',N'-tetramethylethylenediamine was added dropwise to the r...

Embodiment 3

[0041] (1) Preparation of fluorine-containing acrylate copolymer microemulsion with nanoscale particles: Add 1.5 g of deionized water to a 25 ml reaction bottle (three-neck flask) equipped with a high-speed stirrer, and dissolve 0.7 g of octafluoropentyl methacrylate ester, 3.55g butyl methacrylate, 0.2g acetoacetoxy ethyl methacrylate and 4.25g polymerizable surfactant C 1 -PEO-C 11 -MA-40 was dissolved in deionized water, stirred at 20,000 rpm for 20 minutes at a water bath temperature of 60°C, taken out, cooled to room temperature, and then ultrasonically dispersed for 10 minutes to obtain a W / O microemulsion. Add 10 mM ammonium persulfate to the W / O microemulsion, stir at 20,000 rpm for 20 min at room temperature, ultrasonically emulsify for 5 min, and pass nitrogen gas into the reaction bottle at a rate of 0.5 L / h for 10 min to ensure that the polymerization reaction is carried out under nitrogen protection. While stirring at 400 rpm, 10 mM N,N,N',N'-tetramethylethylened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com