Phosphorizing liquid doped with silicon carbide nanoparticles or hydroxyapatite particlesas well as phosphorizing treatment method of magnesium or magnesium alloy

A technology of hydroxyapatite and nano-silicon carbide, which is applied in the coating process of metal materials, can solve the problems of poor corrosion resistance and wear resistance of phosphating film, burns, dyspnea, shock, etc., and achieve improved shape Effects of nuclear rate, risk reduction, and promotion of further refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

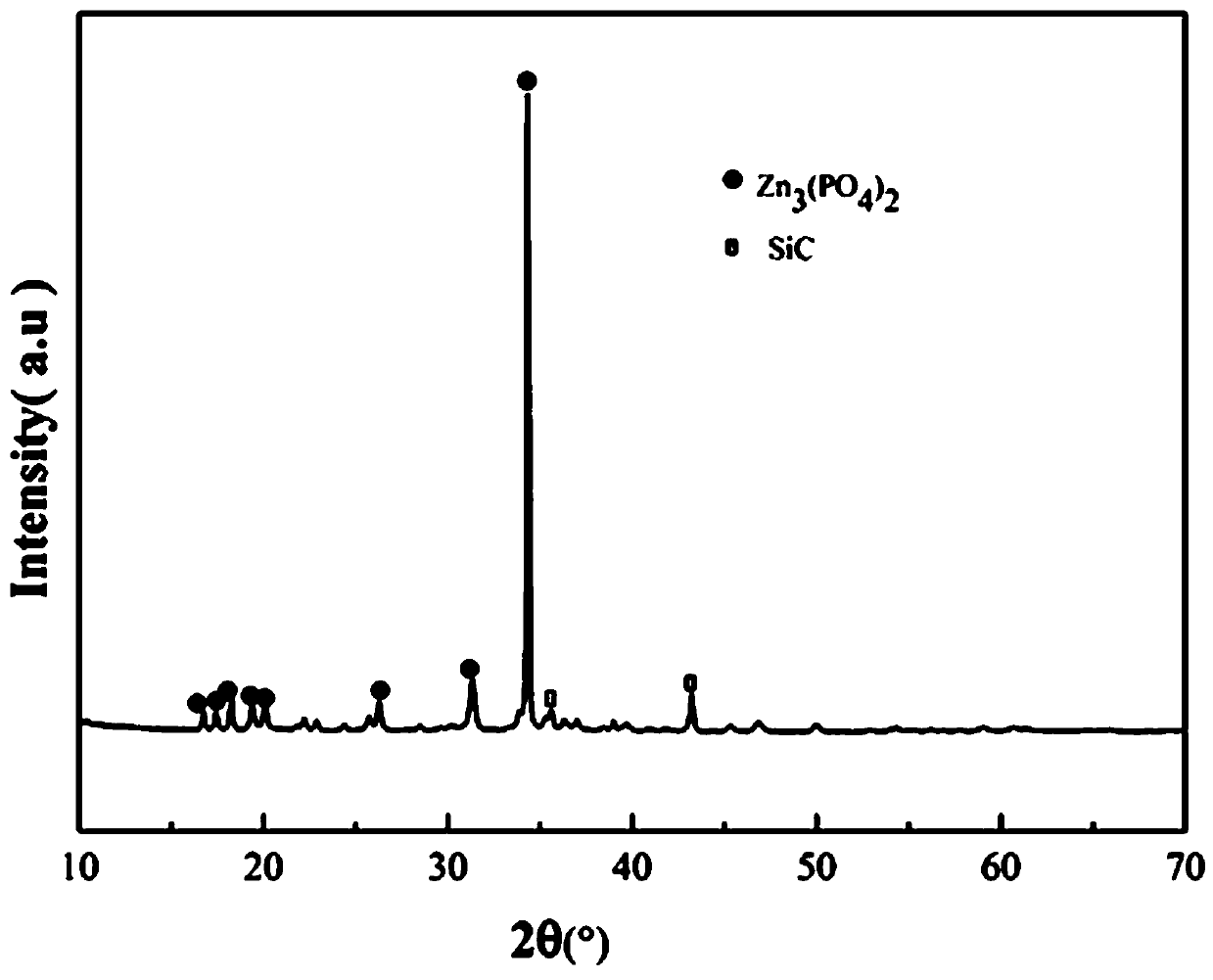

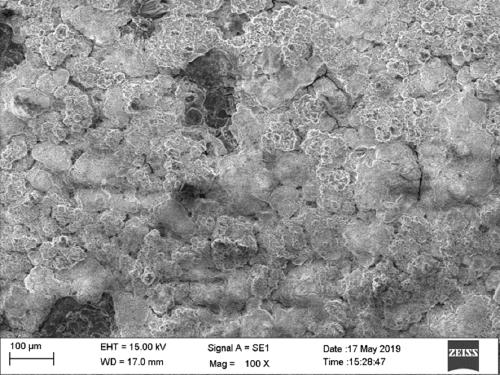

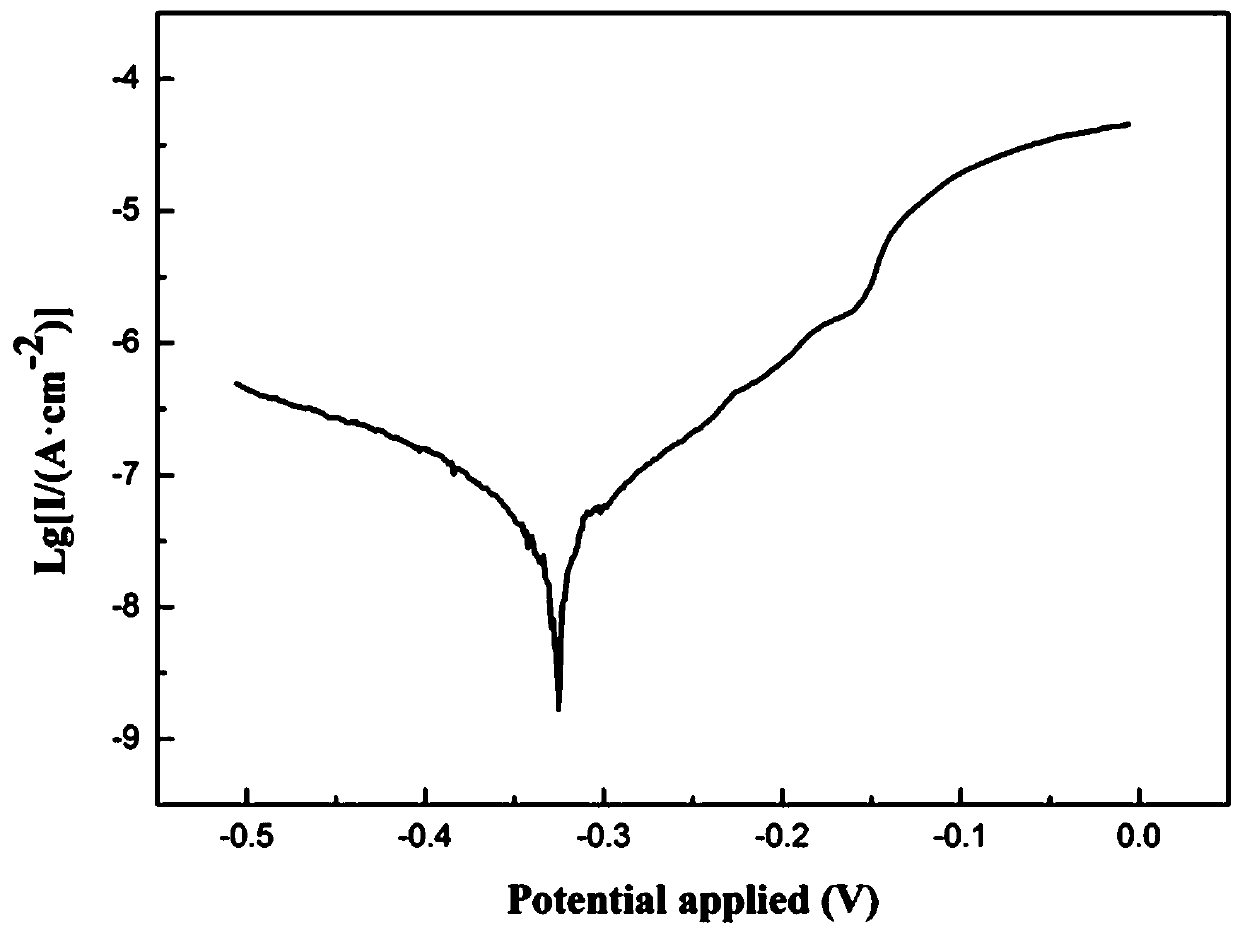

[0032] A kind of phosphating solution doped with nano-silicon carbide particles, comprising the following components: zinc nitrate 80g / L, zinc dihydrogen phosphate 35g / L, phosphoric acid 5g / L, nano-silicon carbide particles 0.4g / L, which is obtained by the following method Prepared from:

[0033] S1. Put nano-silicon carbide particles with a size of 100nm into acetone and ethanol in turn for ultrasonic cleaning, and then place them in a drying oven for drying;

[0034] S2. Dissolve zinc nitrate and zinc dihydrogen phosphate in water, and then place them in an ultrasonic environment and mix for 30 minutes. After mixing, add phosphoric acid solution and heat to 60°C. Finally, add the dried nano-silicon carbide particles in step S1 and place them again. It is obtained after mixing for 5 minutes in an ultrasonic environment.

[0035] Wherein, the power of the two ultrasonic mixing in step S2 is 200W, and the instrument used to provide the ultrasonic environment can be an ultrason...

Embodiment 2

[0041] A phosphating solution doped with nano-silicon carbide particles, comprising the following components: zinc nitrate 80g / L, zinc dihydrogen phosphate 35g / L, phosphoric acid 5g / L, nano-silicon carbide particles 0.001g / L, which is obtained by the following method Prepared from:

[0042] Phosphating solution is prepared by the following method:

[0043] S1. Put nano-silicon carbide particles with a size of 10nm into acetone and ethanol in turn for ultrasonic cleaning, and then place them in a drying oven for drying;

[0044] S2. Dissolve zinc nitrate and zinc dihydrogen phosphate in water, and then mix them in an ultrasonic environment for 20 minutes. After mixing, add phosphoric acid solution and heat to 40°C. Finally, add the dried nano-silicon carbide particles in step S1 and place them again. It is obtained after mixing for 4 minutes in an ultrasonic environment.

[0045] Wherein, the power of the two ultrasonic mixing in step S2 is 50W, the instrument used to provide...

Embodiment 3

[0051] A phosphating solution doped with nano-silicon carbide particles, comprising the following components: zinc nitrate 80g / L, zinc dihydrogen phosphate 35g / L, phosphoric acid 5g / L, nano-silicon carbide particles 1g / L, prepared by the following method into:

[0052] Phosphating solution is prepared by the following method:

[0053] S1. Put nano-silicon carbide particles with a size of 200nm into acetone and ethanol in turn for ultrasonic cleaning, and then place them in a drying oven for drying;

[0054] S2. Dissolve zinc nitrate and zinc dihydrogen phosphate in water, then mix in an ultrasonic environment for 40 minutes, add phosphoric acid solution after mixing and heat to 80°C, and finally add nano-silicon carbide particles dried in step S1 and place again It is obtained after mixing in an ultrasonic environment for 6 minutes.

[0055] Wherein, the power of the two ultrasonic mixing in step S2 is 500W, the instrument used to provide the ultrasonic environment can be an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com